They should tell us how they really feel lolEVERY single barrel is like that.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The "New" Barrett MRAD Thread!!!!!!

- Thread starter IanHusaberg

- Start date

Did you use a torch?

I didn't but should have since I had a torch in the same room -_-Did you use a torch?

Welcome to the club!

Welcome to the club!

My initial impressions when compared to my AXSR:

- The MRAD is 1000x easier to disassemble.

- MRAD trigger is easier to access and adjust.

- MRAD barrel is quicker to remove. Although, my area419 arca mlok bolts are a tad too long and need filed down so i can remove the barrel without needing to loosen the mlok bolts.

- in terms of cleaning the "receiver," which the barrel extension is, it is much easier to clean because you can remove the barrel.

- MRAD sits lower on my tripod.

- Bolt lift feels the same to me which is alright because the AXSR compared to the ATX has a much better bolt lift.

- MRAD bolt cycling is much better because of the guides. It feels like it doesn't bind (very minor but worth mentioning) like my AXSR.

- I have mine setup for tripod shooting with the length of pull at its minimum and then I extend the LOP for prone shooting. It is much faster to make that adjustment on the MRAD because of the push button.

Last edited:

Funny how this subject came up after I just talked to Bugholes about a custom barrel. They said that flats would have to be done on the barrel nut and the above picture shows that clearly. Problem is that a heavy varmint barrel has to be used due to the back end of the barrel length. Didn't exactly understand that part, and not wild about the extra weight.If you're not looking for a custom barrel, the shot out barrel is basically throw away and you buy a new one off Barrett's website. If you want a custom barrel, a competent gunsmith can re-use the interface to spin up a new barrel. Barrett also has Maker's kits ($450), which include the factory barrel interface and bolt to allow use of custom barrels. The only restriction is the cartridge you pick has to match one of the available Barrett bolt faces. The interface typically needs to be removed by a gunsmith. I currently have a factory 338NM barrel, a 28" custom Bartlein 300PRC MRAD barrel, a 30" 33XC Bartlein Mod BB MRAD barrel (single feed only) and I'm waiting for a Bartlein 41XC barrel to arrive which I will most likely finish at 28".

Every barrel I've gotten from SPR shoots sub 1/3 MOA. I got a 1/4" MOA group at 500 yards with the 33XC barrel.

At this point, I wonder if I should go with a Proof ss barrel or talk with SPR.

Great info here fellows.

What they mean by the back end barrel length is that the first 5 inch's at the breach/chamber end have to be 1.25in for 5 inches to install the barrel extension. Then the barrel can taper. So often from "factory" or mfg based contours only a heavy varmint barrel works. You can really custom order any type of taper you want. I have bartlien's that have the required 5 inch shank and then taper like light, med, and heavy palmas. Heck i have a 6.5 saum barrel in light palma. The "B" part needs to be 5 inches just like contour #9.Funny how this subject came up after I just talked to Bugholes about a custom barrel. They said that flats would have to be done on the barrel nut and the above picture shows that clearly. Problem is that a heavy varmint barrel has to be used due to the back end of the barrel length. Didn't exactly understand that part, and not wild about the extra weight.

At this point, I wonder if I should go with a Proof ss barrel or talk with SPR.

Great info here fellows.

Last edited:

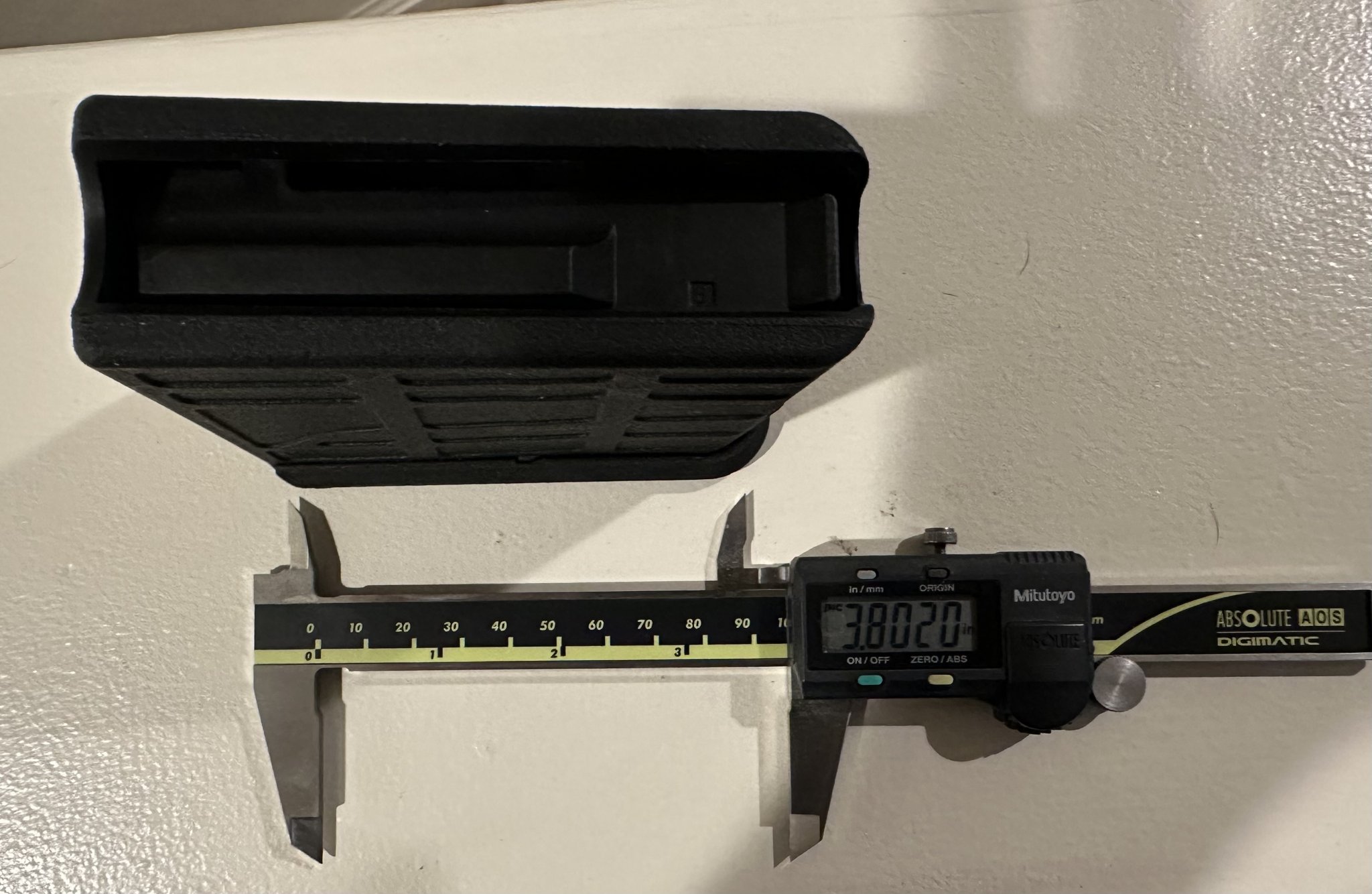

6.5 saum in light palma modified( 5 inchs of 1.25 vs traditional 3inches) vs 1.25 straight 6.5cm

Last edited:

Thanks for the education and great info on this Schmi. That really lays it out for me, as I'm travelling here in uncharted waters.What they mean by the back end barrel length is that the first 5 inch's at the breach/chamber end have to be 1.25in for 5 inches to install the barrel extension. Then the barrel can taper. So often from "factory" or mfg based contours only a heavy varmint barrel works. You can really custom order any type of taper you want. I have bartlien's that have the required 5 inch shank and then taper like light, med, and heavy palmas. Heck i have a 6.5 saum barrel in light palma. The "B" part needs to be 5 inches just like contour #9.

View attachment 8315045

Problem now is the wait time for the barrel maker's kits,,,,,,4-6 months, then the additional wait for the smithing services.

Why the wait? Barrett’s website says the kits are in stock. 4-6 week delivery time though.Thanks for the education and great info on this Schmi. That really lays it out for me, as I'm travelling here in uncharted waters.

Problem now is the wait time for the barrel maker's kits,,,,,,4-6 months, then the additional wait for the smithing services.Reaallly want a custom barrel though.

Yep, they’ve been in stock the back part of the year. Shipping won’t take that long either.Why the wait? Barrett’s website says the kits are in stock. 4-6 week delivery time though.

Shipping is really like 5-7 days at most.Why the wait? Barrett’s website says the kits are in stock. 4-6 week delivery time though.

According to the Barrett rep that my vendor uses, b.m.k's take from 4-6 months.Shipping is really like 5-7 days at most.

Same as above. I have a barrel on order with this vendor (Hinterland) and this is a constant problem with Barrett's "in stock" on their website. My "in stock" barrel has a 4-8 week wait time. The bmk's are 4-6 months, so if you fellows have a work around that I'm not aware of, feel free to let me know.............I'm all ears at this point.Why the wait? Barrett’s website says the kits are in stock. 4-6 week delivery time though.

According to the Barrett rep that my vendor uses, b.m.k's take from 4-6 months.

Same as above. I have a barrel on order with this vendor (Hinterland) and this is a constant problem with Barrett's "in stock" on their website. My "in stock" barrel has a 4-8 week wait time. The bmk's are 4-6 months, so if you fellows have a work around that I'm not aware of, feel free to let me know.............I'm all ears at this point.

Barrett Store - MRAD Barrel Makers Kit "A" 338 Family

MRAD Barrel Makers Kit "A" 338 Family

store.barrett.net

Barrett Store - MRAD Barrel Makers Kit "B" 300 Family

MRAD Barrel Makers Kit "B" 300 Family

store.barrett.net

Barrett Store - MRAD Barrel Makers Kit "C" 308 Family

MRAD Barrel Makers Kit "C" 308 Family

store.barrett.net

I ordered a kit a little over a week ago from Barrett and haven’t heard anything since. I just assumed the 4-6 week delivery is what to expect. Luckily, I’m not in a hurry to get a new barrel spun up. I’m eyeing a 37XC and a 33XC though. I have all the stuff from my other two XC rifles.

Order it direct from Barrett, why go through a vendor that doesn't have it in stock or has a long lead time? I've order a ton from the Barrett website and its been 3-10 business days for it to ship. I've ordered like 6 extensions in the past two years.

I'll have to look into that and call barrett direct.Order it direct from Barrett, why go through a vendor that doesn't have it in stock or has a long lead time? I've order a ton from the Barrett website and its been 3-10 business days for it to ship. I've ordered like 6 extensions in the past two years.

Would be interested in what happens with your purchase. Please let me/us know how long it takes......ThanksI ordered a kit a little over a week ago from Barrett and haven’t heard anything since. I just assumed the 4-6 week delivery is what to expect. Luckily, I’m not in a hurry to get a new barrel spun up. I’m eyeing a 37XC and a 33XC though. I have all the stuff from my other two XC rifles.

I ordered a 300WM barrel the third week of November and it just rolled in on Saturday - so 7 weeks between order and delivery of the barrel. Everything else in the order arrived a few days after it was placed.

Barrett was kind enough to finish the barrel in Tactical Peanut Butter for my Mk22 Only had 30 minutes or so to shoot yesterday so I got a rough zero after switching out the 300NM and took it over to 600 yards. Overall, really pleased with the performance and the barrel change process left quite an impression. MRAD is a very well thought out platform at this point, especially with the toolless bolt. I'll probably get back out in two weeks to shoot groups and try different factory loads before developing my own.

Only had 30 minutes or so to shoot yesterday so I got a rough zero after switching out the 300NM and took it over to 600 yards. Overall, really pleased with the performance and the barrel change process left quite an impression. MRAD is a very well thought out platform at this point, especially with the toolless bolt. I'll probably get back out in two weeks to shoot groups and try different factory loads before developing my own.

Ended up ripping all the LaRue shit off the front of the Mk22 and putting on a Badger/KMW assembly for the trip. Thinking Atlas CAL for the long term, potentially on the A419 ARCA rail made for the latest gen MRAD. Anyone given that piece a try, yet? @JB.IC yours looks similar but possibly not the MRAD-specific unit

Barrett was kind enough to finish the barrel in Tactical Peanut Butter for my Mk22

Ended up ripping all the LaRue shit off the front of the Mk22 and putting on a Badger/KMW assembly for the trip. Thinking Atlas CAL for the long term, potentially on the A419 ARCA rail made for the latest gen MRAD. Anyone given that piece a try, yet? @JB.IC yours looks similar but possibly not the MRAD-specific unit

The Area419 arca I have currently is not the MRAD specific. I’ll have that specific one in a few day.I ordered a 300WM barrel the third week of November and it just rolled in on Saturday - so 7 weeks between order and delivery of the barrel. Everything else in the order arrived a few days after it was placed.

Barrett was kind enough to finish the barrel in Tactical Peanut Butter for my Mk22Only had 30 minutes or so to shoot yesterday so I got a rough zero after switching out the 300NM and took it over to 600 yards. Overall, really pleased with the performance and the barrel change process left quite an impression. MRAD is a very well thought out platform at this point, especially with the toolless bolt. I'll probably get back out in two weeks to shoot groups and try different factory loads before developing my own.

Ended up ripping all the LaRue shit off the front of the Mk22 and putting on a Badger/KMW assembly for the trip. Thinking Atlas CAL for the long term, potentially on the A419 ARCA rail made for the latest gen MRAD. Anyone given that piece a try, yet? @JB.IC yours looks similar but possibly not the MRAD-specific unit

View attachment 8317543

I have the MK22 A419 rail. Great fit and finish. If you utilize their clamps on bipods, then it is not going anywhere.I ordered a 300WM barrel the third week of November and it just rolled in on Saturday - so 7 weeks between order and delivery of the barrel. Everything else in the order arrived a few days after it was placed.

Barrett was kind enough to finish the barrel in Tactical Peanut Butter for my Mk22Only had 30 minutes or so to shoot yesterday so I got a rough zero after switching out the 300NM and took it over to 600 yards. Overall, really pleased with the performance and the barrel change process left quite an impression. MRAD is a very well thought out platform at this point, especially with the toolless bolt. I'll probably get back out in two weeks to shoot groups and try different factory loads before developing my own.

Ended up ripping all the LaRue shit off the front of the Mk22 and putting on a Badger/KMW assembly for the trip. Thinking Atlas CAL for the long term, potentially on the A419 ARCA rail made for the latest gen MRAD. Anyone given that piece a try, yet? @JB.IC yours looks similar but possibly not the MRAD-specific unit

View attachment 8317543

Did you request the barrel cerakoted from Barrett? If so, I will order straight from Barrett for my next MK22 barrel.

Well it looks like you guys were right regarding the barrel maker kits. 4-6 weeks, don't know why the vendor has the extended time........Oh well.I'll have to look into that and call barrett direct.

Would be interested in what happens with your purchase. Please let me/us know how long it takes......Thanks

That aside, which barrel maker, gunsmith would you go with? Bartlein, Krieger? Bugholes or others that are familiar with the kits? Does the receiver need to be sent in? Thanks for any input.

Whatever barrel you want or can get your hand on. What caliber? Bartlein has a barrel serial # 2LA28121 in stock right now that would work.Well it looks like you guys were right regarding the barrel maker kits. 4-6 weeks, don't know why the vendor has the extended time........Oh well.

That aside, which barrel maker, gunsmith would you go with? Bartlein, Krieger? Bugholes or others that are familiar with the kits? Does the receiver need to be sent in? Thanks for any input.

6.5 5R 1 – 8.00 to 7.00 1.250” straight 30” finish SS 31” You can find it listed here and call them. https://www.bartleinbarrels.com/_files/ugd/a03e59_946653e1b36f4aa58ab965edd9130c33.pdf Any number of gunsmiths can do these now. Bugholes, PVA, LRI, GA Precision, Spartan Rifles etc Receiver does not need to be sent in, just barrel kit and barrel.

Yes! I threw it in the order comments, asking for peanut butter instead of the default black cerakote, and a very helpful sales rep informed me they could do it and I would see an extra $50 line item on the transaction. IMO it was very reasonable for an exception to the regular process and I'm happy to not have to mess around with the muzzle device!I have the MK22 A419 rail. Great fit and finish. If you utilize their clamps on bipods, then it is not going anywhere.

Did you request the barrel cerakoted from Barrett? If so, I will order straight from Barrett for my next MK22 barrel.

When you get a moment, could you share some photos of the A419 rail and your accessories? I'm still torn on ARCA... As a card carrying member of the quad rail master race™, the features of a proprietary dovetail with rail slots and QD attachment aren't exactly novel to me but I'm no troglodyte and happy to appreciate something new.

No. What did you do? Put rifle vertical so its on buttstock, insert barrel, make sure it "set's in" on the indexing slot, close the bolt, then tighten the two forward screws to 140 in/lbs.Just got my first mrad, anyone else have a slight wobble to their barrel after swap?

Not at allJust got my first mrad, anyone else have a slight wobble to their barrel after swap?

nopeJust got my first mrad, anyone else have a slight wobble to their barrel after swap?

Just reinstalled my barrel for shits. There's the slightest wobble without the fasteners but it's gone by the time there's resistance on the Torx screws - it's 100% secure. I originally installed my 300WM with my MRAD resting on its bipod (directions and Barrett videos don't indicate and direction) but I'm going to try installing it vertically and see what effect it has on POI this weekend. I'd be pleased if the POI rises in that it would be closer to where the 300NM was from the factory!

Last edited:

Go bigger! I have a dedicated 41XC rifle but I'm spinning up an MRAD 1:11 barrel in 41XC to shoot 500gr A-tips, which are $1.65 each vs. $3.90 each for the Warner Flatline 505gr.I ordered a kit a little over a week ago from Barrett and haven’t heard anything since. I just assumed the 4-6 week delivery is what to expect. Luckily, I’m not in a hurry to get a new barrel spun up. I’m eyeing a 37XC and a 33XC though. I have all the stuff from my other two XC rifles.

My MRAD was pre-Mlok so I just got the generic ARCA rail.I ordered a 300WM barrel the third week of November and it just rolled in on Saturday - so 7 weeks between order and delivery of the barrel. Everything else in the order arrived a few days after it was placed.

Barrett was kind enough to finish the barrel in Tactical Peanut Butter for my Mk22Only had 30 minutes or so to shoot yesterday so I got a rough zero after switching out the 300NM and took it over to 600 yards. Overall, really pleased with the performance and the barrel change process left quite an impression. MRAD is a very well thought out platform at this point, especially with the toolless bolt. I'll probably get back out in two weeks to shoot groups and try different factory loads before developing my own.

Ended up ripping all the LaRue shit off the front of the Mk22 and putting on a Badger/KMW assembly for the trip. Thinking Atlas CAL for the long term, potentially on the A419 ARCA rail made for the latest gen MRAD. Anyone given that piece a try, yet? @JB.IC yours looks similar but possibly not the MRAD-specific unit

View attachment 8317543

I bought a like 2000 of 375cal CEB a few years ago a for $1.33 a piece and have only shot like 500. So I need to get rid of them before moving up.Go bigger! I have a dedicated 41XC rifle but I'm spinning up an MRAD 1:11 barrel in 41XC to shoot 500gr A-tips, which are $1.65 each vs. $3.90 each for the Warner Flatline 505gr.

Weird. That’s what I did. I’ll try to reseat it. I held the handguard with one hand another with the barrel and noticed a slight wobbleNo. What did you do? Put rifle vertical so its on buttstock, insert barrel, make sure it "set's in" on the indexing slot, close the bolt, then tighten the two forward screws to 140 in/lbs.

Drop the barrel in, spin and make sure to seat against the pin, lock the bolt.Weird. That’s what I did. I’ll try to reseat it. I held the handguard with one hand another with the barrel and noticed a slight wobble

Took a quick side profile shot of my MK22 with the following A419 items:Yes! I threw it in the order comments, asking for peanut butter instead of the default black cerakote, and a very helpful sales rep informed me they could do it and I would see an extra $50 line item on the transaction. IMO it was very reasonable for an exception to the regular process and I'm happy to not have to mess around with the muzzle device!

When you get a moment, could you share some photos of the A419 rail and your accessories? I'm still torn on ARCA... As a card carrying member of the quad rail master race™, the features of a proprietary dovetail with rail slots and QD attachment aren't exactly novel to me but I'm no troglodyte and happy to appreciate something new.

- A419 MK22 Arcalock Rail

- A419 Harris Arcalock Clamp Kit

I like how the MK22 arca comes flush with the portion where the barrel clamps. I'll have mine Thursdays.Took a quick side profile shot of my MK22 with the following A419 items:

I also have an Atlas CAL bipod that I switch in and out for the Harris, which also has the A419 Arcalock clamp. My only complaint with the MK22 compared to the AXSR, is that there was not proprietary Arca built-in to the rail.

- A419 MK22 Arcalock Rail

- A419 Harris Arcalock Clamp Kit

View attachment 8319218

Thank you Schmi for all of this. You've been a great help along with the others on this forum.Whatever barrel you want or can get your hand on. What caliber? Bartlein has a barrel serial # 2LA28121 in stock right now that would work.

6.5 5R 1 – 8.00 to 7.00 1.250” straight 30” finish SS 31” You can find it listed here and call them. https://www.bartleinbarrels.com/_files/ugd/a03e59_946653e1b36f4aa58ab965edd9130c33.pdf Any number of gunsmiths can do these now. Bugholes, PVA, LRI, GA Precision, Spartan Rifles etc Receiver does not need to be sent in, just barrel kit and barrel.

As others have responded, my guess is that you didn't lock the bolt once you dropped the barrel in. Done that a time or two and I got that wobble you speak of. That notch is what I always look for and place the whole rig vertically, drop the barrel in and feel for the notch slipping into place. You'll also notice that the caliber size is on the top surface of the barrel near the muzzle brake. A great check for barrel seating and timing on a muzzle brake,btw.Just got my first mrad, anyone else have a slight wobble to their barrel after swap?

I always alternately tighten the screws until I reach the 140 in lbs of torque. Very important to have a torque wrench like the fix it sticks. Barrett sells those, but I'm sure you can get those cheaper elsewhere.

Have fun.......................

Last edited:

Any one know the oal capacity of the 300 PRC magazine? I'm looking at a custom barrel chambering and want to know if it will fit.

The SAAMI spec for .300 PRC OAL is 3.575-3.700" the B magazine for 300wm has internals of 3.8. Obv you will want it a little short to ensure feeding.

Took a quick side profile shot of my MK22 with the following A419 items:

I also have an Atlas CAL bipod that I switch in and out for the Harris, which also has the A419 Arcalock clamp. My only complaint with the MK22 compared to the AXSR, is that there was not proprietary Arca built-in to the rail.

- A419 MK22 Arcalock Rail

- A419 Harris Arcalock Clamp Kit

View attachment 8319218

Thank you! Mine should be here tomorrow

Agreed! They did a great job with it!I like how the MK22 arca comes flush with the portion where the barrel clamps. I'll have mine Thursdays.

Thanks,The SAAMI spec for .300 PRC OAL is 3.575-3.700" the B magazine for 300wm has internals of 3.8. Obv you will want it a little short to ensure feeding.View attachment 8319620

I have a friend that custom chambered 3 barrels with a shorter lead to allow Berger's to seat deeper in the case neck. I'll see what his COAL turns out to be. Certainly shorter than it is now.

The fix it sticks are great but I wasn't able to find the 140 in-lb without buying the kit from Barrett.As others have responded, my guess is that you didn't lock the bolt once you dropped the barrel in. Done that a time or two and I got that wobble you speak of. That notch is what I always look for and place the whole rig vertically, drop the barrel in and feel for the notch slipping into place. You'll also notice that the caliber size is on the top surface of the barrel near the muzzle brake. A great check for barrel seating and timing on a muzzle brake,btw.

I always alternately tighten the screws until I reach the 140 in lbs of torque. Very important to have a torque wrench like the fix it sticks. Barrett sells those, but I'm sure you can get those cheaper elsewhere.

Have fun.......................

They sell it individually, LMT people need it too.The fix it sticks are great but I wasn't able to find the 140 in-lb without buying the kit from Barrett.

I like the kit as it is well thought out, but man, the price on that thing.The fix it sticks are great but I wasn't able to find the 140 in-lb without buying the kit from Barrett.

this is straight facts.I like the kit as it is well thought out, but man, the price on that thing.

The same kit from fix it stix is far and away cheaper.... but they are always out of stock for the 140lbs torque limiter which pretty much makes the buying of the MRAD Kit the only reliable way of getting one (atm)

Not that I'm aware of. I wish i could get an unfinished .308 or .300 mag to file feed lips myself to run a 6.5saum.Anyone know of mag extension kits? I’m not really a fan of how my 300NM feels on that first round when I have a full mag.

Hello,

does anyone know what a safe headspace measurement could be for the .338LM version? Can't find any SAAMI specs for this cartridge.

Bought some 1F LAPUA 338LM brass online and getting ready to handload. It's measuring at 2.327-2.328" (Hornady headspace gauge) and will not allow the bolt to close even when pushing forward on the bolt. I have been incrementally bumping the shoulder and can now chamber brass measuring 2.322" headspace. This still requires a light forward push of the bolt before it will turn down. I have tried bumping the shoulder as much as I can down to 2.315" and still the bolt won't close freely without forward push - like it does when no brass is being inserted into the chamber.

I hope I've explained this coherently enough that someone can offer me guidance.

Thanks.

does anyone know what a safe headspace measurement could be for the .338LM version? Can't find any SAAMI specs for this cartridge.

Bought some 1F LAPUA 338LM brass online and getting ready to handload. It's measuring at 2.327-2.328" (Hornady headspace gauge) and will not allow the bolt to close even when pushing forward on the bolt. I have been incrementally bumping the shoulder and can now chamber brass measuring 2.322" headspace. This still requires a light forward push of the bolt before it will turn down. I have tried bumping the shoulder as much as I can down to 2.315" and still the bolt won't close freely without forward push - like it does when no brass is being inserted into the chamber.

I hope I've explained this coherently enough that someone can offer me guidance.

Thanks.

Similar threads

- Replies

- 2

- Views

- 380

- Replies

- 6

- Views

- 444

- Replies

- 0

- Views

- 443