I certainly can, my only problem with that is I don't own one, or have one to measure. I have threatened to buy one though.Can you build them for the HTI as well?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Official (DTA) SRS, HTI, Covert, Hunter Thread

- Thread starter patches

- Start date

I certainly can, my only problem with that is I don't own one, or have one to measure. I have threatened to buy one though.

If you end up wanting to buy one. Let me know.I certainly can, my only problem with that is I don't own one, or have one to measure. I have threatened to buy one though.

Do you have an SRS to compare it to for measurements? If so, measure from the front tip of the grip to the center of the mono pod on both. If not, measure your HTI. If you can tell me all the points you need measured, I'll measure mine a few times.

I wish I had an SRS. My HTI measures 13 5/8" from the front of the grip to the center of the monopod.Do you have an SRS to compare it to for measurements? If so, measure from the front tip of the grip to the center of the mono pod on both. If not, measure your HTI

Attachments

I wish I had an SRS. My HTI measures 13 5/8" from the front of the grip to the center of the monopod.

Attachments

Ok, thanks.I wish I had an SRS. My HTI measures 13 5/8" from the front of the grip to the center of the monopod.

I will compare to mine.

You're welcome. Let me know if you need any other measurements.Ok, thanks.

I will compare to mine.

I checked it out, the HTI is 2-3/8" longer in that dimension than an SRS. I can make that easy enough. I took some pictures of the modification that you would have to do to attach the bag rider to the DT. I did this with a diagonal wire cutter, then razor knife and die grinder. To finish the job, you should epoxy the aluminum insert in the skin half with the groove, this gives more surface for the epoxy.You're welcome. Let me know if you need any other measurements.

Once this is done the bag rider clips onto the monopod and is screwed on with a 1/4-20 flathead cap screw. It can be installed and removed that easily as needed. The monopod maintains full elevation of the bag rider, and is very solid especially on a good leather bag with ears.

I am not sure how to go about selling these here. I think I would have to get the proper membership level? Unless I made them for someone that already is a commercial sponsor maybe? Any suggestions would be helpful.

That looks simple enough.I checked it out, the HTI is 2-3/8" longer in that dimension than an SRS. I can make that easy enough. I took some pictures of the modification that you would have to do to attach the bag rider to the DT. I did this with a diagonal wire cutter, then razor knife and die grinder. To finish the job, you should epoxy the aluminum insert in the skin half with the groove, this gives more surface for the epoxy.

Once this is done the bag rider clips onto the monopod and is screwed on with a 1/4-20 flathead cap screw. It can be installed and removed that easily as needed. The monopod maintains full elevation of the bag rider, and is very solid especially on a good leather bag with ears.

I am not sure how to go about selling these here. I think I would have to get the proper membership level? Unless I made them for someone that already is a commercial sponsor maybe? Any suggestions would be helpful.

View attachment 8372379View attachment 8372381View attachment 8372382View attachment 8372383View attachment 8372380

The grip on the HTI is hollow/open in the bottom so I'd have to figure out a way to connect it. I'll look at it more when I get home later today. It might be possible to modify the original monopod to bolt a square piece of aluminum to it without needing to connect to the grip as well?The stock monopod threads inside 3"s or so.

I may have some interest in stocking and selling some of these.I checked it out, the HTI is 2-3/8" longer in that dimension than an SRS. I can make that easy enough. I took some pictures of the modification that you would have to do to attach the bag rider to the DT. I did this with a diagonal wire cutter, then razor knife and die grinder. To finish the job, you should epoxy the aluminum insert in the skin half with the groove, this gives more surface for the epoxy.

Once this is done the bag rider clips onto the monopod and is screwed on with a 1/4-20 flathead cap screw. It can be installed and removed that easily as needed. The monopod maintains full elevation of the bag rider, and is very solid especially on a good leather bag with ears.

I am not sure how to go about selling these here. I think I would have to get the proper membership level? Unless I made them for someone that already is a commercial sponsor maybe? Any suggestions would be helpful.

View attachment 8372379View attachment 8372381View attachment 8372382View attachment 8372383View attachment 8372380

That can be arranged, I would appreciate that. How would you like to proceed?I may have some interest in stocking and selling some of these.

The DT monopod in my opinion has the best adjustability and range, and with my bag rider and a quality leather bag with ears is extremely solid and stable. I would not suggest removing your monopod.That looks simple enough.

The grip on the HTI is hollow/open in the bottom so I'd have to figure out a way to connect it. I'll look at it more when I get home later today. It might be possible to modify the original monopod to bolt a square piece of aluminum to it without needing to connect to the grip as well?The stock monopod threads inside 3"s or so.

Let me know what else you need.The DT monopod in my opinion has the best adjustability and range, and with my bag rider and a quality leather bag with ears is extremely solid and stable. I would not suggest removing your monopod.

4237089399

What's the width of your bag rider?The DT monopod in my opinion has the best adjustability and range, and with my bag rider and a quality leather bag with ears is extremely solid and stable. I would not suggest removing your monopod.

I like how the mag can be run with your design. The ABR design removes the factory monopod. It's very precise but Id prefer to be able to run my mag.

The width is 1-1/2"What's the width of your bag rider?

I like how the mag can be run with your design. The ABR design removes the factory monopod. It's very precise but Id prefer to be able to run my mag.

I would not want to give up the magazine for the bag rider either. As for precision, the DT monopod's adjustment very precise, as well as rapidly adjustable. I didn't know ABR made one for the DT until I read this thread a few days ago. I think they are a good unit for most other rifles, but I would not want to give up the monopod or have to disassemble the gun to install it. And I’m not sure it would stay aligned with the gun, being mounted on a single post.

My intention was never selling this or any of the other custom items I made for my DT, frankly I didn't think many really appreciated the DT as a precision rifle like I do. If you are still interested PM me and we can talk about it.

You guys are going to want to think twice about straight taper barrels in your A2 chassis. This is just the third problem. I am troubleshooting after having “upgraded” to an A2.

This channel at the front of the receiver, that the hand guard screws to is exactly 1.250 inches in diameter. It starts at approximately 9.25 inches from where the extension seats in the receiver. If you look at the attached photo, my 32 inch Lilja, which is a straight taper, starting at 8 inches barely fits through that area. I had to put it in the leave and use some memory cloth to remove 0.002 inches today because this barrel which was great in my A1 would not seat in the chassis of the A2.

Furthermore, as you can see, the barrel is no longer free floated through that channel in the front of the chassis ahead of the clamping bolts. I hope that this does not adversely affect accuracy. I would think that ideally you would want at least a couple of thousands clearance on either side there and I’m not sure what the hell I should do.

In the second photo, you can see the marks where the screw holes for the hand guard in that forward section of the chassis leaves marks on the barrel because of how tight it is fit when seated in there, and I rotate it back-and-forth a couple of degrees in each direction

The taper on this barrel is 1.250" for 10" then straight taper to 32"

From now on, I will have the straight taper start at 6"

This channel at the front of the receiver, that the hand guard screws to is exactly 1.250 inches in diameter. It starts at approximately 9.25 inches from where the extension seats in the receiver. If you look at the attached photo, my 32 inch Lilja, which is a straight taper, starting at 8 inches barely fits through that area. I had to put it in the leave and use some memory cloth to remove 0.002 inches today because this barrel which was great in my A1 would not seat in the chassis of the A2.

Furthermore, as you can see, the barrel is no longer free floated through that channel in the front of the chassis ahead of the clamping bolts. I hope that this does not adversely affect accuracy. I would think that ideally you would want at least a couple of thousands clearance on either side there and I’m not sure what the hell I should do.

In the second photo, you can see the marks where the screw holes for the hand guard in that forward section of the chassis leaves marks on the barrel because of how tight it is fit when seated in there, and I rotate it back-and-forth a couple of degrees in each direction

The taper on this barrel is 1.250" for 10" then straight taper to 32"

From now on, I will have the straight taper start at 6"

Last edited:

Here you can clearly see what I’m talking about. Where I am pointing is the channel in the front of the receiver, to which the hand guard screws. If your barrel does not have an aggressive enough taper in this area, it will ride snuggly in that 1.250 inch channel, indeed my Lilja was about 0.0015 inches oversized, and would not even seat in the chassis because of getting hung up in that channel

I think you will be ok, perhaps even better. The DT clamps on 5+ inches of the 1.250" diameter, as long as the receiver bore is straight 1.250" all the way out, and your barrel is straight 1.250" minus enough to slip fit you should have the most ridgid and repeatable barrel receiver combination possible! This isn't the typical "free float" scenario seen in threaded receiver / barrel rifles. The DT is more of a "barrel block" like in a benchrest rifle. This is why they are such a stable platform. Full receiver bore contact in a in a tight tollerance round straight bore will enhance repeatable barrel changes with less poi shift. The barrel will not whip as much and should group better. I think you have a great if not perfect DT setup!

I don't think you should be afraid of the M2's tight tollerance receiver bore. You need to fit your barrel to the correct diameter straight all the way out of the receiver for the most ridgid repeatable setup. This may not be what you want if you are looking for less weight.

I agree with you in theory. Not looking for light with this setup, just looking for a steel smasher that has some more weight out front. I would go even longer than 24” but there is a used barrel already made with only 20 rounds on for a decent price.I don't think you should be afraid of the M2's tight tollerance receiver bore. You need to fit your barrel to the correct diameter straight all the way out of the receiver for the most ridgid repeatable setup. This may not be what you want if you are looking for less weight.

Only problem I had was with MLOK screws contacting the barrel. I had to remove one from the top rail (it's okay - there are 7) and grind down a couple to get the needed clearance.

OK, guys, here is what you need to know:

The Lilja was ordered at 1.250 - it arrived at 1.2515. That alone was enough to make it a "no-go" in the A2. It would not even fit till we skimmed some material off.

Previously, there was a fair amount of slop in the A1 chassis, and you could be several thous over and it would fit. No longer.

You will just have to tell your gunsmith to make sure he skims the barrel down to <=1.250 for it to fit.

In order to get this barrel to fit *AT ALL* today, we put it in the lathe and removed 0.002" with emory cloth. Just should have gone out a full foot, rather than concentrate on the first 8"

Another thing I would look out for: Cerakote. If you start with 1.250 and it just fits like mine in the pics, one layer of cerakote is going to make it a "no-go"

The Lilja was ordered at 1.250 - it arrived at 1.2515. That alone was enough to make it a "no-go" in the A2. It would not even fit till we skimmed some material off.

Previously, there was a fair amount of slop in the A1 chassis, and you could be several thous over and it would fit. No longer.

You will just have to tell your gunsmith to make sure he skims the barrel down to <=1.250 for it to fit.

In order to get this barrel to fit *AT ALL* today, we put it in the lathe and removed 0.002" with emory cloth. Just should have gone out a full foot, rather than concentrate on the first 8"

Another thing I would look out for: Cerakote. If you start with 1.250 and it just fits like mine in the pics, one layer of cerakote is going to make it a "no-go"

When ordering barrels for the DT SRS I spec 1.2500"+ 0 /-0.0010" diameter of the shank, this dimensional tollerance should fit all DT SRS's and is a reasonable tollerance for major barrel manufacturers to hold. I have had both Bartlein and Lija do this with zero issues. My SRS-A1 is not that tight, I wish it was. I deal with .0001" dimensions every day at my shop, not a big deal with the proper tools and experience. In precision accuracy, thight tollerance is your friend!OK, guys, here is what you need to know:

The Lilja was ordered at 1.250 - it arrived at 1.2515. That alone was enough to make it a "no-go" in the A2. It would not even fit till we skimmed some material off.

Previously, there was a fair amount of slop in the A1 chassis, and you could be several thous over and it would fit. No longer.

You will just have to tell your gunsmith to make sure he skims the barrel down to <=1.250 for it to fit.

In order to get this barrel to fit *AT ALL* today, we put it in the lathe and removed 0.002" with emory cloth. Just should have gone out a full foot, rather than concentrate on the first 8"

Another thing I would look out for: Cerakote. If you start with 1.250 and it just fits like mine in the pics, one layer of cerakote is going to make it a "no-go"

We order most of our barrel blanks at 1.2500"+ 0 /-0.0020". We had a batch come in at 1.2515 and all the barrels needed to be turned down to work in the A2/M2 chassis. With the A1 and prior generation chassis that would not have been a problem. I've also seen laser engraving on barrel shanks cause an issue when some of the material elevated a couple thousands during the engraving process. As secondofangle mentioned above, cerakote can cause issues too.When ordering barrels for the DT SRS I spec 1.2500"+ 0 /-0.0010" diameter of the shank, this dimensional tollerance should fit all DT SRS's and is a reasonable tollerance for major barrel manufacturers to hold. I have had both Bartlein and Lija do this with zero issues. My SRS-A1 is not that tight, I wish it was. I deal with .0001" dimensions every day at my shop, not a big deal with the proper tools and experience. In precision accuracy, thight tollerance is your friend!

Last edited:

My barrel no longer shoots like it used to, guys.

Maybe it was me maybe it’s a bad day maybe it’s getting a little long in the tooth but it shot fine in my A1.

You guys are gonna want to make sure that the area between 9 1/2 and 11 inches on whatever profile you have spun up has significantly smaller diameter than 1.250” so that it doesn’t create harmonics issues with your barrel from inadequate clearance

I am not positive that is what’s going on with mine but I’m confident enough that I’m not going to screw around and try to make it work. I’m gonna get a new barrel or reprofile this one and have it re-chambered at the same time

Suggestions on a 338 reamer appreciated. This will be my fourth 338 chambering and it’s time to get my own reamer.

Maybe it was me maybe it’s a bad day maybe it’s getting a little long in the tooth but it shot fine in my A1.

You guys are gonna want to make sure that the area between 9 1/2 and 11 inches on whatever profile you have spun up has significantly smaller diameter than 1.250” so that it doesn’t create harmonics issues with your barrel from inadequate clearance

I am not positive that is what’s going on with mine but I’m confident enough that I’m not going to screw around and try to make it work. I’m gonna get a new barrel or reprofile this one and have it re-chambered at the same time

Suggestions on a 338 reamer appreciated. This will be my fourth 338 chambering and it’s time to get my own reamer.

Yeah I was looking at them, just need to figure out freebore so I can seat 285 ELD to about 3.825" COAL

I got mine from Dave Manson, he made it so I can seat 300 grain Bergers to 3.9375" coal, standard case dimensions. I would have to look up the paper work and find the numbers on it. I do like the reamers he has done for me.My barrel no longer shoots like it used to, guys.

Maybe it was me maybe it’s a bad day maybe it’s getting a little long in the tooth but it shot fine in my A1.

You guys are gonna want to make sure that the area between 9 1/2 and 11 inches on whatever profile you have spun up has significantly smaller diameter than 1.250” so that it doesn’t create harmonics issues with your barrel from inadequate clearance

I am not positive that is what’s going on with mine but I’m confident enough that I’m not going to screw around and try to make it work. I’m gonna get a new barrel or reprofile this one and have it re-chambered at the same time

Suggestions on a 338 reamer appreciated. This will be my fourth 338 chambering and it’s time to get my own reamer.

What are the chamber dimensions like on the factory DT barrels? Just picked up a factory barrel for a screaming deal and it’ll be my first 338. Have a bunch of Lapua brass and plan on using 300gr scenars.

Tight..What are the chamber dimensions like on the factory DT barrels? Just picked up a factory barrel for a screaming deal and it’ll be my first 338. Have a bunch of Lapua brass and plan on using 300gr scenars.

Factory barrel is awesome ...well the 3 i have used are !! Running 300gr A-tips and they shoot phenomenally well !

Thanks! I’ve had great success with other DT barrels so I figured this would be no different.Tight..

Factory barrel is awesome ...well the 3 i have used are !! Running 300gr A-tips and they shoot phenomenally well !

Eric at ES-Tactical says he can skim my barrel down in a jiffy. Meeting him Sunday. Woohoo!

^Oooh, that's tempting.

I was just talking to Blake who called me from Manson reamers. Super helpful folks! He knew just what I was talking about, recommended .100" extra freebore, but said "send in a dummy round so we make sure we get it right." That's a good business there

I was just talking to Blake who called me from Manson reamers. Super helpful folks! He knew just what I was talking about, recommended .100" extra freebore, but said "send in a dummy round so we make sure we get it right." That's a good business there

That's what I did with my 6.5 prc and^Oooh, that's tempting.

I was just talking to Blake who called me from Manson reamers. Super helpful folks! He knew just what I was talking about, recommended .100" extra freebore, but said "send in a dummy round so we make sure we get it right." That's a good business there

.338 lm reamers, Manson did a fine job!

My first .338 LM barrel was a factory DTA.What are the chamber dimensions like on the factory DT barrels? Just picked up a factory barrel for a screaming deal and it’ll be my first 338. Have a bunch of Lapua brass and plan on using 300gr scenars.

I throated it about .100 deeper with a PTG throating reamer so I could run 300 Berger's seated where they should be, it shot well, .25 to .50 moa.

Alright, this is a dumb question, but:

Where the heck are y’all finding 338LM primers and powder. Any of y’all playing with custom reamers gotta have a source.

I got plenty of once fired brass.

I can find projectiles.

I can’t find a reliable source for primers or powder to get into bigger boomer reloading.

Where the heck are y’all finding 338LM primers and powder. Any of y’all playing with custom reamers gotta have a source.

I got plenty of once fired brass.

I can find projectiles.

I can’t find a reliable source for primers or powder to get into bigger boomer reloading.

I buy it when I find it and I don’t shoot but a couple hundred rounds per year these days. 1000 215M and 8# of Retumbo and 500 285s goes a long way

Plus I don’t have a powder dispenser till IP finally starts shipping

Plus I don’t have a powder dispenser till IP finally starts shipping

Grafs has Retumbo in stock. Right now 215m primers are a little tough to source.Alright, this is a dumb question, but:

Where the heck are y’all finding 338LM primers and powder. Any of y’all playing with custom reamers gotta have a source.

I got plenty of once fired brass.

I can find projectiles.

I can’t find a reliable source for primers or powder to get into bigger boomer reloading.

Large Rifle Magnum primers are hard to come by for the past few years. They seem to show up in batches and go quickly, so just get what you can. I used to have a large amount of GM215Ms I used exclusively for many years, but it's been near impossible to replenish, so now I use CCI 250s in new loads and have Winchester primers as backup, while I reserve the 215Ms for legacy loads I still use.

I haven't had much of a problem getting 300gr Scenar/A-Tips/Hybrids in the past couple of years. They used to go as fast as primers, but these days if you follow the In-Stock thread you'll see them from time to time and they tend to linger at least a few days and not go "poof" instantly.

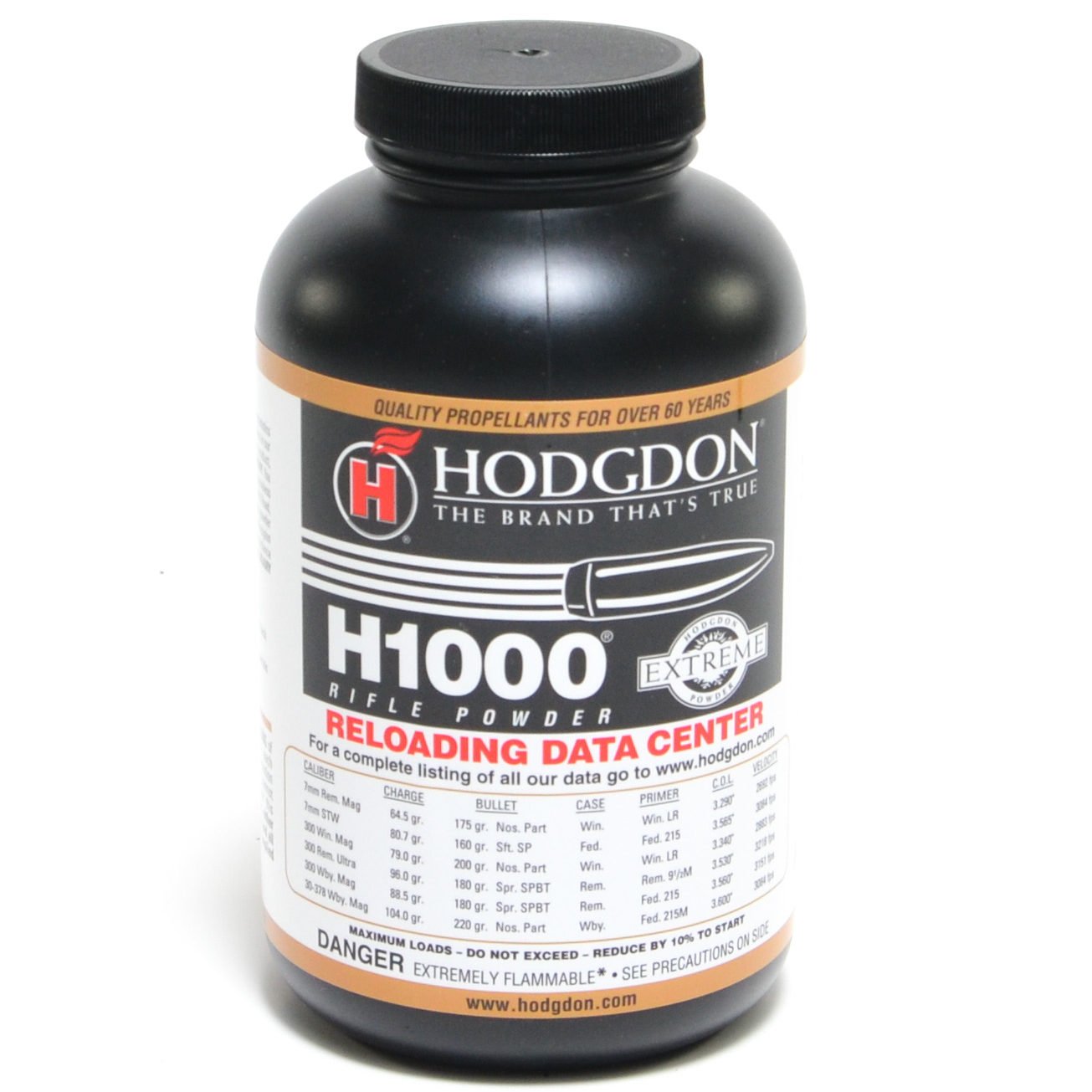

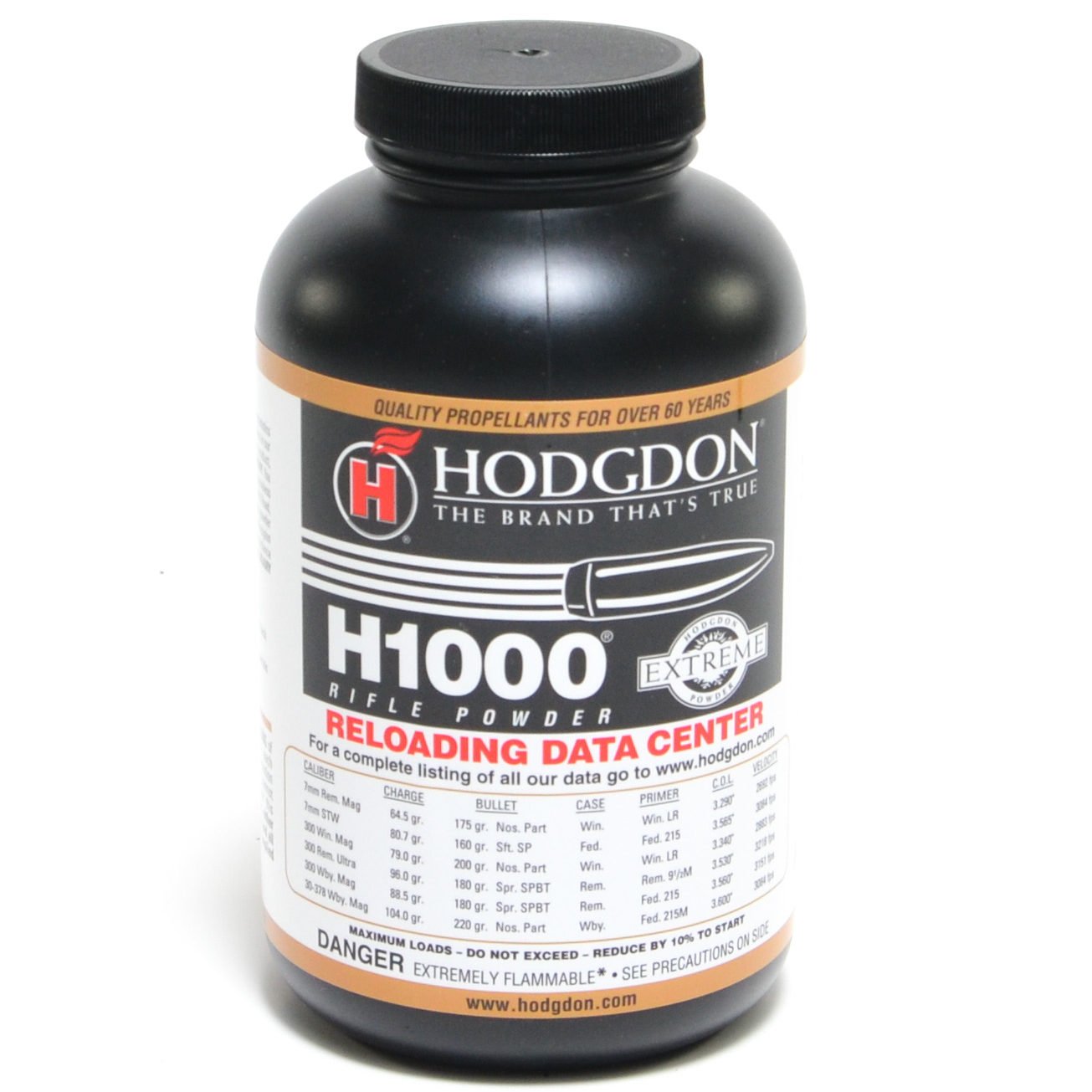

For powders, if you're married to H1000 or Retumbo, then you're just going to have to buy large amounts when they become available. It's not like 2021-2022 when they were impossible to find, but they do tend to disappear within several hours of being in-stock. RL 25, 26 & 33 are much more rare and are now prohibitively expensive for most people. I think because of that, Ramshot LRT has become popular and now it's harder to find. N560 & N565 tend to be more readily available, but N170 and N570 tend to disappear within a day.

I haven't had much of a problem getting 300gr Scenar/A-Tips/Hybrids in the past couple of years. They used to go as fast as primers, but these days if you follow the In-Stock thread you'll see them from time to time and they tend to linger at least a few days and not go "poof" instantly.

For powders, if you're married to H1000 or Retumbo, then you're just going to have to buy large amounts when they become available. It's not like 2021-2022 when they were impossible to find, but they do tend to disappear within several hours of being in-stock. RL 25, 26 & 33 are much more rare and are now prohibitively expensive for most people. I think because of that, Ramshot LRT has become popular and now it's harder to find. N560 & N565 tend to be more readily available, but N170 and N570 tend to disappear within a day.

@DoctorBen

Here's some quality bullets from just one source:

Here's some H1000 & Retumbo

www.powdervalley.com

www.powdervalley.com

www.powdervalley.com

www.powdervalley.com

Here's some N568 & N570

www.powdervalley.com

www.powdervalley.com

www.powdervalley.com

www.powdervalley.com

Here's some quality bullets from just one source:

Here's some H1000 & Retumbo

Hodgdon H1000 Smokeless Gun Powder

Hodgdon H1000 Smokeless Powder is a favorite for big bore competitive shooting rifles. Buy at Powder Valley for Best Prices Guaranteed.

www.powdervalley.com

www.powdervalley.com

Hodgdon Retumbo Smokeless Gun Powder | Powder Valley Outdoors

Hodgdon Retumbo is an Extreme Rifle Powder that is a favorite among big bore competitive shooters. Get best prices guaranteed at Powder Valley

Here's some N568 & N570

Vihtavuori N568 Smokeless Gun Powder

Vihtavuori N568 smokeless powder from Powder Valley is the perfect choice for reloading magnum rifle ammunition. Find 1lb and 8lb containers at low prices.

www.powdervalley.com

www.powdervalley.com

Vihtavuori N570 Smokeless Gun Powder | Powder Valley Outdoors

Reload your ammunition with Vihtavuori N570 smokeless powder from Powder Valley. Experienced reloaders know that using premium powder is the key to consistency.

Thanks guys; I’m not married to a particular powder, just haven’t tried the 338LM loading because can’t find primers. I ordered a few thousand rounds of 6.5 Creedmoor when I found that factory loads worked very well, and Still have a bunch Of CCI larger rifle primers leftover from 308 loading 10 year ago (bought 2000). But, want to see what I could push 338LM to. Biggest reason I stuck with the factory 6.5 instead of reloading was that the Hornady 143gr ELDX hunter loads just had a ridiculously low SD and were plenty fast enough. But who doesn’t want more speed……. Think I’m still waiting for some ammunition from Prime ammo from a while back too.

If you can get Vihtavouri N570 or Reloader 33 do it. I started with RL33, worked great in my factory 26" barrel, switched to N570, I like it better. I found it interesting that it works well in both my .338 LM with 300 gr Berger's and my 6.5 PRC with 153.5 gr Berger's, both 31" barrels, N570 works great in longer barrels.

But...reloading and load development is almost as fun as actually shooting

Has anybody made/printed plugs for the ports in the action above the clamping screws. I’m prepping for a trip out to the Rockies and I’m thinking about ways to keep sand and crud out of the shank flutes and action block during a hike.

Similar threads

- Replies

- 4

- Views

- 660