Re: New M118LR loading from Federal

I did a hasty test of IMR-3031 this afternoon at the farm.

It was about 66 degrees and 92% humidity, my location is about 250' asl.

My rifle has a 26.25 inch, 4 groove, 1/10 barrel and an SWR Omega suppressor.

I have been shooting hBN coated bullets in the rifle so I scrubbed it thoroughly before shooting.

I loaded 20 rounds with an oal of 2.810, 40.2 grains of IMR-3031 with a naked 175 Sierra.

15 in FGGM brass and 5 in LC M118LR brass primed with 210M's.

Both were FL resized with a .336 neck bushing. All loads were thrown with a Lee Perfect powder measure then trickled to 40.2

In the 20 throws I felt 1 kernel catch slightly.

I set up a target at 100 yards and my Oehler 35P with 3 screens 2' apart 10' from the muzzle of the rifle.

I was shooting from the prone and it was tough to get the Oehler in a good position. I resorted bolting it onto a milk crate.

To obtain a clear sight picture and not shoot my screens I used a cinder block under my bipod and supported the rear with my off hand.

It was not a rock solid position but proved to be adequate as my Oehler survived and I hit the target.

I shot the 5 rounds using the LC cases first to check zero and foul the barrel.

5 shots went into about an inch with the following numbers:

hi 2622

lo 2588

av 2605

es 34

sd 13

The upper left hole is cbs, upper right I jerked.

To simulate colder weather I put 5 rounds in my freezer then transferred them to the farm in a cooler sandwiched between two gel freezer packs.

I used an indoor outdoor thermometer with a wired probe to check the temperature in the cooler.

The cooler temp was 40 degrees and when I inserted the probe between the ice packs it was 23 degrees.

I did not have sufficient time to let the barrel cool between shots so I purged the barrel and suppressor with dustoff in an attempt to cool the barrel and chamber. One shot was left too long in the chamber and I think it shows in the high ES/SD.

hi 2668

lo 2608

av 2640

es 70

sd 23

I purged the rifle and let it cool while I checked the target then fired 5 rounds at ambient temperature. I tried using another rear rest technique and it was unsatisfactory.

hi 2702

lo 2648

av 2678

es 54

sd 22

My brother was taking notes for me and I used him to simulate warm weather by stowing the last 5 rounds in his armpit. I took advantage of the warm rifle and fired the last 5 rounds immediately after the ambient temp string. His pit hovered around 96 degrees and the chamber area was warm to the touch.

hi 2707

lo 2674

av 2697

es 33

sd 12

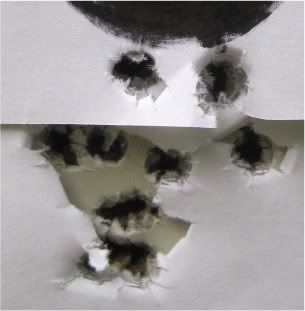

Last 2 groups, 1 MOA elevation adjustment between them, ambient on top: