Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

**6 Creedmoor**

- Thread starter Sportin Wood

- Start date

Finally finished up load development. Its a little slow but I'm still above transsonic at 1250.

2905 fps avg- 10 shots, SD 6.6

Origin action, 26" Proof prefit.

Lapua brass, 3rd firing.

115 DTAC, coated

.060 jump

43.0 grains IMR 4955

CCI 450

ETA: this load is slightly compressed even with a Blue Ribbon drop tube. I was having a +/- .0025 seating depth variance with my micro seater. I tried a Redding type B seater and that went away. I can hear a very faint crunch at the very end of the ram stroke.

2905 fps avg- 10 shots, SD 6.6

Origin action, 26" Proof prefit.

Lapua brass, 3rd firing.

115 DTAC, coated

.060 jump

43.0 grains IMR 4955

CCI 450

ETA: this load is slightly compressed even with a Blue Ribbon drop tube. I was having a +/- .0025 seating depth variance with my micro seater. I tried a Redding type B seater and that went away. I can hear a very faint crunch at the very end of the ram stroke.

Last edited:

Kelbly atlas tactical

Mpa ba comp

Bartlein 1:7.5 twist medium Palma 27”

Heathen brake

Tt diamond

Alpha brass 5x fired

H-4350

105 hybrids

3150fps

Sd 8

Mpa ba comp

Bartlein 1:7.5 twist medium Palma 27”

Heathen brake

Tt diamond

Alpha brass 5x fired

H-4350

105 hybrids

3150fps

Sd 8

Good info here, gents.

I jumped On the 6creed bandwagon after having fun with the 6.5. It seems like the 6 creed may be one of the easiest cartridges to load for.

im eagerly awaiting my chassis from MDT then it’s go time. Already got 108, 109 hybrid, and the 112mb loaded using 4350 ready to test.

for those that have mentioned uniforming necks via mandrel, this helped bring down my SD and helped me set to .001-.002“ neck tension consistently. While I have the 21st century stuff, Sinclair’s makes a kit that isn’t that expensive. sizing on the progressive, the extra die isn’t a worry and has helped my load consistency.

P.S. I scored several pounds of staball 6.5 last night off Recobs! Looking forward to working with this powder, too.

I jumped On the 6creed bandwagon after having fun with the 6.5. It seems like the 6 creed may be one of the easiest cartridges to load for.

im eagerly awaiting my chassis from MDT then it’s go time. Already got 108, 109 hybrid, and the 112mb loaded using 4350 ready to test.

for those that have mentioned uniforming necks via mandrel, this helped bring down my SD and helped me set to .001-.002“ neck tension consistently. While I have the 21st century stuff, Sinclair’s makes a kit that isn’t that expensive. sizing on the progressive, the extra die isn’t a worry and has helped my load consistency.

P.S. I scored several pounds of staball 6.5 last night off Recobs! Looking forward to working with this powder, too.

Tried out my new Huber trigger today. This is the load in post #882. Target 5 are first shots of the day, cold bore and cold shooter. Target 6 was immediately after. The app inverted the pics for some reason.

Attachments

-Zues terminus action with QC barrel setup

-6cm prefit Bartlein Heavy Varmint 400MODBB barrel for matches

- Triggertech diamond trigger

- MPA BA comp chassis with full weight kit

- ZCO 5-27 scope

Lapua brass

115 DTACS

42.2 grains of H4350

Federal gold metal SRP

3064 fps

-6cm prefit Bartlein Heavy Varmint 400MODBB barrel for matches

- Triggertech diamond trigger

- MPA BA comp chassis with full weight kit

- ZCO 5-27 scope

Lapua brass

115 DTACS

42.2 grains of H4350

Federal gold metal SRP

3064 fps

109 LRHT 2.20 Ogive

40.5 gr H4350

CCI 450/ lapua brass

3040 avg / 9 ES / 6 SD pacing myself, 3077 avg / 26 ES / 14 SD running hard and hot.

1/8 groups, if I running it hard groups grow to 1/4 as things get hot.

26 Bartlein 7 twist 4 groove.

40.5 gr H4350

CCI 450/ lapua brass

3040 avg / 9 ES / 6 SD pacing myself, 3077 avg / 26 ES / 14 SD running hard and hot.

1/8 groups, if I running it hard groups grow to 1/4 as things get hot.

26 Bartlein 7 twist 4 groove.

109 LRHT 2.20 Ogive

40.5 gr H4350

CCI 450/ lapua brass

3040 avg / 9 ES / 6 SD pacing myself, 3077 avg / 26 ES / 14 SD running hard and hot.

1/8 groups, if I running it hard groups grow to 1/4 as things get hot.

26 Bartlein 7 twist 4 groove.

I am experimenting with two 6 creed 7.5 twists now. One is a 28" brux on a remington, one is a ruckus with Proof Prefit. I had to back off on the brux on remington to 40 grs flat h4350 (3147fps) behind 109's after it leveled out (compared to 2 other rifles chambered with same reamer, this brux is much faster than the other 2 rifles). The Proof on Ruckus is leveled out at 40.5 H4350 (3054fps) behind the 109. Both jumping .020" My ES is smaller if I add half a grain to both but the groups are smaller/more consistent where I'm at.

I’m jumping about .020 as well. I did the Eric cortina style seating depth ladder and that is where it just ended up landing.I am experimenting with two 6 creed 7.5 twists now. One is a 28" brux on a remington, one is a ruckus with Proof Prefit. I had to back off on the brux on remington to 40 grs flat h4350 (3147fps) behind 109's after it leveled out (compared to 2 other rifles chambered with same reamer, this brux is much faster than the other 2 rifles). The Proof on Ruckus is leveled out at 40.5 H4350 (3054fps) behind the 109. Both jumping .020" My ES is smaller if I add half a grain to both but the groups are smaller/more consistent where I'm at.

keep us posted on that Brux. I have a 29 inch bartlein 7.5 mated to a ruckus getting fitted at the smith now and I’m going to experiment with the longer barrel as well. I have a 8lb jug of n560 that showed a lot of promise in my 26 inch. But I believe a few extra inches might be what it needs to shine.

I did jump test with the brux also. Mine ran very similar point of impact, very similar group size from .020 to .055 so I left it there and set my proof at the same jump. The brux is a hammer for sure. One friend has the same barrel/same length/same twist/same profile as my brux and is a full 80fps slower. My brux sped up at 300. His has 250 on it now. I'm not convinced the extra length is worth the handling but I have no intentions of cutting my brux off. It is shooting too well to try to make better.

Handling is definitely on the mind. figure I would do some experimenting, train of thought was the extra weight is better utilized in a barrel than adding weights to the stock( cooling + velocity + recoil reduction) figure if I don’t get the velocity I want or it’s to cumbersome I could always dock it down and add weights to the stock

What kind of groups is that brux spitting out?

What kind of groups is that brux spitting out?

Last edited:

I only shoot off bipods and bags. Between it and me, it’s solid under half moa gun. With someone that actually knows what they’re doing I’m sure it’d be better. I’m not a big fan of paper punching but it hits steel for me very well. I’ve shot my best two scores with it on an unsanctioned steel match.

Last edited:

That Brux has a tighter bore, .236” versus .237” so much of that speed comes from that. It’s building more pressure with the same load.I am experimenting with two 6 creed 7.5 twists now. One is a 28" brux on a remington, one is a ruckus with Proof Prefit. I had to back off on the brux on remington to 40 grs flat h4350 (3147fps) behind 109's after it leveled out (compared to 2 other rifles chambered with same reamer, this brux is much faster than the other 2 rifles). The Proof on Ruckus is leveled out at 40.5 H4350 (3054fps) behind the 109. Both jumping .020" My ES is smaller if I add half a grain to both but the groups are smaller/more consistent where I'm at.

Good to know. I have a brux on order thinking sometime in October I should have my hands on it. There back log isn’t as bad as Bartlein.That Brux has a tighter bore, .236” versus .237” so much of that speed comes from that. It’s building more pressure with the same load.

Last edited:

Is he using the exact same brass, bullet, primer and powder lots as you? Powder can be a huge variable. I just opened a new jug and it takes about a grain more to get the same speed.My buddy has one built on a Brux same length same chamber same reamer and it’s 80fps slower. Strange..

Not really a wildcat, more a product of post-covid stock levels and necessity: is it a 6-250? a 6mm creed-less? IDK...

I do know I won't need to buy any brass marking gadget, since I'm pretty sure there won't be too many guys shooting 22-250 at most PRS matches

I do know I won't need to buy any brass marking gadget, since I'm pretty sure there won't be too many guys shooting 22-250 at most PRS matches

Haven’t seen a lot of N555 in here, thought I’d post something worked for me:

41.7 N555

6.5 Hornady Brass resized w/ .268 bushing (2-5x or more… fired)

CCI BR2

Berger 109LRTH

.075 jump

Tying knots at 100m, 1/2 moa group at 400m

2982, 5SD, ES 17… DAlt 2000

I have verified that MV over 3 days now and it’s consistently hitting 2982 with 50 rounds chrono’d with a magneto V3.

I definitely recommend this powder and it meters well.

Edit: adding, I saw no major pressure in a ladder of 40.1-42.2.

42 began to flatten the primer, no heavy bolt, no primer flow or ejector swipes. MV was in the 3030 region. I believe I could run in that area, but I’m shooting trigger tech diamonds… every time I pierce a primer… my trigger breaks. So stay well away from pressure.

41.7 N555

6.5 Hornady Brass resized w/ .268 bushing (2-5x or more… fired)

CCI BR2

Berger 109LRTH

.075 jump

Tying knots at 100m, 1/2 moa group at 400m

2982, 5SD, ES 17… DAlt 2000

I have verified that MV over 3 days now and it’s consistently hitting 2982 with 50 rounds chrono’d with a magneto V3.

I definitely recommend this powder and it meters well.

Edit: adding, I saw no major pressure in a ladder of 40.1-42.2.

42 began to flatten the primer, no heavy bolt, no primer flow or ejector swipes. MV was in the 3030 region. I believe I could run in that area, but I’m shooting trigger tech diamonds… every time I pierce a primer… my trigger breaks. So stay well away from pressure.

Last edited:

+1 on this!Is he using the exact same brass, bullet, primer and powder lots as you? Powder can be a huge variable. I just opened a new jug and it takes about a grain more to get the same speed.

My current lot of H4350 is .8gr different then my previous data! All of the other components are 100% the same.

I gather about 90% of my load data directly from these forums. But I always back off at least a gr and work up. 3 shots in .3/4 gr increments.

"sixty-two fifty" >-> 6CM:

Before anyone says "what an idiot" to using up barrel-life to fire-form... hear me now, believe me later, it's not so bad, here's what 10 rounds at 750 yards off a Shmedium and tank-trap looked like:

...and here's what rounds #47-50 out of the barrel looked like, 4 for 4 at 1250 yards:

I also added a little more to my barrel break-in procedure than usual: this time I ran 3 dry patches through it before shooting at least 100 rounds, instead of only 2 like with my last barrel. I always thought barrel break-in was bullshit, but apparently not.

Before anyone says "what an idiot" to using up barrel-life to fire-form... hear me now, believe me later, it's not so bad, here's what 10 rounds at 750 yards off a Shmedium and tank-trap looked like:

...and here's what rounds #47-50 out of the barrel looked like, 4 for 4 at 1250 yards:

I also added a little more to my barrel break-in procedure than usual: this time I ran 3 dry patches through it before shooting at least 100 rounds, instead of only 2 like with my last barrel. I always thought barrel break-in was bullshit, but apparently not.

So having fire-formed all my 22-250 cases, in order to further experiment with a non-traditional way of doing load development I decided to just load up 100 to the same CBTO/COAL like the fire-forming rounds, only with one more grain of powder for 40gr to see where my velocity was sitting (39gr in the fire-forming rounds was getting me ~2800fps)... the "6-250" rounds shot great, so figured what the hell...

I didn't measure shit as far as where jam/the lands were in my barrel until after I shot 50 of them... but turns out copying the fire-form rounds had me jumping ~.150" to jam, longer than I would have tried probably, but they shot awesome. Strange thing though: lost 30fps even though I added 1 more grain of powder. This makes sense though: as now the fire-formed cases have greater capacity, but by jumping the same .150" I wasn't adding any pressure by hitting the lands any sooner. 40gr = 2770fps.

350 rounds in and I still hadn't shot a single group, but I was curious and a little shocked that the gun shot so well jumping .150". I already had 50 more loaded up and couldn't make them any longer, so I said what the hell and seated them all .050" deeper for a bullet-jump to jam of .200"... I figured surly I had just fucked up 50 rounds and they were going to be terrible, .200" off is a little much. Nope, they shot great too, velocity stayed the same as before, no change to the dope or POI at all that I could see. Didn't expect that. 40gr = 2770fps.

Today, I loaded 50 with another grain of powder (41gr), and with a relatively "short" .100" bullet-jump to jam. Accuracy was outstanding, there was a fair amount of wind and I was holding at least .5mils most of the time, but 1moa targets at 750 and 1000 seemed huge, just solid and predictable, aim at spot, bullet hits spot, no surprises. WIth around 20rds left, I finally shot one 5 round group on paper quick and dirty on the corner of someone else's target they had abandoned at 100: 2 through the same hole, 2 more touching those , last one 1/2" over because I suck and pulled it. Totally happy.

Only issue I have now is that I was only getting 2850fps, kinda slow. I was hoping to be ~2900fps because that's what I'm used to and that's already throttled back quite a bit from what 6 creed is capable of and how it has been loaded traditionally in the past, but in a way, since I'm running it like I think it's a Dasher or some smaller 6mm anyways, 2850 actually sounds pretty good. Honestly, based on what I'm seeing at 1000/1250yrds, I'm not sure dicking around any further with adding more powder to gain some speed and a tenth or two in wind-resistance is even worth it.

I probably should mention: I chrono'd 5 rounds each from the 40gr/.150" jump load and the 40gr/.200" jump load, then 5 rounds today of the 41gr/.100" jump load... I haven't seen an SD in double digits yet. For SD, the lowest was 6, then I had an 8 and a 9, ES was never over 24. Not bad for dropping powder straight into cases, spending maybe 5 minutes per 50.

So for now, the Dasher-wannabee load I arrived at is: 41gr Sta-Ball, Barnes 112gr Match Burner, Federal 210, Lapua ex-22-250, CBTO 2.190" COAL ~2.83" 2850fps @ 89degF 29.25in (26" Proof competition contour 7.5t)

750 yards:

1250 yards:

I didn't measure shit as far as where jam/the lands were in my barrel until after I shot 50 of them... but turns out copying the fire-form rounds had me jumping ~.150" to jam, longer than I would have tried probably, but they shot awesome. Strange thing though: lost 30fps even though I added 1 more grain of powder. This makes sense though: as now the fire-formed cases have greater capacity, but by jumping the same .150" I wasn't adding any pressure by hitting the lands any sooner. 40gr = 2770fps.

350 rounds in and I still hadn't shot a single group, but I was curious and a little shocked that the gun shot so well jumping .150". I already had 50 more loaded up and couldn't make them any longer, so I said what the hell and seated them all .050" deeper for a bullet-jump to jam of .200"... I figured surly I had just fucked up 50 rounds and they were going to be terrible, .200" off is a little much. Nope, they shot great too, velocity stayed the same as before, no change to the dope or POI at all that I could see. Didn't expect that. 40gr = 2770fps.

Today, I loaded 50 with another grain of powder (41gr), and with a relatively "short" .100" bullet-jump to jam. Accuracy was outstanding, there was a fair amount of wind and I was holding at least .5mils most of the time, but 1moa targets at 750 and 1000 seemed huge, just solid and predictable, aim at spot, bullet hits spot, no surprises. WIth around 20rds left, I finally shot one 5 round group on paper quick and dirty on the corner of someone else's target they had abandoned at 100: 2 through the same hole, 2 more touching those , last one 1/2" over because I suck and pulled it. Totally happy.

Only issue I have now is that I was only getting 2850fps, kinda slow. I was hoping to be ~2900fps because that's what I'm used to and that's already throttled back quite a bit from what 6 creed is capable of and how it has been loaded traditionally in the past, but in a way, since I'm running it like I think it's a Dasher or some smaller 6mm anyways, 2850 actually sounds pretty good. Honestly, based on what I'm seeing at 1000/1250yrds, I'm not sure dicking around any further with adding more powder to gain some speed and a tenth or two in wind-resistance is even worth it.

I probably should mention: I chrono'd 5 rounds each from the 40gr/.150" jump load and the 40gr/.200" jump load, then 5 rounds today of the 41gr/.100" jump load... I haven't seen an SD in double digits yet. For SD, the lowest was 6, then I had an 8 and a 9, ES was never over 24. Not bad for dropping powder straight into cases, spending maybe 5 minutes per 50.

So for now, the Dasher-wannabee load I arrived at is: 41gr Sta-Ball, Barnes 112gr Match Burner, Federal 210, Lapua ex-22-250, CBTO 2.190" COAL ~2.83" 2850fps @ 89degF 29.25in (26" Proof competition contour 7.5t)

750 yards:

1250 yards:

Last edited:

update. the Norma recipe has proven as the best in hotter conditions due to better % fill and powder stability. barrel in its best days now, speed at 3050 fps at 80F same SD and ES. 20rnd sample. same lapua brass, CCI 450.settled upon a pussycat load of 38.5 gn of VV N160 in lapua brass, CCI 450, 105 Berger Hybrids, going out at 2865fps SD 1 ES 4 over a sample of 10 rounds.

another recipe I developed just in case I have to change components, that has more or less the same consistency is 42.5 gn of Norma MRP behind 109 Bergers LHRT, 2935 fps SD3 ES 10

both PRS match proven, I'll call 'em good. YMMV as usual, guys...

@ceekay1 I ran my my Creed at Dasherish speeds too. DTACs at 2880. Easy on the barrel, still supersonic way out there, no special mags or spacers needed.

After looking into it further, I'm totally fine with running a little slower than usual.

It's funny, because shooting 6CM, anything in the ~2800's sounds slow, but for just about anything else that'd be great...

I guess "faster = better" has always been drilled into our heads, and objectively it's true: a clone of you on your best day, with a faster rifle, would beat you on your best day with a slower one.

But, after reading this: https://precisionrifleblog.com/2015/04/28/how-much-does-muzzle-velocity-matter/ and some other stuff out there, looks like for every 25fps faster you go, you only increase your hit probability .75%, not even 1%... so me going "only" 2850fps vs 2900fps means only giving up ~1.5% in hit probability... I give up way more than that if I don't get enough coffee in the morning.

Plus, FWIW, dude just won the F-class nationals with a Dasher...MV didn't seem to hurt him against all sorts of faster stuff.

Now I wonder how much barrel life we can gain by just going a couple percent slower..?

30" Krieger, 1:7 rot

.199 FB

Lapua SRP

cci 450

H4831sc 43.70 gr

115 JLK +.015, 2.255 cbto, single shot action, F class gun

+/- 3010 FPS

at sea level

when using LRP brass i have to back down to 42.9 gr H4831sc and when using SW4350 i have to go down to 41.9 gr w/ LRP

.199 FB

Lapua SRP

cci 450

H4831sc 43.70 gr

115 JLK +.015, 2.255 cbto, single shot action, F class gun

+/- 3010 FPS

at sea level

when using LRP brass i have to back down to 42.9 gr H4831sc and when using SW4350 i have to go down to 41.9 gr w/ LRP

Last edited:

28” bartlien 5R

Lapua 6mm creedmoor SRP

CCI450

IMR 4451 40.0 grains

110 A-tip

Jumping .010

2.807 COAL

2.204 COTB

AVG 3062, SD 7.2, ES 13

Lapua 6mm creedmoor SRP

CCI450

IMR 4451 40.0 grains

110 A-tip

Jumping .010

2.807 COAL

2.204 COTB

AVG 3062, SD 7.2, ES 13

PSA for bushing die users: pay attention, some work better than others...

A little while back I had to buy a new FL bushing die, and decided to try an L.E. Wilson after a brief disaster/debacle encountered when temporarily trying a Mighty Armory FL sizing die (don't ask, or if you really want to know, PM me, because I don't want to talk shit about Wayne/MA, he's a good dude, his expertise is just more in the realm of semi autos and progressive presses, not loading for bolt guns on single stage presses...).

I'd never owned anything from L.E. Wilson before, but I was really impressed when I got the die, they are really nice, better finished than Forster, Redding, Lee, etc, they're stainless, and I also dig their company's sort of "old timey" vibe with their packaging and such.

Thing is, I'm returning it and going to try something else due to a "crease" the die creates at the top of the shoulder at bottom of the neck at the shoulder/neck transition (see pics attached).

Might just be this particular die, but mine, when setup for an .002" bump, creates the crease shown in the pics every single time, every single case... Now, the crease might not necessarily be a problem... but since I've never encountered it before, and I fear change when I already know what works, I don't like it.

Is it because I fire-formed 22-250 brass into 6CM? Nope, tried born-as 6CM Hornady brass too, same result. Does it have something to do with the fact that I anneal every firing? IDK, could be, but don't really care because I know I don't like it. I know nobody's bushing die sizes the entire neck 100%, they all leave a tiny bit at the base of the neck unsized (and that's ok usually), but to my eye it looks like the crease may actually make donuts forming an inevitable thing, because it's scoring the brass towards the bottom of the portion of the necks where they aren't being resized, and it'll eventually send me down the path to neck-turning (which is somewhere I have no interest in going when I already get single digit SD's without neck-turning).

Anyways, keep your eyes open, glad I caught it before it caught me.

Since I anneal every firing (AMP Aztec mode), and overworking the brass isn't a concern, as a replacement I've decided to go with a good ol' traditional non-bushing FL die, in fact, a Lee, which is next to free at $18 hahaha. In fact, I've actually heard some guys far more knowledgeable than me mention that using a die/bushing tight enough that it allows one's mandrel to make full contact with inside of the case necks when sizing, combined with annealing every time, leads to some of the most consistent and repeatable neck tension one can really get: guess I'll find out if there's any truth to that...

>-> Oh, and an update on how running the 6creed slow (2850fps) with a healthy jump (.100") in shorter neck ex-22-250 brass is going... took a couple shots at the waterline at 1,250 yards to check on my BC yesterday: yep, works great, not bad for a "hard to tune and load for, barrel burner" cartridge

A little while back I had to buy a new FL bushing die, and decided to try an L.E. Wilson after a brief disaster/debacle encountered when temporarily trying a Mighty Armory FL sizing die (don't ask, or if you really want to know, PM me, because I don't want to talk shit about Wayne/MA, he's a good dude, his expertise is just more in the realm of semi autos and progressive presses, not loading for bolt guns on single stage presses...).

I'd never owned anything from L.E. Wilson before, but I was really impressed when I got the die, they are really nice, better finished than Forster, Redding, Lee, etc, they're stainless, and I also dig their company's sort of "old timey" vibe with their packaging and such.

Thing is, I'm returning it and going to try something else due to a "crease" the die creates at the top of the shoulder at bottom of the neck at the shoulder/neck transition (see pics attached).

Might just be this particular die, but mine, when setup for an .002" bump, creates the crease shown in the pics every single time, every single case... Now, the crease might not necessarily be a problem... but since I've never encountered it before, and I fear change when I already know what works, I don't like it.

Is it because I fire-formed 22-250 brass into 6CM? Nope, tried born-as 6CM Hornady brass too, same result. Does it have something to do with the fact that I anneal every firing? IDK, could be, but don't really care because I know I don't like it. I know nobody's bushing die sizes the entire neck 100%, they all leave a tiny bit at the base of the neck unsized (and that's ok usually), but to my eye it looks like the crease may actually make donuts forming an inevitable thing, because it's scoring the brass towards the bottom of the portion of the necks where they aren't being resized, and it'll eventually send me down the path to neck-turning (which is somewhere I have no interest in going when I already get single digit SD's without neck-turning).

Anyways, keep your eyes open, glad I caught it before it caught me.

Since I anneal every firing (AMP Aztec mode), and overworking the brass isn't a concern, as a replacement I've decided to go with a good ol' traditional non-bushing FL die, in fact, a Lee, which is next to free at $18 hahaha. In fact, I've actually heard some guys far more knowledgeable than me mention that using a die/bushing tight enough that it allows one's mandrel to make full contact with inside of the case necks when sizing, combined with annealing every time, leads to some of the most consistent and repeatable neck tension one can really get: guess I'll find out if there's any truth to that...

>-> Oh, and an update on how running the 6creed slow (2850fps) with a healthy jump (.100") in shorter neck ex-22-250 brass is going... took a couple shots at the waterline at 1,250 yards to check on my BC yesterday: yep, works great, not bad for a "hard to tune and load for, barrel burner" cartridge

Last edited:

I've only shot 50rds of the 100 I loaded with it, but looks like switching from a bushing die to a regular FL die might have been pretty stupid.

So far, the Lee FL die doesn't look like it's going to work and I don't think I can recommend using a regular FL sizing die before a mandrel, regardless/including whether one anneals every firing or not... I think a bushing die (or better yet a custom honed die, wish they didn't take so long) is the way to go.

After squashing the neck down with a tighter FL die, the mandrel does engage the necks more, but I think it ends up being pretty heavy-handed and the actual neck tension goes way up and becomes inconsistent. You can't see it on calipers because the numbers end up the same, but the grip the case mouths end up putting on the bullets is far greater and far less consistent than I had been used to when sizing more minimally...

I went from using a .268" bushing (that really measured out at ~.268" ID) and produced case necks at ~.268" OD within half a thou, to the FL die, that produces cases ~.260"... but, after running the mandrel through them (.241" turning arbor), BOTH end up with the same OD of ~.268".

However, while seating bullets, it was obvious in the feel at the handle that the non-bushing ones were f'ed up tension-wise, and I could see it downrange in my impacts that the elevation was all wonky. Saw it at the chrono too, and wasn't planning on chrono'ing anything but I wanted to try and figure out what was up: didn't shoot a bunch over it, just enough to see what was going on (well, sort of), 5 shots, SD 24 ES 24 WTF!!!??? The worst SD24/ES24 offender looked like it could've maybe been an error at first so I shot another one and even if I throw it out use the 6th shot it's still an SD of 14, which over 5 shots is pretty garbage, lately that's been a 3-6 SD over 5 shots, 6-9 SD over 10 shots, not more than that.

So, looks like brass, while malleable, isn't play-doh, seems for more consistent neck tension, best to not bend the shit out of it if you don't have to.

I ordered brand new versions of the LE Wilson die and Redding TiNi bushing I was using before, hopefully the new one won't slice into my brass, but even if it does, I'll live with it if I have to in order to get consistent neck tension again.

So far, the Lee FL die doesn't look like it's going to work and I don't think I can recommend using a regular FL sizing die before a mandrel, regardless/including whether one anneals every firing or not... I think a bushing die (or better yet a custom honed die, wish they didn't take so long) is the way to go.

After squashing the neck down with a tighter FL die, the mandrel does engage the necks more, but I think it ends up being pretty heavy-handed and the actual neck tension goes way up and becomes inconsistent. You can't see it on calipers because the numbers end up the same, but the grip the case mouths end up putting on the bullets is far greater and far less consistent than I had been used to when sizing more minimally...

I went from using a .268" bushing (that really measured out at ~.268" ID) and produced case necks at ~.268" OD within half a thou, to the FL die, that produces cases ~.260"... but, after running the mandrel through them (.241" turning arbor), BOTH end up with the same OD of ~.268".

However, while seating bullets, it was obvious in the feel at the handle that the non-bushing ones were f'ed up tension-wise, and I could see it downrange in my impacts that the elevation was all wonky. Saw it at the chrono too, and wasn't planning on chrono'ing anything but I wanted to try and figure out what was up: didn't shoot a bunch over it, just enough to see what was going on (well, sort of), 5 shots, SD 24 ES 24 WTF!!!??? The worst SD24/ES24 offender looked like it could've maybe been an error at first so I shot another one and even if I throw it out use the 6th shot it's still an SD of 14, which over 5 shots is pretty garbage, lately that's been a 3-6 SD over 5 shots, 6-9 SD over 10 shots, not more than that.

So, looks like brass, while malleable, isn't play-doh, seems for more consistent neck tension, best to not bend the shit out of it if you don't have to.

I ordered brand new versions of the LE Wilson die and Redding TiNi bushing I was using before, hopefully the new one won't slice into my brass, but even if it does, I'll live with it if I have to in order to get consistent neck tension again.

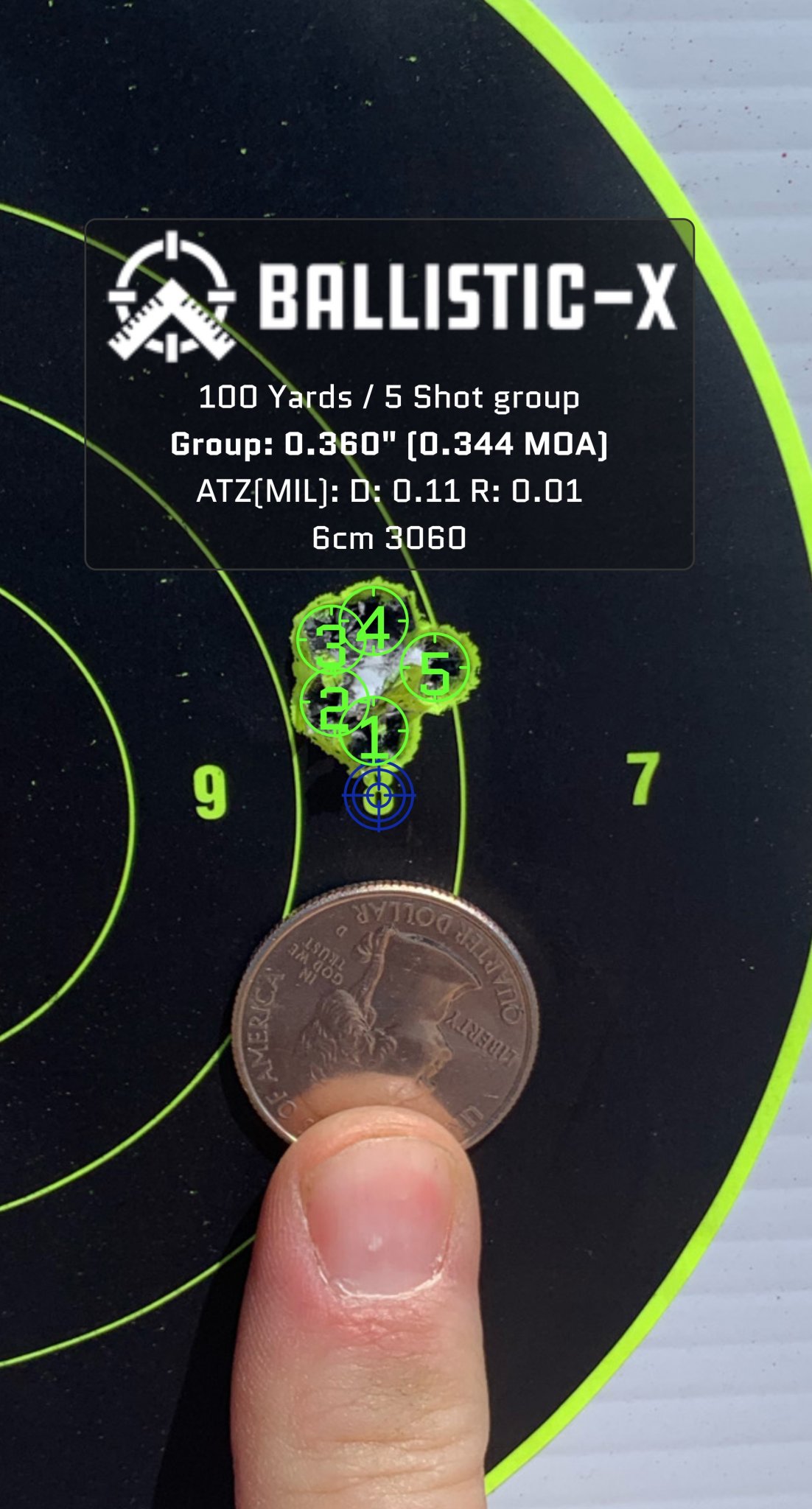

Quick update after 1200 rounds down the tube running a "slow" 6mm Creedmoor (~2870 @ and 85degF) in necked up Lapua 22-250 cases with a healthy amount of jump (.100"+): no load development, no "nodes", no OCW nonsense.

I just picked 41 grains of powder out of thin air (that and it got me to near 2900fps which was all I was after), shot a few different seating depths, but really just too see if the bullets I had seemed to work with a healthy amount of jump, I really just parked it at .100" off and have kept it there (if it starts to shoot bad, my first move will be to lengthen the rounds so they're jumping .100" again, but I may not even have to touch it).

Switched back to my old die setup (.268" bushing, followed by .241" mandrel) and things got right again, seating bullets returned to feeling smooth and consistent again (single digit SD's returned too).

The ex-22-250 brass looks like it'll last for another barrel or two, I started with 300 cases and they've all got 4 firings on them now, and all the primer pockets are tight and about as good as new.

I know a lot of guys might be sort of weary and/or tepid about trying a bunch of jump because it's usually not the the go-to recipe for small groups... but hear me now, believe me later, it pays off huge in your vertical, and it's actually starting to make me get kind of OCD about how good the BC number is I've got in the calculator, because if it even looks like I'm off by a click at 1250 yards it annoys me...

1200 round check-up today:

Vertical at 750yrds

Vertical at 1250yrds

3-shot group at 300yrds (first and only group I've shot at any distance in weeks)

- I think I've got enough of the same exact components I've been running left to get me to 2500rds if the barrel will make it... Seeing as I've never loaded closer than .080" to the lands (and I increased the jump to .100" not long after) or faster than 2900fps, I kind of have the feeling I can get there..?

I just picked 41 grains of powder out of thin air (that and it got me to near 2900fps which was all I was after), shot a few different seating depths, but really just too see if the bullets I had seemed to work with a healthy amount of jump, I really just parked it at .100" off and have kept it there (if it starts to shoot bad, my first move will be to lengthen the rounds so they're jumping .100" again, but I may not even have to touch it).

Switched back to my old die setup (.268" bushing, followed by .241" mandrel) and things got right again, seating bullets returned to feeling smooth and consistent again (single digit SD's returned too).

The ex-22-250 brass looks like it'll last for another barrel or two, I started with 300 cases and they've all got 4 firings on them now, and all the primer pockets are tight and about as good as new.

I know a lot of guys might be sort of weary and/or tepid about trying a bunch of jump because it's usually not the the go-to recipe for small groups... but hear me now, believe me later, it pays off huge in your vertical, and it's actually starting to make me get kind of OCD about how good the BC number is I've got in the calculator, because if it even looks like I'm off by a click at 1250 yards it annoys me...

1200 round check-up today:

Vertical at 750yrds

Vertical at 1250yrds

3-shot group at 300yrds (first and only group I've shot at any distance in weeks)

- I think I've got enough of the same exact components I've been running left to get me to 2500rds if the barrel will make it... Seeing as I've never loaded closer than .080" to the lands (and I increased the jump to .100" not long after) or faster than 2900fps, I kind of have the feeling I can get there..?

Last edited:

Hi all, need some powder recommendations. On the spur of the moment while *still* waiting for my JP 6CM upper to arrive - I picked up a 24" Proof stainless 6CM barrel for my AI-AT. I have been stockpiling 6CM components when I could find them, so wanted to get some experience with the cartridge. I shot some factory Berger 109 LRHT and Hornady 108 ELDMs match ammo just to see how the barrel shoots and get some fired case data to set up my dies. The factory loads shot VERY well (1/2 MOA) and both loads were right around 2950 fps, so that's going to be my target speed.

I have virgin Lapua brass and Berger 105 Hybrid Target and 109 LR Hybrid Target bullets. My big question mark is what powder to run for those two bullets? I have IMR 4451, H4350, Superperformance, Staball 6.5, and Varget to choose from. Which ones of those choices would you recommend starting the load dev? Would it vary between the two bullets? I'm pretty fat on the 4451 and that is my go to powder for my .260 Rem. But I'm not at all familiar with the 6mm bullets or ballistics.

Thanks in advance.

I have virgin Lapua brass and Berger 105 Hybrid Target and 109 LR Hybrid Target bullets. My big question mark is what powder to run for those two bullets? I have IMR 4451, H4350, Superperformance, Staball 6.5, and Varget to choose from. Which ones of those choices would you recommend starting the load dev? Would it vary between the two bullets? I'm pretty fat on the 4451 and that is my go to powder for my .260 Rem. But I'm not at all familiar with the 6mm bullets or ballistics.

Thanks in advance.

40-41grs h4350 with either 105 or 109 should land you near your target speed with low es/sd. I have no experience with the other powder options you mention.

H4350 and/or StaBall are my go-to's... depending on what you're up to, and how you're loading, one can be better than the other (IMO).

H4350 is boringly temp stable and seems to get better and better numbers-wise the closer you get to 100% case-fill, but those big sticks meter like shit and can be torture if you don't have an AutoTrickler or something like that... If you're patient and have plenty of it, H4350 is probably the best (Alliant Reloader 16 is similar and neck-and-neck with H4350 as well).

StaBall is a little slower and more temp-wonky, but it meters super well and shoots great for practice out to 1000 even if you're just dropping it and not weighing every charge, and also, case-fill doesn't seam to matter with it much in my experience so it's probably better if you want to go slower on purpose (like if the usual 40-42gr of H4350 spits out a fast ~3100fps in your gun, which it can), in my experience anything less than 39gr of H4350 in a 6CM case and the loads starts to fall off and start to kind of suck quick (I think it's the low case-fill)...

H4350 is boringly temp stable and seems to get better and better numbers-wise the closer you get to 100% case-fill, but those big sticks meter like shit and can be torture if you don't have an AutoTrickler or something like that... If you're patient and have plenty of it, H4350 is probably the best (Alliant Reloader 16 is similar and neck-and-neck with H4350 as well).

StaBall is a little slower and more temp-wonky, but it meters super well and shoots great for practice out to 1000 even if you're just dropping it and not weighing every charge, and also, case-fill doesn't seam to matter with it much in my experience so it's probably better if you want to go slower on purpose (like if the usual 40-42gr of H4350 spits out a fast ~3100fps in your gun, which it can), in my experience anything less than 39gr of H4350 in a 6CM case and the loads starts to fall off and start to kind of suck quick (I think it's the low case-fill)...

Does anyone happen to know what powder and charge weight Berger 109 LRHT and Hornady 108 ELDM use for their match rounds? They shot so well, I'd just like to duplicate them around that 2950 node and save all the load dev and barrel life and just shoot it at range.

It’s going to be a proprietary powder for both almost certain of that. Last I heard Nosler was the only one using consumer powders. Probably get stinking close with 39 ish grains of h4350.Does anyone happen to know what powder and charge weight Berger 109 LRHT and Hornady 108 ELDM use for their match rounds? They shot so well, I'd just like to duplicate them around that 2950 node and save all the load dev and barrel life and just shoot it at range.

Yeah, I assumed they probably were proprietary but thought it worth asking. I might pull one of the bullets from a factory Berger round and weigh the powder just to see. It would also be worth seeing if they are using a stick or ball powder.It’s going to be a proprietary powder for both almost certain of that. Last I heard Nosler was the only one using consumer powders. Probably get stinking close with 39 ish grains of h4350.

I might try a quick work up with H4350, but more likely will end up using the Enduron IMR 4451 as I have the most of that and it seems to mirror H4350 in my .260 Rem almost exactly. I'll probably start right around 39.0 with the 105 Hybrids and work up from there. After skimming this thread, it seems that 41.0 is kinda the universal sweet spot.

I ran the ballistics out to about 1200 yds and the wind difference is .2 mils between 2950 and 3150 with a full value 10mph wind. So I don't feel the need to burn out the barrel faster and get loose primer pockets sooner by chasing the high nodes. I learned that lesson the hard way with my .260 Rem Gas gun. IMHO, the performance differences are just not worth the wear and $$ spent to get there.

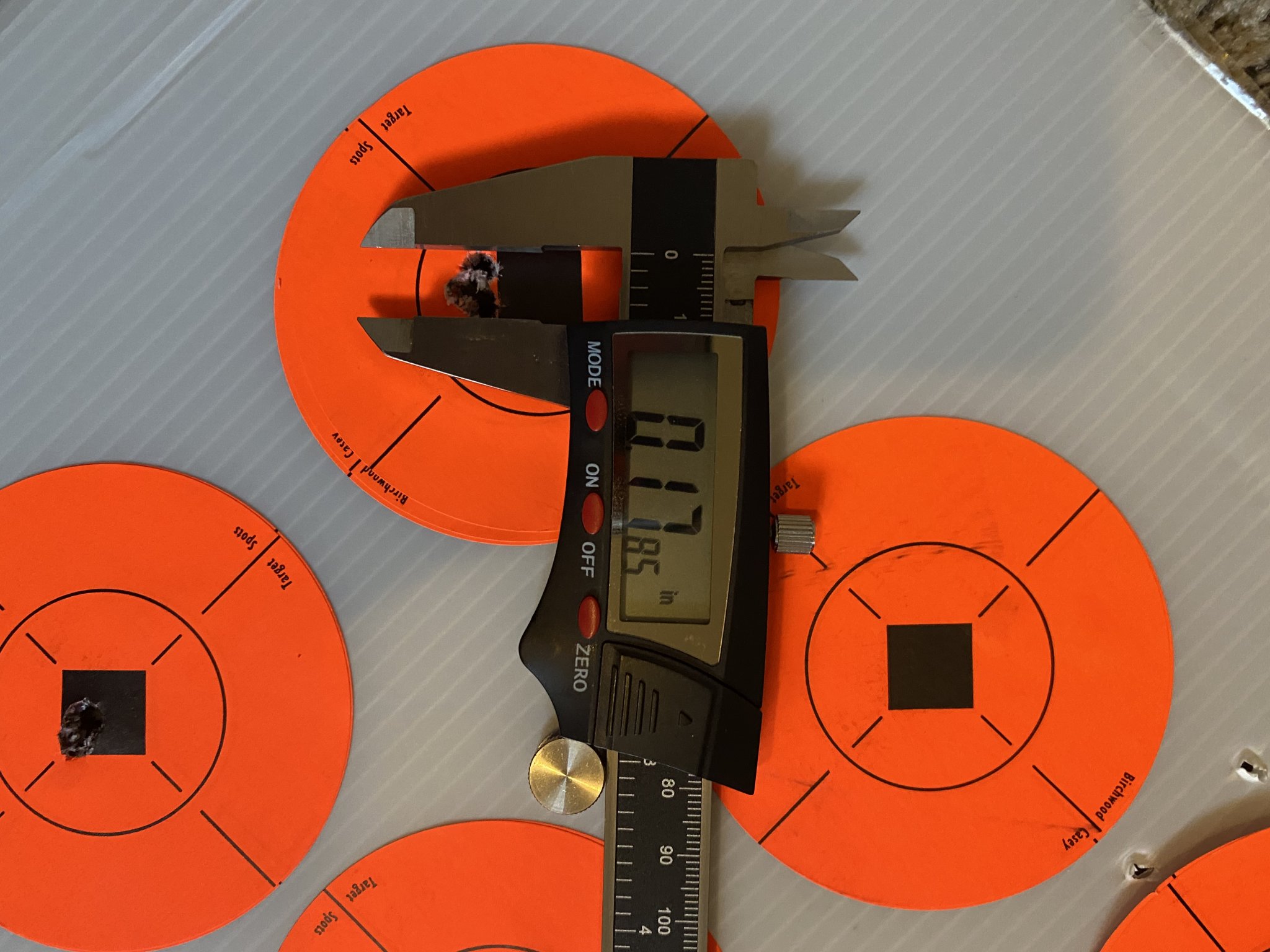

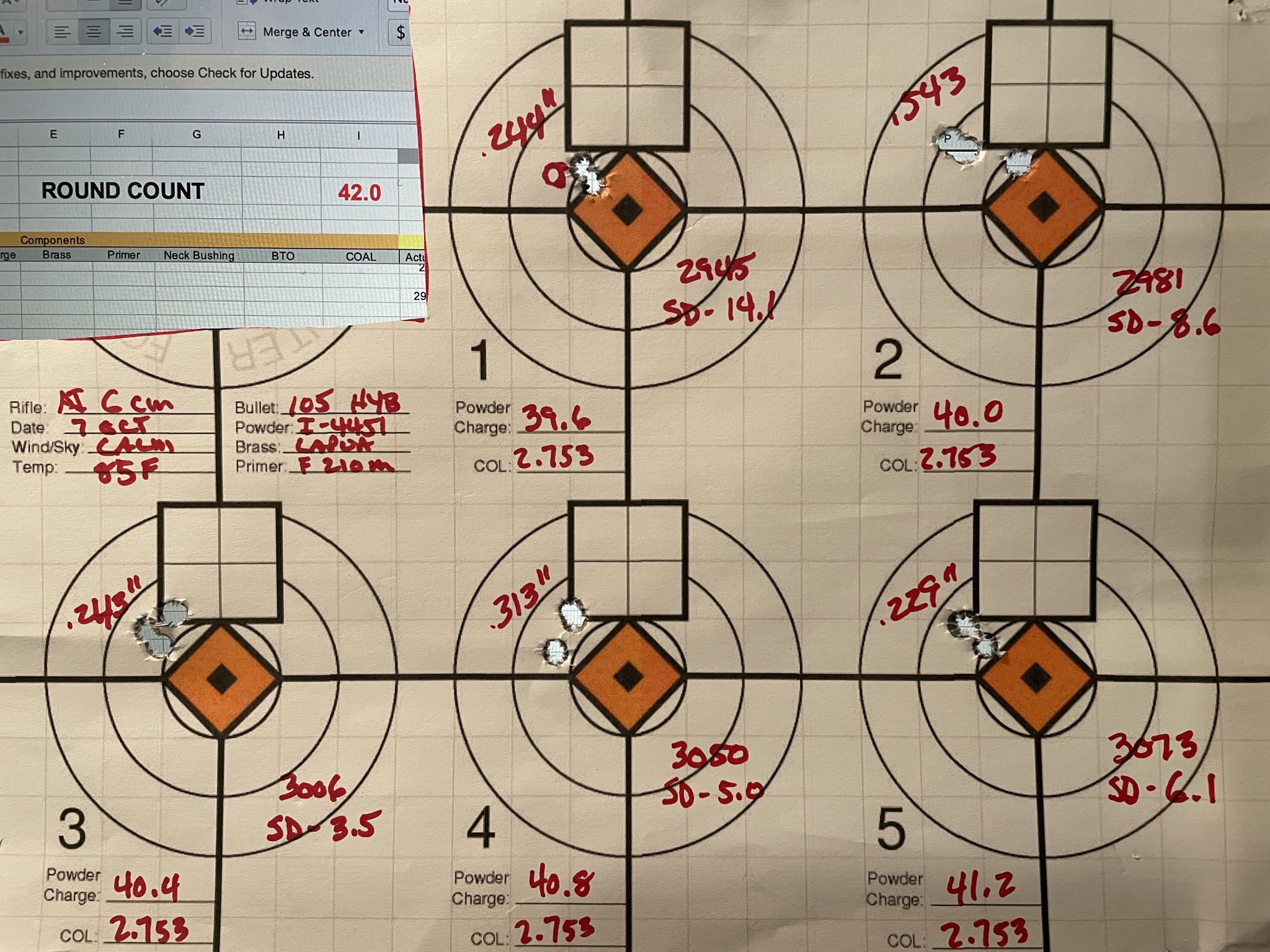

So finally got out and did a load test on my new Proof Research AI-AT Barrel. I initially shot just factory Match ammo to see how they did to get a sorta bench mark. Berger Factory 109 LR Hybrids and Hornady Factory 108 ELDM. Both of those shot well right out of the gate and put me in the 2960 FPS range, so that was my target to try to match them and see if there was a node in that Velocity range. I started with two ladders: 5x 3 each of 109 Berger LRHT with Superperformance and 5x 3 each of Berger 105 HT with IMR-4451. The superperformance sucked ass, as I posted in a recent thread on huge ES and SDs. But the 4451 and 105s were amazing out of the gate. I did 5 strings of 4451 in 0.4 gr increments using the Hogden Min max range as a guide to stay between.

Loaded these to match the factory OAL at 2.753 as a starting point. My thought was the "node" was around #3. I am going to reshoot that one and maybe try a .1 or .2 above and below #3. Right at 3000 is fine with me. Even high 2900s is fine as I don't want to shoot the barrel out any sooner than needed. #4 was just beginning to show pressure and #5 was definite pressure even though it still shot well.

Any thoughts??? Is there even any reason to do a seating depth test at this point?

Loaded these to match the factory OAL at 2.753 as a starting point. My thought was the "node" was around #3. I am going to reshoot that one and maybe try a .1 or .2 above and below #3. Right at 3000 is fine with me. Even high 2900s is fine as I don't want to shoot the barrel out any sooner than needed. #4 was just beginning to show pressure and #5 was definite pressure even though it still shot well.

Any thoughts??? Is there even any reason to do a seating depth test at this point?

Any thoughts??? Is there even any reason to do a seating depth test at this point?

IMO seating depth is more important than powder charge... but I don't look at it like some specific magic number within .001-.003" that is mucho better than everything else.

I see it like a range where the rifle is "happy" with the amount of bullet-jump + speed + bullet... where it shoots consistently well there, and it looks like you're probably in a range that's working.

I'm definitely going to play with seating depth. I chose group #2 & 3 as the focal point and reshot a 5 shot group of those loads 40.0/40.2/40.4 w/ IMR4451 and all the other variables exactly the same - just to see if it was a fluke or if that really was the node. Here are the results:IMO seating depth is more important than powder charge... but I don't look at it like some specific magic number within .001-.003" that is mucho better than everything else.

I see it like a range where the rifle is "happy" with the amount of bullet-jump + speed + bullet... where it shoots consistently well there, and it looks like you're probably in a range that's working.

The previous speeds were right around 2980-3006 fps. But these same loads were ever faster. They shot well and SDs were decent, but they all showed a bit of pressure signs, with the 40.4 piercing one primer. I can't figure out how I picked up 60 fps with all things being the same. The Barrel has about 69 rounds on it so far, so maybe it's that magical "speeding up" of a new barrel after it begins to break in. At least it is shooting to the same POI as before.

Short of cleaning it and trying again..... what would you all suggest as the next step? I'd rather stay away from the pressure issues for barrel life and brass life. So still thinking the high 2900s to right at 3000 seems the sweet spot.

I'm definitely going to play with seating depth. I chose group #2 & 3 as the focal point and reshot a 5 shot group of those loads 40.0/40.2/40.4 w/ IMR4451 and all the other variables exactly the same - just to see if it was a fluke or if that really was the node. Here are the results:

View attachment 7723085

The previous speeds were right around 2980-3006 fps. But these same loads were ever faster. They shot well and SDs were decent, but they all showed a bit of pressure signs, with the 40.4 piercing one primer. I can't figure out how I picked up 60 fps with all things being the same. The Barrel has about 69 rounds on it so far, so maybe it's that magical "speeding up" of a new barrel after it begins to break in. At least it is shooting to the same POI as before.

Short of cleaning it and trying again..... what would you all suggest as the next step? I'd rather stay away from the pressure issues for barrel life and brass life. So still thinking the high 2900s to right at 3000 seems the sweet spot.

To be honest, I don't really start doing any kind of real load development until I've got ~150rds on a barrel, at the very least 100 down the pipe, or one can end up chasing their tail.

I would just load some up that are "middle of the road" and have fun while you get some more rounds on the gun, and come back to it in a bit. Otherwise, you may be wasting time and energy.

Barrels speeding up when new is a real thing, a fact. It's as simple as: it takes a certain number of metal projectiles flying down it to give it its "final polish" or however you want to look at it. It's not nearly as faith-based as the mythical "nodes" people talk about (which more than likely do not even exist and are more than likely just a product of the "Rorschach test" guys give themselves when doing ladder tests).

That's all fair points. Thanks.To be honest, I don't really start doing any kind of real load development until I've got ~150rds on a barrel, at the very least 100 down the pipe, or one can end up chasing their tail.

I would just load some up that are "middle of the road" and have fun while you get some more rounds on the gun, and come back to it in a bit. Otherwise, you may be wasting time and energy.

Barrels speeding up when new is a real thing, a fact. It's as simple as: it takes a certain number of metal projectiles flying down it to give it its "final polish" or however you want to look at it. It's not nearly as faith-based as the mythical "nodes" people talk about (which more than likely do not even exist and are more than likely just a product of the "Rorschach test" guys give themselves when doing ladder tests).

Personally, I've been thinking for a while now that being confident in one's true/real speed is more important than group size.

To me, having my dope working right is what makes it fun, and questioning one's speed all the time sucks.

We all can shoot one-hole groups some days, and on others shoot like crap. We're always the biggest variable when it comes to that IMHO.

To me, having my dope working right is what makes it fun, and questioning one's speed all the time sucks.

We all can shoot one-hole groups some days, and on others shoot like crap. We're always the biggest variable when it comes to that IMHO.

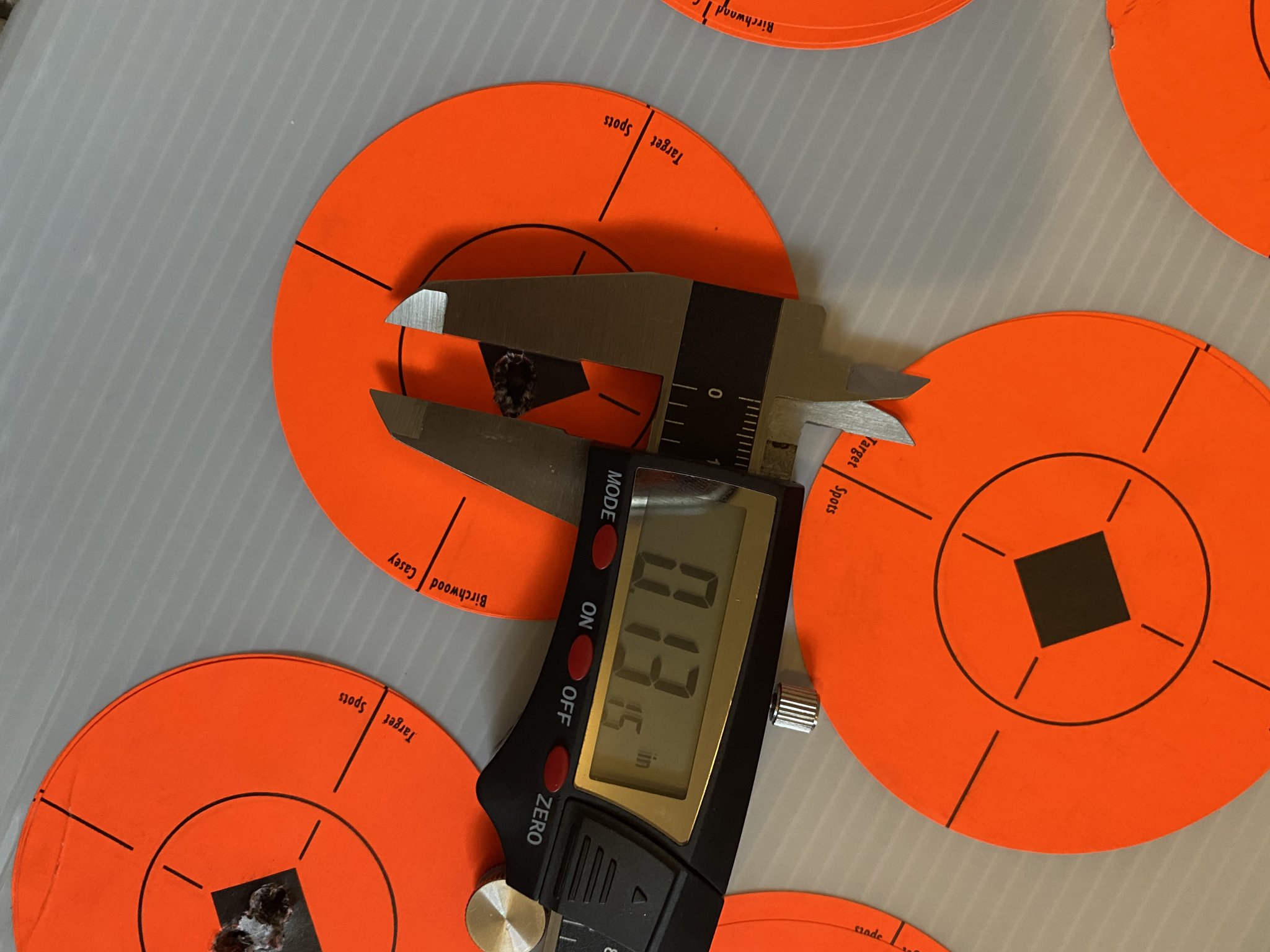

With the cartridges reputation as a barre burner I thought I’d post up my throat erosion.

other than a 150 105 hybrids with a mild load of h4831 for break in. It has been IMR 4451 and 110 A-tips at 3075 for the other 600.

@ 250 rounds -.015 — .016 total

@ 500 rounds -.011 — .026 total

@ 750 rounds -.014 —.040 total

this all been hard use in local matches not babying the barrel. Don’t know if that’s good or bad, still shooting well.

other than a 150 105 hybrids with a mild load of h4831 for break in. It has been IMR 4451 and 110 A-tips at 3075 for the other 600.

@ 250 rounds -.015 — .016 total

@ 500 rounds -.011 — .026 total

@ 750 rounds -.014 —.040 total

this all been hard use in local matches not babying the barrel. Don’t know if that’s good or bad, still shooting well.

With the cartridges reputation as a barre burner I thought I’d post up my throat erosion.

other than a 150 105 hybrids with a mild load of h4831 for break in. It has been IMR 4451 and 110 A-tips at 3075 for the other 600.

@ 250 rounds -.015 — .016 total

@ 500 rounds -.011 — .026 total

@ 750 rounds -.014 —.040 total

this all been hard use in local matches not babying the barrel. Don’t know if that’s good or bad, still shooting well.

How are you measuring the erosion? Like with the Hornady thingy?

I've become a fan of using this, Deep Creek Method:

I kind of wish I had kept track of this sooner, but my barrel is at 1400rds now and still is shooting lights out... jumping a bunch, going slow, and with all those rounds on it now, I'm kind of wondering if it is eroding more slowly..? That's kind of what I've been going for, but like an idiot, I wasn't keeping track doh.

How are you measuring the erosion? Like with the Hornady thingy?

I've become a fan of using this, Deep Creek Method:

I kind of wish I had kept track of this sooner, but my barrel is at 1400rds now and still is shooting lights out... jumping a bunch, going slow, and with all those rounds on it now, I'm kind of wondering if it is eroding more slowly..? That's kind of what I've been going for, but like an idiot, I wasn't keeping track doh.

I use the Sinclair tool. Sinclair TOOL I usually end up doing 6-7 measurements and throw the 1-2 out that are way off. Usually the others are within .003 of each other and then average them. the trick is consistent bullet engagement, the technique that seems to most consistent is letting placing the bullet nose on the breech face and letting it drop into the lands in a vertical rifle.

I’ve seen that method and it looks super consistent, but I’m to lazy to disamble my bolt every time

I’ve been chasing the lands with this load. So every 250 rounds I’ve been bumping it out to maintain .005 jump. At the end of the 250 it‘s jumping .020. Seems to shoot well the whole time.

It's funny, I've been messing around with more and more bullet-jump to where .020" off or closer seems crazy to me now hahaha.

What I like about the Deep Creek Method is that it's so precise: there's no measuring over and over again or throwing anything out, once there's no more "click", you measure your dummy round and you're done, that's it. Though you're right, I guess it can be easier with some actions over others, with an Origin all it takes is a twist to pull the firing pin assembly, and a fixed ejector means no disassembly required.

I was going to take a measurement this morning, but was too lazy to get into it before running errands and before going out and shooting another 50rds. But now, part of me doesn't even want to know where the lands are because it's shooting just fine and sometimes ignorance is bliss.

Someone put a popper at 1250 yards, and I figured if I got an impact on the IPSC I'd try to hit it... ended up going 9 out of 10 going back and forth between the IPSC and the popper (I probably should have stopped for a lottery ticket on the way home hahaha):

What I like about the Deep Creek Method is that it's so precise: there's no measuring over and over again or throwing anything out, once there's no more "click", you measure your dummy round and you're done, that's it. Though you're right, I guess it can be easier with some actions over others, with an Origin all it takes is a twist to pull the firing pin assembly, and a fixed ejector means no disassembly required.

I was going to take a measurement this morning, but was too lazy to get into it before running errands and before going out and shooting another 50rds. But now, part of me doesn't even want to know where the lands are because it's shooting just fine and sometimes ignorance is bliss.

Someone put a popper at 1250 yards, and I figured if I got an impact on the IPSC I'd try to hit it... ended up going 9 out of 10 going back and forth between the IPSC and the popper (I probably should have stopped for a lottery ticket on the way home hahaha):

Ok, got my shit together this morning and using the Deep Creek Method, measured my distance to the lands. 1450rds on the barrel and it's still shooting great (see post above).

Last time I measured the distance to the lands on this barrel it had ~500rds down the pipe... this is a 26" Proof Research Competition Contour Stainless 6CM Origin prefit 7.5T.

@500rds: distance to lands = CBTO 2.235"

@1450rds: distance to lands = CBTO 2.241"

That's only .006 fucking thousandths of throat erosion over ~1000rds!!!

I did this twice, a second time with a different piece of brass and different bullet, same result.

So by running a load that's ~175-200fps slower than @High Desert duck, and jumping a bunch more (+0.095" more to be exact), the throat on my barrel is eroding at a rate MUCH slower than on his barrel.

Someone better at math please help me out, but, it looks like by running hotter and right up on the lands he is getting 2x the amount of erosion as I am, in only 1/4 the rounds...

So, scientifically-speaking: his barrel is wearing a metric fuck-ton faster than mine is. (In fact, sorry dude, but my barrel, with twice the rounds on it, is probably in better condition than yours at this point.)

Comparing one barrel to another isn't really much of anything... so I hope anyone with anything of value to add on this will chime in...

Last time I measured the distance to the lands on this barrel it had ~500rds down the pipe... this is a 26" Proof Research Competition Contour Stainless 6CM Origin prefit 7.5T.

@500rds: distance to lands = CBTO 2.235"

@1450rds: distance to lands = CBTO 2.241"

That's only .006 fucking thousandths of throat erosion over ~1000rds!!!

I did this twice, a second time with a different piece of brass and different bullet, same result.

So by running a load that's ~175-200fps slower than @High Desert duck, and jumping a bunch more (+0.095" more to be exact), the throat on my barrel is eroding at a rate MUCH slower than on his barrel.

Someone better at math please help me out, but, it looks like by running hotter and right up on the lands he is getting 2x the amount of erosion as I am, in only 1/4 the rounds...

So, scientifically-speaking: his barrel is wearing a metric fuck-ton faster than mine is. (In fact, sorry dude, but my barrel, with twice the rounds on it, is probably in better condition than yours at this point.)

Comparing one barrel to another isn't really much of anything... so I hope anyone with anything of value to add on this will chime in...

Last edited:

Nice shooting! I took my 6CM out to 1260 this past thursday. It didn't suck.It's funny, I've been messing around with more and more bullet-jump to where .020" off or closer seems crazy to me now hahaha.

What I like about the Deep Creek Method is that it's so precise: there's no measuring over and over again or throwing anything out, once there's no more "click", you measure your dummy round and you're done, that's it. Though you're right, I guess it can be easier with some actions over others, with an Origin all it takes is a twist to pull the firing pin assembly, and a fixed ejector means no disassembly required.

I was going to take a measurement this morning, but was too lazy to get into it before running errands and before going out and shooting another 50rds. But now, part of me doesn't even want to know where the lands are because it's shooting just fine and sometimes ignorance is bliss.

Someone put a popper at 1250 yards, and I figured if I got an impact on the IPSC I'd try to hit it... ended up going 9 out of 10 going back and forth between the IPSC and the popper (I probably should have stopped for a lottery ticket on the way home hahaha):

View attachment 7727115View attachment 7727117View attachment 7727118

Similar threads

- Replies

- 1

- Views

- 462

- Replies

- 3

- Views

- 293