She purchases her own pallets. The end.no, that was a different guy. Unless the Canadian Olympic committee purchases ammo for athletes or they are super-rich, they won't be purchasing pallets.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lapua lot testing and barrel wear question

- Thread starter catalyst81

- Start date

The most I can get on a pallet order is 48 cases. Though it does make a difference who's ammo you're getting, as some manufacturers have differently sized cases. I fired over 27,000 rounds of 22lr last year personally. When I order ammo, it comes on a pallet. Not a full one, but it ships via freight carrier and is delivered on a pallet. I usually only get 15-30 cases at a time. It's really not hard for me to imagine shooters that take it more seriously than I do, and would get a full pallet. I usually only get 3-4 lot numbers at a time, and with each lot number being a max of 7-8 cases, stocking out a full pallet with desirable lot numbers is a difficult task. You'd need a direct relationship with a manufacturer to accomplish that, and I think many olympians have that relationship.

Thirty thousand rounds of .22LR match ammo is six cases. Perhaps there's economy to be had in buying 15 - 30 cases at a time, a several years supply. That requires a great deal of confidence that the lots chosen will provide the best results with current rifles, not to mention any not yet acquired.The most I can get on a pallet order is 48 cases. Though it does make a difference who's ammo you're getting, as some manufacturers have differently sized cases. I fired over 27,000 rounds of 22lr last year personally. When I order ammo, it comes on a pallet. Not a full one, but it ships via freight carrier and is delivered on a pallet. I usually only get 15-30 cases at a time. It's really not hard for me to imagine shooters that take it more seriously than I do, and would get a full pallet. I usually only get 3-4 lot numbers at a time, and with each lot number being a max of 7-8 cases, stocking out a full pallet with desirable lot numbers is a difficult task. You'd need a direct relationship with a manufacturer to accomplish that, and I think many olympians have that relationship.

A full pallet conservatively has over 200 000 rounds. That would be much more than one 3P shooter would shoot annually, and much more than a BR shooter would use. Shooting that amount in a year would mean shooting almost 550 rounds every single day of the year. Small bore training involves much more than shooting and more shooting. Position shooters devote considerable of time in areas such as mental preparation, physical fitness, and developing good breathing technique. Dry firing practice also is necessary.

Olympic and potential Olympic shooters number in the thousands in Europe and North America alone. Few of them have anything like a relationship with the three major match ammo makers, but they should have relationships with ammo dealers. Like most everyone else, Olympic and BR shooters have to test ammo to find the best lots for competition. They get their ammo from ammo dealers and don't order directly from the factory.

In North America, where there are Lapua and Eley ammo testing facilities, shooters can only choose from the lots that the facilities have available. The ammo chosen is sent to a dealer so that the testing facility doesn't cut out the dealer from the transaction.

At this point I have no idea what your argument even is. I only know that no matter what is said in this thread, someone will take exception to it.Thirty thousand rounds of .22LR match ammo is six cases. Perhaps there's economy to be had in buying 15 - 30 cases at a time, a several years supply. That requires a great deal of confidence that the lots chosen will provide the best results with current rifles, not to mention any not yet acquired.

A full pallet conservatively has over 200 000 rounds. That would be much more than one 3P shooter would shoot annually, and much more than a BR shooter would use. Shooting that amount in a year would mean shooting almost 550 rounds every single day of the year. Small bore training involves much more than shooting and more shooting. Position shooters devote considerable of time in areas such as mental preparation, physical fitness, and developing good breathing technique. Dry firing practice also is necessary.

Olympic and potential Olympic shooters number in the thousands in Europe and North America alone. Few of them have anything like a relationship with the three major match ammo makers, but they should have relationships with ammo dealers. Like most everyone else, Olympic and BR shooters have to test ammo to find the best lots for competition. They get their ammo from ammo dealers and don't order directly from the factory.

In North America, where there are Lapua and Eley ammo testing facilities, shooters can only choose from the lots that the facilities have available. The ammo chosen is sent to a dealer so that the testing facility doesn't cut out the dealer from the transaction.

This has been some read, not only has it taken a left turn off the road, it's went through the ditch and over the hill out of sight. LOL

orkan, I can only wish I could shoot as many rounds a year as you do. You have a very accurate rifle and the skills to take advantage of it, my hats off to you sir.

orkan, I can only wish I could shoot as many rounds a year as you do. You have a very accurate rifle and the skills to take advantage of it, my hats off to you sir.

I see your problem. You're looking for an argument where there is none. The addition of information is not meant to be contentious. It's meant to add accuracy. Have a thicker skin and don't take everything personally. Accept information for what it is.At this point I have no idea what your argument even is. I only know that no matter what is said in this thread, someone will take exception to it.

If I may, I'll explain what I said more simply and succinctly.

When you said you buy .22LR ammo 15 -30 cases at a time, I said it takes confidence to be sure that an investment like that is sound. There's no argument.

You imagined that shooters more serious than you -- perhaps those who compete in 3P internationally? -- buy more ammo than you and do so through a "relationship" with ammo makers. I explained why they don't. If they don't, there's no argument.

I thought initially that this would not be necessary. Taking a light short approach would be sufficient however that has turned out to not be the case. We have to many bull shitters and wind bags on this forum. The information that would help you is being cluttered by these idiots.

This will get progressively to where you will get present day information. Please take the time to stay with it to the end. I have tried to stay with firearms barrels as much as possible. When you get into general manufacturing things open up into another great world.

Being a Tool and die maker and Metrology Laboratories are both vastly different fields and require different skills. However, the Tool and Die Maker uses both in manufacturing industries. They are split into numerous different groups and we will not go into that here. I am just covering simple straight forward as I can be without all the clutter. These two groups work very heavily with all engineering departments as well.

First off, the “tooling is not cheap” and I have stated that in the past. The Deltronic pins are used to measure a hole that is straight through the material or straight into a material nothing more nothing less. If it is used to measure an angle it is not possible. That is not what it was designed for.

They normally have a green and a red end. Green has a specific dimension as well as red has. Green is normally the “go end” and red is normally the “no go” end. Therefore, they are known as “GO or NO GO gage in the trades. Only lets you know the hole is large enough or not large enough and what the size may be .250 in diameter or may not be .250 in diameter. Will tell you nothing about concentricity nor perpendicularity. Will not tell you anything about wear in a forcing cone area.

As I stated before it is for “Haggie from the east side”. They will not measure a bore land groove relationship nor the groove size. Further they cannot be ground nor made to do so. There way too many variations to even consider this possibility. Think about it. Further you will not be able to get them through a bore and know that the size is. They are only to say the bore is large enough for its passage. In the center it could be fifty thousand .050 to large. It passed the interior. Or it may be too tight it did not make it and it is to tight. But how tight? Give that a little thought.

It has been stated that they must be ground for that purpose. “Show ME” I will apologize.

Then there is the US Government Arsenal barrel gage or throat erosion gage. This wonderful piece of equipment was to help various units in the field determine when it was time to send in their weapons for a new barrel. Nothing more nothing less.

It is a rough gage from 0 to 10 that is all. It only checks the wear on the lands in the forcing cone area. When the wear on the lands was to a pre-determined depth the rifle was returned to the arsenal for a new barrel. It measures nothing in a .001 relationship. It is only saying it needs to be replaced or does not need to be replaced.

This gage does not check concentricity in any way shape or form. Concentricity and cylindricity is the checking of a hole for an out of round condition like an egg or a bad location. The tool does not check a specific dimension you cannot say it is X amount of thousands of wear. It is a “GAGE”. Just like the Deltronic pin.

These two tools the Deltronic Pin and the US Government Arsenal Barrel Gauge are both circa 1940’s and possibly before. Not necessarily under the same names but approximately aged in both cases.

Here is the next step up and it is a mechanical gage that will suffice in many cases to measure the interior of a barrel. If you are able to do this with this simple gage just think of what is possible with an air tester attached. Or a Fanuc control to the same tool rather than that simple gage head. it would measure within millionths. the Fanuc control unit is the control for a Computer Numerical Control machine of any type. There are others as well this is just one control type.

https://willrich.com/product/gun-barrel-diameter-gages/

Now on to the “Air Gauge”. My god dare I use these words. Someone here stated as a fact that no one has ever used this to check gun barrels and it has been tried and never worked. Well let’s take a very short look at this. Pure bovine fecal material. How do you think they measured these barrels in the past? With a tree branch. How did they keep the barrels consistent prior to 1960. Come on.

Is everyone familiar with Dan Lilja? All who are please raise your hands. OK here we go short version. I have a web site here.

Articles: The Details of Accuracy

http://www.riflebarrels.com/articles/barrel_making/details_of_accuracy.htm

Please scroll down to where you see the paragraph on Rifling Dimensions. There in the very last sentence you will find this verbiage. “After Lilja or one of his workers judges the inside of a barrel is done, it is checked with the bore scope for blemishes and on a Shefield air gauge for variations in diameter. The air gauge is set for a known diameter and passed down the barrel. More air passing through the gauge reveals wide spots in the barrel. Less air shows tight spots.

This is the air gauge that Lilja used at this time. They have highly likely moved on to far better equipment at this time. I say this because we are going up to date this measuring method before we come to the end.

Please read through this and open the PDF files at the bottom of the page.

http://dmetool.com/products/rifle-buttons-mandrels/

https://www.pgtgage.com/products-and-services/air-to-electronic-and-sheffield-gages/

This company will make any gauge you wish for any barrel you wish. All you have to do is send them the dimensions you wish and they will of have made it in the past.

http://www.dmetool.com/wp-includes/images/pdf/rifle/RIFLE_gage Model.pdf

Some will say these do not measure anything. Well here we are right in the middle. I will not get into this but what would you think of you attached this to an air tool to send into the bore of a rifle barrel. Believe me this happens. And this is only one company. There may be many others out here that manufacture air gage heads that are jeweled and work in the same manner. They are able to run this probe either as an electrical, mechanical or laser product into a barrel and measure the interior within .00001.

http://www.mechatronics.co.th/product-detail.php?id=97956

Yes we have the feeble that will try to pick this apart as well. Here is a head that would be possibly attached that will do the groove as well as the top of the lands for the bore.

Cost? Expensive for the average person. If you are in the business, not so. If you are in the business or thinking about it and can’t afford it you are in the wrong business, period. Run a “trash collection business” it is less expensive to get into and more lucrative.

All of this information is out of the 1950 to 2000 era and not to take a large jump and make this as short as possible and still make the point.

Today 2021, we have these types of measuring devices for barrel interior and measuring. Not only in inspection departments but on the machining equipment itself or not far away from the machine tool. I would have to say almost everything that is in production is CNC “Computer Numerical Controlled”. For the Tool and Die Makers it is a different story. Some tools are CNC and others are not.

Today due to this CNC Control we have X, Y, and Z axis that is worked with. Known as 3 axis machines and we also have 5 axis equipment. This also applies to the Metrology Laboratory and the Metrologist employee must know these as well. This is one of those pieces of equipment today.

https://machines4sale.com/it/News/46/609

“I believe I am getting to long here so I will even shorten it from original plans”.

Today we also have the inspection equipment that is along the lines of this.

These are some of the latest and to date the best. This does not say there are not more methods because there are many more being developed as we see this.

Yes, these are applicable to rifle barrels due to the 5 axis measuring and machining methods we have present day.

https://en.wikipedia.org/wiki/Coordinate-measuring_machine#:~:text=A coordinate measuring machine (CMM,, laser, and white light.

I have given you access to some of the today equipment necessary. All you really need is someone to give you a direction to the information. You can keep up with it yourself and learn. Just take the time.

This unit is about as good as it gets. Presented here by Justin Amateur. He is spot on for present day. Not saying something else may not come up that is better just saying today this is one of the best. Things change.

https://www.novacam.com/barrel-inspection-and-3d-measurement/

Another you may be able to relate to is here with H-S Precision.

https://hsprecision.com/resources/3dlc/

These units will give you interior profile graph along with the dimensions from one end to the other within .0001 in the case of the newer units.

What Justin Amature is doing and his way of measurement the bore scope is perfect for his application. He certainly does not need to purchase a 1.5M piece of equipment to prove anything to the people on this web site because they want to know, or any other. You want that get your ass in gear.

There are many items out here that have not even been mentioned here. So far, I have kept this quite simple and short. Remember I did not say this was cheap or inexpensive from the start and never have said that. Machine and Metrology tools are expensive and require clean and stable environments.

Many of the newer pieces of equipment are laser and there are newer methods as well.

Have I put everything in here that should be? No certainly not however it should give you a slight idea of what is available. Should you add in here "True Position Tolerancing" along with the normal math and CNC control codes it becomes real confusing. Some people make it into these fields, most do not.

Any gunsmith out here putting together a firearm with the cave man tools of yester year is to be avoided completely.

.

Now back to the original posters and how many cases on a pallet.

This will get progressively to where you will get present day information. Please take the time to stay with it to the end. I have tried to stay with firearms barrels as much as possible. When you get into general manufacturing things open up into another great world.

Being a Tool and die maker and Metrology Laboratories are both vastly different fields and require different skills. However, the Tool and Die Maker uses both in manufacturing industries. They are split into numerous different groups and we will not go into that here. I am just covering simple straight forward as I can be without all the clutter. These two groups work very heavily with all engineering departments as well.

First off, the “tooling is not cheap” and I have stated that in the past. The Deltronic pins are used to measure a hole that is straight through the material or straight into a material nothing more nothing less. If it is used to measure an angle it is not possible. That is not what it was designed for.

They normally have a green and a red end. Green has a specific dimension as well as red has. Green is normally the “go end” and red is normally the “no go” end. Therefore, they are known as “GO or NO GO gage in the trades. Only lets you know the hole is large enough or not large enough and what the size may be .250 in diameter or may not be .250 in diameter. Will tell you nothing about concentricity nor perpendicularity. Will not tell you anything about wear in a forcing cone area.

As I stated before it is for “Haggie from the east side”. They will not measure a bore land groove relationship nor the groove size. Further they cannot be ground nor made to do so. There way too many variations to even consider this possibility. Think about it. Further you will not be able to get them through a bore and know that the size is. They are only to say the bore is large enough for its passage. In the center it could be fifty thousand .050 to large. It passed the interior. Or it may be too tight it did not make it and it is to tight. But how tight? Give that a little thought.

It has been stated that they must be ground for that purpose. “Show ME” I will apologize.

Then there is the US Government Arsenal barrel gage or throat erosion gage. This wonderful piece of equipment was to help various units in the field determine when it was time to send in their weapons for a new barrel. Nothing more nothing less.

It is a rough gage from 0 to 10 that is all. It only checks the wear on the lands in the forcing cone area. When the wear on the lands was to a pre-determined depth the rifle was returned to the arsenal for a new barrel. It measures nothing in a .001 relationship. It is only saying it needs to be replaced or does not need to be replaced.

This gage does not check concentricity in any way shape or form. Concentricity and cylindricity is the checking of a hole for an out of round condition like an egg or a bad location. The tool does not check a specific dimension you cannot say it is X amount of thousands of wear. It is a “GAGE”. Just like the Deltronic pin.

These two tools the Deltronic Pin and the US Government Arsenal Barrel Gauge are both circa 1940’s and possibly before. Not necessarily under the same names but approximately aged in both cases.

Here is the next step up and it is a mechanical gage that will suffice in many cases to measure the interior of a barrel. If you are able to do this with this simple gage just think of what is possible with an air tester attached. Or a Fanuc control to the same tool rather than that simple gage head. it would measure within millionths. the Fanuc control unit is the control for a Computer Numerical Control machine of any type. There are others as well this is just one control type.

https://willrich.com/product/gun-barrel-diameter-gages/

Now on to the “Air Gauge”. My god dare I use these words. Someone here stated as a fact that no one has ever used this to check gun barrels and it has been tried and never worked. Well let’s take a very short look at this. Pure bovine fecal material. How do you think they measured these barrels in the past? With a tree branch. How did they keep the barrels consistent prior to 1960. Come on.

Is everyone familiar with Dan Lilja? All who are please raise your hands. OK here we go short version. I have a web site here.

Articles: The Details of Accuracy

http://www.riflebarrels.com/articles/barrel_making/details_of_accuracy.htm

Please scroll down to where you see the paragraph on Rifling Dimensions. There in the very last sentence you will find this verbiage. “After Lilja or one of his workers judges the inside of a barrel is done, it is checked with the bore scope for blemishes and on a Shefield air gauge for variations in diameter. The air gauge is set for a known diameter and passed down the barrel. More air passing through the gauge reveals wide spots in the barrel. Less air shows tight spots.

This is the air gauge that Lilja used at this time. They have highly likely moved on to far better equipment at this time. I say this because we are going up to date this measuring method before we come to the end.

Please read through this and open the PDF files at the bottom of the page.

http://dmetool.com/products/rifle-buttons-mandrels/

https://www.pgtgage.com/products-and-services/air-to-electronic-and-sheffield-gages/

This company will make any gauge you wish for any barrel you wish. All you have to do is send them the dimensions you wish and they will of have made it in the past.

http://www.dmetool.com/wp-includes/images/pdf/rifle/RIFLE_gage Model.pdf

Some will say these do not measure anything. Well here we are right in the middle. I will not get into this but what would you think of you attached this to an air tool to send into the bore of a rifle barrel. Believe me this happens. And this is only one company. There may be many others out here that manufacture air gage heads that are jeweled and work in the same manner. They are able to run this probe either as an electrical, mechanical or laser product into a barrel and measure the interior within .00001.

http://www.mechatronics.co.th/product-detail.php?id=97956

Yes we have the feeble that will try to pick this apart as well. Here is a head that would be possibly attached that will do the groove as well as the top of the lands for the bore.

Cost? Expensive for the average person. If you are in the business, not so. If you are in the business or thinking about it and can’t afford it you are in the wrong business, period. Run a “trash collection business” it is less expensive to get into and more lucrative.

All of this information is out of the 1950 to 2000 era and not to take a large jump and make this as short as possible and still make the point.

Today 2021, we have these types of measuring devices for barrel interior and measuring. Not only in inspection departments but on the machining equipment itself or not far away from the machine tool. I would have to say almost everything that is in production is CNC “Computer Numerical Controlled”. For the Tool and Die Makers it is a different story. Some tools are CNC and others are not.

Today due to this CNC Control we have X, Y, and Z axis that is worked with. Known as 3 axis machines and we also have 5 axis equipment. This also applies to the Metrology Laboratory and the Metrologist employee must know these as well. This is one of those pieces of equipment today.

https://machines4sale.com/it/News/46/609

“I believe I am getting to long here so I will even shorten it from original plans”.

Today we also have the inspection equipment that is along the lines of this.

These are some of the latest and to date the best. This does not say there are not more methods because there are many more being developed as we see this.

Yes, these are applicable to rifle barrels due to the 5 axis measuring and machining methods we have present day.

https://en.wikipedia.org/wiki/Coordinate-measuring_machine#:~:text=A coordinate measuring machine (CMM,, laser, and white light.

I have given you access to some of the today equipment necessary. All you really need is someone to give you a direction to the information. You can keep up with it yourself and learn. Just take the time.

This unit is about as good as it gets. Presented here by Justin Amateur. He is spot on for present day. Not saying something else may not come up that is better just saying today this is one of the best. Things change.

https://www.novacam.com/barrel-inspection-and-3d-measurement/

Another you may be able to relate to is here with H-S Precision.

https://hsprecision.com/resources/3dlc/

These units will give you interior profile graph along with the dimensions from one end to the other within .0001 in the case of the newer units.

What Justin Amature is doing and his way of measurement the bore scope is perfect for his application. He certainly does not need to purchase a 1.5M piece of equipment to prove anything to the people on this web site because they want to know, or any other. You want that get your ass in gear.

There are many items out here that have not even been mentioned here. So far, I have kept this quite simple and short. Remember I did not say this was cheap or inexpensive from the start and never have said that. Machine and Metrology tools are expensive and require clean and stable environments.

Many of the newer pieces of equipment are laser and there are newer methods as well.

Have I put everything in here that should be? No certainly not however it should give you a slight idea of what is available. Should you add in here "True Position Tolerancing" along with the normal math and CNC control codes it becomes real confusing. Some people make it into these fields, most do not.

Any gunsmith out here putting together a firearm with the cave man tools of yester year is to be avoided completely.

.

Now back to the original posters and how many cases on a pallet.

Last edited:

“They normally have a green and a red end. Green has a specific dimension as well as red has. Green is normally the “go end” and red is normally the “no go” end. Therefore, they are known as “GO or NO GO gage in the trades. Only lets you know the hole is large enough or not large enough and what the size may be .250 in diameter or may not be .250 in diameter. Will tell you nothing about concentricity nor perpendicularity. Will not tell you anything about wear in a forcing cone area.”

You do realize that that is not a deltronics pin but a gage assembled with the high and low limit deltronics pins right?

Anyway what you have said is pretty telling, carry on

You do realize that that is not a deltronics pin but a gage assembled with the high and low limit deltronics pins right?

Anyway what you have said is pretty telling, carry on

I am a Tool and Die maker, and just got 50 shades of dumber after reading that. Yowza.

Do I know you? You seem familiar...I am a Tool and Die maker, and just got 50 shades of dumber after reading that. Yowza.

I am aware this is an assembly. Just trying to stay out of the weeds and keep it simple.“They normally have a green and a red end. Green has a specific dimension as well as red has. Green is normally the “go end” and red is normally the “no go” end. Therefore, they are known as “GO or NO GO gage in the trades. Only lets you know the hole is large enough or not large enough and what the size may be .250 in diameter or may not be .250 in diameter. Will tell you nothing about concentricity nor perpendicularity. Will not tell you anything about wear in a forcing cone area.”

You do realize that that is not a deltronics pin but a gage assembled with the high and low limit deltronics pins right?

Anyway what you have said is pretty telling, carry on

Shop owner 30ish years. Heavy on CNC and computer tech. Specialty is small high precision parts. Aerospace, defense, commercial and some medical.Seems to be alot of T&D folks in on this thread. Curious what back grounds yall came from. Mines primarily aviation commercial and defense with 14 years additional down hole tooling technology.

Ah your like my neighbor down the road you'd never know he made titanium screws for joint replacement.Shop owner 30ish years. Heavy on CNC and computer tech. Specialty is small high precision parts. Aerospace, defense, commercial and some medical.

Never made any titanium screws, but I did once make gage tooling for a human body parts supplier. Did you know there are people that recycle your body parts??? Mainly bones and tendons. Gruesome info at first. Then it becomes really interesting. There are actually body parts machinists out there...Ah your like my neighbor down the road you'd never know he made titanium screws for joint replacement.

Currently Cnc grinder for turbine jet engine manufacturer. Commercial engines and defense subcontractor. Some of our stuff eventually intentionally goes boom.Seems to be alot of T&D folks in on this thread. Curious what back grounds yall came from. Mines primarily aviation commercial and defense with 14 years additional down hole tooling technology.

Been there done that I traveled all over to Boeing plants Lockheed, General Dynamics ,Bell Textron did work for every branch on MIL. Theres a ole guy not far from a old deer lease I had you drive by his shop you'd think it was a dump ! But inside was some of the most complex dynamic balancers my eyes ever saw he did mil turbine repair so you know what I'm talking about. He wasnt to far from Barksdale AFB.Currently Cnc grinder for turbine jet engine manufacturer. Commercial engines and defense subcontractor. Some of our stuff eventually intentionally goes boom.

Not a tool and die guy, but also work mostly aerospace, defense and medical mixed here and there.

Interesting how a lot of have very similar backgrounds.

Interesting how a lot of have very similar backgrounds.

Looks like someone swaged a small ball bearing into the nose of a hollowpoint.Since yall are talking about Lapua lot testing tell me what is the .0025 ring around the end of this center x cartridge? Reason ? Maybe purpose ?

Thanks

Last edited:

Now you bench shooters! Otta say or know somethin! What's up !

Seating stem mark from excessive seating pressure???

Doesnt the guy that does the gun testing at the lapua buildings come on here? I wonder if he would say? I got my ideas, but I'm holding them yall ever look at your center x ammo you use ?Seating stem mark from excessive seating pressure???

Do you have an entire box of Center X like this, or just one bullet?Doesnt the guy that does the gun testing at the lapua buildings come on here? I wonder if he would say? I got my ideas, but I'm holding them yall ever look at your center x ammo you use ?

The whole brickDo you have an entire box of Center X like this, or just one bullet?

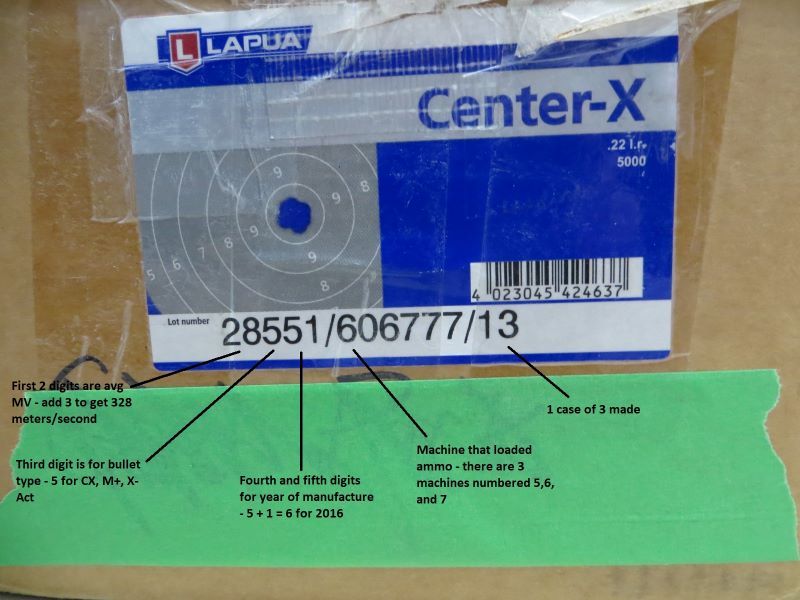

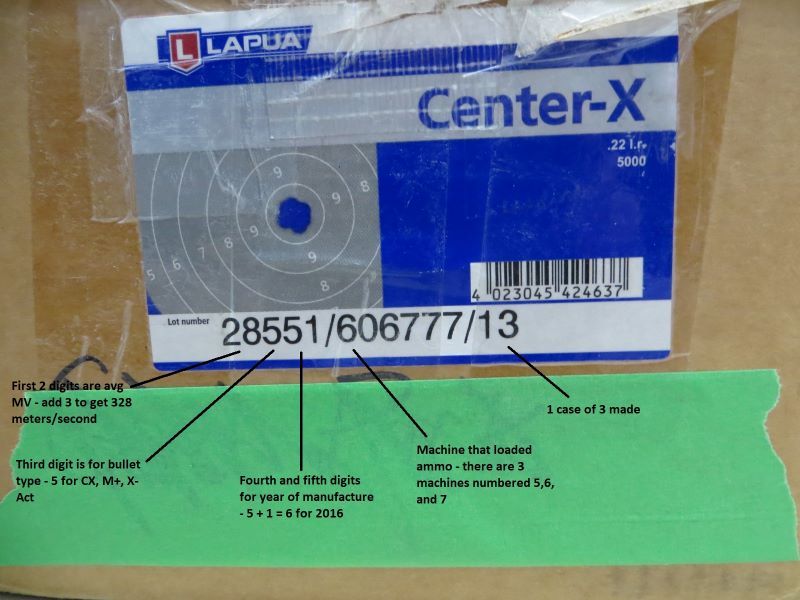

Lapua uses the same bullets on Center X, Midas +, and X-Act. On the lot number it's denoted by the third number -- "5". On one hand, it's possible that Lapua grades the bullets as well as the casing, priming, and propellant; on the other it's possible the grading is by entirely other means or a combination.Since yall are talking about Lapua lot testing tell me what is the .0025 ring around the end of this center x cartridge? Reason ? Maybe purpose ?

Thanks

In any event, here's some pictures of Lapua X-Act and Midas +. I also had some SK Rifle Match on hand and it looks remarkably similar, perhaps similar enough to be the same bullet as with the Lapua. Shown below in order of X-Act on left, Midas + in middle, and SK RM on right.

For information on how to decipher the Lapua lot numbers, see the image at bottom. I hope I haven't made any errors on it. Note that the lot number is on a complete label that's on the end of a case of ammo.

_X-Act_resized_300.JPG?width=1920&height=1080&fit=bounds)

_Midas_+_resized_300.JPG?width=1920&height=1080&fit=bounds)

_SK_RM_resized_300.JPG?width=1920&height=1080&fit=bounds)

Clean the lube off real good and take another pic I'll tell yall what I believe it is.Lapua uses the same bullets on Center X, Midas +, and X-Act. On the lot number it's denoted by the third number -- "5". On one hand, it's possible that Lapua grades the bullets as well as the casing, priming, and propellant; on the other it's possible the grading is by entirely other means or a combination.

In any event, here's some pictures of Lapua X-Act and Midas +. I also had some SK Rifle Match on hand and it looks remarkably similar, perhaps similar enough to be the same bullet as with the Lapua. Shown below in order of X-Act on left, Midas + in middle, and SK RM on right.

For information on how to decipher the Lapua lot numbers, see the image at bottom. I hope I haven't made any errors on it. Note that the lot number is on a complete label that's on the end of a case of ammo.

It's not a guessing game. The pictures are of the bullets I described.Clean the lube off real good and take another pic I'll tell yall what I believe it is.

Well I dug out an old brick of Center-X lot number 27548 53794, and it has the identical ring at the tip of the bullet.It's not on my SK or wolf

Last edited:

I initially thought you were pointing out a defect. Now that it looks intentional, I'd venture the guess it has a positive effect on the drag properties of the bullet. Though, I suspect, at shorter ranges. I dug out some old books and found an illustration from McCoy showing the transition from laminar flow to turbulent flow. That ring, and also the flat point on Eley, likely starts the flow to turbulent. Though I don't understand the ballistic value. This is the stuff that keeps me up at night.Since yall are talking about Lapua lot testing tell me what is the .0025 ring around the end of this center x cartridge? Reason ? Maybe purpose ?

Thanks

As I don't find it on any of my CenterX, I'm gonna offer a much more simplistic answer.

It's a dent left by the automated seating tool caused by it exceeding set tolerances.

It's a cartridge assembly defect. Maybe, I think.

It's a dent left by the automated seating tool caused by it exceeding set tolerances.

It's a cartridge assembly defect. Maybe, I think.

I have to ask -- naked eye or magnified?As I don't find it on any of my CenterX, I'm gonna offer a much more simplistic answer.

It's a dent left by the automated seating tool caused by it exceeding set tolerances.

It's a cartridge assembly defect. Maybe, I think.

I can't see it without a loupe or looking at photos with a magnified macro lens.

If it's a defect as you suggest, it's a most curious one. I checked four random lots of CX that I have conveniently available and it's on each random round I looked at. It's also found on each of the random bullets I checked from three different lots of M+. It's also on the one lot of SK Standard Plus I found.

I just sent Lapua an email with photo's asking them if those marks were from the manufacturing process or were placed there for a purpose.Naked eye, G.

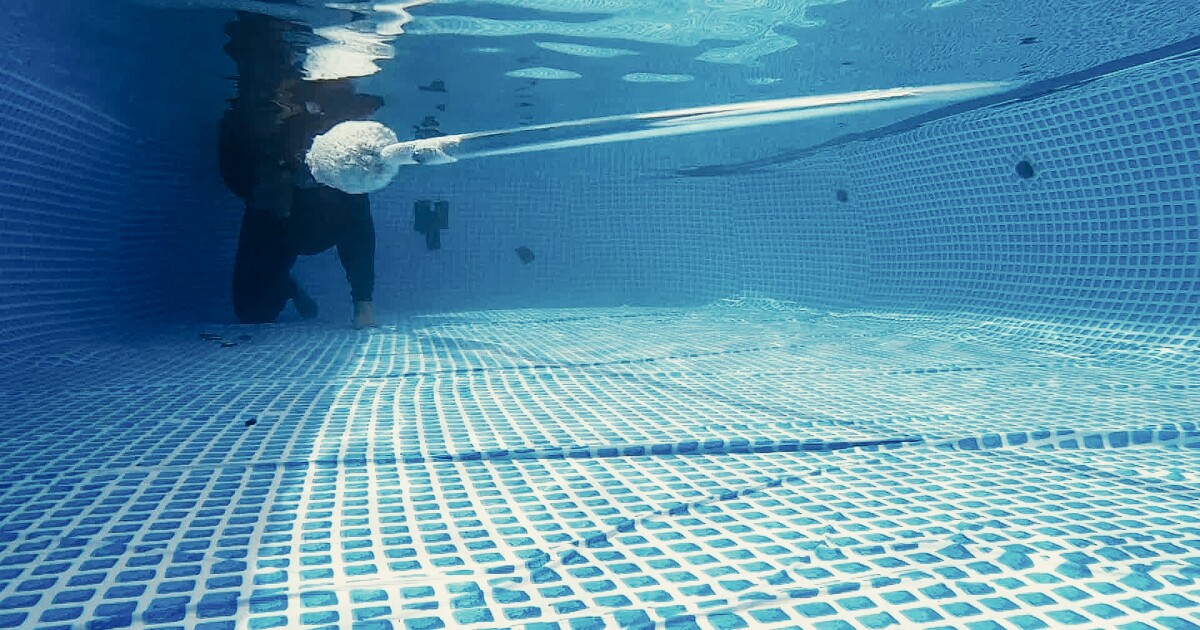

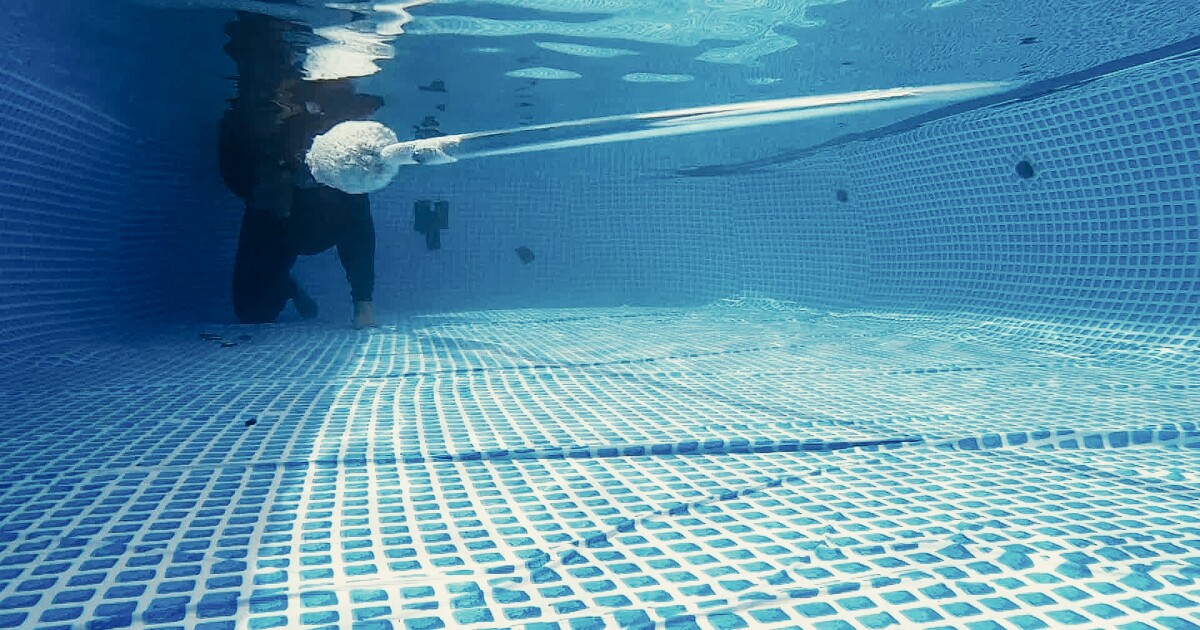

I believe its intentional listen to my theroy. I have spoke to No one about this till now and have reviewed alot of information. Including direct work with engineers from Textron Marine and the Navy during the Mid 90's. One day 20 large aluminum appearing foragings showed up at our facility. 8 days later the Rear Admarial and 3 under brass with 4 Textron engineers showed up.

We had only been allow to do a roughing quote on the job, with final machining pending. Material was described as a 7075 t651 aluminum substrate. I was like a Wolf I saw the Company making a killing off this I was in management. We had 5axis pallet changes with 30k spindles that feed rates, were 900 to 1100 ipm and rapid at 2100 ipm. Then we set down with the group that showed up and things went south they discussed the recommended machineing practices the 7075 foraging substrate was atomized tungsten. We were able to machine it with cbn tooling and was awarded the final machining. This part finished close to 4 feet in diameter the technology in it was crazy it looked similar to the bullet but not quite. The part was a nose cone for a torpedo designed with stealth technology. I asked the engineer about that similar ring he said it was, I quote to create dissimilar force to stablelize the torpedo during underwater current shift or veloicty change. I looked at alot of old German military artillery shells that had this as well we use it today in our advanced weapons like the photo you posted here his acronym for it was FAT forward advanced technology. I have searched for this and never found nothing. The idea of opposing forces is keeping the nose centered during disruptions. Now heres the kicker the Cartriadge Is called Center X on the very center of the nose is a precise ring centered on the precise center on the rim is a x which creates one of the flatest rims or perpendicular I've seen hence Center X.

I could be wrong, but there's something to it.

We had only been allow to do a roughing quote on the job, with final machining pending. Material was described as a 7075 t651 aluminum substrate. I was like a Wolf I saw the Company making a killing off this I was in management. We had 5axis pallet changes with 30k spindles that feed rates, were 900 to 1100 ipm and rapid at 2100 ipm. Then we set down with the group that showed up and things went south they discussed the recommended machineing practices the 7075 foraging substrate was atomized tungsten. We were able to machine it with cbn tooling and was awarded the final machining. This part finished close to 4 feet in diameter the technology in it was crazy it looked similar to the bullet but not quite. The part was a nose cone for a torpedo designed with stealth technology. I asked the engineer about that similar ring he said it was, I quote to create dissimilar force to stablelize the torpedo during underwater current shift or veloicty change. I looked at alot of old German military artillery shells that had this as well we use it today in our advanced weapons like the photo you posted here his acronym for it was FAT forward advanced technology. I have searched for this and never found nothing. The idea of opposing forces is keeping the nose centered during disruptions. Now heres the kicker the Cartriadge Is called Center X on the very center of the nose is a precise ring centered on the precise center on the rim is a x which creates one of the flatest rims or perpendicular I've seen hence Center X.

I could be wrong, but there's something to it.

Last edited:

I just checked some two year old center x , current center x, year old Midas + , and they all have the ring

Ditto

They might not tell youI just sent Lapua an email with photo's asking them if those marks were from the manufacturing process or were placed there for a purpose.

I just sent Lapua an email with photo's asking them if those marks were from the manufacturing process or were

There is do you think any bullet manufacture with automated optic laser inspection equipment would let something like that on the directional surface get out unless it added to the performance? With their name on it ? I mean think about that.I have a lots of Center X from 19 and 20 and both have the ring. I'm betting there is a reason Lapua put it there.

It directs and contains the nose to CENTERI initially thought you were pointing out a defect. Now that it looks intentional, I'd venture the guess it has a positive effect on the drag properties of the bullet. Though, I suspect, at shorter ranges. I dug out some old books and found an illustration from McCoy showing the transition from laminar flow to turbulent flow. That ring, and also the flat point on Eley, likely starts the flow to turbulent. Though I don't understand the ballistic value. This is the stuff that keeps me up at night.

View attachment 7575622

If my memory serves me, subsonic bullets are affected by forces acting on the bullet surface in the laminar flow area. Which also happens to projectiles under water. This made me think of an article I read on bullets designed for underwater so I did a quick search and here it is:

newatlas.com

newatlas.com

"Supercavitation effect can be produced, rather counter-intuitively perhaps, by giving the projectile a flat, disc-shaped nose with a sharp edge lip."

DSG's supercavitating underwater bullets annihilate ballistics tests

Regular bullets decelerate so quickly in water that they only make it a few feet, which is why diving into a conveniently located pool or waterway when under fire from assassins can be such a good idea. But Norway's DSG has used the drag-reducing abilities of supercavitation to produce some truly…

"Supercavitation effect can be produced, rather counter-intuitively perhaps, by giving the projectile a flat, disc-shaped nose with a sharp edge lip."

Maybe a more important clip from the article:

"Supercavitating bullet designs, which appear to use rounded tips that lead back to flat, sharp ridge discs at the point, as well as other ridges positioned further back on the bullet body."

Sure sounds like the wording is describing a Center X to me.

"Supercavitating bullet designs, which appear to use rounded tips that lead back to flat, sharp ridge discs at the point, as well as other ridges positioned further back on the bullet body."

Sure sounds like the wording is describing a Center X to me.

Those sly devils used it on us in war time and competition !Maybe a more important clip from the article:

"Supercavitating bullet designs, which appear to use rounded tips that lead back to flat, sharp ridge discs at the point, as well as other ridges positioned further back on the bullet body."

Sure sounds like they are describing a Center X to me.

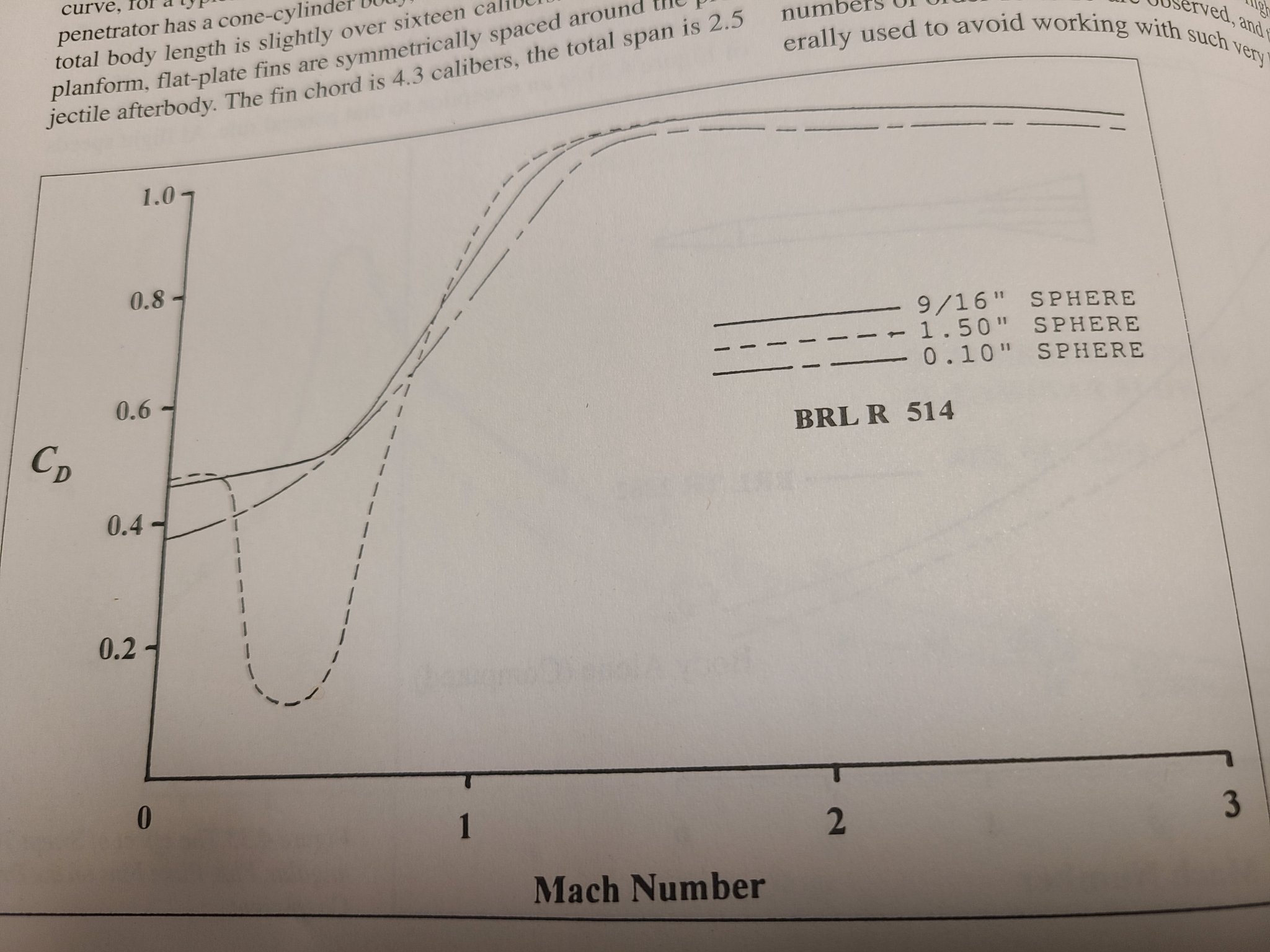

I've been doing some reading on this. This is really interesting! When a projectiles leading surfaces break from laminar flow to turbulent flow, it goes through a dramatic decrease in drag that McCoy describes as "anomalous". This does not happen with conventional bullet profiles but it does with certain size spheres at certain speeds. Here is another illustration showing the drag anomaly as it occurs on a 1.5" sphere at around mach .5 :

If this same effect is induced by the ring, it would mean less velocity loss and less wind drift than predicted. The problem I see with long range 22 is using a drag model like G1 wouldn't be accurate.

If this same effect is induced by the ring, it would mean less velocity loss and less wind drift than predicted. The problem I see with long range 22 is using a drag model like G1 wouldn't be accurate.

Similar threads

- Replies

- 8

- Views

- 626

- Replies

- 20

- Views

- 2K

- Replies

- 29

- Views

- 2K