@

obelisk57. This thread is old and the info below is pretty much a summary of earlier posts but I hope it helps.

There is so much confusion on the use of Redding comp shellholders. Primarily because of Redding’s worthless description/instructions on their use

From Redding: “ Each shellholder has a distinct black oxide finish and is clearly marked to indicate the amount it will decrease case-to-chamber headspace”. What? totally incomprehensible.

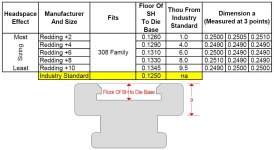

The Comp Shellholders sold by Redding and the modular Shellholders from Area 419 work the same way. They lower the floor of the shellholder that the case base sits on. So for one marked +4, the floor is dropped 0.004” and generates a sized case with 0.004” less bump (longer base-to-datum length) relative to a standard .125” shellholder. This difference is important because you don’t have to touch the die to see the change and you can adjust bump w/o having the die in firm solid contact with the shellholder. However, many of us like that solid contact and these comp shellholders can be interchanged w/o adjusting the die because the shellholder shelf that contacts the die is not shifted.

Note: if you are not getting sufficient bump (ie your case base-to-shoulder datum measurement is longer than you want and you have firm die-to-shellholder contact (camover), then these comp shellholders

will not help, with one exception: The Modular Shellholder kit from Area 419 does come with a -2 insert which effectively reduces the shellholder depth to .123, giving you .002” more bump than a standard SH.

The diagram and the numbers below were produced by a New Zealand shooter on another forum using his Mitutoyo micrometer. The column “headspace effect” really should read “shoulder setback effect.”