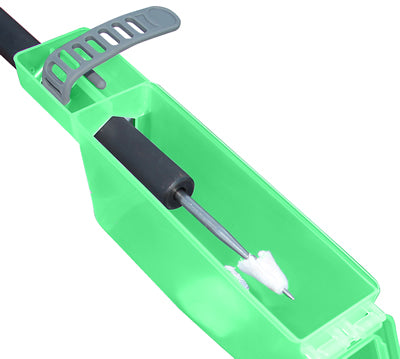

I use Parker Hale jags with wrapped patches, and also nylon brushes, and I run them in both directions. With the jag/patch, I stop the stroke when the tip of the jag has exited the muzzle, but before the entire wrapped patch has exited (ie. half-way out the muzzle). If you let the whole thing exit, the patch may try to ball-up at the muzzle on the return stroke and be excessively hard to return.Ok ok, so why no brush in and out? I used to be a one way only pass kind of guy and unscrew the brush after it exists muzzle and so on. However, after watching people like Erik Cortina run his in an out at 100mph, I don’t see why it’s a big deal? Thoughts? I always thought it was a little silly because it’s barrel steel and it’s hard for me to believe that a nylon brush with a brass collar coming out or riding back over the muzzle is going to do anything. Brass is much softer than barrel steel. I mean it flings copper jacketed lead out of it as thousands of feet per second. Is coming backwards over the muzzle really going to do anything?

With a brush, you pretty much have to let it completely exit, because if you don't, the bristles have to reverse direction within the bore and that causes difficulty. I let the brush exit, then slowly let it re-center itself in the muzzle on the return stroke before bringing it back to the chamber end. I can't see how you could possibly do any damage to the crown if you are gentle (as above) when you are transiting through it in either direction. I DO, however, always finish the final stroke of either patch or brush on the way OUT of the barrel to push any dislodged debris out with it, and I finish up with dry patches in the same one-way direction to push everything out the muzzle. I have not experienced any premature loss of barrel life using these techniques, and I believe that going in both directions does a better job of scrubbing the bore clean.