It’s on the intersection of Flavorless and Gut Rot ?I'm sorry, Sir. That's classified.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Introducing the AI Obsession Chassis

- Thread starter samb300

- Start date

Serious question for anyone contemplating this chassis:

Are you willing to sacrifice the ability to use 16” barrels for a longer forend? Since it’s bonded, if I go longer than 13” on the forend, it will be all but impossible to tighten a 16” barrel.

I could get to an ACC-ish forend length if 18” is the shortest compatible barrel. Since this is competition oriented (and I don’t run shorty barrels) it doesn’t seem like a huge deal, but from the beginning I designed it to accept 16” barrels since I didn’t want the end user to not be able to use what they already have.

Are you willing to sacrifice the ability to use 16” barrels for a longer forend? Since it’s bonded, if I go longer than 13” on the forend, it will be all but impossible to tighten a 16” barrel.

I could get to an ACC-ish forend length if 18” is the shortest compatible barrel. Since this is competition oriented (and I don’t run shorty barrels) it doesn’t seem like a huge deal, but from the beginning I designed it to accept 16” barrels since I didn’t want the end user to not be able to use what they already have.

I'd ask AI about using keyslot....sawtooth and RRS use it on their arca accessories...admittedly both were for use on ai chassis, so maybe AI was more inclined, but I doubt either can expect to sell enough to make it worth it if the licensing was very expensive. If you are forced to use MLok, could you make the sidewalls thicker, but inlet a groove on the inside of the MLOK slots for the T-nuts to sit in and not project beyond the inside of the side walls?

Personally I would never run a 16" barrel on a comp gun... However, you could always make an integral spigot with no sidewalls past the current length, thus allowing the best of both worlds ....extra length for bipod mounting and still with the ability to use a 16" if desired (as long as a supressor or a brake with no bottom ports is used. Thoughts?

Personally I would never run a 16" barrel on a comp gun... However, you could always make an integral spigot with no sidewalls past the current length, thus allowing the best of both worlds ....extra length for bipod mounting and still with the ability to use a 16" if desired (as long as a supressor or a brake with no bottom ports is used. Thoughts?

Serious question for anyone contemplating this chassis:

Are you willing to sacrifice the ability to use 16” barrels for a longer forend? Since it’s bonded, if I go longer than 13” on the forend, it will be all but impossible to tighten a 16” barrel.

I could get to an ACC-ish forend length if 18” is the shortest compatible barrel. Since this is competition oriented (and I don’t run shorty barrels) it doesn’t seem like a huge deal, but from the beginning I designed it to accept 16” barrels since I didn’t want the end user to not be able to use what they already have.

I can't speak for the others, but I'd prefer to be able to run 16". Personally though, I'm not a comp guy. I'm primarily interested in your chassis because I think it looks like a better balanced design. Any rifle that balances better, typically equates to efficiency and ease of use in the field.

It’s on the intersection of Flavorless and Gut Rot ?

Agreed. I've got a michelob Lane sign too. Both are equally grotesque and unpalatable. If it ain't an IPA, I ain't drinking it.

I don't think I really understand a 16" barrel on an AI, for the most part. If you want light & handy for hunting, get a rifle designed for that. Personally, I'd rather see an 18" Obsession, but I might be in the minority there... Probably not the first time, haha!

Serious question for anyone contemplating this chassis:

Are you willing to sacrifice the ability to use 16” barrels for a longer forend? Since it’s bonded, if I go longer than 13” on the forend, it will be all but impossible to tighten a 16” barrel.

I could get to an ACC-ish forend length if 18” is the shortest compatible barrel. Since this is competition oriented (and I don’t run shorty barrels) it doesn’t seem like a huge deal, but from the beginning I designed it to accept 16” barrels since I didn’t want the end user to not be able to use what they already have.

I have multiple ATs I’m waiting on your chassis for and I don’t care about running a 16” barrel.

@PBWalsh

I do get that, and honestly, that setup would only be what, 6 oz heavier than the same thing with a clone action? I guess my point is that if you took every AI action out there & logged what barrel is on it (most of the time, considering the switch-barrel nature of it), I think 16" is going to be a VERY small percentage.

I do get that, and honestly, that setup would only be what, 6 oz heavier than the same thing with a clone action? I guess my point is that if you took every AI action out there & logged what barrel is on it (most of the time, considering the switch-barrel nature of it), I think 16" is going to be a VERY small percentage.

Why not make two different versions? A "covert" version and "competition" version?

It would be pricey to have two different configurations, but if there is a market for both it could pay off.

It would be pricey to have two different configurations, but if there is a market for both it could pay off.

@PBWalsh

I do get that, and honestly, that setup would only be what, 6 oz heavier than the same thing with a clone action? I guess my point is that if you took every AI action out there & logged what barrel is on it (most of the time, considering the switch-barrel nature of it), I think 16" is going to be a VERY small percentage.

for 10 months of the year probably right. but for two - three months of hunting season many would want to put on shortys for in their blinds.

as the ax / axmc are now id never run one in a box blind, even with my 16" in it. but with the lower profile / flats on sam's and the asr designs, it would be a little better. like was said, for now i have a dedicated rem 700 clone that serves that purpose. but people live on budgets and the point of a multi cal switch barrel setup is for it to do as many things as possible

Oh absolutely, my AT I had a 20” barrel. Amazing rifle. I really don’t see any AI clones on the market. Some close ones, but I can see where anything has the same exact features (namely the insanely quick barrel changes).

Sorry, I meant 700 clone.

I suppose you're right, @bhanley . I really just think about my own switch barrel experience... Had a rifle built to do that & while waiting for it, just bought a rifle in the 'other caliber' so I never switch it.

I'm reminded of the story John Paul tells about building an AR scope mount... Everyone said it had to be QD but when he got to asking people how often they were pulling their scopes off & on and expecting them to return to zero, no one did it so he made his mount with 5 torx screws, haha!

I suppose you're right, @bhanley . I really just think about my own switch barrel experience... Had a rifle built to do that & while waiting for it, just bought a rifle in the 'other caliber' so I never switch it.

I'm reminded of the story John Paul tells about building an AR scope mount... Everyone said it had to be QD but when he got to asking people how often they were pulling their scopes off & on and expecting them to return to zero, no one did it so he made his mount with 5 torx screws, haha!

Last edited:

Yes I remember kicking that idea around. The current design does have the removable front spigot, but is ~1/2” closer to the bore than the bottom of the forend. If I go that far out I’d prefer to be closer to the bore axis unless the forend is continuous.Or if enough people want to use 16" barrels for portability, maybe a removable spigot that interfaces with the chassis arca rail for 18" of continuous arca like we talked about a while back is better....

I don’t disagree with you, but it’s going to be a challenge to even do a production run of one style of chassis. I’m still trying to figure out real numbers of how many people would put money down and buy a kit for their AI. Unfortunately for me I don’t have a CNC so they can’t be made to order. I need to have some idea of how many to order in a production batch without going broke.Why not make two different versions? A "covert" version and "competition" version?

It would be pricey to have two different configurations, but if there is a market for both it could pay off.

My guess is since it’s comp oriented the “long” version would be more popular.

Thanks for all the comments!

I’m left in some ways wondering how many people currently HAVE a 16” barrel for their AI - meaning it would be a semi deal breaker to not be able to use it with a new chassis? Or are people speaking hypothetically in terms of WANTING to use a 16” barrel, but don’t yet have one that short? To me, there’s very little difference if you have to go 18” instead of 16”, even for a hunting situation.

I’m also wondering how many people that are interested in this chassis use their AI for everything? 26” MTU 6BR on Saturday for a match, then 16” Proof 308 on Sunday for hunting? I’m a “one rifle” guy due to economics, but it seems to me that most people have multiple rifles for different applications. Like mentioned above, an AI even with a light 16” barrel isn’t exactly the ideal hunting/packing rifle.

I’m left in some ways wondering how many people currently HAVE a 16” barrel for their AI - meaning it would be a semi deal breaker to not be able to use it with a new chassis? Or are people speaking hypothetically in terms of WANTING to use a 16” barrel, but don’t yet have one that short? To me, there’s very little difference if you have to go 18” instead of 16”, even for a hunting situation.

I’m also wondering how many people that are interested in this chassis use their AI for everything? 26” MTU 6BR on Saturday for a match, then 16” Proof 308 on Sunday for hunting? I’m a “one rifle” guy due to economics, but it seems to me that most people have multiple rifles for different applications. Like mentioned above, an AI even with a light 16” barrel isn’t exactly the ideal hunting/packing rifle.

Sam - whats the longer forend achieve, aside from putting the bipod farther out (no sarcasm intended). i could be wrong but most NV or thermal clip ons will work on the shorter version, correct? and the utility of that is probably even less than the number of people potentially tossing in shorter barrels for hunting and the like. i wonder what victor is seeing in buying habits with his hammer rail in terms of 13" vs 16" demand.

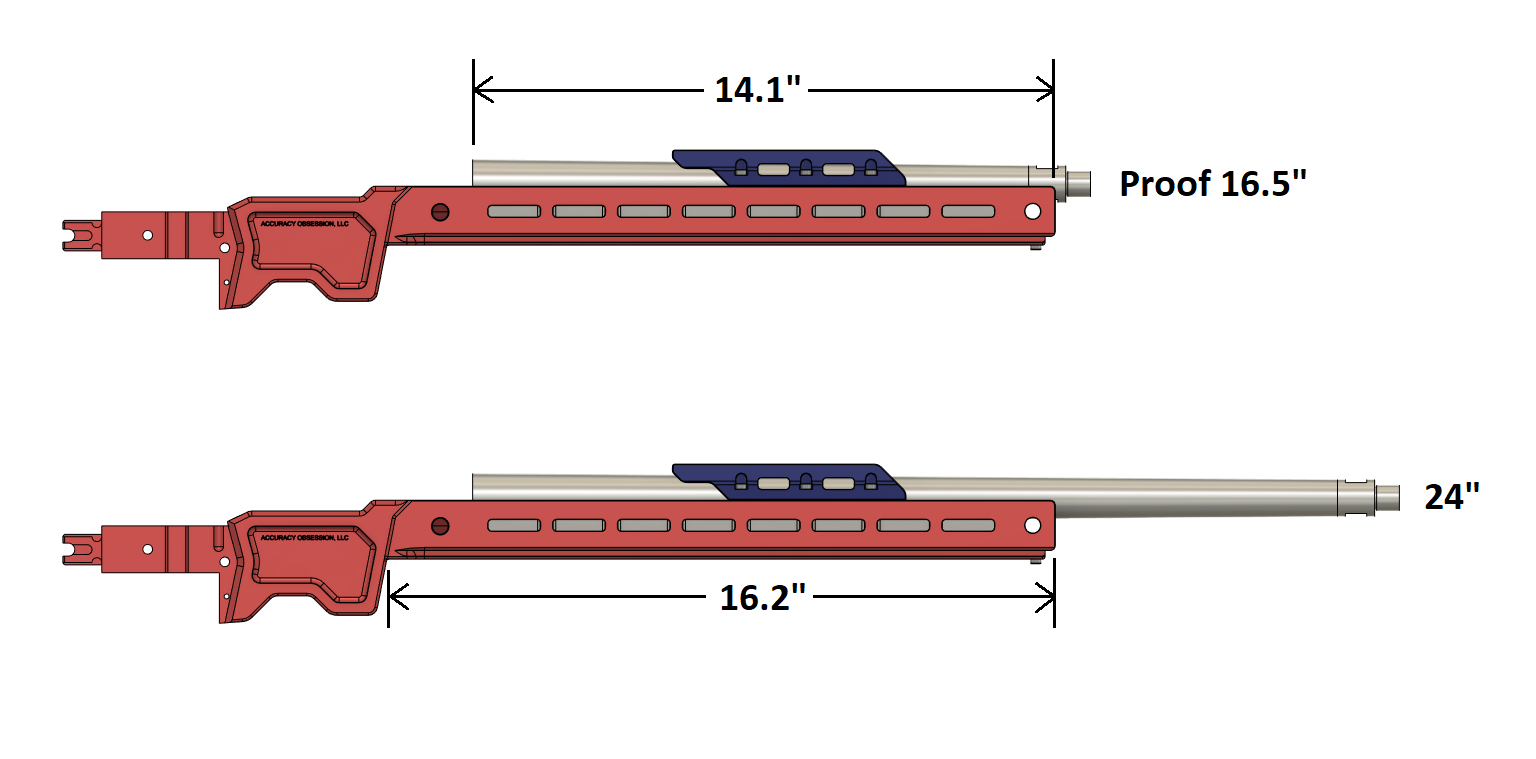

I’m going to look at this further while I’m in CAD. The Proof 308 AI prefit is technically 16.5”, as is the AT LE 308 barrel. So unless you have a custom barrel cut to 16.00” maybe I’ve got a little more to work with.

What is your guys best guess as to how much barrel you’d need exposed in front of the chassis to get it hand tight? Is 1” enough? (That 1” will include the 0.6” of threads and likely a brake or mounting device)

To share the math I’m using:

Barrel length - tenon length - exposure = chassis forend length.

So right now the prototype is:

16.5” - 1.5” - 2.25” = 12.75” forend

I’m thinking about:

16.5” - 1.5” - 1.00” = 14” MAX forend length

What is your guys best guess as to how much barrel you’d need exposed in front of the chassis to get it hand tight? Is 1” enough? (That 1” will include the 0.6” of threads and likely a brake or mounting device)

To share the math I’m using:

Barrel length - tenon length - exposure = chassis forend length.

So right now the prototype is:

16.5” - 1.5” - 2.25” = 12.75” forend

I’m thinking about:

16.5” - 1.5” - 1.00” = 14” MAX forend length

Especially with the M-Lok slots, the longer forend at the muzzle makes things a lot easier for how I have things designed (spigot, integrated flush cups). That won’t be seen by most users but I’m over here pulling my hair out over it haha.Sam - whats the longer forend achieve, aside from putting the bipod farther out (no sarcasm intended). i could be wrong but most NV or thermal clip ons will work on the shorter version, correct? and the utility of that is probably even less than the number of people potentially tossing in shorter barrels for hunting and the like. i wonder what victor is seeing in buying habits with his hammer rail in terms of 13" vs 16" demand.

The extra length allows 8 M-Lok slots instead of the 7 I have now, which then allows 4 MDT weights instead of 3. It also allows more internal weight.

You’re correct, the NV Bridge would not need to be further out than a couple inches in front of the scope’s objective lens.

I personally like to have the bipod only as far forward on the forend where I can still reach it from prone. But you can’t argue with the success of the MDT ACC and no one that I know of dislikes how long the forend is. For reference, the BOTTOM forend flat length of the ACC (not the action face to muzzle forend length I was discussing above) is 18”. The prototype right now is 15”. So if I increase the forend length as mentioned above to give 1” of exposure on a 16.5” barrel, the bottom forend length would be 16.25”. Still 1.75” shorter than an ACC but that far out I don’t know if it matters.

@samb300

Keyslot = AI

Keymod = VLTOR (And is open source)

The difference is Keyslot by AI uses a left hand threaded grub screw with an upside down cone on the end to self-center in the keyslot.

Keymod uses a screw&nut like mlok but uses the same self-centering cone idea for the nut part of it. Keymod is the 'better' design compared to mlok, but is more expensive/difficult to produce. I guess sort of how beta video was better, but cost more than VHS.

Keyslot = AI

Keymod = VLTOR (And is open source)

The difference is Keyslot by AI uses a left hand threaded grub screw with an upside down cone on the end to self-center in the keyslot.

Keymod uses a screw&nut like mlok but uses the same self-centering cone idea for the nut part of it. Keymod is the 'better' design compared to mlok, but is more expensive/difficult to produce. I guess sort of how beta video was better, but cost more than VHS.

AI KeySlot is KeyMod done right. It's better, stronger, and simpler.@samb300

Keyslot = AI

Keymod = VLTOR (And is open source)

The difference is Keyslot by AI uses a left hand threaded grub screw with an upside down cone on the end to self-center in the keyslot.

Keymod uses a screw&nut like mlok but uses the same self-centering cone idea for the nut part of it. Keymod is the 'better' design compared to mlok, but is more expensive/difficult to produce. I guess sort of how beta video was better, but cost more than VHS.

Based on the testing I've read about, M-Lok is superior to KeyMod in terms of strength/performance.

If I can do AI KeySlot I will pursue it; if not I will continue with the M-Lok design used in the prototypes.

@samb300

For what it's worth, I think that is absolutely the correct approach. And keep in mind this is coming from a guy that just HATES M-LOK & is holding tight to his KeyMod on AR's, haha!

For what it's worth, I think that is absolutely the correct approach. And keep in mind this is coming from a guy that just HATES M-LOK & is holding tight to his KeyMod on AR's, haha!

AI KeySlot is KeyMod done right. It's better, stronger, and simpler.

Based on the testing I've read about, M-Lok is superior to KeyMod in terms of strength/performance.

If I can do AI KeySlot I will pursue it; if not I will continue with the M-Lok design used in the prototypes.

Lot's of issues with

I think it's smart to stay away from

*Edit - Keymod, not keyslot.

KeySlot is AI's proprietary interface. KeyMod is the open-source interface that was all but replaced with M-Lok.Lot's of issues with keyslots on ar15's. I've seen numerous examples of handguards with the keyslot get damaged from moderate use.

I think it's smart to stay away from keyslot.

I'm assuming KeyMod is what you meant

KeySlot is AI's proprietary interface. KeyMod is the open-source interface that was all but replaced with M-Lok.

I'm assuming KeyMod is what you meant

Haha that is what I meant, oops...

No worries! I'm pretty sure the patented "post-14" AI KeySlot came out after KeyMod was designed, so they definitely had an opportunity to name it something slightly more different that would help people distinguish the two, especially since from the outside surface they look very similar. Really anything that didn't start with "Key" would've been good ?Haha that is what I meant, oops...

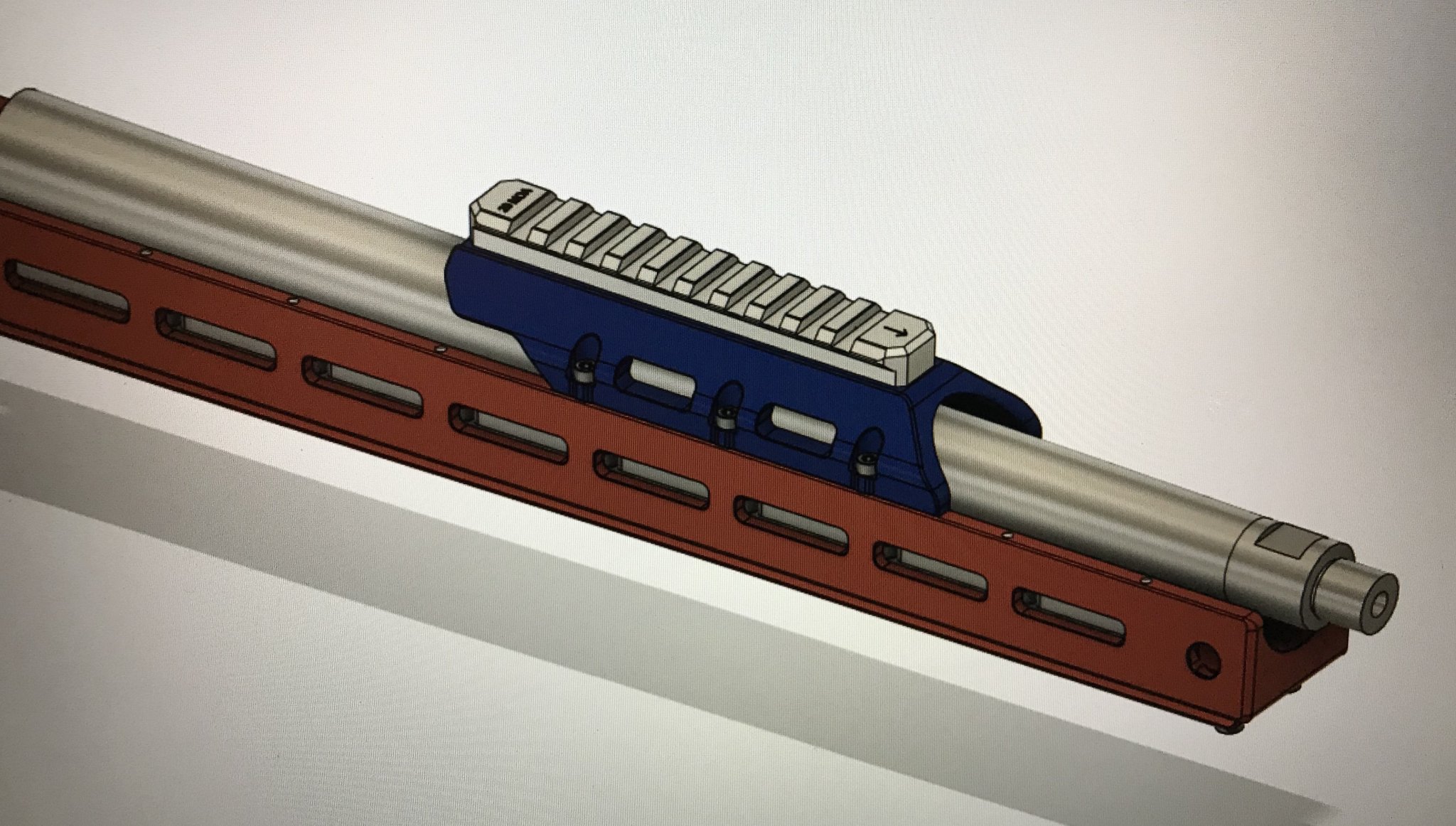

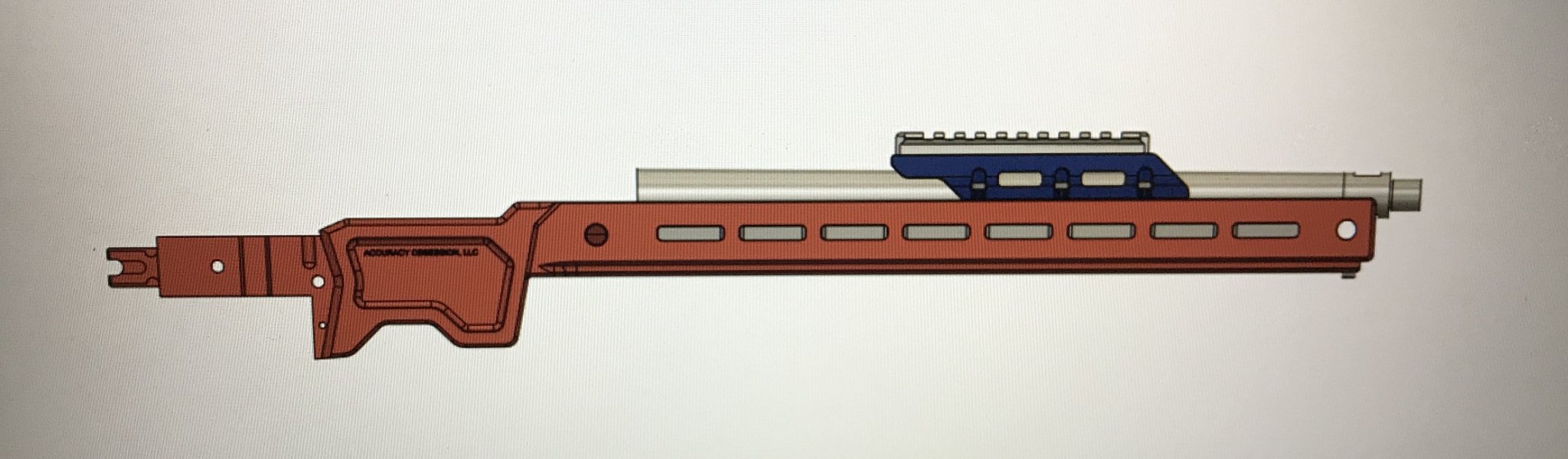

I've been spending a bunch of time in CAD refining the design of the M-Lok chassis, and I think I'm happy with what I have. There are some minor and some more significant changes, all of which will add up to better and more robust product for the production version. The changes are based mostly on my initial use of the chassis as well as the feedback from the other testers and the input here on SH.

The changes so far:

- Forend length increased from 15" to 16.2"

- M-Lok slots increased from 7 to 8 slots, which will allow the use of 4 total MDT weight kits (3.12# total)

- Forend wall thickness increased from 0.150" to 0.200", to increase stiffness and allow more robust NV Bridge mount

- NV Bridge changed to a top-bolt attachment design. This will be much more robust and easier to machine.

- Internal Weight increased from 1.44# to 1.89#

- Total possible combined bolt-on forend weight increased from 3.78# to 5.01#

- Larger screws for RRS rail bipod "stops" at front of forend

- Spigot deleted due to longer forend length

- Chassis weight increased from 29.9oz to 34.0oz

The chassis still retains:

- Fits with AW, AT, and AX short actions

- Ambidextrous with RH and LH actions

- Bonded interface - user will need to bond (epoxy) action to new chassis

- Works with fixed and folding stocks, either AT or AX buttstocks

- Ability to use 1.25" straight taper barrel (NV Bridge has 1.35" dia. clearance)

- RRS spec dovetail "Arca Swiss" rail

- M-Lok spec slots

I went back and forth with retaining the ability to use a 16.5" barrel, and ultimately decided to keep that ability - although it may be a bit of a challenge to get the barrel hand tight if there's no muzzle device. Both Proof and AT-LE barrels are 16.5", so I am allowing 0.25" clearance behind the shoulder of a nominal 0.600" deep muzzle thread. That means any true 16.5" barrel with a muzzle brake or suppressor will work without issue. Since the chassis is intended to be bonded I wanted to give 16.5" users the option, but please recognize the target use is the match shooter using the typical 24-28" barrel.

I deleted the spigot due to wanting to retain the integrated QD anti-rotation sling mount. With the increase from 7 to 8 M-Lok slots, real estate was limited for the spigot to mount from the bottom. Since the forend length was increased I also felt the benefit of the spigot decreased. For reference, the 16.2" bottom forend length is just 1.8" shorter than an MDT ACC, and is equal to an XLR Envy JV chassis WITH the spigot attached.

Sam

The changes so far:

- Forend length increased from 15" to 16.2"

- M-Lok slots increased from 7 to 8 slots, which will allow the use of 4 total MDT weight kits (3.12# total)

- Forend wall thickness increased from 0.150" to 0.200", to increase stiffness and allow more robust NV Bridge mount

- NV Bridge changed to a top-bolt attachment design. This will be much more robust and easier to machine.

- Internal Weight increased from 1.44# to 1.89#

- Total possible combined bolt-on forend weight increased from 3.78# to 5.01#

- Larger screws for RRS rail bipod "stops" at front of forend

- Spigot deleted due to longer forend length

- Chassis weight increased from 29.9oz to 34.0oz

The chassis still retains:

- Fits with AW, AT, and AX short actions

- Ambidextrous with RH and LH actions

- Bonded interface - user will need to bond (epoxy) action to new chassis

- Works with fixed and folding stocks, either AT or AX buttstocks

- Ability to use 1.25" straight taper barrel (NV Bridge has 1.35" dia. clearance)

- RRS spec dovetail "Arca Swiss" rail

- M-Lok spec slots

I went back and forth with retaining the ability to use a 16.5" barrel, and ultimately decided to keep that ability - although it may be a bit of a challenge to get the barrel hand tight if there's no muzzle device. Both Proof and AT-LE barrels are 16.5", so I am allowing 0.25" clearance behind the shoulder of a nominal 0.600" deep muzzle thread. That means any true 16.5" barrel with a muzzle brake or suppressor will work without issue. Since the chassis is intended to be bonded I wanted to give 16.5" users the option, but please recognize the target use is the match shooter using the typical 24-28" barrel.

I deleted the spigot due to wanting to retain the integrated QD anti-rotation sling mount. With the increase from 7 to 8 M-Lok slots, real estate was limited for the spigot to mount from the bottom. Since the forend length was increased I also felt the benefit of the spigot decreased. For reference, the 16.2" bottom forend length is just 1.8" shorter than an MDT ACC, and is equal to an XLR Envy JV chassis WITH the spigot attached.

Sam

It's possible, yes. But most likely the user will have a muzzle brake or suppressor already on it, so tightening the barrel on 'hand tight' shouldn't be too bad to do. A wrench flat tool will be difficult because if the flats are aligned horizontally, it will be really hard to get anything in the chassis channel to go around the flats. If the flats ended up aligned vertically it would be super easy to get a tool in.@samb300 , could you make a barrel installation tool that’s threaded 5/8-24 (or whatever thread the barrel is) hat screws onto the muzzle, install the barrel and torque to 49in lbs and then remove the install tool. Maybe put wrench flats on it?

The real problem would be getting the barrel off if it's put on hand tight or harder. I think a strap wrench would work, but could be tough.

This is what I struggled with: give the rare few users with a 16.5" barrel the full clearance to the wrench flats, and the forend ends up 1-2" shorter. Make the forend longer for comp shooters and 16.5" or even 18" barrels won't work.

De-bonded the AX again. I have the production CAD model completely re-done, drawings in work, and model 3D printed for final verification.

Next steps:

- Test final design fitment with 3D print and AX action

- Finalize all CAD models and drawings

- Submit new files to machine shop for production quote

- Drop off remaining 2 raw prototype chassis for Cerakote at local certified applicator.

- Figure out how many people actually want one of these things ?

- Put in production order

Target date for putting in the order will be early January. Machine shop rough estimate is 8 weeks, add 4 weeks for coating of all parts.

I got the OK to do a group buy here on the Hide, I’ll let you guys know when I get a better idea of pricing and when that will go live. I’d love to hear some feedback on how many people are interested!

Thanks,

Sam

Next steps:

- Test final design fitment with 3D print and AX action

- Finalize all CAD models and drawings

- Submit new files to machine shop for production quote

- Drop off remaining 2 raw prototype chassis for Cerakote at local certified applicator.

- Figure out how many people actually want one of these things ?

- Put in production order

Target date for putting in the order will be early January. Machine shop rough estimate is 8 weeks, add 4 weeks for coating of all parts.

I got the OK to do a group buy here on the Hide, I’ll let you guys know when I get a better idea of pricing and when that will go live. I’d love to hear some feedback on how many people are interested!

Thanks,

Sam

Still working hard. I’m printing a “final” final prototype, then will go over everything with a fine tooth comb to confirm fitment. Drawings are 95% done. Also added a bolt-on 20 MOA pic rail to the NV Bridge for anyone running a NV optic.

The prototypes were 6061, but I am considering 7075 for the production chassis due to the NV Bridge hardware threading into the chassis with the revised design.Hi,

@samb300

I have forgotten what aluminum you are using for the production batch; 7075 or 6061?

Looking forward to meeting with you at Shot Show.

Sincerely,

Theis

How many different barrels/calibers/magazines have you tried with the chassis, I am looking at the .223 conversion thread, looks like a modded MDT, that works with the AT and AX short action, concerned about tolerance stacking. Does your chassis run all the 6mm flavored magazines and their modifications or only AI factory magazines?The prototypes were 6061, but I am considering 7075 for the production chassis due to the NV Bridge hardware threading into the chassis with the revised design.

My magazine aperture is made per AI dimensional specs. It is the same as the AT and AX in terms of size, and uses the AT magazine catch, spring, and dowel. It is designed to be plug and play with factory AW magazines, exactly as a factory AT rifle would be.How many different barrels/calibers/magazines have you tried with the chassis, I am looking at the .223 conversion thread, looks like a modded MDT, that works with the AT and AX short action, concerned about tolerance stacking. Does your chassis run all the 6mm flavored magazines and their modifications or only AI factory magazines?

Unfortunately I can’t comment on how it will work with anything other than an AW mag. If the 223 conversions are working in an AX with other mags, then there’s a good chance it will work in my chassis. I also cannot comment on the 223 conversion itself; I have a LH action and will not (at least for the time being) be able to try that.

The chassis is designed to allow 1.25” straight taper barrels with clearance for all accessories.

Quick comparison between the Obsession, AT, and AX on a sideways GameChanger bag. Not only does the Obsession chassis allow the rifle to rest completely in front of the magwell instead of on top, it sits approximately 3/4” LOWER into the bag (ref. the tape measure marks in the second picture). Sitting that much lower drastically increases the stability, as well as reducing the tendency of the rifle to “cam” over when lifting the bolt to cycle a new round.

I’ve run the MDT, AI polymer & Accurate mags with my favorite being the Accurate, just cause they feed smoother. The AI mag works well but I started to have the feed lips loosen up.How many different barrels/calibers/magazines have you tried with the chassis, I am looking at the .223 conversion thread, looks like a modded MDT, that works with the AT and AX short action, concerned about tolerance stacking. Does your chassis run all the 6mm flavored magazines and their modifications or only AI factory magazines?

if it’s mimicking the AT & AX magwells it should be fine.

That lower profile is another good selling point @samb300.

It’s only when I tried shooting my AT through a small barricade aperture in a precison rifle practice event that I realised how ‘tall’ the AT sits compared to my 700 in a Whiskey 3 chassis.

This chassis solves a few issues that the AI's have when used as "gamer guns".

After being behind my fair share of AI's (never owned one), I never really liked the chassis for a few reasons. Sam's forend makes an AI much more desirable for someone like myself, IMO.

Now someone just needs to come up with a solution for that horrid pistol grip...

Exactly. Especially with an AX where you’re likely to have the tall action rail and 1.5” tall scope rings in order to clear the continuous forend pic rail on top of the handguard tube. I’ve been bit quite a few times by smaller port holes and even closely spaced barricade and cattle gate rungs.That lower profile is another good selling point @samb300.

It’s only when I tried shooting my AT through a small barricade aperture in a precison rifle practice event that I realised how ‘tall’ the AT sits compared to my 700 in a Whiskey 3 chassis.

I just bought an AXMC....I still have an AT....looking to be upgraded.

Currently in the market for my first AI. Been debating back and forth for awhile. After reading 7 pages of post. I realized Sam has solved the problems I had with getting a AI. Hopefully here soon I’ll be calling up Mile High to order my AI AT LE in 16.5” 308. And once this is in production and able to be purchased. I’ll be getting a new chassis for it.

Have you shopped the Firearms- classified on this forum. Some dude is selling an AT in an MPA and the original AT chassis for $3800. For that price you get to try both aftermarket chassis.

I’ve looked but didn’t notice that one. Gonna have to go look now.

Just went and found it. Sadly not a caliber I’m interested in. And I know I could just buy another barrel. But I think it will be a great deal for another buyer.Have you shopped the Firearms- classified on this forum. Some dude is selling an AT in an MPA and the original AT chassis for $3800. For that price you get to try both aftermarket chassis.

Just went and found it. Sadly not a caliber I’m interested in. And I know I could just buy another barrel. But I think it will be a great deal for another buyer.

I’m not interested in either caliber and I already have an AT LE. If I had the coin right now it would be mine.

The barrel can be sold off and if you didn’t like the MPA chassis it could be sold off to pay for for an AX stock. Then once assembled to AT LE specs the factory folder can be sold off.

Oh and there’s a 16.75” .308 barrel for sale on the PX as well.

I’m not interested in either caliber and I already have an AT LE. If I had the coin right now it would be mine.

The barrel can be sold off and if you didn’t like the MPA chassis it could be sold off to pay for for an AX stock. Then once assembled to AT LE specs the factory folder can be sold off.

Oh and there’s a 16.75” .308 barrel for sale on the PX as well.

PM sent

Similar threads

- Replies

- 7

- Views

- 670

- Replies

- 3

- Views

- 480