Ergos? Quality? Functionality? I own one and couldn’t disagree more. You are literally the first person I’ve seen complain about any of these. What would you consider a good press then? Maybe stick to factory ammo, you wont have to worry about any of these made-up issues

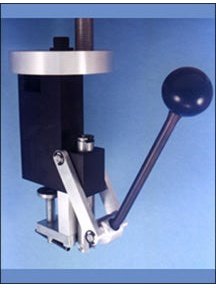

No, I'm not the only one. Have you ever noticed the extensive catalog of aftermarket parts sold by Forster for the CoAx? Those are patches for the shortcomings countless end users have encountered. This thread is literally about a new high end redesigned CoAx.