Re: Look @ the job DPMS did on my .30 remington ar

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: DPMS Firearms</div><div class="ubbcode-body">Bob,

We have the rifle here now and it is being fixed as we speak. It will ship today or tomorrow.

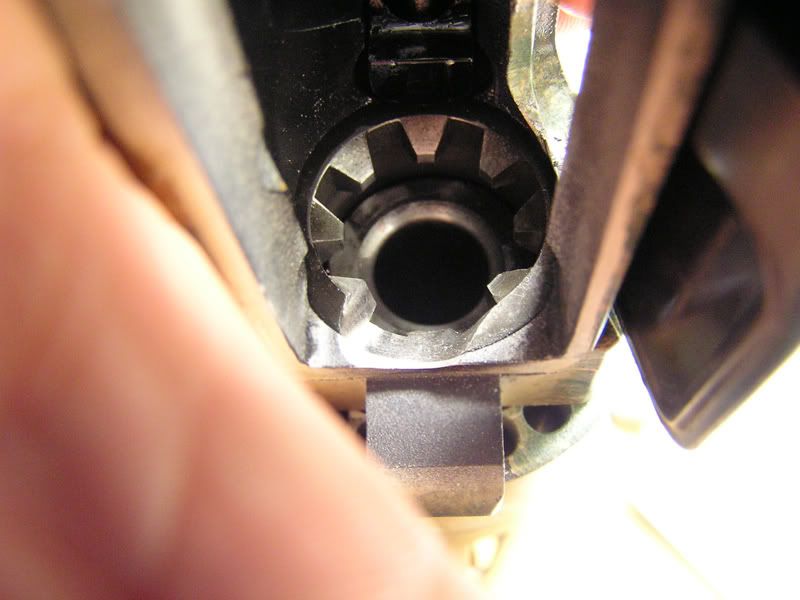

The old style of feed ramps for the R30 were vertical and caused feed issues. With the single side feed mags we need to use a <span style="text-decoration: underline">canted feed ramp</span>.

Given the size of the ramp and the lack of material on the upper and the required angle of the ramp the uppers cannot be cut very much and this causes the odd cut on the upper. This will always end up being an unattractive feed ramp.

I understand how strange this feed ramp looks to avid AR-15 users but we assure you this is the configuration required for operation. We are looking at a new polishing technique to make the ramp look better, this will have no effect on function but simply form.

To answer one other posters question the R30 does not have a center lug, it is a special design.

To answer the dust cover fix, plans are already in place to change the bolt carrier slightly to allow a tighter fit of the dust cover.

</div></div>

DPMS,

Welcome aboard, I'm glad to see someone brought this thread to your attention. Hopefully this time around my rifle will be corrected and we can put this all behind us. I am looking forward to seeing what was done to make this right. I see you mentioned "plans are already in place to change the bolt carrier slightly to allow a tighter fit of the dust cover". What kind of change to the bolt is going to be preformed? When I received the rifle back from the first trip in for repair, the dust cover was still not latching correctly. I called DPMS, spoke to Mark and explained the situation. I explained that my fathers rifle had the same problem and it was fixed at DPMS by the tech milling away the bolt carrier group where the dust cover contacted it. The tech also replaced the stock buffer with a tungsten buffer (my guess was a heavier buffer was required to compensate for the weight loss of the BCG due to the milling performed). Mark adamantly explained to me repeatedly that this could not have been done because it would cause the rifle to malfunction (even though it was already done to my fathers rifle). After going back and forth during this conversation, I explained to Mark that my fathers rifle was back at DPMS a second time for repair and if he did not believe what I was saying then he could go inspect it for himself since it was in their possession. I'm curious, with this being mentioned, what plan is in place to change the bolt carrier slightly to allow a tighter fit of the dust cover?

"Given the size of the ramp and the lack of material on the upper and the required angle of the ramp the uppers cannot be cut very much and this causes the odd cut on the upper. This will <span style="color: #FF0000">always</span> end up being an unattractive feed ramp."

ALWAYS?

Here is a photo of another .30 remington ar feed ramp. It doesn't appear to be unattractive to me. As a matter of fact, if mine came back and looked like this, I would be happy.

Respectfully,

Bob