Yesterday I chambered a Krieger SS barrel in 6.5 Creedmoor and noticed the reamer wasn't clearing chips. The reamer cut normally up to the shoulder/body junction. Past that point I was going to take about .100" per pass, but noticed by .060" that no chips were being cleared through the flutes. I stopped and withdrew the reamer and the reamer had been cutting, but the chips were compacted in the flutes inside the hole being cut. The chips were tightly packed and most popped out when the reamer was withdrawn. While the feed rate was slow, I could feel increasing resistance by .040" - .050".

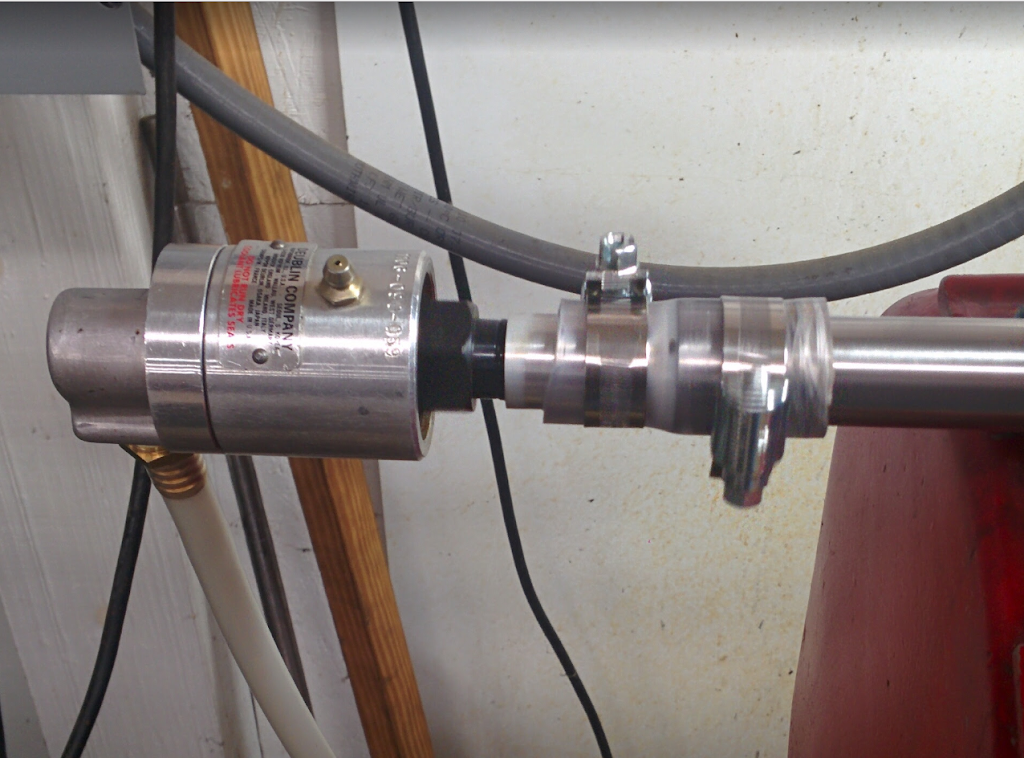

The reamer was a new PTG finish reamer w/live pilot on a Manson floating reamer holder. The reamer and bore were well oiled, and the feed rate was about .010" per 5-6 seconds. I'm using a PM 1340GT lathe at 90 rpm. After each pass the reamer was removed, blown clear of all chips, as was the chamber. I inspected the reamer and found no visible defects.

The chamber finish was fine, and I continued but was forced to withdraw and clear the reamer every .040". No chatter or noise, just forced to make many small passes. The end product was fine, but my previous experience has been that following the same procedure, chips flow evenly from the flutes and are not compacted. Any ideas?

The reamer was a new PTG finish reamer w/live pilot on a Manson floating reamer holder. The reamer and bore were well oiled, and the feed rate was about .010" per 5-6 seconds. I'm using a PM 1340GT lathe at 90 rpm. After each pass the reamer was removed, blown clear of all chips, as was the chamber. I inspected the reamer and found no visible defects.

The chamber finish was fine, and I continued but was forced to withdraw and clear the reamer every .040". No chatter or noise, just forced to make many small passes. The end product was fine, but my previous experience has been that following the same procedure, chips flow evenly from the flutes and are not compacted. Any ideas?