I always us a boreguide.

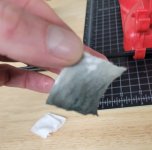

I use VFG plain pellets w/ Bore Tech C4 followed by KG3 solvent degreaser.

Finally a pellet w/ Montana X-Treme Bore Conditioner and 1 last dry pellet for any excess left behind.

Once in a while I will throw the bore-tech copper remover in the mix. KG3 between all chemical changes.

I live in a semiarid climate but as a precaution I leave the can off and action open to allow any missed moisture to evaporate.

I personally think that not removing cans after shooting leads to potential problems.

I use VFG plain pellets w/ Bore Tech C4 followed by KG3 solvent degreaser.

Finally a pellet w/ Montana X-Treme Bore Conditioner and 1 last dry pellet for any excess left behind.

Once in a while I will throw the bore-tech copper remover in the mix. KG3 between all chemical changes.

I live in a semiarid climate but as a precaution I leave the can off and action open to allow any missed moisture to evaporate.

I personally think that not removing cans after shooting leads to potential problems.