I wish mine looked that nice.

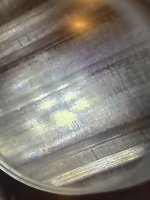

1The bore is not shiny and the groves look like tank tracks down the barrel

(I do realize that this is zoomed many times so like if you look at your thumb, you’ll see dividing lines in your skin…)

The gas port now looks like someone spit black goo and it travel from the edge of the gas port and slowly formed a tingle pattern of black goo (not sure how to even describe it

I will post photos.

This is a barrel that I had initially called the manufacturer and he had said shoot it and if it doesn’t work out, he would make it right. He had thought that I was having some recoil issues going on so I put another hundred down the tube and it’s shooting horrible ..worse

I shot off essentially a adjustable height, rest, and a bag in the back

1The bore is not shiny and the groves look like tank tracks down the barrel

(I do realize that this is zoomed many times so like if you look at your thumb, you’ll see dividing lines in your skin…)

The gas port now looks like someone spit black goo and it travel from the edge of the gas port and slowly formed a tingle pattern of black goo (not sure how to even describe it

I will post photos.

This is a barrel that I had initially called the manufacturer and he had said shoot it and if it doesn’t work out, he would make it right. He had thought that I was having some recoil issues going on so I put another hundred down the tube and it’s shooting horrible ..worse

I shot off essentially a adjustable height, rest, and a bag in the back