So, what was different in your reloading between first and 2nd rd of testing? Or are we gonna chalk it up to barrel? On 2nd rd, did you do more than 3 rd groups/velocity strings?

You kind of conflated those. Initial load work showed promise, even bragged on best group youd ever shot. Wandered about retumbo and QL prediction and opined about saving components. Sorry you weren't clear about that. If you would have said "computer predictions can be useful if you don't know where to start," I'd have agreed with you. It just sounded weird with your initial load work and best group ever comment.

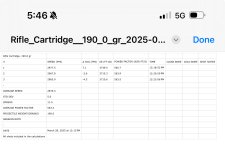

Nothing was different. Same lot of brass, same primer, same trim length, same powder charge, & same bullet / seating depth etc…

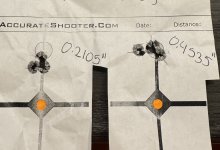

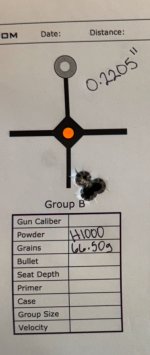

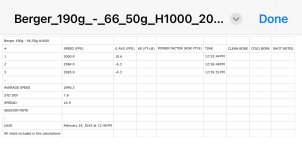

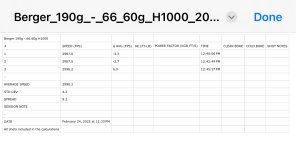

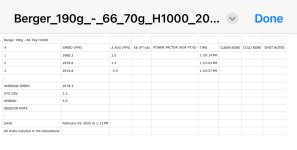

I left the barrel uncleaned, and repeated the test. No I did not retest shot strings greater than three. My reason for that is because if the load I’m retesting doesn’t repeat why shoot more.

(Barrel was cleaned during 1st test and 5 fouling shots were fired on the paper, followed by a 8-10minute cool down.

Normal I shoot x1 shot string of three till

I find something that shows promise. If it shows good ES/SD with acceptable accuracy .5” or better, then I load up another three shoot paper again, and what I’m looking for is consistent ES/SD, similar group size or better, and same point of aim/same point of impact. If the second group repeats, then I load up 6 more retest everything I said above, & if it checks out okay I’ll then test at distance.

Sorry if I wasn’t clear @6brshooter