Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Coup De Grâce, New Action from American Rifle Company, $899 WOW!

- Thread starter karagias

- Start date

One other thing, would it be possible to cone a savage prefit without touching the chamber or would you have to run the chamber deeper to get it to work?

I run savage prefits with Barlocs on all my ARC actions and I currently have a new Proof savage Prefit getting muzzle threads so if it’s as simple as coning the breach I could have the smith do it now and run it on the CDG instead.

I run savage prefits with Barlocs on all my ARC actions and I currently have a new Proof savage Prefit getting muzzle threads so if it’s as simple as coning the breach I could have the smith do it now and run it on the CDG instead.

You’ll need to push the chamber.One other thing, would it be possible to cone a savage prefit without touching the chamber or would you have to run the chamber deeper to get it to work?

I run savage prefits with Barlocs on all my ARC actions and I currently have a new Proof savage Prefit getting muzzle threads so if it’s as simple as coning the breach I could have the smith do it now and run it on the CDG instead.

I've been extremely impressed with the receivers that ARC has designed. I have both generations of Mausingfield, older one in short action 308, other one in long action 338 bolt face.

Aside from the Archimedes receiver, is the nucleus or the Mausingfield going to be discontinued?

Aside from the Archimedes receiver, is the nucleus or the Mausingfield going to be discontinued?

Damn, may have to buy 2 or 3 of these. Was going to say I'm done building rifles but need two for father/daughter matching build, and the 3rd well lets just see if @MikeRTacOps would build a .308 Delta on one of these....

As I stated earlier, cases are surprisingly strong but I also acknowledge that case head separation do happen but almost never with new brass unless the barrel work is really really bad or the case is defective in a big way.

We have run the Coup De Grâce with 223 from and Accurate mag. Seems to work well but coned breech is a must for that one.

Ted

This seals the deal for me. I’ll be ordering one when they’re available.

Will they be available nitrided? Not sure if I missed that or not.

Ted will have to confirm, but I suspect your answer is the ejector blade window. It looks like there is a slot in the bolt that aligns with that ejector port. Plus whatever bleeds through the mag & ejection port.Is there a vent hole in the action in case there's a case head separation?

He did say they were explosively tested. Also not yet confirmed, but I doubt this action is SS. Something stronger most likely?

Last edited:

Yep.This seals the deal for me. I’ll be ordering one when they’re available.

Will they be available nitrided? Not sure if I missed that or not.

"Simply put, the Coup De Grâce does more with less and looks great doing it with its beautiful design, DLC and salt bath nitrided finishes."

@karagias, given that you’re going to sell thousands of these in the coming years, might you have plans to sell a trigger of your own design, too?

I think doing so would be smart.

Ted

Missed this exchange while I was busy yesterday, would this be able to operate like a three position and lock the bolt? That’s pretty much the only thing I wish they had coming from hunting with the Model 70 prior.

I remember a few years back we had talked about it and you reached out to the guy from NULA about the modified trigger he used on his actions that locked the bolt but I believe he stopped doing that on his recent builds.

Just buy more.

New year. New rifle.

I am but a poor and no rifles this year.

Maybe a couple barrels.

This is cool as crap.

I hope Ted sells piles of them.

New year. New rifle.

I am but a poor and no rifles this year.

Maybe a couple barrels.

This is cool as crap.

I hope Ted sells piles of them.

Never any doubt about ARC actions, but the reason I hopped on the AI train was because of the action/magazine interface is virtually flawless. Any questions about which magazine will operate with the Coup?

One other thing, would it be possible to cone a savage prefit without touching the chamber or would you have to run the chamber deeper to get it to work?

I run savage prefits with Barlocs on all my ARC actions and I currently have a new Proof savage Prefit getting muzzle threads so if it’s as simple as coning the breach I could have the smith do it now and run it on the CDG instead.

Hope this CDG pricing hangs around until the lefty’s roll out so my Nuke can get a cousin to hang out with.

Also hope ARC gets invited on the Proof prefit wagon - had LRI chamber/thread/cerekote a cf blank for a hunting build. Yes, it’s a beautiful laser and I’ve got “no ragrets” but there’s probably 13 bills in that barrel.

Also hope ARC gets invited on the Proof prefit wagon - had LRI chamber/thread/cerekote a cf blank for a hunting build. Yes, it’s a beautiful laser and I’ve got “no ragrets” but there’s probably 13 bills in that barrel.

Well.

Dont get CF.

Dont flute.

Dont cerakote.

Krylon at home.

See, saving you $$$ already.

Just get a Bart 2 or 3 blank to start….

Dont get CF.

Dont flute.

Dont cerakote.

Krylon at home.

See, saving you $$$ already.

Just get a Bart 2 or 3 blank to start….

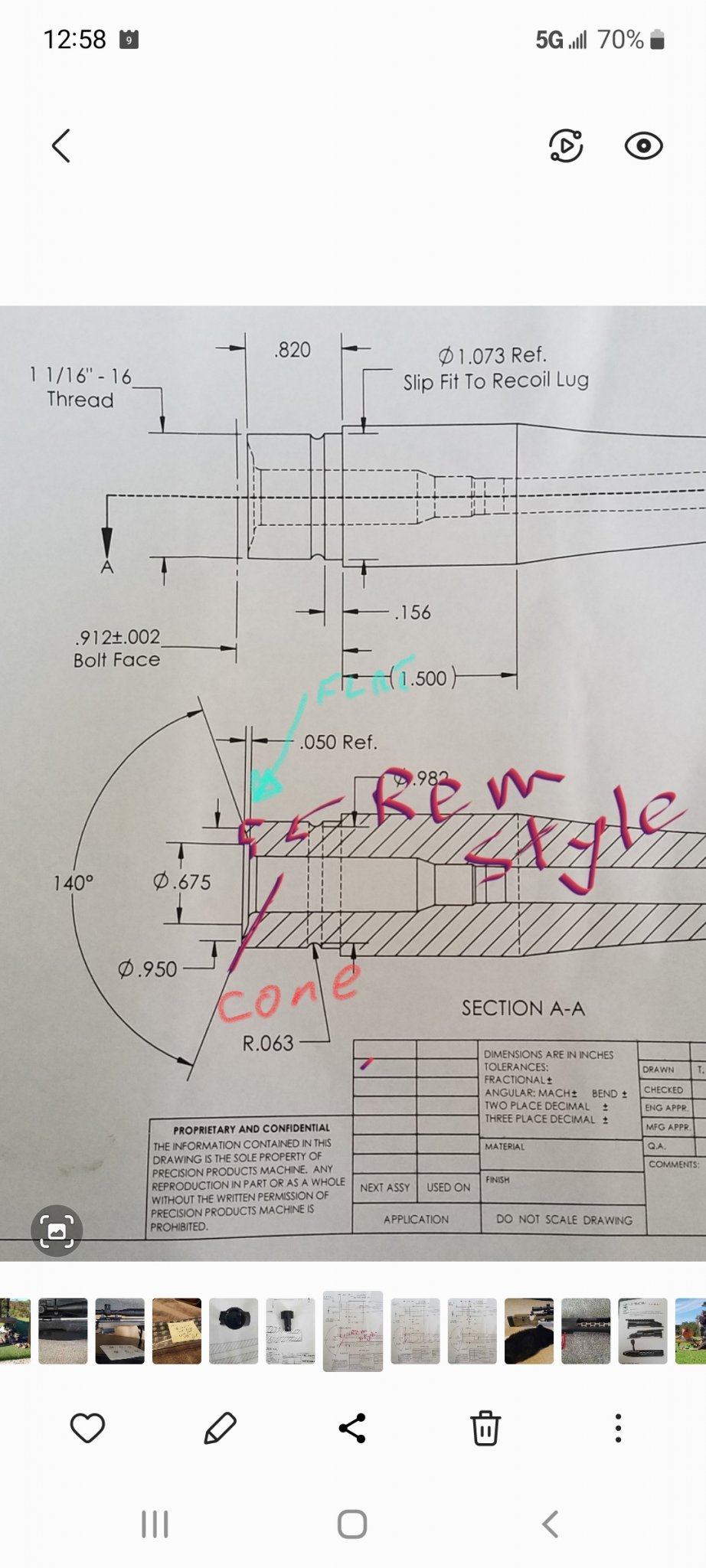

That won't work. If you look at a tenon drawing of the flat back barrels and one with a cone, you'll know why.

Both barrels support the cartridge all the way back to where the extractor groove begins.

The flat back barrel stops there.

The cone breech continues further back. Probably somewhere on the order of .050.

To use a cone breech barrel on a flat nosed bolt, you'd have to remove the coned section. A flat breech barrel works on both but you might have feeding issues with smaller diameter cartridges.

I'd provide a drawing, but I likely wouldn't get it modified before I get called back, because I'm at the eye clinic. If someone doesn't beat me to it, I'll provide it after I get home.

It'll be a few hours

If I’m reading OP right, I’ll need a spacer or something between the action and chassis to run AICS mags (that many of us are heavily invested in) with optimal reliability, which is essentially the requirement for .223 since there’s no AW format mag readily available that I’m aware of. That means after swapping the bolt head to standard short action carrier he’s, I need to remove said spacer to run AW mags or continue to run AICS mags?

EDIT: I guess it doesn’t matter, you’re pulling the action out of the stock to change the barrel anyway right?

EDIT: I guess it doesn’t matter, you’re pulling the action out of the stock to change the barrel anyway right?

Last edited:

That won't work. If you look at a tenon drawing of the flat back barrels and one with a cone, you'll know why.

Both barrels support the cartridge all the way back to where the extractor groove begins.

The flat back barrel stops there.

The cone breech continues further back. Probably somewhere on the order of .050.

To use a cone breech barrel on a flat nosed bolt, you'd have to remove the coned section. A flat breech barrel works on both but you might have feeding issues with smaller diameter cartridges.

I'd provide a drawing, but I likely wouldn't get it modified before I get called back, because I'm at the eye clinic. If someone doesn't beat me to it, I'll provide it after I get home.

It'll be a few hours

Correct you cannot just cut a cone into a flat back barrel unless you want to see

a rifle grenade.

Green arrow against the black line represents a flat breech barrel. Note the .050 between the lines.

Remington style with the "3 rings of steel" step. Also called a counter bore.

Cone breech represented by the angled line. Note that it is .050 longer than the flat back barrel.

A flat backed barrel will work with all three, but most likely not optimal.

My work or terrible, but it's the best I can do right now with my phone and dilated pupils.

Remington style with the "3 rings of steel" step. Also called a counter bore.

Cone breech represented by the angled line. Note that it is .050 longer than the flat back barrel.

A flat backed barrel will work with all three, but most likely not optimal.

My work or terrible, but it's the best I can do right now with my phone and dilated pupils.

For under 30 cal with a flat breach yes.feeding may be compromised?

maybe I should have prefaced that with " hold my beer"Correct you cannot just cut a cone into a flat back barrel unless you want to see

a rifle grenade.

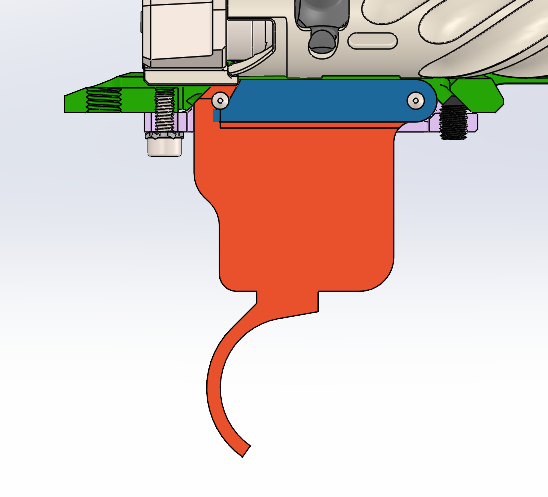

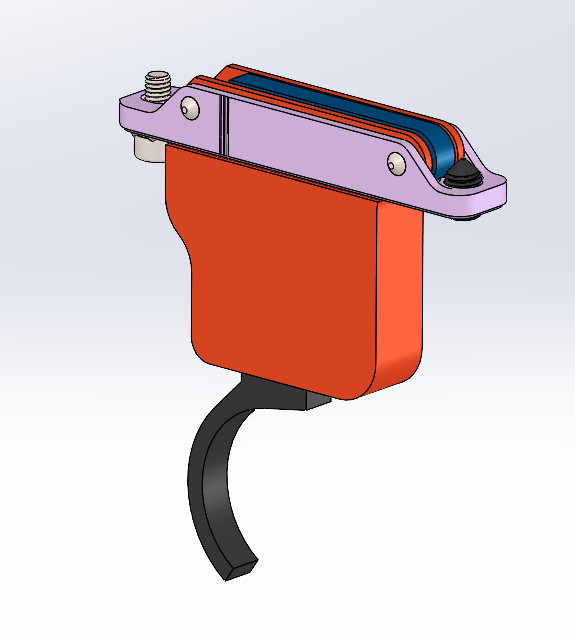

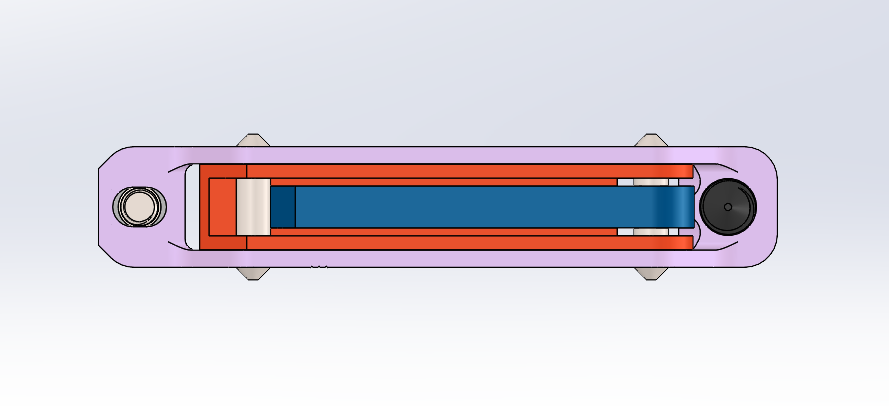

I'll try to get back here later today and answer some more questions but I just want to address the trigger hanger since people have asked about it.

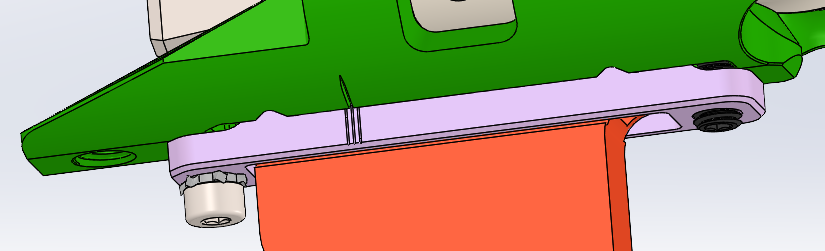

The trigger hanger provides for 1.6mm of adjustment along the bore axis to accommodate various R700 triggers having slight variations in the positions of their cocking-piece bearing surfaces. See pictures below.

If closing the bolt results in a slight drop of the striker/firing pin, tightening the set screw at the forward end of the trigger hanger will push the trigger back to eliminate the drop-on-close. Similarly, if closing the bolt results in some additional cocking, then loosening the set screw will allow the force of the striker spring to push the trigger forward thus eliminating the cock-on-close. The set screw simply impinges on an 45° inclined surface of the receiver which enables the change in position between the trigger hanger and the receiver.

What's nice about this design is that adjustments are really quick and easy to make. The set screw coupled with the forward bias resulting from the mainspring force enables precise and deliberate control. Once you're happy with the way the action feels when you close it, simply tighten the socket head cap screw at the back of the trigger hanger to lock it in place.

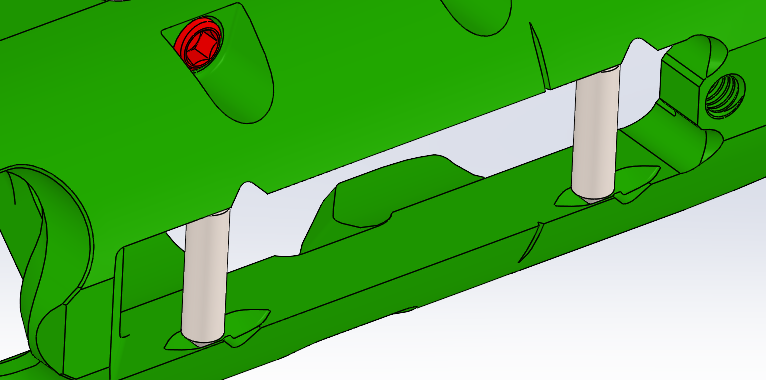

So what holds the trigger hanger and trigger in the receiver when the cocking piece is trying to push it out with the force of the main spring? Is it just the screw at the back of the hanger since the forward screw set can only push the hanger away from the receiver? Well of course not. That would be silly. The 1/8" trigger pins actually protrude laterally from the hanger to directly engage slots machined into the receiver. The slots serve as a track along which the trigger and hanger assembly move. The screws only maintain position longitudinally.

Additionally, this setup makes installing the trigger extremely easy. Once the trigger has been pinned to the hanger, present the assembly to the receiver so that each of the protruding pin tips aligns with its respective passage way, and then push up and forward into the receiver. You can then keep the assembly from falling out by inserting the screw at the back of the hanger.

The set screw can be held in place with three levels of security. First, friction. We've machined the thread in the hanger with an interference fit so you'll feel resistance when turning it. For second level security, add a tiny bit of blue Loctite. And if you're the paranoid type, replace the set screw with a longer one and add a lock nut. I suppose adding Loctite to level 3 gets you to level 4 but maybe that's a bit much. Personally, I'm running level two.

We have included index marks on both the receiver and the hanger to serve as a visual reference but you need only to feel the bolt closing to make your next adjustment.

Clever, huh? Patent is pending so don't get any ideas ;-]

I'll be back later today.

Ted

The trigger hanger provides for 1.6mm of adjustment along the bore axis to accommodate various R700 triggers having slight variations in the positions of their cocking-piece bearing surfaces. See pictures below.

If closing the bolt results in a slight drop of the striker/firing pin, tightening the set screw at the forward end of the trigger hanger will push the trigger back to eliminate the drop-on-close. Similarly, if closing the bolt results in some additional cocking, then loosening the set screw will allow the force of the striker spring to push the trigger forward thus eliminating the cock-on-close. The set screw simply impinges on an 45° inclined surface of the receiver which enables the change in position between the trigger hanger and the receiver.

What's nice about this design is that adjustments are really quick and easy to make. The set screw coupled with the forward bias resulting from the mainspring force enables precise and deliberate control. Once you're happy with the way the action feels when you close it, simply tighten the socket head cap screw at the back of the trigger hanger to lock it in place.

So what holds the trigger hanger and trigger in the receiver when the cocking piece is trying to push it out with the force of the main spring? Is it just the screw at the back of the hanger since the forward screw set can only push the hanger away from the receiver? Well of course not. That would be silly. The 1/8" trigger pins actually protrude laterally from the hanger to directly engage slots machined into the receiver. The slots serve as a track along which the trigger and hanger assembly move. The screws only maintain position longitudinally.

Additionally, this setup makes installing the trigger extremely easy. Once the trigger has been pinned to the hanger, present the assembly to the receiver so that each of the protruding pin tips aligns with its respective passage way, and then push up and forward into the receiver. You can then keep the assembly from falling out by inserting the screw at the back of the hanger.

The set screw can be held in place with three levels of security. First, friction. We've machined the thread in the hanger with an interference fit so you'll feel resistance when turning it. For second level security, add a tiny bit of blue Loctite. And if you're the paranoid type, replace the set screw with a longer one and add a lock nut. I suppose adding Loctite to level 3 gets you to level 4 but maybe that's a bit much. Personally, I'm running level two.

We have included index marks on both the receiver and the hanger to serve as a visual reference but you need only to feel the bolt closing to make your next adjustment.

Clever, huh? Patent is pending so don't get any ideas ;-]

I'll be back later today.

Ted

Last edited:

exactly what I was thinking.This will be the beginning of my 300Norma. Thanks Ted!!!

Just wonder if the LA will get introductory pricing if it's gonna be a late release.

Why all the boners for Proof when Bartlien exists? Heck, I’m excited to try one of these new Osprey barrels over anything from Proof.

The boner comes from usually on the shelf, and current price of $579. If you have an FFL they can be had for significantly less than that.

I also run 2 PVA osprey prefits and they are awesome as well but both took months to get when I ordered them about a year ago and price is $599 for ready to ship and $685 otherwise and M24 contour.

I love my PVA barrels and will order more when it’s something I can’t get from proof simply due to price, but the FFL discount is killer with proof and I prefer the heavier contour.

I also run 2 PVA osprey prefits and they are awesome as well but both took months to get when I ordered them about a year ago and price is $599 for ready to ship and $685 otherwise and M24 contour.

I love my PVA barrels and will order more when it’s something I can’t get from proof simply due to price, but the FFL discount is killer with proof and I prefer the heavier contour.

Why all the boners for Proof when Bartlien exists? Heck, I’m excited to try one of these new Osprey barrels over anything from Proof.

Because I can pay $700 and get a CF barrel from proof off the shelf vs the $1200 and several months it takes to get a CF Bartlien from Straightjacket. I torched my first 6.5 PRC barrel in a year, having to buy multiples adds up.

Good thing a picture tells a thousand words. My previous post was full of typos. Sorry...

Ted

Ted

This is awesome. Now people like me who want maximum ignition reliability and don’t care about a little cock on close can get that without installing a longer cocking piece.I'll try to get back here later today and answer some more questions but I just want to address the trigger hanger since people have asked about it.

The trigger hanger provides for 1.6mm of adjustment along the bore axis to accommodate various R700 triggers having slight variations in the positions of their cocking-piece bearing surfaces. See pictures below.

If closing the bolt results in a slight drop of the striker/firing pin, tightening the set screw at the forward end of the trigger hanger will push the trigger back to eliminate the drop-on-close. Similarly, if closing the bolt results in some additional cocking, then loosening the set screw will allow the force of the striker spring to push the trigger forward thus eliminating the cock-on-close. The set screw simply impinges on an 45° inclined surface of the receiver which enables the change in position between the trigger hanger and the receiver.

What's nice about this design is that adjustments are really quick and easy to make. The set screw coupled with the forward bias resulting from the mainspring force enables precise and deliberate control. Once you're happy with the way the action feels when you close it, simply tighten the socket head cap screw at the back of the trigger hanger to lock it in place.

So what holds the trigger hanger and trigger in the receiver when the cocking piece is trying to push it out with the force of the main spring? Is it just the screw at the back of the hanger since the forward screw set can only push the hanger away from the receiver? Well of course not. That would be silly. The 1/8" trigger pins actually protrude laterally from the hanger to directly engage slots machined into the receiver. The slots serve as a track along which the trigger and hanger assembly move. The screws only maintain position longitudinally.

Additionally, this setup makes installing the trigger extremely easy. Once the trigger has been pinned to the hanger, present the assembly to the receiver so that each of the protruding pin tips aligns with its respective passage way, and then push up and forward into the receiver. You can then keep the assembly from falling out by inserting the screw at the back of the hanger.

The set screw can be held in place with three levels of security. First, friction. We've machined the thread in the hanger with an interference fit so you'll feel resistance when turning it. For second level security, add a tiny bit of blue Loctite. And if you're the paranoid type, replace the set screw with a longer one and add a lock nut. I suppose adding Loctite to level 3 gets you to level 4 but maybe that's a bit much. Personally, I'm running level two.

We have included index marks on both the receiver and the hanger to serve as a visual reference but you need only to feel the bolt closing to make your next adjustment.

Clever, huh? Patent is pending so don't get any ideas ;-]

I'll be back later today.

Ted

View attachment 8042810View attachment 8042812View attachment 8042813View attachment 8042814View attachment 8042828

I second this question!Will lefties be available at the intro price when they are ready, or should we just order now?

When does the intro expire?

I reached out to Proof given the desire here and am happy to say, "We ... are working with ARC." The response appeared to reflect CDG only.

Proofs are (hopefully) on the table bois.

Proofs are (hopefully) on the table bois.

question is...I reached out to Proof given the desire here and am happy to say, "We ... are working with ARC."

Proofs are (hopefully) on the table bois.

CDG or the existing ARC standard (hopefully both)

The response appeared to reflect CDG only.question is...

CDG or the existing ARC standard (hopefully both)

@karagias I third this question and maybe I missed it when will the pre orders start happening?I second this question!

I think ARC is waiting to make sure that they have all of the pieces in place for volume production before opening any pre-ordering.@karagias I third this question and maybe I missed it when will the pre orders start happening?

So i was at KRG site cause i was looking at using there stock with this action. it says possible issues with trigger hangers. Is there other stocks out there we can't use with this action

You should just have to relieve some material is all.So i was at KRG site cause i was looking at using there stock with this action. it says possible issues with trigger hangers. Is there other stocks out there we can't use with this action

So i was at KRG site cause i was looking at using there stock with this action. it says possible issues with trigger hangers. Is there other stocks out there we can't use with this action

You can usually take care of it with a file and 5 minutes.

Similar threads

- Replies

- 12

- Views

- 2K

Left Hand Sale

WTS/SOLD: WTT ARC Coup De Grace LA

- Replies

- 3

- Views

- 773

- Replies

- 5

- Views

- 968