Call the manufacturer of the barrel and ask them. They will know better.What’s the recommended left hand gain twist for 6.5 Creedmoor 22”? I’m thinking 8.5-7.75?... maybe 8.25-7.5? I need to listen to the podcast again but I believe Frank suggests .75” over a full 1”.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bartlein New Barrel Material 400MODBB

- Thread starter Frank Green

- Start date

8 twist seems to be best overall twist for 6.5 creed, so I would probably go with 8.75-8 unless you’re planning to shoot 156s. But id imagine frank will chime in on that shortlyWhat’s the recommended left hand gain twist for 6.5 Creedmoor 22”? I’m thinking 8.5-7.75?... maybe 8.25-7.5? I need to listen to the podcast again but I believe Frank suggests .75” over a full 1”.

Less is better. I tried a 14-10. Wildest damn thing I ever shot. It would puke shots 16" at 1K

.5-.75 gain

.5-.75 gain

I got my mod400bb 6.5 CM barrel for my AX from Dave Tooley (thank you sir) this week. Worked up a quick load with rl16 and Berger 144s. Shot this morning out to 1025 and its holding sub 1/2 moa of vertical. I cleaned it after 18 rounds during load development and it had very little fouling, and no copper fouling, which is about like every other bartlein barrel I've owned so I don't know if it's better in that respect or not. All in all, it's a typical bartlein and if it gets close to 50% increase in life, the extra $200 is a bargain. Btw, it was a pleasure doing business with Mr Tooley and he'll be my first call when i get ready for another barrel.

@Frank Green I understand heat is always the killer, so can we expect the throat to erode under the same amount of fire as the other steel or are you seeing longer throat life as well?

We try! Thanks for buying the stick!Can't beat Bartlein, barrel I made payment on Monday arriving today and completed months under quote on a custom order.

Later, Frank

@Frank Green I understand heat is always the killer, so can we expect the throat to erode under the same amount of fire as the other steel or are you seeing longer throat life as well?

The throat life seems to be going longer as well. In terms of erosion and heat checking.

With the exception of one or two cases and there will always be something going on that you don't always get all the details or for the lack of a better phrase like....ran it till the tires burned off syndrome which does happen we can't cover everything.

I’m sold. Going to have SAC spin me up a 7 SAUM for my SRS throated for 184 Hybrids.

So I got my MODBB Alloy 6 dasher barrel up and shooting finally. 28inch M24 Contour spun up by DMR with my reamer for a Zeus action.

Got the barrel Saturday after shooting a match with my smith, spun it on and loaded some ammo at midnight 105 HYBs with 31.3 varget 30 thou off the lands. Took it to a another match Sunday. First 3 rounds touching, zeroed and sent it. Shot well all day, managed a top 10 after remembering to hold a little bit more wind with the 105s...

The most interesting thing is in about the 100 rounds, there was ZERO speed up. First 3 rounds chronoed the same as the 100th. Can't wait to burn it out, hope it takes awhile. But another boringly accurate barrel from Bartlein.

Got the barrel Saturday after shooting a match with my smith, spun it on and loaded some ammo at midnight 105 HYBs with 31.3 varget 30 thou off the lands. Took it to a another match Sunday. First 3 rounds touching, zeroed and sent it. Shot well all day, managed a top 10 after remembering to hold a little bit more wind with the 105s...

The most interesting thing is in about the 100 rounds, there was ZERO speed up. First 3 rounds chronoed the same as the 100th. Can't wait to burn it out, hope it takes awhile. But another boringly accurate barrel from Bartlein.

Mine sped up but it was closer to 200 rounds. 6 Dasher sped up about 40 FPS.So I got my MODBB Alloy 6 dasher barrel up and shooting finally. 28inch M24 Contour spun up by DMR with my reamer for a Zeus action.

Got the barrel Saturday after shooting a match with my smith, spun it on and loaded some ammo at midnight 105 HYBs with 31.3 varget 30 thou off the lands. Took it to a another match Sunday. First 3 rounds touching, zeroed and sent it. Shot well all day, managed a top 10 after remembering to hold a little bit more wind with the 105s...

The most interesting thing is in about the 100 rounds, there was ZERO speed up. First 3 rounds chronoed the same as the 100th. Can't wait to burn it out, hope it takes awhile. But another boringly accurate barrel from Bartlein.

Mine sped up but it was closer to 200 rounds. 6 Dasher sped up about 40 FPS.

This is good to know, I am going to be about 300 rounds worth of local matches before a 2 day national so hopefully it's settled in by then.

How many rounds do you have on it so far? any chance close to burning it out?

I have about 350 rounds on mine.This is good to know, I am going to be about 300 rounds worth of local matches before a 2 day national so hopefully it's settled in by then.

How many rounds do you have on it so far? any chance close to burning it out?

Frank, any more feed back from the guys with barrel burner cartridges?

(300 Norma/300RUM?)

Thanks

(300 Norma/300RUM?)

Thanks

Where the 400MODBB Bartlein blanks can be ordered?

Nothing is on the website https://bartleinbarrels.com/

Nothing is on the website https://bartleinbarrels.com/

Where the 400MODBB Bartlein blanks can be ordered?

Nothing is on the website https://bartleinbarrels.com/

You have to call them and it's $200 extra, they are 12 months out right now.

Otherwise you can call up dealers like Altrus/Bugholes/Grizzy etc and see if they have one in stock or get on a waiting list. Dealers are getting stock usually regularly.

Last edited:

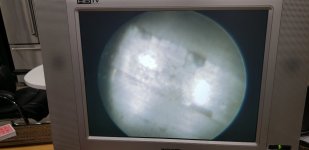

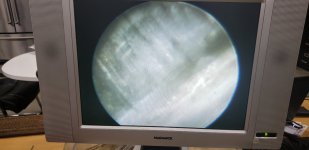

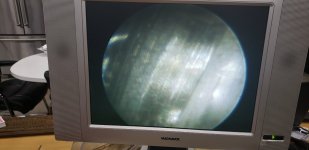

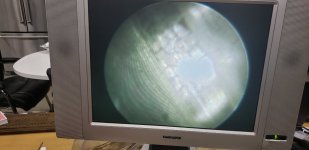

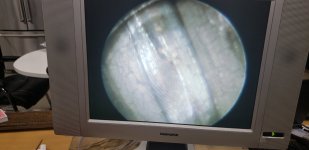

Here are some pic's of two ammunition pressure test barrels I just got back. Both are 6.5CM. One is standard 416R material and the other is the BB material. Round counts are with in a 150 rounds. So about as close a comparison your going to get out of the barrels being fired in controlled conditions, same cleaning technique and intervals, and bullets and powder etc...being run thru them.

Other than running a dry patch down the bores to take any loose junk out of them no cleaning was done. This is as they where received in.

First five pictures are of the standard material. At the case mouth of the chamber you can see gouges/streaks cutting into the material. Those are the first two pic's. The 3rd picture is of the throat area of the chamber...virtually no lands are left from what I can see. The last two pictures are just in front of the throat area. You can see chunks of material coming out of the edges of the lands.

Last five pictures are of the BB material. I don't see those heavy gouges/tears per say at the case mouth...some starting but nothing like the standard material barrel, no chunks of material missing from the edges of the lands...yes the cracking/heat checking is there but again no chunks of metal gone per say and the throat area still shows nicely. Not like it's completely burnt down to nothing.

I'm going to try and measure the throat lengths and see what can come up with as well.

Later, Frank

Bartlein Barrels

Other than running a dry patch down the bores to take any loose junk out of them no cleaning was done. This is as they where received in.

First five pictures are of the standard material. At the case mouth of the chamber you can see gouges/streaks cutting into the material. Those are the first two pic's. The 3rd picture is of the throat area of the chamber...virtually no lands are left from what I can see. The last two pictures are just in front of the throat area. You can see chunks of material coming out of the edges of the lands.

Last five pictures are of the BB material. I don't see those heavy gouges/tears per say at the case mouth...some starting but nothing like the standard material barrel, no chunks of material missing from the edges of the lands...yes the cracking/heat checking is there but again no chunks of metal gone per say and the throat area still shows nicely. Not like it's completely burnt down to nothing.

I'm going to try and measure the throat lengths and see what can come up with as well.

Later, Frank

Bartlein Barrels

Attachments

-

Standard material 6.5cm test bbl case mouth.jpg322.6 KB · Views: 318

Standard material 6.5cm test bbl case mouth.jpg322.6 KB · Views: 318 -

Standard material 6.5cm case mouth 2.jpg304.7 KB · Views: 326

Standard material 6.5cm case mouth 2.jpg304.7 KB · Views: 326 -

Standard material 6.5cm throat.jpg303.5 KB · Views: 298

Standard material 6.5cm throat.jpg303.5 KB · Views: 298 -

Standard material 6.5cm lands in front of the throat.jpg249.7 KB · Views: 291

Standard material 6.5cm lands in front of the throat.jpg249.7 KB · Views: 291 -

Standard material 6.5cm lands in front of throat 2.jpg306.8 KB · Views: 309

Standard material 6.5cm lands in front of throat 2.jpg306.8 KB · Views: 309 -

BB material 6.5cm case mouth.jpg309.2 KB · Views: 309

BB material 6.5cm case mouth.jpg309.2 KB · Views: 309 -

BB material case mouth 2.jpg287.5 KB · Views: 283

BB material case mouth 2.jpg287.5 KB · Views: 283 -

BB material throat.jpg297.6 KB · Views: 275

BB material throat.jpg297.6 KB · Views: 275 -

BB material throat 2.jpg313.2 KB · Views: 283

BB material throat 2.jpg313.2 KB · Views: 283 -

BB material 6.5cm past the throat area.jpg269.4 KB · Views: 318

BB material 6.5cm past the throat area.jpg269.4 KB · Views: 318

Great pics and thanks for sharing. What's the current lead time on these barrels?Here are some pic's of two ammunition pressure test barrels I just got back. Both are 6.5CM. One is standard 416R material and the other is the BB material. Round counts are with in a 150 rounds. So about as close a comparison your going to get out of the barrels being fired in controlled conditions, same cleaning technique and intervals, and bullets and powder etc...being run thru them.

Other than running a dry patch down the bores to take any loose junk out of them no cleaning was done. This is as they where received in.

First five pictures are of the standard material. At the case mouth of the chamber you can see gouges/streaks cutting into the material. Those are the first two pic's. The 3rd picture is of the throat area of the chamber...virtually no lands are left from what I can see. The last two pictures are just in front of the throat area. You can see chunks of material coming out of the edges of the lands.

Last five pictures are of the BB material. I don't see those heavy gouges/tears per say at the case mouth...some starting but nothing like the standard material barrel, no chunks of material missing from the edges of the lands...yes the cracking/heat checking is there but again no chunks of metal gone per say and the throat area still shows nicely. Not like it's completely burnt down to nothing.

I'm going to try and measure the throat lengths and see what can come up with as well.

Later, Frank

Bartlein Barrels

Frank,Here are some pic's of two ammunition pressure test barrels I just got back. Both are 6.5CM. One is standard 416R material and the other is the BB material. Round counts are with in a 150 rounds. So about as close a comparison your going to get out of the barrels being fired in controlled conditions, same cleaning technique and intervals, and bullets and powder etc...being run thru them.

Other than running a dry patch down the bores to take any loose junk out of them no cleaning was done. This is as they where received in.

First five pictures are of the standard material. At the case mouth of the chamber you can see gouges/streaks cutting into the material. Those are the first two pic's. The 3rd picture is of the throat area of the chamber...virtually no lands are left from what I can see. The last two pictures are just in front of the throat area. You can see chunks of material coming out of the edges of the lands.

Last five pictures are of the BB material. I don't see those heavy gouges/tears per say at the case mouth...some starting but nothing like the standard material barrel, no chunks of material missing from the edges of the lands...yes the cracking/heat checking is there but again no chunks of metal gone per say and the throat area still shows nicely. Not like it's completely burnt down to nothing.

I'm going to try and measure the throat lengths and see what can come up with as well.

Later, Frank

Bartlein Barrels

Can you say what the total round count was (roughly)?

No different than a standard barrel. Only thing different when we make them we have is the material.Great pics and thanks for sharing. What's the current lead time on these barrels?

General customer stuff....we are currently quoting 10-12 months regardless of what it is. I'm hoping when we go thru all of our open orders the first of the next month....we gained some ground on the back log. If so I'm considering on dropping the lead time possibly but no guarantees.

Both barrels had over 3500 rounds on them.Frank,

Can you say what the total round count was (roughly)?

Frank, were they still shooting? Neither of them looks bad for high mileage barrels.Both barrels had over 3500 rounds on them.

Frank, were they still shooting? Neither of them looks bad for high mileage barrels.

Remember on ammunition pressure test barrels they can use them for both accuracy and pressure. When they start seeing a velocity/pressure swing that is usually an indicator that the barrel is on it's last legs or has given up the ghost per say. Remember they are loading factory loaded ammunition and have to hold the ammo to limits for pressure and velocity...and not just accuracy.

Standard 416R material or C.M. test barrels in 6.5CM are getting pulled from service at about 1700 rounds. Give or take a few.

The BB material went 3500 before they seen a swing in velocity/pressures.

Doesn't mean the barrels cannot hold accuracy still.

A good example is 50bmg test barrels. If the testing is strictly accuracy (no pressure and velocity testing being done) a 50bmg barrel can make it to 5k rounds but as soon as they have to hold pressure and velocity spec's.....they said rarely does a 50BMG pressure test barrel make it past 3k rounds.

They will get the velocity loss and pressure swings when the throat area of the chamber starts to show the wear. You or I shooting a bolt gun etc...when we see a velocity loss and a small swing in accuracy we can bump the seating depth of the bullet to compensate for the throat wearing and bump the powder charge to bring the gun/barrel back into tune. They are not allowed to do that though on a pressure/velocity test barrel when making box ammo to a given spec.

The BB material barrel they did want to keep it and when time was available to keep shooting it to see where it truly gave up the ghost accuracy wise but with the state all of the ammunition makers/bullet makers are in / the gun industry as a whole....it just wasn't feasible at this time for them to do it.

Again the barrels showed us great numbers. Standard material P&V test barrels in 6.5CM get pulled at 1700 rounds....1900 tops. They know when they hit 1700 if it made it that far they are on borrowed time with the barrel and if they got 1900 out of it...they we're babying it. The BB material performed excellent till just shy of 3500. Then they ran another 100-200 rounds thru it to confirm the data that it was giving them. So they officially considered done just past the 3500 mark.

Later, Frank

At the case mouth on the standard material barrel with those small tears etc...running into the bore of the barrel....it is rough enough/sharp enough to pull fibers off of the cleaning patch.

The BB material barrel didn't do that at all when I was dry patching the bores.

The BB material barrel didn't do that at all when I was dry patching the bores.

What was your load by chance? I'm just starting with RL16 and the 144I got my mod400bb 6.5 CM barrel for my AX from Dave Tooley (thank you sir) this week. Worked up a quick load with rl16 and Berger 144s. Shot this morning out to 1025 and its holding sub 1/2 moa of vertical. I cleaned it after 18 rounds during load development and it had very little fouling, and no copper fouling, which is about like every other bartlein barrel I've owned so I don't know if it's better in that respect or not. All in all, it's a typical bartlein and if it gets close to 50% increase in life, the extra $200 is a bargain. Btw, it was a pleasure doing business with Mr Tooley and he'll be my first call when i get ready for another barrel.

Anyone notice that the harder alloy takes longer to break in? My bartleins usually are sped up by 80-100 rounds.

I am 1200 rounds in with no speed up.

How's the accuracy been on these? Typical bartlein?

Yep... it's a dasher everything shoots bugholes and ES of 20 or less.... it's kinda of amazing. Showed up to a match with zero rounds fried 31.5gr of Varget jumping 105s 60 thou. 5 rounds to foul it and zero it and off the the races it went.

How's the accuracy been on these? Typical bartlein?

Excellent. It’s the most accurate barrel I have ever shot, matter of fact. Also cleans up real quick. Very smooth.

Anyone notice that the harder alloy takes longer to break in? My bartleins usually are sped up by 80-100 rounds.

Guys....regardless of the material.... cm steel, standard ss or even our new material....I've had plenty of barrels where there was no significant velocity/change speed up. Some will....some will not.

If a barrel is going to change....I tell everyone (depending on caliber) it's going to change with in the first 100 rounds usually. Some go a little longer some quicker and some not at all.

How are you cleaning it?

How often between rounds fired do you clean it?

Type of powder/load?

A lot of variables to contend with.

Later, Frank

Bartlein Barrels

You should have this post and a few others on “auto post” mid way through every pageGuys....regardless of the material.... cm steel, standard ss or even our new material....I've had plenty of barrels where there was no significant velocity/change speed up. Some will....some will not.

If a barrel is going to change....I tell everyone (depending on caliber) it's going to change with in the first 100 rounds usually. Some go a little longer some quicker and some not at all.

How are you cleaning it?

How often between rounds fired do you clean it?

Type of powder/load?

A lot of variables to contend with.

Later, Frank

Bartlein Barrels

your prob tired of typing the same thing after a few years lol

thanks

@Frank Green

Just ordered an MTU in 400MODBB, .264/6.5mm, 7.5-8 T Cut (gain twist, yeah).

As has been discussed, lead times are stretching and I was given a conservative time line of 10-11 months. I agreed with Mark....better to beat a long lead time and be a hero and than miss a delivery projection and be a bum.

I have 1000 rounds on the current Proof SS MTU in 7.5 (and its a really nice barrel also) and hoping it will last until I get the new one but I doubt it.

Its entirely my fault...been thinking for 3-4 months that I needed to place this order and just procrastinated.

Frank - Mark was OUTSTANDING in his CS attitude, technical knowledge, and just general friendliness and helpfulness. It was an outstanding ordering experience and you deserve to be proud of this employee and his professionalism. Just could not have been better.

Cheers

Just ordered an MTU in 400MODBB, .264/6.5mm, 7.5-8 T Cut (gain twist, yeah).

As has been discussed, lead times are stretching and I was given a conservative time line of 10-11 months. I agreed with Mark....better to beat a long lead time and be a hero and than miss a delivery projection and be a bum.

I have 1000 rounds on the current Proof SS MTU in 7.5 (and its a really nice barrel also) and hoping it will last until I get the new one but I doubt it.

Its entirely my fault...been thinking for 3-4 months that I needed to place this order and just procrastinated.

Frank - Mark was OUTSTANDING in his CS attitude, technical knowledge, and just general friendliness and helpfulness. It was an outstanding ordering experience and you deserve to be proud of this employee and his professionalism. Just could not have been better.

Cheers

Could be worse. Life went to hell on me a month ago and I forgot to confirm my order with a smith. They gave me a 6 week lead time for what I needed. I finally emailed them back this morning 5 weeks later. I told them its perfectly fine if the lead time changed as thankfully I am in no rush.Its entirely my fault...been thinking for 3-4 months that I needed to place this order and just procrastinated.

Really tempted to place a ModBB order for a custom build I have in mind, but I also have no clue if/when I would even get to the build. lol Thinking it might be best to just have the barrel in hand rather than wait if I do go ahead on it.

How bad can it get...if its a reasonably popular bore and you don't do the custom build, you can always sell it for at least full price as there is no lead time....no?Thinking it might be best to just have the barrel in hand rather than wait if I do go ahead on it.

Thanks for the order!@Frank Green

Just ordered an MTU in 400MODBB, .264/6.5mm, 7.5-8 T Cut (gain twist, yeah).

Frank - Mark was OUTSTANDING in his CS attitude, technical knowledge, and just general friendliness and helpfulness. It was an outstanding ordering experience and you deserve to be proud of this employee and his professionalism. Just could not have been better.

Cheers

Mark is good....deals in the real world also! He should run for President or at a minimum for Gov.! The Dems wouldn't like him very much!

Thanks for the compliments!

I’d vote Mark for governor! Give the commie the boot!Thanks for the order!

Mark is good....deals in the real world also! He should run for President or at a minimum for Gov.! The Dems wouldn't like him very much!

Thanks for the compliments!

Just to confirm, you do mean tightening from 8 at the chamber to 7.5 at the muzzle?7.5-8 T

That's what he meant I'm sure....just put it down in writing wrong.Just to confirm, you do mean tightening from 8 at the chamber to 7.5 at the muzzle?

Don't worry will make it the correct way!

Yep. My current Proof SS MTU is 7.5 and I like it. I shoot mostly 140 Berger Hybrid Targets and ELD-M's but I like the 7.5 part for if I want to shoot a heavier projectile like Berger's 153 LR.Just to confirm, you do mean tightening from 8 at the chamber to 7.5 at the muzzle?

And yes, Frank is correct....I should have typed it 8-7.5

Also, I should mention that Mark strongly recommended 5R rifling for 6.5 CM calibrer/bullet weight and I went with his rec.

I have a fairly recent vintage Rem 700 5R SS Gen 1 (don't you love these naming conventions...FFS haha) and I got lucky and have a pretty dang good barrel and 5R rifling seems to work well there so....I'm going with Mark on this also.

Cheers

Last edited:

The 5R rifling now we've been getting more and more data is showing to help the flight of the bullet.Yep. My current Proof SS MTU is 7.5 and I like it. I shoot mostly 140 Berger Hybrid Targets and ELD-M's but I like the 7.5 part for if I want to shoot a heavier projectile like Berger's 153 LR.

And yes, Frank is correct....I should have typed it 8-7.5

Also, I should mention that Mark strongly recommended 5R rifling for 6.5 CM calibrer/bullet weight and I went with his rec.

I have a fairly recent vintage Rem 700 5R SS Gen 1 (don't you love these naming conventions...FFS haha) and I got lucky and have a pretty dang good barrel and 5R rifling seems to work well there so....I'm going with Mark on this also.

Cheers

I do also believe that the odd number of grooves (lands don't directly oppose one another) does help fight bullet failure as well.

Later, Frank

I guess I better get a 7mm barrel ordered and run my own 7RM barrel life test.

Sounds like a great development!

Sounds like a great development!

Bugholes.com had them in stock last week for $600. They might still have a fewWhat’s the prices on the bb steel? Looking for 6mm m24 26 inch?

What’s the prices on the bb steel? Looking for 6mm m24 26 inch?

Bartlein 6mm 7.5 twist SS 1.250'' 31'' BB Steel

www.bugholes.com

Anyone pull a 6 Dasher barrel yet? Just ordered my barrel this weekend...having my gunsmith chamber 6 Dasher...was wonder if I could get 3500 on a Dasher....

I just pulled my MOD400 Dasher. 31xx rounds on it. Still shoots great, but SD/ES opened up quite a bit. May just need a good cleaning, but I didn't have time to try to diagnose. I'll revisit it over the winter and seeAnyone pull a 6 Dasher barrel yet? Just ordered my barrel this weekend...having my gunsmith chamber 6 Dasher...was wonder if I could get 3500 on a Dasher....

I'll say the Dasher is going to be harder on the barrel vs a 6BRA or 6BR but we have guys with 6BRA's that are over 4k and still shooting.I just pulled my MOD400 Dasher. 31xx rounds on it. Still shoots great, but SD/ES opened up quite a bit. May just need a good cleaning, but I didn't have time to try to diagnose. I'll revisit it over the winter and see

Greg at SPR pulled his test barrel in 6XC at 3500 rounds I think it was.

Loss in velocity typically means the throat has worn enough and that is a sign that your on borrowed time. Still might shoot for a while but it's a sign.

Later, Frank

Still!! 4k is great reviews in a BR. Basically a 2 for 1, or thereabouts. Even though the blank is a bit less than 2x, you’re still saving $250-ish in ‘smith fees.

I still have 3 blanks on the shelf for my personal use. However, next spring I will be ordering a couple modbb blanks.

@Frank Green , I’ve heard conflicting reports on weather a standard reamer from, say, Manson will chamber the new material effectively or not. Is there a different “process”, per say, in chambering? I spin my own barrels, and have for 20yrs. So, use to the typical “feel” while Chambering. Just need to know if I need to purchase another type of reamer before dialing in a modbb blank. I’d hate to get 3/4 way thru a chamber and bad things happen to the reamer. Ya know.

I still have 3 blanks on the shelf for my personal use. However, next spring I will be ordering a couple modbb blanks.

@Frank Green , I’ve heard conflicting reports on weather a standard reamer from, say, Manson will chamber the new material effectively or not. Is there a different “process”, per say, in chambering? I spin my own barrels, and have for 20yrs. So, use to the typical “feel” while Chambering. Just need to know if I need to purchase another type of reamer before dialing in a modbb blank. I’d hate to get 3/4 way thru a chamber and bad things happen to the reamer. Ya know.

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 30

- Views

- 1K