Have you tried an evac setup that uses the exhaust velocity to keep negative crank case pressure and help keep rings sealed? I know circle track guys used to use them, not sure if they still do. I believe they were worth a small amount of horsepower on the dyno as well.I'm likely the worst person to ask on this as I tend to follow the "use new parts, but build it like it has 100K+ miles on it rule."

Case in point:

2 seasons ago I took an iron 5.3 truck block and filled the water jacket with concrete. We punched it +.03", gapped the rings like a pair of 8-year front teeth, and set the mains up with .004" and the thrust with .0045'. Rod bearings were around .0029" if I recall. (don't quote me on that as the mains were the big deal) I ran 5-40 Rotella through that thing on a HV/HP Melling pump. We had 65 psi all the way down the track and when I pulled caps mid-season, there was almost no evidence of anything. One or two little smears here and there. The thrust bearing had nothing other than a scratch from some dirt.

This was a 10.5:1 CR motor on methanol with 35psi worth of 8.3L Whipple blower plopped on it. The guess on power was somewhere in the 1100 zone. We spun that thing up to 7500 on a .670" lift hydraulic roller camshaft. -Morel High RPM hydraulic lifters.

As for imperial to metric conversions and bearings. A tenth by itself likely won't hurt a thing. Just be sure your rounding to a tenth and not a thousandths. (.0001" vs .001")

On another note for anyone running boost and methanol. Something I recently ran accross that makes a great deal of sense to me. (like DUH! sense):

Gap your top ring as called by the setup. (ring material, piston material, bore size, distance from the crown, fuel, boost, nitrous, whatever...)

Gap your #2 Compression ring fatter than the top as called by the setup. (see above)

Gap your TOP OIL RING the same as you do the #2 compression! (Meh?!)

Lots of sneeze (boost) and methanol translates into a metric piss ton of blowby. It's going to happen. The trick then becomes venting off that pressure from between the #1 and #2 compression rings. Gapping the top oil ring all fatty like allows that pressure to piss its way through the oil return holes poked into the oil ring holes of the piston. The poison to avoid here is lifting a compression ring off of its seat when under load (power/pressure) as this is how ring flutter starts and that kills the seal and beats the snot out of the piston and the bore.

Good luck. Eat well tomorrow gents.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Horse Power, Track Shit, Torque, Cubic Inches, Liters, Run What Ya Brung, Auto or Cycle

- Thread starter DarnYankeeUSMC

- Start date

Meanwhile, back in reality, we're engaged in the less glamorous parts of the LS swap process:

It's really not bad at all for 20 years and 240,000 miles. I did have to laugh at the smear of RTV around one of the exhaust ports Gonna finish letting it stew in Simple Green, slap some Chevrolet Engine Red on the block, and get 'er sealed up with some new gaskets. Really not sure I'm even going to bother looking at the rod and main bearings because things spiral out of control too quickly. (I lack self-control.)

Gonna finish letting it stew in Simple Green, slap some Chevrolet Engine Red on the block, and get 'er sealed up with some new gaskets. Really not sure I'm even going to bother looking at the rod and main bearings because things spiral out of control too quickly. (I lack self-control.)

@gigamortis hooked me up with some great advice for the 4L80E in the background, so tearing into that is probably a Christmas break project. Everything for the engine other than the accessory drive is either here or inbound, so that'll likely get tossed together over the next few weeks. Maybe it'll get dropped in for a test fit by the new year? That'd be nice.

It's really not bad at all for 20 years and 240,000 miles. I did have to laugh at the smear of RTV around one of the exhaust ports

@gigamortis hooked me up with some great advice for the 4L80E in the background, so tearing into that is probably a Christmas break project. Everything for the engine other than the accessory drive is either here or inbound, so that'll likely get tossed together over the next few weeks. Maybe it'll get dropped in for a test fit by the new year? That'd be nice.

Not exactly a race car, but this little thing will be able to pull its weight. My BIL is rebuilding this Cat for his dump truck

I can very realistically see a 5th gen F100 with a bonkers 460 stroker in my futureFuelTech's YouTube channel is like pornography in that it basically rewires the brain for unrealistic expectations. I, too, could have a 2500 RWHP car! Sick, sick stuff. I love it.

I've been a GM guy my whole life, but my younger son really digs 1970-80s Ford pickups. I could see getting talked into buying a project truck with a 460 in the near future.

I caught this Fuel Tech episode a few days ago. I went to school with this guys middle son. That whole family has been very very good at drag racing for a very long time

There's a few Ford fanatics in my area that have been playing around with the 7.3 godzilla engine and boost. Pretty impressive numbers for their investment vs a Coyote build. The 7.3 is more compact in its exterior dimensions vs a Coyote engine as well. That makes it easier to swap into some of the tighter engine bays.

They make electric powered crankcase evac pumps.Have you tried an evac setup that uses the exhaust velocity to keep negative crank case pressure and help keep rings sealed? I know circle track guys used to use them, not sure if they still do. I believe they were worth a small amount of horsepower on the dyno as well.

Used to run them on the race boats.

On a 900'ish horse n/a 632 BBC they would get us about 50 horse at the crank.

Not legal in quite a few car classes, but offshore unlimited boat is cool to use em.

They work way better than those exhaust check valve/reed valve setups.

We had gauges to monitor crankcase pressures and it would be ~about~ 15 inches vac at idle and 2-3 inches at WOT under load.

If you're 50-100 miles offshore and suddenly get a spike in crankcase pressures it's real important to know so you can shut down before shit gets life threatening.

Punch a rod thru the block and you're probably going to sink and drown.

I'll have to dig for em....but I have lotsa pics of the 44ft Fountain and the 44ft Skater cat both with the dual BBCs all glorious in custom purple anodizing.

The captain and navigator canopies are F16 fighter canopies on the Skater, seriously, with ejection bolts in place.

So in case you flip the boat......

Emergency O2 is mandatory too.....in case...

You get the idea.

Last edited:

I can very realistically see a 5th gen F100 with a bonkers 460 stroker in my future

The kid seems partial to a 6th-gen F-series but probably wouldn't complain with an older generation.

There's a '76 F350 for sale locally that's pretty rough but would make a good project. 390 FE, 3sp manual, body's in rough shape but still generally solid - I can see something like that in his future. Gotta finish up a few more of my own projects and get the older kid squared away with his own vehicle first, however.

Did some Christmas parade driving for the local Cub Scout pack last night:

Cool van

Might as well put a pic or two to my scribbling. Something like thisI can very realistically see a 5th gen F100 with a bonkers 460 stroker in my future

With something like this under the hood, maybe with some sort of fuel injection system

Speaking of FuelTech and unrealistic expectations, this car is absolutely gorgeous and insanely powerful:

Mark Micke's New Pro Mod Belts Out 4,779 HP On FuelTech's Dyno

Micke's new twin-turbo, Hemi-powered Pro Modified Camaro ripped on FuelTech's hub dyno ahead of its competition debut.www.dragzine.com

And apparently it can put that horsepower to the track:

Breaking: Jose Gonzalez Resets 1/4-Mile Pro Mod World Record

Jose Gonzalez reclaimed the outright 1/4-mile Pro Mod world record today, piloting Mark Micke's twin-turbo Camaro to a 5.35 at 272 mph.www.dragzine.com

My rough bar napkin math says that thing is pulling 1.4g down the back half of the track. Put slightly differently, it's accelerating from 220 to 270 quicker than a Porsche 911 Turbo S goes 0-50. Absolutely mind-bending.

Pro Mod and the various Outlaw Drag Radial classes scene has literally breathed new life into drag racing IMO.

Pro Stock is cool too as far as the autism-level engineering that goes into the cylinder heads but not nearly as fun as Pro Mod or the small tire/big power stuff.

Either way Im a doorslammer guy all the way...

Gonna make it a birthday gift to visit Proline Racing's shop over in Marietta(the main ones responsible for setting most of the records and pushing the envelope in Pro Mod, Outlaw Drag Radial, etc).

If moneys no object.. throw some Boss heads on that bad boy for the cool factorMight as well put a pic or two to my scribbling. Something like this

View attachment 8287630

With something like this under the hood, maybe with some sort of fuel injection system

View attachment 8287647

Kaase Boss Nine Cylinder Heads

Despite the racing successes of the original Boss 429 Mustang the semi-hemi cylinder heads were weak. The combustion chambers cracked and their thin decks leaked around the O-ring head gaskets. Als…

jonkaaseracingengines.com

jonkaaseracingengines.com

I am well aware of Kaase and his big block magic. And if I was using someone else’s bank account I would already have a Boss 9 in somethingIf moneys no object.. throw some Boss heads on that bad boy for the cool factor

Kaase Boss Nine Cylinder Heads

Despite the racing successes of the original Boss 429 Mustang the semi-hemi cylinder heads were weak. The combustion chambers cracked and their thin decks leaked around the O-ring head gaskets. Als…jonkaaseracingengines.com

View attachment 8287812

One minute the project car is running, kinda, and then you just wanna investigate one little thing and before you know it this happens. I am my own worst enemy.

What did you do?One minute the project car is running, kinda, and then you just wanna investigate one little thing and before you know it this happens. I am my own worst enemy. View attachment 8292078

Kept poking around till I decided the head gasket was leaking. Then I just wanted to see what it would take to pull it. An hour later and I'd accidentally pulled it, covered in oil and late for my work Christmas party.What did you do?

Obviously I didn't take the time to try to drain the coolant system or anything, like I said, this was not intended.

Kept poking around till I decided the head gasket was leaking. Then I just wanted to see what it would take to pull it. An hour later and I'd accidentally pulled it, covered in oil and late for my work Christmas party.

Obviously I didn't take the time to try to drain the coolant system or anything, like I said, this was not intended.

I've done a lot of things in my amateur wrenching career, but I gotta say that "accidentally pulling a head gasket" isn't yet on that list. Can relate to the general feeling, though.

Gotta be vigilant, that shit will sneak up on you.I've done a lot of things in my amateur wrenching career, but I gotta say that "accidentally pulling a head gasket" isn't yet on that list. Can relate to the general feeling, though.

I’ve done a lot of shit on accident in my career. None of it ever ended with a cylinder head laying on my tool box. A lot of it cost me some $, some of it hurtI've done a lot of things in my amateur wrenching career, but I gotta say that "accidentally pulling a head gasket" isn't yet on that list. Can relate to the general feeling, though.

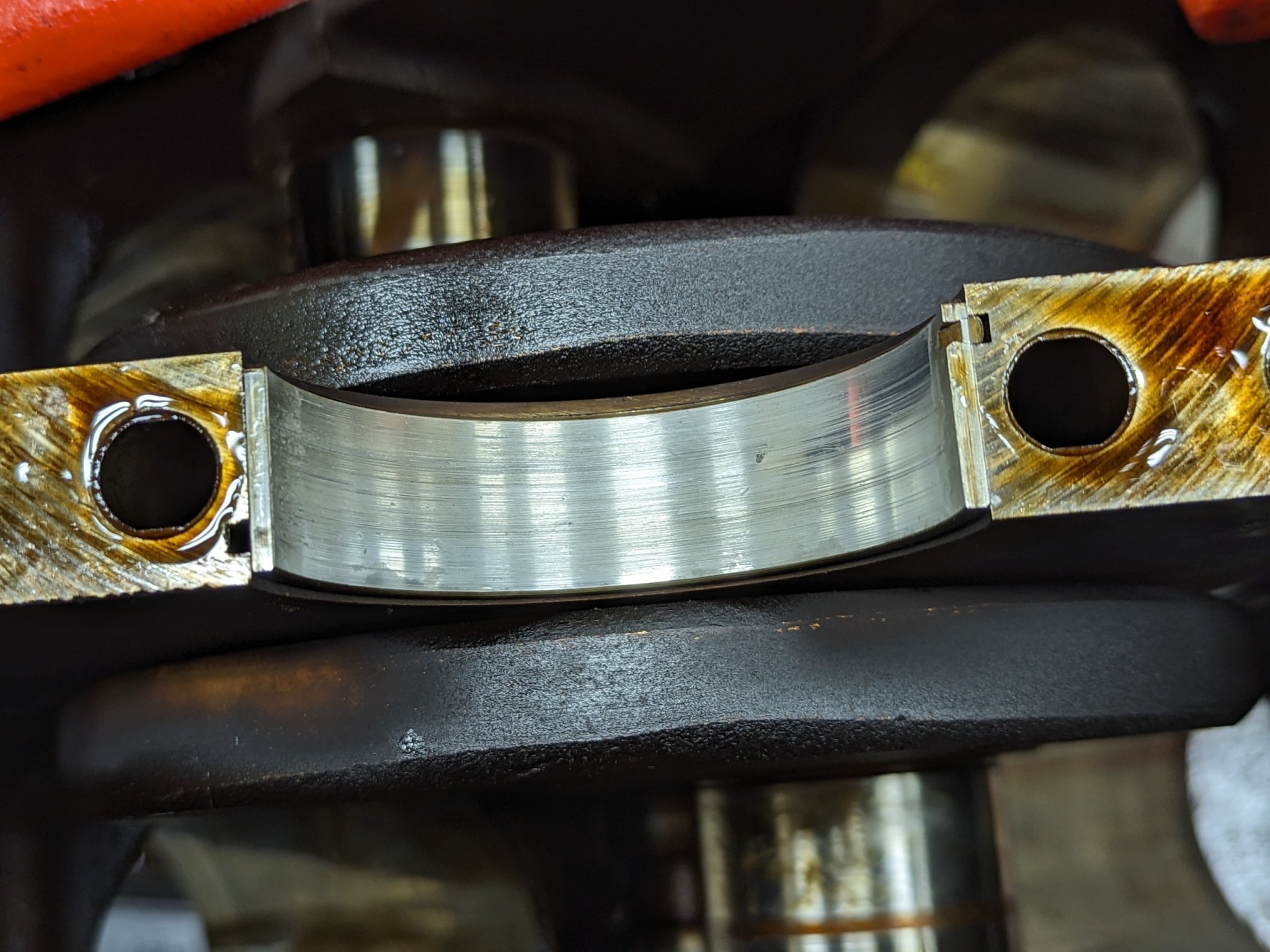

Here's what the inside of an engine might look like after 245,000 miles if the factory did its job correctly and maintenance is performed and a bit of luck keeps the oil flowing to all the important places:

Probably should have just left the bottom end of this thing buttoned-up, because it's far more likely that I will make a mistake in the process of "refreshing" the bearings and rings than it would be that any of the original parts would have failed in the next 100,000 miles. Oh well - I've cracked the seal, now it's time to do the best job I can.

Probably should have just left the bottom end of this thing buttoned-up, because it's far more likely that I will make a mistake in the process of "refreshing" the bearings and rings than it would be that any of the original parts would have failed in the next 100,000 miles. Oh well - I've cracked the seal, now it's time to do the best job I can.

Dragged the carcass of the ol' G2500 to the scrapyard:

Automotive scrap is going for $200/gross ton, so I walked away with $611 in cash for my efforts.

Found out that the weight of my E250 + the tongue of the empty trailer is 8200 lbs, which puts the curb weight of the van itself in the neighborhood of 7850 lbs with 1/4 tank of fuel

Automotive scrap is going for $200/gross ton, so I walked away with $611 in cash for my efforts.

Found out that the weight of my E250 + the tongue of the empty trailer is 8200 lbs, which puts the curb weight of the van itself in the neighborhood of 7850 lbs with 1/4 tank of fuel

I am hoping that we will have a mild winter so I will have some time to finish this up and get the car painted.

The 350 currently in it only has 130K miles on it so I am going to swap it into the wagon. It's got a 305 that's seriously under powered.

Can't decide if I will put a mild cam in it before the swap or not.

Mild? I don’t understandView attachment 8295883

View attachment 8295884

I am hoping that we will have a mild winter so I will have some time to finish this up and get the car painted.

View attachment 8295889

The 350 currently in it only has 130K miles on it so I am going to swap it into the wagon. It's got a 305 that's seriously under powered.

View attachment 8295893

Can't decide if I will put a mild cam in it before the swap or not.

The woman wants to take the wagon next year on the power tour. I am going to paint her 66 Oldsmobile this year.Mild? I don’t understand

Plus I have a few other things to finish on it. Then I have a few things to do on my 91 Heritage Softail to do. True duals are sitting in the box waiting.

I also have a farm and a HVAC business to run. So I really don't want to get into a full blown engine build. Maybe just a cam to make it sound better with a few more HP and some headers and dual exhaust and an intake and.... See how it goes out of control?

The tear down begins! Tremec T5 out for the last time to be sold. Will be replaced with a TKX or T56 6 speed, don’t know yet. Fenders off and 408 W stroker will come out this weekend. All new coil overs, rear end, disc brakes and power steering arrived earlier this week.

Going to be a fun build.

Going to be a fun build.

which puts the curb weight of the van itself in the neighborhood of 7850 lbs with 1/4 tank of fuel

Four fucking tons lmao. I'm surprised you scrapped it with all the "Van Life" stuff going on they are becoming a fad vehicle again. Here in Arizona people spend big money on vans.

If you are that far take a wire wheel to the backing plate and slap on a coat of paint.

I will take a sec to praise those induction heater thingies. Just amazing and those bolts will come right off, no damage to nut or threads. I am really amazed at how well they work. Really a "where have you been all my life" type tool

I have a cheapo amazon chinese example and have used it A LOT. The coating on the wire got hard and fell off, but new "fabric" to go over it is cheap and so easy even I can do it.

It'll be a money pit once the warranty expires.

Four fucking tons lmao. I'm surprised you scrapped it with all the "Van Life" stuff going on they are becoming a fad vehicle again. Here in Arizona people spend big money on vans.

The blue G2500 spent 20 years in the Midwest, so it was pretty much rotted out by this point in its life. Gotta know when it's time to call it quits.

Who keeps a car that long anymore?It'll be a money pit once the warranty expires.

It's no longer the 80's. That one and the "don't buy the first generation" thing are long dead.Who keeps a car that long anymore?

Laughing my ass off in 1st Gen 3.0 turbo diesel from mopar.It's no longer the 80's. That one and the "don't buy the first generation" thing are long dead.

Carry on, I won’t distract the thread any further

It's no longer the 80's. That one and the "don't buy the first generation" thing are long dead.

I remember my family back in the 70's getting a new car every two years no matter what. It was not till I started driving did the "old" car hang around, but I had little say on keeping something I liked till I bought my first car myself. And that was a real interesting story I will tell one day.

That one should still be adhered to.the "don't buy the first generation" thing are long dead.

ok it still applies to mopar even if it's not a new design. Don't buy any mopar.Laughing my ass off in 1st Gen 3.0 turbo diesel from mopar.

Carry on, I won’t distract the thread any further

The blue G2500 spent 20 years in the Midwest, so it was pretty much rotted out by this point in its life. Gotta know when it's time to call it quits.

Floor rust? I’ve seen ones that were like a flintstone car. Watch the highway go by underneath your feet.

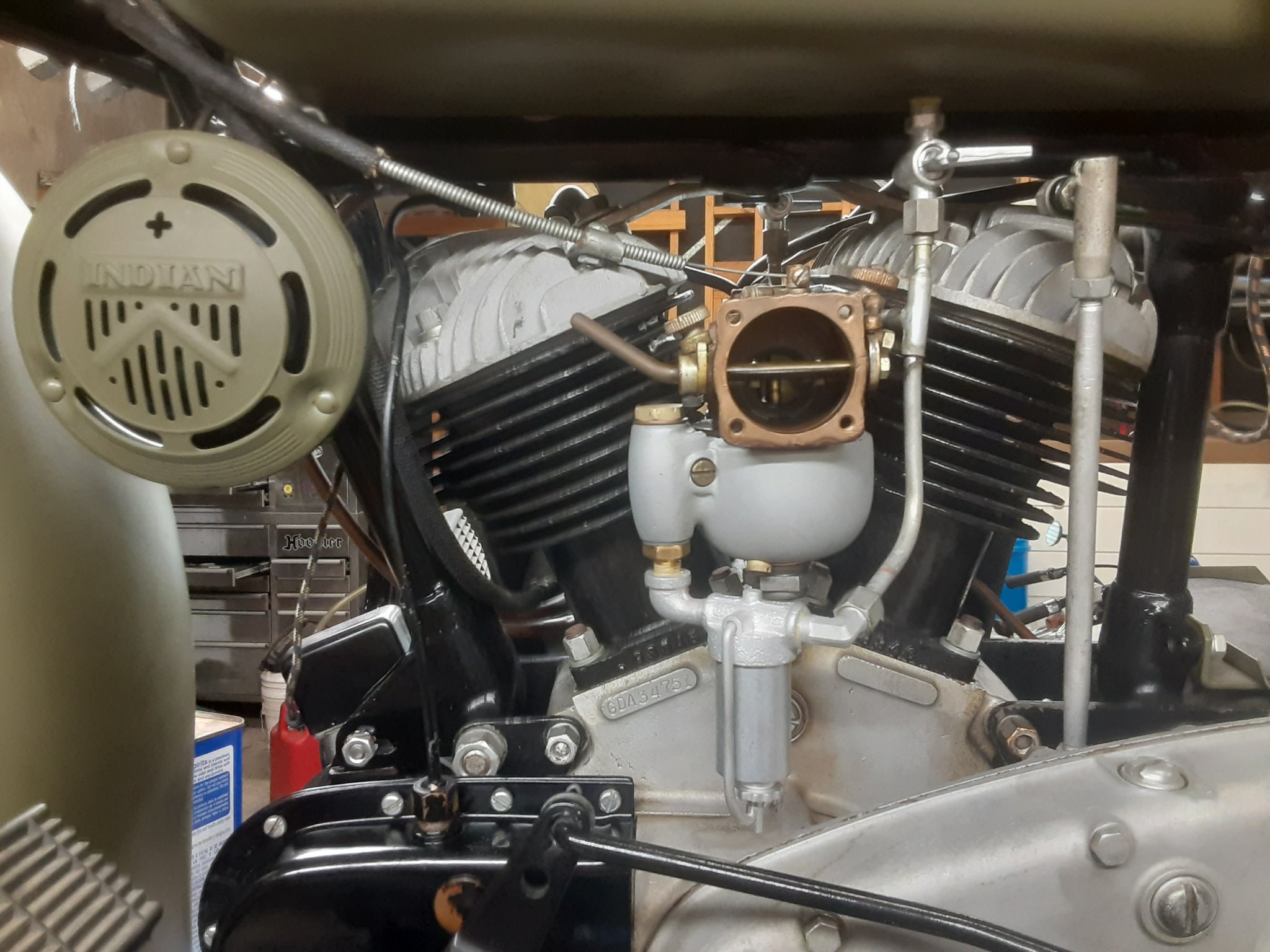

finally got around to replacing leaky petcocks, bowl fitting seals and fit the proper filter on it today.

So far no leaks

So far no leaks

Will be replaced with a TKX or T56 6 speed, don’t know yet.

TKX if you can tolerate the gear ratio's... Otherwise T56(or TR6060 if you can find a bell housing)...

Used T56's are way to much money when you can get a TKX for 2900 bucks...

You can get a TKX face plated from Liberty if you need some high RPM lovin...

The TKX is already designed for 7.5k shifts and peak RPM at 8k. What exactly is wrong with the gear ratios?

Mine has these gears and will work well with 3.55 rear diff ratio

Spline 1st 2nd. 3rd. 4th. 5th. R

Mine has these gears and will work well with 3.55 rear diff ratio

26 | 2.87 | 1.89 | 1.28 | 1.00 | 0.68 | 2.56 |

The TKX is already designed for 7.5k shifts and peak RPM at 8k. What exactly is wrong with the gear ratios?

Mine has these gears and will work well with 3.55 rear diff ratio

Spline 1st 2nd. 3rd. 4th. 5th. R

262.87 1.89 1.28 1.00 0.68 2.56

I never said there was anything wrong with the gear ratio's... however they ARE limited. So if they work for what he is looking to do, fantastic, if he wants something different, he's out of luck as they dont offer anything custom. I'm planning to run the 2.87 first out to the .81 5th in my track car with a 3.31 rear end. Again, might not work for everybodies setup, but for me in a 2200lb Miata it will be great.

You could get a T56 with a 3.36 first out to a .50 6th... and a few iterations in between. The TKX is available in 3 configurations. I believe you can get T56 gear sets in a bunch of different ratio's if you want to get real crazy.

And the TKX gets sketchy on shifts above 7k... thats from people I know running them. Buddy redlines at 8k and he says the trans is 50/50 at not locking him out. He understands its not rated to shift that high, but he's also not willing to pay the money Liberty wants to do a faceplate'd internal setup.

I ran a bunch of scenarios on the Tremec ratio calculator trying to figure out the best combo for my set up. I'm not going to spin this 408 stroker to the stratosphere so I'm not really that concerned about really high RPM shifts, but the car will see spirited street driving and will visit the quarter mile from time to time. I ordered a 3.89 Strange rear end and will be ordering either the exact TKX you have or the T56 with 2.97 - .63 range. I figure the T56 will cost a bit more and will require a lot more tunnel modification to fit, but I'm doing a complete floor replacement anyway. Leaning towards the T56, but we shall see. Range is 2.97 2.10 1.46 1.00 .80 .63The TKX is already designed for 7.5k shifts and peak RPM at 8k. What exactly is wrong with the gear ratios?

Mine has these gears and will work well with 3.55 rear diff ratio

Spline 1st 2nd. 3rd. 4th. 5th. R

262.87 1.89 1.28 1.00 0.68 2.56

It's no longer the 80's. That one and the "don't buy the first generation" thing are long dead.

There's differing levels of "don't buy the first year of a new model". You've got something like the Accord on one end (generally safe!), and then the hell experienced by owners of certain Ford and Stellantis products.

I avoid this by generally not buying new cars. In fact, the junk I'm buying is typically old enough to have gone through some sort of natural selection process. If something like a Ford 6.0 has made it this far, it's probably not garbage.

There are also plenty of cars that I wouldn't own outside of the warranty period, and that list is getting longer as repair part prices continue to skyrocket. The cost of a replacement long block or transmission is eye-watering for a lot of late-model used vehicles, so even a statistically low likelihood of failure still merits some consideration.

I ran a bunch of scenarios on the Tremec ratio calculator trying to figure out the best combo for my set up. I'm not going to spin this 408 stroker to the stratosphere so I'm not really that concerned about really high RPM shifts, but the car will see spirited street driving and will visit the quarter mile from time to time. I ordered a 3.89 Strange rear end and will be ordering either the exact TKX you have or the T56 with 2.97 - .63 range. I figure the T56 will cost a bit more and will require a lot more tunnel modification to fit, but I'm doing a complete floor replacement anyway. Leaning towards the T56, but we shall see. Range is 2.97 2.10 1.46 1.00 .80 .63

The previous iteration of drivetrain in my Impala SS utilized a 396 LT1 (the crappy Gen II one, not the cool Gen V) and the M10 version of the T56 (originally from the Chevrolet SSR). This had a 3.07 1st gear and 0.57 6th, and combined with a 3.73 rear gear and 27" tire, it worked pretty dang well for a variety of purposes. I'd probably go deeper with the axle ratio if I did it over again, but that's more from the standpoint of driveability than performance, particularly in light of that vehicle's curb weight and the not-exceptional low-end performance that came with a larger cam and that engine's short-runner intake.

For all the complaints I've heard over the years about the difficulty of shifting various modern transmissions at higher RPM, it most often comes down to the clutch or hydraulics. I would recommend the later versions of the T56 that have the multi-cone synchronizers on the lower gears, and if you end up with an earlier gearbox then there are single-cone "carbon" frictions that will work better than the "paper" parts that came in the F-body.

And if you have the opportunity, avoid the 27-spline output shafts. I quickly broke one of those, did a Viper 30-spline conversion, killed the input shaft next, and then stopped breaking stuff with the M10. This shouldn't be a problem with the new aftermarket versions of the trans, and I'm not sure that buying an F-body version is all that economical nowadays (the newest of those is now old enough to legal buy alcohol).

18 spline A-833.

It's all you need.