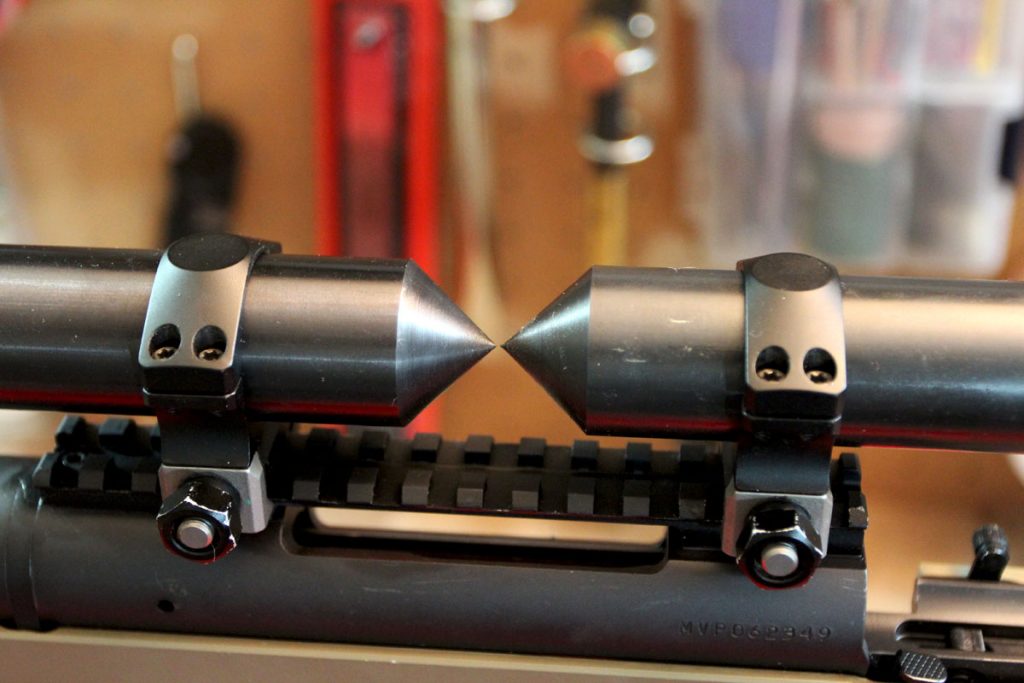

Back in the 1970s, my father & his shooting buddies had a “gizmo” that was a true steel rod with a 90degree handle in the middle. It looked like a “T” with en extremely short stem.

After they installed scope mounts, they used 600 or 800 grit sand paper to polish the mounts & ensure they were true & didn’t effect the scope.

I’ve never seen it since & never used this practice on my Leupolds & factory mounts.

Is this practice to align scope rings still recommended for precision rifles, or gas CNC & modern tech rendered it obsolete?

Thank you.

After they installed scope mounts, they used 600 or 800 grit sand paper to polish the mounts & ensure they were true & didn’t effect the scope.

I’ve never seen it since & never used this practice on my Leupolds & factory mounts.

Is this practice to align scope rings still recommended for precision rifles, or gas CNC & modern tech rendered it obsolete?

Thank you.