I know, I know and I know.....But for arguments sake, if we were going to do something that was based on sound engineering principle; not some Liability Attorneys best idea.

What could we do?

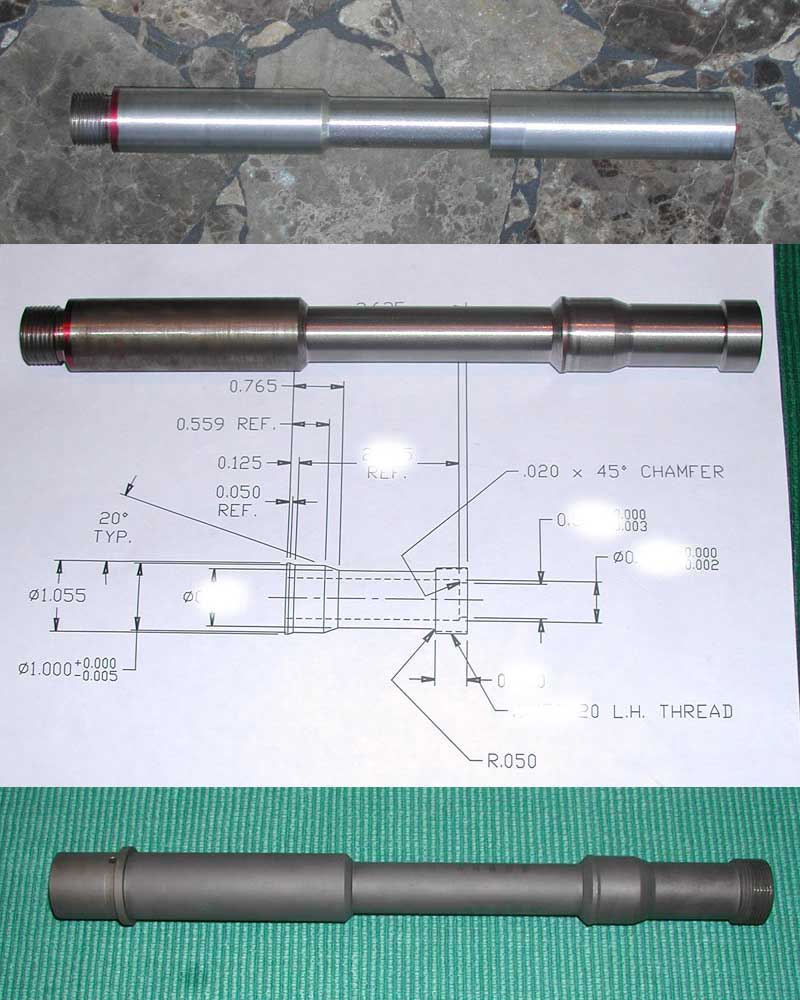

Background info, I have a halo that I really enjoy, but it's only mountable on A2 flashhiders. So, it sits in the safe more than I'd like it to. Would it reasonable to make a short 2" barrel section fitted with an A2 flashider, that I could thread onto some of my small bore bolt actions and still use my Halo?

Any other ideas, besides getting another thread on can. I'm trying to save a few pennies up for a titanium srt 338 can.

Any smiths to recommend? I'm a chief engineer, mechanic and have been my entire working life, so I "get" the stipulations and requirements of torquing or torque indexing, the use of thread locking compounds and so forth. I intend to use Rocksett for weapon attachment. No full auto use or even long & hot firing strings, mostly just predator control.

Cheers and thanks for info/ideas you care to share,

Breeze

What could we do?

Background info, I have a halo that I really enjoy, but it's only mountable on A2 flashhiders. So, it sits in the safe more than I'd like it to. Would it reasonable to make a short 2" barrel section fitted with an A2 flashider, that I could thread onto some of my small bore bolt actions and still use my Halo?

Any other ideas, besides getting another thread on can. I'm trying to save a few pennies up for a titanium srt 338 can.

Any smiths to recommend? I'm a chief engineer, mechanic and have been my entire working life, so I "get" the stipulations and requirements of torquing or torque indexing, the use of thread locking compounds and so forth. I intend to use Rocksett for weapon attachment. No full auto use or even long & hot firing strings, mostly just predator control.

Cheers and thanks for info/ideas you care to share,

Breeze