i have already read most the common thread pertaining to the title. i will be finishing up my 38 special/357 case with set screw or ball bearing tomorrow. i will then machine down my bolst assemble screw (bas) to create a cleaner look than adding a spacer the thickness the cartridge rim and ball bearing or set crew pertude above normal surface. i will take an image or two for those that may be confused by my pour description.

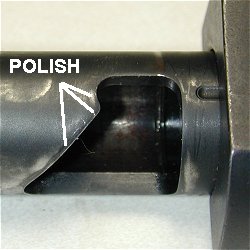

i also plan on polishing the surfaces highlighted in the following link; http://www.steyrscout.org/savscout.htm

here in lies my question:

have any of you ever removed some material from the ramp the cocking mechanism rides? i do not want to make it knife edge but i think because there is not much pressure on it i should be able to grind some of the inside edge away resulting in less available surface thus possible reducing friction. after this i will polish the surface to.

this image is taken from the above link to describe the surface i am referring to.

i am open to other advice as well.

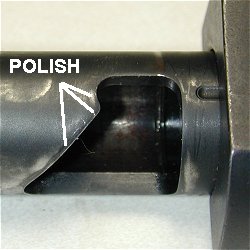

i also plan on polishing the surfaces highlighted in the following link; http://www.steyrscout.org/savscout.htm

here in lies my question:

have any of you ever removed some material from the ramp the cocking mechanism rides? i do not want to make it knife edge but i think because there is not much pressure on it i should be able to grind some of the inside edge away resulting in less available surface thus possible reducing friction. after this i will polish the surface to.

this image is taken from the above link to describe the surface i am referring to.

i am open to other advice as well.