Another option is to level the stock out with Bondo, and then paint it FDE.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Remington 700 DBM opinions from guys that put them in.....and use them.

- Thread starter pmclaine

- Start date

You know there are very few Marines that don’t secretly long to create such a stock…we’re not the sky penis pilots Marines?Lol.

Must be a Navy rifle.

It’s only gay if you put one on the cheek rest facing the butt of the stock.

Anybody got the bubble sheet?!You know there are very few Marines that don’t secretly long to create such a stock…

View attachment 8013233

Obviously a stock for a belted magnum cartridge.

Anything in the 6mm range……Obviously a stock for a belted magnum cartridge.

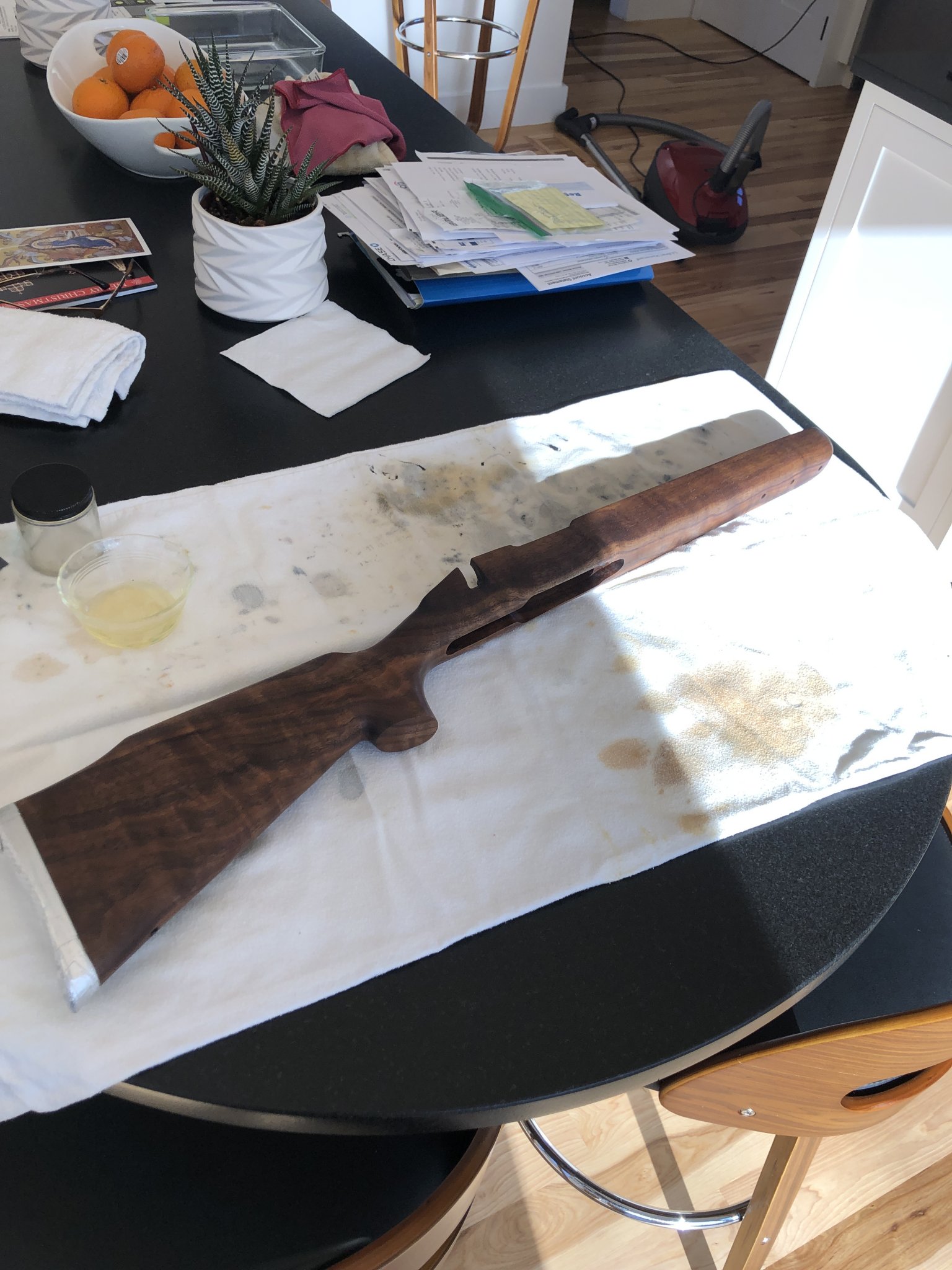

I’ve been hand burnishing it for a few times now and it’s getting a pretty good gloss and has the feel of poly….

It’s got sort of a haze though that I think would go away with a finer polish, kind of clearing the “windshield” so you can see inside.

This is the dangerous part though. I am probably happy how it is and it would be real easy for it to go bad fast.

It’s got sort of a haze though that I think would go away with a finer polish, kind of clearing the “windshield” so you can see inside.

This is the dangerous part though. I am probably happy how it is and it would be real easy for it to go bad fast.

That is looking great. Perfect amount of sheen for me, but I can see exactly what you are saying

Yes, no, maybe? Lol. Hard to quantify since it breaks down further as you use it, but it is a polish vs material remover.Is rotten stone a finer polishing media than 2000 wet dry?

Who has that answer?

The chatoyance and depth came out very well.

You are at that moment in the project where it is very nice, and you could call it done. Or you could try that one extra thing and totally fuck it up, or elevate it to a higher level.

Choose your own adventure, lol.

Those red marks are hot spot blisters forming…….What are you using to burnish?

DW

Going to go for it……..there is always krylon.Yes, no, maybe? Lol. Hard to quantify since it breaks down further as you use it, but it is a polish vs material remover.

The chatoyance and depth came out very well.

You are at that moment in the project where it is very nice, and you could call it done. Or you could try that one extra thing and totally fuck it up, or elevate it to a higher level.

Choose your own adventure, lol.

Respect.Going to go for it……..there is always krylon.

Once a decision has been made it’s important to rush and hurry up to see where it brings you….

Nice vacuum!Once a decision has been made it’s important to rush and hurry up to see where it brings you….

View attachment 8013597

Yep, you got it right. Wonderful job that deserves a high quality bourbon and a good smoke. I’d recommend hookers too, but don’t think your wife would appreciate it!

Depth, color, and glow are all on point. Plus you have an easily repairable finish.

It sucks.Nice vacuum!

That’s the first “heavy” coat I left on it.Yep, you got it right. Wonderful job that deserves a high quality bourbon and a good smoke. I’d recommend hookers too, but don’t think your wife would appreciate it!

Depth, color, and glow are all on point. Plus you have an easily repairable finish.

All others I paper toweled down shortly after application.

This one will haze up I am guessing.

I will let it sit in the sun window for the day before putting it back in the boiler room tonight.

I may get two more full strength “light” coats of tung oil before Friday. I’ll burnish the shit out of it between coats.

Saturday morning I’m hitting it with Rottenstone mixed with tung oil to see if that will smooth the surface.

I think the tung will be satin but the wood is so smooth now it is the gloss underneath.

Last edited:

Brownells is what I bought.Brownells site says theirs is rated 3f. Other websites are saying between 2000 and 4000

This thing right now is better than I expected it to be….

I am going to go for fucking it all up though.

Can’t stop now,

I am going to go for fucking it all up though.

Can’t stop now,

I gave it a real light coat last night and it finally started to pop.

It feels great totally dry but you can feel the build up, no sensation of wood. I have been burnishing it in with hand heat.

I am going to give it another light coat tomorrow night to further build up a finish to polish.

I’ll hit it with 3F rottenstone/oil on Saturday. It will be like spit shining light work. May steal some of my wife’s cotton make up pads to rub it in like Mr. Miyagi.

I’ll let that dry in probably all week than hit it with 5F next Saturday.

I’ll hand burnish it all week to give it as much simulated carry use as time will allow.

It feels great totally dry but you can feel the build up, no sensation of wood. I have been burnishing it in with hand heat.

I am going to give it another light coat tomorrow night to further build up a finish to polish.

I’ll hit it with 3F rottenstone/oil on Saturday. It will be like spit shining light work. May steal some of my wife’s cotton make up pads to rub it in like Mr. Miyagi.

I’ll let that dry in probably all week than hit it with 5F next Saturday.

I’ll hand burnish it all week to give it as much simulated carry use as time will allow.

Honestly, I’d give it a full week from last coat before you hit it with the rotten stone.

How do you plan to use the rotten stone? Will you make a slurry, or will you sprinkle it onto the applicator?

How do you plan to use the rotten stone? Will you make a slurry, or will you sprinkle it onto the applicator?

I’m thinking oil the stock nice and wet than wet the applicator and just dip a little stone off a flat plate.Honestly, I’d give it a full week from last coat before you hit it with the rotten stone.

How do you plan to use the rotten stone? Will you make a slurry, or will you sprinkle it onto the applicator?

I’ll wipe polished areas with a paper towel to remove any media.

All polish will be along the length of the grain.

All polish will be along the length of the grain.

Absolutely gorgeous

Makes me want to touch my own wood. I've got a stock that could use some tlc. Yours looks amazing. Thanks for sharing the process!

Makes me want to touch my own wood. I've got a stock that could use some tlc. Yours looks amazing. Thanks for sharing the process!

You are more brave than I am. That is beautiful as isThis thing right now is better than I expected it to be….

View attachment 8015377

View attachment 8015379

View attachment 8015380

View attachment 8015381

I am going to go for fucking it all up though.

Can’t stop now,

I am going to do my best to screw this up…I was probably Montgomery in a past life…..

When do the festivities Begin

Thinking of hitting it with the 3F rotten stone or @Bigfatcock will call me a pussy for chickening out.When do the festivities Begin

My 5F rouge will be here for next weekend than I will be done.

I took a factory Tupperware stock that came on 700 VS and installed a Magpul DBM in it. Inverted the stock, secured the DBM via the action holes and then carefully traced outline on the stock. A lot of slow dremel work and constant checking fit with some filing on the DBM I finally got it to fit. Put rifle, stock and bottom metal together. Filled the mag up with ammo and slowly ran ammo. Worked like butter.

Now you tell me!I took a factory Tupperware stock that came on 700 VS and installed a Magpul DBM in it. Inverted the stock, secured the DBM via the action holes and then carefully traced outline on the stock. A lot of slow dremel work and constant checking fit with some filing on the DBM I finally got it to fit. Put rifle, stock and bottom metal together. Filled the mag up with ammo and slowly ran ammo. Worked like butter.

Where were you so many years ago?

Send me that old boat paddle, I’ll dremel some magpul magic into it for you.Now you tell me!

Where were you so many years ago?

You going to use water or oil?

Pure Tung Oil

The men at the range will be asking for you digits.

If it was pink Krylon you’d be rolling in poontang.

Similar threads

- Replies

- 7

- Views

- 789

- Replies

- 33

- Views

- 4K