I'm pretty new to Long Range shooting, and thus long gun cleaning.. But my bore NEVER comes clean.. Can I get your opinions on my situation, please?

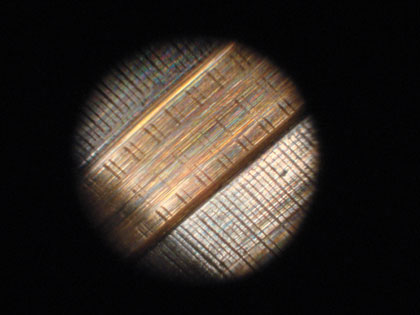

I am shooting a Savage Axis .308 (inexpensive but accurate starter rifle). I have put 338 rounds through it lifetime, and wet patch / dry patch after each range session (30-40 rounds), until the patches come out 99% clean. This time I decided to bronze brush it this time, and patches keep coming out dirty as heck. I wet patch with Hoppes #9 (wait 30 min), 10 strokes of the bronze brush, dry patch, and I am on my 30th cycle of this method.. Below are my first patch (LEFT), and latest patch (RIGHT), so you can see how dirty the patches still are.. Will this ever end?

However, before this deep cleaning project, the rifle was still shooting sub-MOA, so am I overly concerned about this?? Thanks

As info, the green patch wasnt that green when it first came out.. the patches seem to turn greener as they dry.. not sure why.

I am shooting a Savage Axis .308 (inexpensive but accurate starter rifle). I have put 338 rounds through it lifetime, and wet patch / dry patch after each range session (30-40 rounds), until the patches come out 99% clean. This time I decided to bronze brush it this time, and patches keep coming out dirty as heck. I wet patch with Hoppes #9 (wait 30 min), 10 strokes of the bronze brush, dry patch, and I am on my 30th cycle of this method.. Below are my first patch (LEFT), and latest patch (RIGHT), so you can see how dirty the patches still are.. Will this ever end?

However, before this deep cleaning project, the rifle was still shooting sub-MOA, so am I overly concerned about this?? Thanks

As info, the green patch wasnt that green when it first came out.. the patches seem to turn greener as they dry.. not sure why.

Attachments

Last edited: