Forgive my question that comes from ignorance, but in talking to my friend who is a machinist by trade, he was asking why a floating reamer holder or one of the fancy morse taper mounted reamer holders was needed, as opposed to ensuring your tailstock was properly aligned (both vertically and horizontally) and just using a tap handle braced against the carriage?

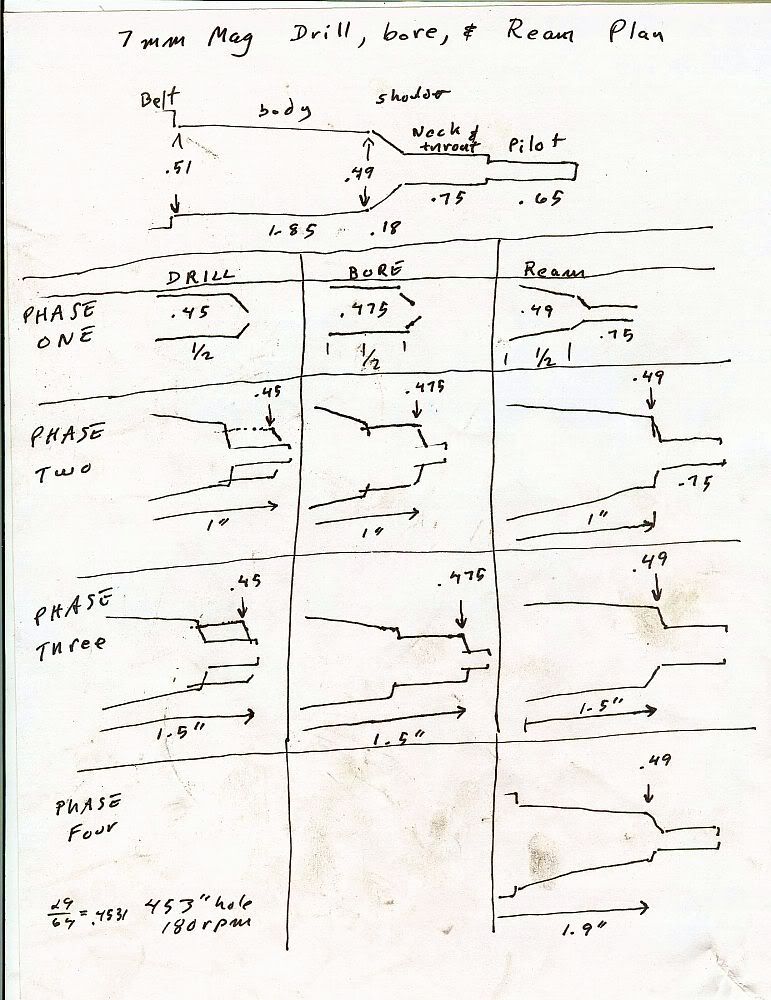

When I mentioned that it might be of help when retracting the reamer to peck at the chamber, he stated that we probably should have roughed the chamber via drilling then boring to within a very close tolerance of the final dimension in order to save wear on the reamer, and that with the flush coolant it shouldn't be pecked, but done to almost finish dimension, measured, and finished.

Since I didn't have a good answer, I thought I would ask here where someone would surely know, and my dumb questions might provide some humor at the same time.

Onyx

When I mentioned that it might be of help when retracting the reamer to peck at the chamber, he stated that we probably should have roughed the chamber via drilling then boring to within a very close tolerance of the final dimension in order to save wear on the reamer, and that with the flush coolant it shouldn't be pecked, but done to almost finish dimension, measured, and finished.

Since I didn't have a good answer, I thought I would ask here where someone would surely know, and my dumb questions might provide some humor at the same time.

Onyx