Test it out and see if you even need one. I am not currently using one but haven't measure a chambered round to see if it changes.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.224 Valkyrie

- Thread starter Niles Coyote

- Start date

Chambered and ejected some of my not crimped rounds (with different OAL's, all under 2.26", to make sure I wasn't hitting rifling) and my bullets are indeed slipping forward. I found this Sierra article below, which sites the issue. Ironically (or maybe not), I was seeing almost the exact same amount of slip on my bullets (0.004" to 0.008"). Sierra stated forward slip range of 0.003" up to 0.007". Maybe even still, .008" isn't enough to actually matter in the real world, I'm not sure. I'm going to order that Lee crimper and see if I can get bullets to stay put better with a light crimp.

http://www.exteriorballistics.com/reloadbasics/gasgunreload.cfm

http://www.exteriorballistics.com/reloadbasics/gasgunreload.cfm

I have the RCBS die set which taper crimps, although I haven't crimped any rounds yet. I'm not sure if I want to crimp bullets which don't have cannelures. I'll chamber, extract, and re-measure some cases in the next few days to see if the length changes.

The Sierra article is indeed an excellent source of information, I’ve seen it before. But the last two sentences of third paragraph under “neck tension” says it all about the subject at hand:

“That having been said, crimping is still, at best, an occasionally necessary evil. Avoid it if at all possible.”

Further reading gives more information about the better option, which is “adjusting neck tension.” It provides two methods to do this. The first method, grinding the expander ball, is kind of funky and if done incorrectly may introduce excessive out-of-concentricity in the final product. The second solution - use of a full-length bushing die - is the better option. This is the one that I use. It’s a bit of a pain in the butt, because you most likely will need to change the bushing diameter when changing brass types or brands (or even when changing lot numbers). But, when you get it right, it works well to produce consistent, accurate handloads.

“That having been said, crimping is still, at best, an occasionally necessary evil. Avoid it if at all possible.”

Further reading gives more information about the better option, which is “adjusting neck tension.” It provides two methods to do this. The first method, grinding the expander ball, is kind of funky and if done incorrectly may introduce excessive out-of-concentricity in the final product. The second solution - use of a full-length bushing die - is the better option. This is the one that I use. It’s a bit of a pain in the butt, because you most likely will need to change the bushing diameter when changing brass types or brands (or even when changing lot numbers). But, when you get it right, it works well to produce consistent, accurate handloads.

Last edited:

The second solution - use of a full-length bushing die - is the better option. This is the one that I use. It’s a bit of a pain in the butt, because you most likely will need to change the bushing diameter when changing brass types or brands (or even when changing lot numbers). But, when you get it right, it works well to produce consistent, accurate handloads.

Gotcha. Sounds like a better option than crimping, can you share what parts/brand you're using? And what diameter is working for your brass?

JPatzig,

I use RCBS Competition series dies. There are two sizing die flavors in these sets: 1. a full-length bushing sizer, and 2. a neck-size only bushing sizer. Stay away from the neck-size only, that’s for the bolt-action guys. As for bushing choice, you will need to determine that for yourself by one of two methods, using your brass and bullets. Here’s the instructions from RCBS on that:

“Proper neck bushing size can be determined two ways. Measure the outside neck diameter of a sample loaded cartridge, subtract .002" to .003". This allows approximately .001" of brass spring back for correct neck tension. The other is to measure the neck wall thickness of your case, multiply by two, add the diameter of your bullet and subtract .001". For example: loaded case neck diameter is .333-.002=.331 neck bush- ing or .012 case neck thickness, .308 diameter bullet is .012+.012+.308 =.332-.001=.331 neck bushing. RCBS suggests that you have neck bushings one to two sizes above and below your target diameter.”

Be advised, there are two types of bushings available: coated and non-coated. The coated bushings behave like carbide dies...you don’t have to lube the neck. This is important when you want maximum grip with minimum distortion of the bullet during seating, like what we are talking about here. So, I use coated all the time. More expensive, but you don’t risk getting lube inside the case neck during sizing.

Be advised that for first-time sizing of brand-new brass you will need to use the provided expander ball with no bushing in the die chamber. Fired brass uses the bushings, but there is no expander ball.

If you load some test ammo and find that the bullet slips as described in previous posts, it’s a simple matter to pull the bullets and put the next smaller bushing in the die and run them through the sizer again, being careful not to get lube down into the neck.

I use RCBS Competition series dies. There are two sizing die flavors in these sets: 1. a full-length bushing sizer, and 2. a neck-size only bushing sizer. Stay away from the neck-size only, that’s for the bolt-action guys. As for bushing choice, you will need to determine that for yourself by one of two methods, using your brass and bullets. Here’s the instructions from RCBS on that:

“Proper neck bushing size can be determined two ways. Measure the outside neck diameter of a sample loaded cartridge, subtract .002" to .003". This allows approximately .001" of brass spring back for correct neck tension. The other is to measure the neck wall thickness of your case, multiply by two, add the diameter of your bullet and subtract .001". For example: loaded case neck diameter is .333-.002=.331 neck bush- ing or .012 case neck thickness, .308 diameter bullet is .012+.012+.308 =.332-.001=.331 neck bushing. RCBS suggests that you have neck bushings one to two sizes above and below your target diameter.”

Be advised, there are two types of bushings available: coated and non-coated. The coated bushings behave like carbide dies...you don’t have to lube the neck. This is important when you want maximum grip with minimum distortion of the bullet during seating, like what we are talking about here. So, I use coated all the time. More expensive, but you don’t risk getting lube inside the case neck during sizing.

Be advised that for first-time sizing of brand-new brass you will need to use the provided expander ball with no bushing in the die chamber. Fired brass uses the bushings, but there is no expander ball.

If you load some test ammo and find that the bullet slips as described in previous posts, it’s a simple matter to pull the bullets and put the next smaller bushing in the die and run them through the sizer again, being careful not to get lube down into the neck.

PS...Don’t forget to check neck concentricity after sizing, and bullet concentricity in your final product. About a year ago I was having trouble with my handloads not being consistent. I discussed this problem with a shooter friend who is an accomplished machinist and he explained to me how important concentricity is in this whole process. My handloads were all over the charts, some with near-perfect concentricity, others out of round by as much as 0.008”. I traced the problem to my 40-year-old Reloader Special press that was just flat worn out. I now use RCBS Summit presses exclusively for both sizing and seating. Problem solved. Of course, the are any number of other good, solid, perfectly linear presses out there that will do just as well, even progressives. The friend that tipped me to about concentricity issues uses a Dillon 650.

I've been running at max pressure with 88 ELD and it works but I'm stressing primer pockets too much. Barrel has speed up about 75fps since new so I think I can back down and maintain better brass life with good speed.

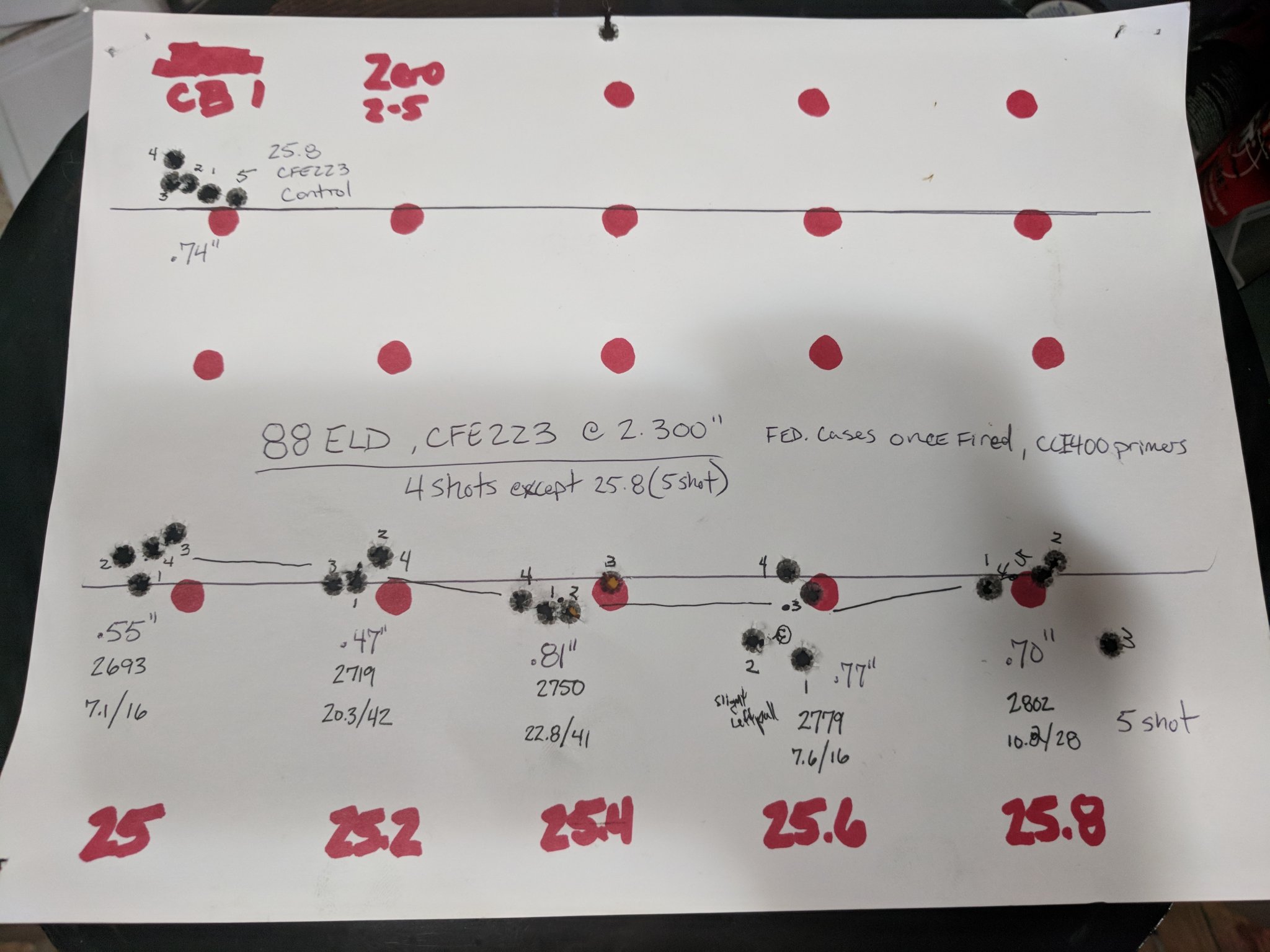

Here is OCW with 88ELD and CFE 223. Nodes at 25-25.2 and 25.8-26 (very hot load and 26 is known from prior testing). SD is my fault for changing shoulder pressure/bipod load for middle two groups.

Here is OCW with 88ELD and CFE 223. Nodes at 25-25.2 and 25.8-26 (very hot load and 26 is known from prior testing). SD is my fault for changing shoulder pressure/bipod load for middle two groups.

Well, 25.2 looks pretty dang good to me, and 2719 fps is nothing to sneeze at.Good shooting!I've been running at max pressure with 88 ELD and it works but I'm stressing primer pockets too much. Barrel has speed up about 75fps since new so I think I can back down and maintain better brass life with good speed.

Here is OCW with 88ELD and CFE 223. Nodes at 25-25.2 and 25.8-26 (very hot load and 26 is known from prior testing). SD is my fault for changing shoulder pressure/bipod load for middle two groups. View attachment 6930998

I have a long freebore and am sick of wasting time and money doing unsecessful load development. I have a cavity back bullet extended COAL magazine on order before I load any more.

What happened to this thread? The silence is deafening. Did you guys all sell your rifles? LOL!

For me, I've just been busy with other projects and shooting matchs. My valkyries will be making range trips again come October.

I have been watching this thread, along with the other Valkyrie threads, and do have my rifle together and shooting, but am only shooting factory right now. Hornady 88 ELDM is doing pretty well in my 22" 6.7 twist Rock Creek barrel from Craddock at about 2750 fps. I've only had it out to 800 so far as I'm waiting on a scope, but the results have been very good so far. At some point I plan on picking up some CFE 223 and Hornady 88s to play with, but really do not have the time right now, so that will probably have to wait until the winter months. Really pleased so far with this barrel.

FWIW, the Federal factory Fusion 90g loads also did well in my rifle, but I'm comfortable with the Hornady results at this point.

FWIW, the Federal factory Fusion 90g loads also did well in my rifle, but I'm comfortable with the Hornady results at this point.

They shoot much better in my 224's than Federal. All guns are 1-7 twist.i realize this is the reloading forum, but has anyone gotten and shot the factory hornady 88 eldm loads yet? any input, and any comparisons with the fed gm 90's?

I have been watching this thread, along with the other Valkyrie threads, and do have my rifle together and shooting, but am only shooting factory right now. Hornady 88 ELDM is doing pretty well in my 22" 6.7 twist Rock Creek barrel from Craddock at about 2750 fps. I've only had it out to 800 so far as I'm waiting on a scope, but the results have been very good so far. At some point I plan on picking up some CFE 223 and Hornady 88s to play with, but really do not have the time right now, so that will probably have to wait until the winter months. Really pleased so far with this barrel.

FWIW, the Federal factory Fusion 90g loads also did well in my rifle, but I'm comfortable with the Hornady results at this point.

Is that velocity correct? You're 75 fps over the box-listed velocity of the 88ELD load (2675 fps) and that is set through a 24" test barrel. Does the brass or primer on your spent cases show any high-pressure signs?

Seems like it could be loaded pretty hot.

Yes, it is correct. I double checked, using my Magnetospeed because of the listed box velocity difference. The ballistics so far are also spot on to the projected drops for 2750 out to 800 yards. There are no undue signs of pressure showing. I can try and remember to take a picture of the primers for you tonight as a reference.Is that velocity correct? You're 75 fps over the box-listed velocity of the 88ELD load (2675 fps) and that is set through a 24" test barrel. Does the brass or primer on your spent cases show any high-pressure signs?

Seems like it could be loaded pretty hot.

It is not unknown for Rock Creek barrels to run a little faster than some others, but I honestly cannot tell you why. I just know what it is doing and that the results are good for me. Prior to hitting the long range side of things last Saturday, I took a few quick minutes and popped 5 rounds at 100 yards, as I still did not have the gas block adjusted exactly right. With the exception of a fourth round called flyer caused by the idiot behind the trigger, it was a ragged hole group of less than 1/2". The flyer was 1/2" from that group of four and was purely my fault due to lack of focus for split second. Or too much focus, as is sometimes the case.

Here you go:Interesting info about the Rock Creek barrels. May have to look into picking one up.

https://craddockprecision.com/224-valkyrie-rock-creek-6-7t/

Finally received notification that my JP barrel has shipped. Any recommendations on dies? I usually go with Redding but am willing to try others.

Finally received notification that my JP barrel has shipped. Any recommendations on dies? I usually go with Redding but am willing to try others.

A lot of people like Forster dies in general.

A lot of people like Forster dies in general.

I recently tried Forster dies with 6 Dasher and had a lot of issues due to the sizing die. Has left a bad taste.

Having good results with 88elds and cfe out of my 24" rock creek. I will post more on it when I verify a couple setting deep test but at this point I'm getting 2750fps with 26.2gr cfe with about 1 inch for 10rounds and an sd of 15 with virgin starline brass.

I’ve been quietly following along here for some time.

The WOA 24” Varmint upper with a 6.5 twist Krieger barrel that I ordered from WOA last month is due here this Friday.

I’ve got my dedicated lower built , an optic and mount ready to go, Redding dies, magazines, 95 and 90SMKs and 88ELDs and a couple hundred pieces of Hornady brass. Hell, I even bought a bob sled and 200 rounds of loaded Hornady 88ELDs.

The plan is to zero it Saturday morning with the loaded Hornady ammo, get some velocities with the LabRadar, and try to run it to 1K on Range 4 Sunday.

With one of the fired cases from Saturday morning, I’ll be able to make a modified case for my Hornady OAL gauge. I’d really want to see how generous the throat is gonna be, or not.

I’m anxious to see for myself if this cartridge lives up to all the hype.

The WOA 24” Varmint upper with a 6.5 twist Krieger barrel that I ordered from WOA last month is due here this Friday.

I’ve got my dedicated lower built , an optic and mount ready to go, Redding dies, magazines, 95 and 90SMKs and 88ELDs and a couple hundred pieces of Hornady brass. Hell, I even bought a bob sled and 200 rounds of loaded Hornady 88ELDs.

The plan is to zero it Saturday morning with the loaded Hornady ammo, get some velocities with the LabRadar, and try to run it to 1K on Range 4 Sunday.

With one of the fired cases from Saturday morning, I’ll be able to make a modified case for my Hornady OAL gauge. I’d really want to see how generous the throat is gonna be, or not.

I’m anxious to see for myself if this cartridge lives up to all the hype.

Last edited:

So I just received my brand spankin’ new WOP 24” 1-6.5 twist Krieger barreled upper and this notice was inside:

I guess I’m gonna be loading up fifty 55gr SGKs over RL7 and break in the barrel as per John Holliger....

I've been quietly following this thread for a while as well. I'm running a 24" CCMG 1:7 twist with rifle length gas system. I did the break in with the 77 grain Federal American Eagle which is grouping just over an inch. For the cheap box ammo (I got it for $10.99/box) I was impressed with the way it shoots. I couldn't get the Federal 90 grain Fusion to group under 2". Locally the other box ammo is not on the self at the moment. After getting out to the range to test my hand loads, I am seeing the best results with the 88 ELDs over 26.7 - 27 grains for RL17 with a COAL of 2.26. I'm getting consistant 5 round groups of under an inch with the higher loads. The 27 grain is showing signs of pressure in the primers so I'm going to run with 26.8 grains for now. I'm using the once shot Federal Brass and the primer pockets do feel loose but I haven't had any blow primers yet. I did have an issue with the ASC 6.8 SPC magazines and I had to file down the front of the mag about 1mm to get the cases to cycle.

It’s hard to wrap my head around why the first 50 rounds would determine the fate of a gas blockView attachment 6936067

So I just received my brand spankin’ new WOP 24” 1-6.5 twist Krieger barreled upper and this notice was inside:

View attachment 6936066

I guess I’m gonna be loading up fifty 55gr SGKs over RL7 and break in the barrel as per John Holliger....

the letter said 'port.' guess they're saying it erodes with the higher initial pressures. i actually replaced my block after a few hundred rounds (of 75-90g) for another reason, and didn't notice any port erosion, but wasn't looking for it.It’s hard to wrap my head around why the first 50 rounds would determine the fate of a gas block

I figured he meant port and wrote block...

As I understood it, the longer bearing surface on the heavies during initial break in erodes the gas port.

At least that’s their theory for the moment .

As much as I paid for the barrel , I figure why not?

As I understood it, the longer bearing surface on the heavies during initial break in erodes the gas port.

At least that’s their theory for the moment .

As much as I paid for the barrel , I figure why not?

Last edited:

I get it. Following simple instructions is an easy way to hedge against screwing up an expensive barrel. Erosion of a PORT ? seems insane as it is literally full thickness of the barrel. I’m scratching my head but at the same time realizing most of this stuff is voodoo anyways.I figured he meant port and wrote block...

As I understood it, the longer bearing surface on the heavies during initial break in erodes the gas port.

At least that’s their theory for the moment .

As much as I paid for the barrel , I figure why not?

Longer barrels (past gas block) and slower bullets would increase the amount of time the port is under pressure, but if velocities aren’t changing much, what would be so different about the first 50 versus others? Simply smoothing out the gas port tap?

I get it. Following simple instructions is an easy way to hedge against screwing up an expensive barrel. Erosion of a PORT ? seems insane as it is literally full thickness of the barrel. I’m scratching my head but at the same time realizing most of this stuff is voodoo anyways.

They do not mean the entire port, but rather just where it meets the bore. They normally have a burr when new. As far as why a longer bearing surface exacerbates it while a shorter bearing surface wears it away, I do not know why.

Brand new barrel:

Well, I guess that my barrel will have issues, if this truly is a thing. As one would expect, I broke my barrel in using 90g and 88g bullets.

The only reason I can currently imagine that could be why this could make a difference is that it might be something to do with work hardening.

The only reason I can currently imagine that could be why this could make a difference is that it might be something to do with work hardening.

Has anyone tried RL16? Or Varget? Seems most people are using 17 or CFE but I was hoping to avoid just another powder to keep track of.

Niles Coyote has some testing that he did with Varget and RL15 on pages 1 and 2 of this thread.Has anyone tried RL16? Or Varget? Seems most people are using 17 or CFE but I was hoping to avoid just another powder to keep track of.

So I did the White Oak Precision recommended “gas port break in” on my Krieger 1:6.5 twist barrel yesterday morning. It was already 85F with 96%RH @ 0900.

What a pain in the ass with the BCG short cycling with the itty bitty 55gr SGKs.

The bore probably got cleaned more times that morning than it will be cleaned in the next three months.

I’m amazed the jackets of the 55s didn’t rip themselves off with a 6.5 twist....

I finally finished with that dumb shit and ran some Hornady 88ELD factory ammo. The rifle began to cycle perfectly.

Who’s running 95gr SMKs? Got any data?

I’ve got Starline and Hornady brass and a lot of RL17......

What a pain in the ass with the BCG short cycling with the itty bitty 55gr SGKs.

The bore probably got cleaned more times that morning than it will be cleaned in the next three months.

I’m amazed the jackets of the 55s didn’t rip themselves off with a 6.5 twist....

I finally finished with that dumb shit and ran some Hornady 88ELD factory ammo. The rifle began to cycle perfectly.

Who’s running 95gr SMKs? Got any data?

I’ve got Starline and Hornady brass and a lot of RL17......

How did the factory 88 ELD shoot in your rifle? I shoot the 88 under handloads. Curious about the factory ammo though for substitute in a pinch.So I did the White Oak Precision recommended “gas port break in” on my Krieger 1:6.5 twist barrel yesterday morning. It was already 85F with 96%RH @ 0900.

View attachment 6938044

What a pain in the ass with the BCG short cycling with the itty bitty 55gr SGKs.

The bore probably got cleaned more times that morning than it will be cleaned in the next three months.

View attachment 6938043View attachment 6938045

I’m amazed the jackets of the 55s didn’t rip themselves off with a 6.5 twist....

View attachment 6938047

I finally finished with that dumb shit and ran some Hornady 88ELD factory ammo. The rifle began to cycle perfectly.

View attachment 6938046

Who’s running 95gr SMKs? Got any data?

I’ve got Starline and Hornady brass and a lot of RL17......

I bought the factory stuff for break in and brass before I discovered I couldn’t use it for that....

I was surprised that the primer pockets were all crimped, but no matter.....

Grouped about .75 @100 but I was shooting off of a bench and I really couldn’t get comfortable.

I’m sure it will group better when I shoot it prone-

it was so fucking hot, all I wanted to do was leave after I chronographed the 88s.

I was surprised that the primer pockets were all crimped, but no matter.....

Grouped about .75 @100 but I was shooting off of a bench and I really couldn’t get comfortable.

I’m sure it will group better when I shoot it prone-

it was so fucking hot, all I wanted to do was leave after I chronographed the 88s.

I've only shot a couple hundred, but am buying more. I like how they do in my rifle.How did the factory 88 ELD shoot in your rifle? I shoot the 88 under handloads. Curious about the factory ammo though for substitute in a pinch.

Bison armory barrels? Can anyone vouch for them?

They're good quality, you do want to follow the break-in procedure to the T if you want to see the accuracy. The 18" i had was an MOA shooter if i did my part and made sure the barrel nut was torqued to spec.

For me, I've just been busy with other projects and shooting matchs. My valkyries will be making range trips again come October.

Niles, do you still have the 18" Rainier Arms Rock Creek? I was curious with all the talk about excessive freebore if whether or not this barrel is affected. I have the same barrel and bought it after your review on RA. Its shooting great with 75gr ELD to 80gr ELD but havent tested it with the 88gr ELD yet.

Yes I do, but I have not shot it with the 88's yet either. I will say the 88's consistently group tighter than the 90smk in my 22" Bartlien during load development, I'll be surprised if they don't shoot well in the 18" barrel.

Yes I do, but I have not shot it with the 88's yet either. I will say the 88's consistently group tighter than the 90smk in my 22" Bartlien during load development, I'll be surprised if they don't shoot well in the 18" barrel.

How about the 80gr ELD's? I have a load that works well with the 75gr ELD's with Power Pro 2000MR @ 27.1gr to 27.3gr at 2.260". Is the lead to spec in the RA Rock Creek?

Yes I do, but I have not shot it with the 88's yet either. I will say the 88's consistently group tighter than the 90smk in my 22" Bartlien during load development, I'll be surprised if they don't shoot well in the 18" barrel.

I mean freebore, not sure the terminology. From what others are reporting, RA did get the proper SAAMI reamer...not sure i guess i just want to confirm it.

My freebore seems spot on (RA UM 26") but chamber may have been run just a touch deeper than I'd want for best brass life. But it's a drill with 88ELDs. This was cold bore 10 shot group with virgin Federal. Had some trouble keeping recoil perfectly straight on the upper right shots.I mean freebore, not sure the terminology. From what others are reporting, RA did get the proper SAAMI reamer...not sure i guess i just want to confirm it.

I assume the chamber is correct, I did not have pressure problems like others have reported with some barrels and my length to lands is nearly the same as the 22" barrel made by Craddock.

@Subwrx300 what load are you shooting above?

@Subwrx300 what load are you shooting above?

Similar threads

- Replies

- 9

- Views

- 836

- Replies

- 10

- Views

- 1K