My latest welding project, needed a spreader bar for picking a Cummins qsx15 because the last time they broke the valve cover. Welds kind of sucked because of a junk whip, I hate our shop welder.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maggie’s The Welding and Metalworking Thread

- Thread starter bogeybrown

- Start date

It will work, it will hold, it will lift. And, better yet, it will last a long, long time.

What's great is it worked perfect for that and we used it the other day for a 6.4 power stroke. I would have liked to done it a little differently but that was the material we had on hand and we needed it right away.

Necessity being the mother of invention.What's great is it worked perfect for that and we used it the other day for a 6.4 power stroke. I would have liked to done it a little differently but that was the material we had on hand and we needed it right away.

Spun a bolt knob for a gun

Last edited:

Today’s project a new aluminum lightweight hammer. Effed up the first head cause I wasn’t paying attention and drilled my hole too big. Nothing like a case of head up the ass to mess up a good time

turned new head and threaded it still need to clean up the fit a little bit and tap for the inserts but should be a fairly decent hammer for around the gun room. I recycled the inserts from my old busted hammer to this one for time and headaches sake

turned new head and threaded it still need to clean up the fit a little bit and tap for the inserts but should be a fairly decent hammer for around the gun room. I recycled the inserts from my old busted hammer to this one for time and headaches sake

Last edited:

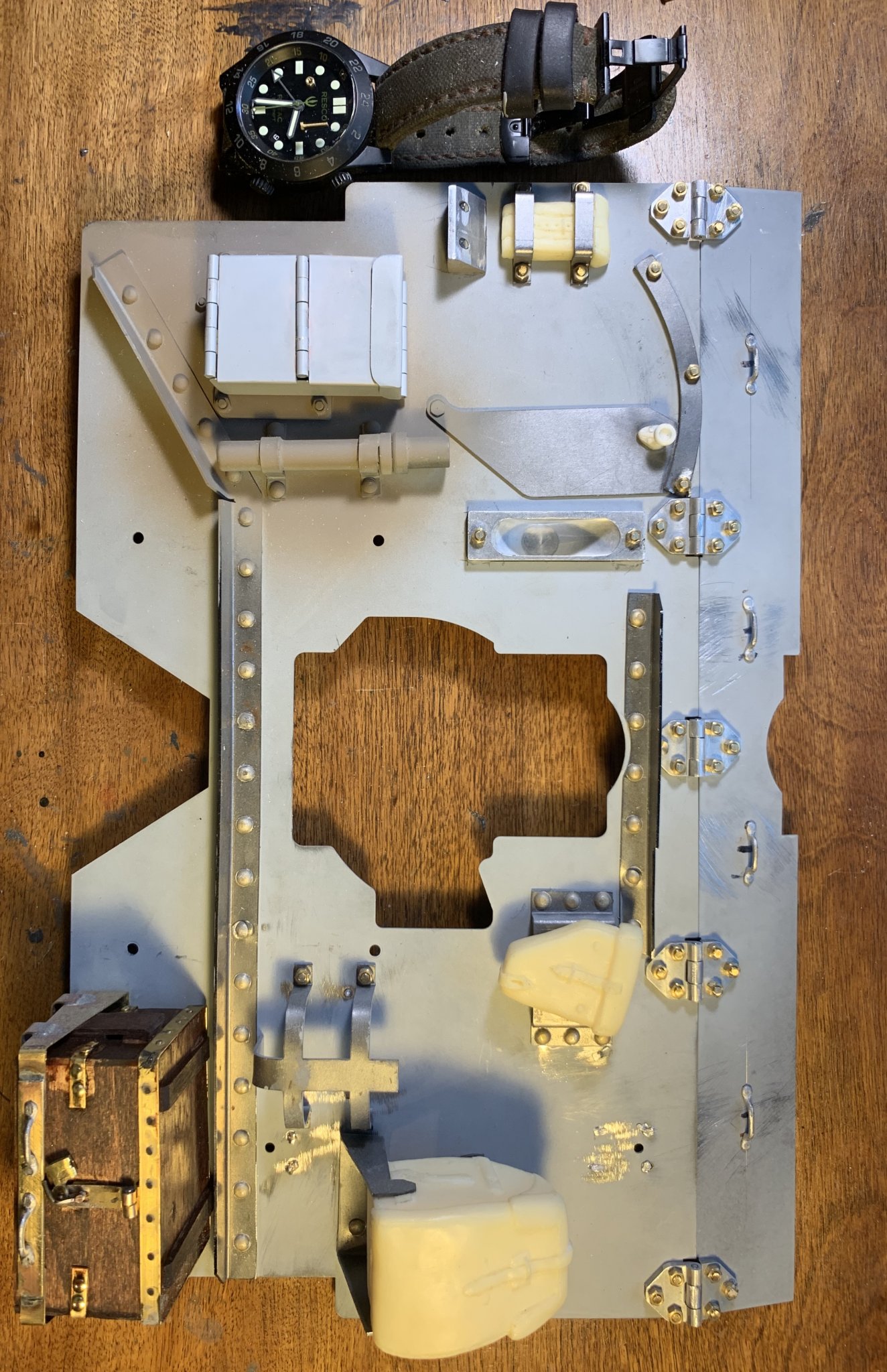

So you guys know my penchant for miniatures... firearms, sea mines, cannons... whatever.

For the past several months, on and off, I've been working on a 1/6th scale model of a British 25 pdr artillery piece. It's all metal... aluminum, brass, steel, german silver... Here's a few pictures.

We never grow up. Our toys just get bigger.

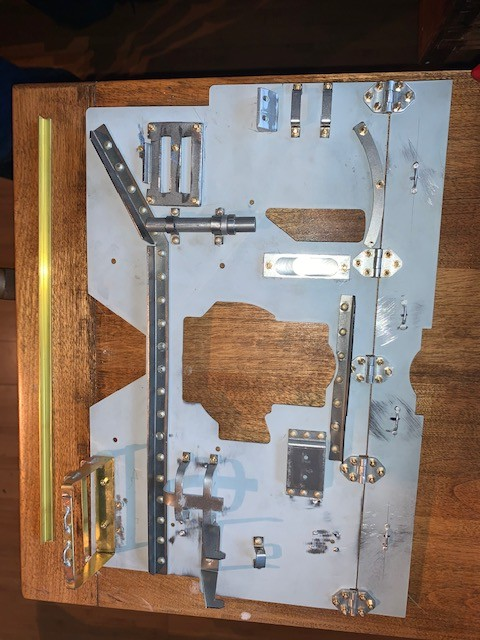

Shield inside... lots of small screws and rivets

Brakes, drums and a carrier I made from brass for one of the wood side boxes.

Carriage coming together. Lots of rivets... Lots and lots of rivets!

Machining the trunnion carrier/yoke to make sure it is square on the carriage. Otherwise it may lock up when its trying to traverse.

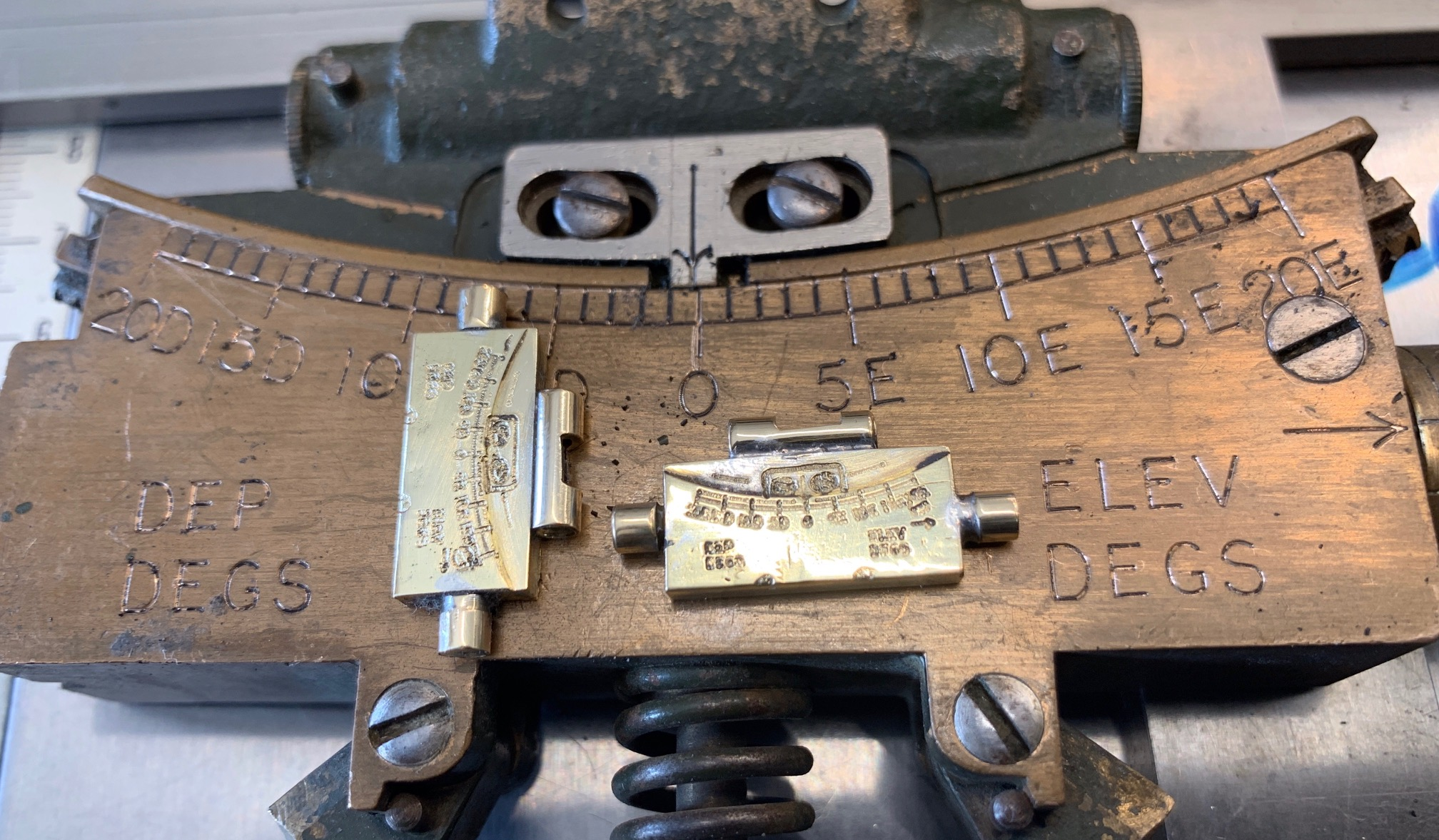

How about some scratch-built 1/6th scale clinometers?

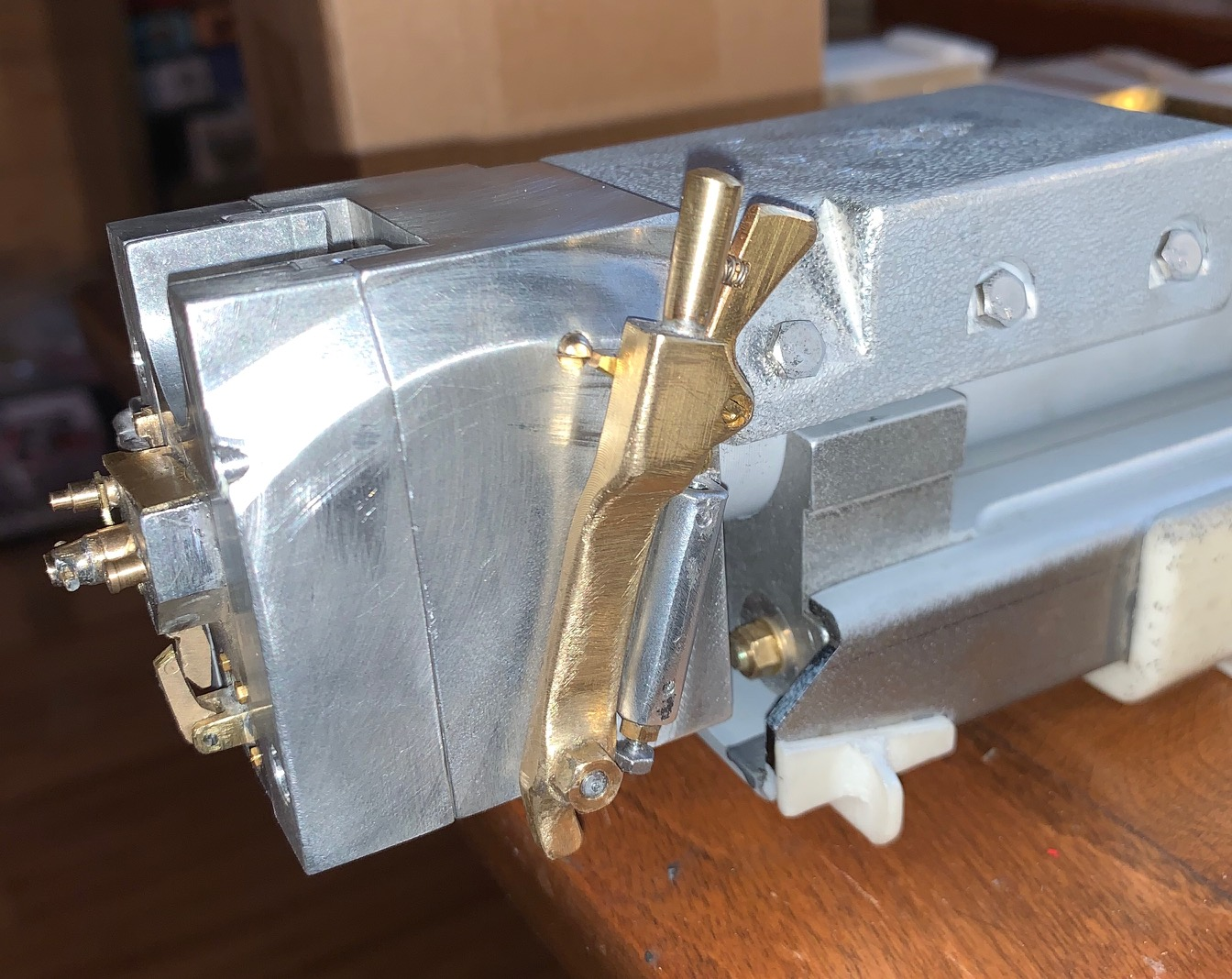

And a couple of the finished breech... gun mechanism is basically finished, though a lot more to go.

Something to stay busy with when not vertically stacking rocks...

Cheers,

Sirhr

For the past several months, on and off, I've been working on a 1/6th scale model of a British 25 pdr artillery piece. It's all metal... aluminum, brass, steel, german silver... Here's a few pictures.

We never grow up. Our toys just get bigger.

Shield inside... lots of small screws and rivets

Brakes, drums and a carrier I made from brass for one of the wood side boxes.

Carriage coming together. Lots of rivets... Lots and lots of rivets!

Machining the trunnion carrier/yoke to make sure it is square on the carriage. Otherwise it may lock up when its trying to traverse.

How about some scratch-built 1/6th scale clinometers?

And a couple of the finished breech... gun mechanism is basically finished, though a lot more to go.

Something to stay busy with when not vertically stacking rocks...

Cheers,

Sirhr

So you guys know my penchant for miniatures... firearms, sea mines, cannons... whatever.

For the past several months, on and off, I've been working on a 1/6th scale model of a British 25 pdr artillery piece. It's all metal... aluminum, brass, steel, german silver... Here's a few pictures.

We never grow up. Our toys just get bigger.

Shield inside... lots of small screws and rivets

View attachment 7189609

Brakes, drums and a carrier I made from brass for one of the wood side boxes.

View attachment 7189611

Carriage coming together. Lots of rivets... Lots and lots of rivets!

View attachment 7189619

Machining the trunnion carrier/yoke to make sure it is square on the carriage. Otherwise it may lock up when its trying to traverse.

View attachment 7189622

How about some scratch-built 1/6th scale clinometers?

View attachment 7189623

And a couple of the finished breech... gun mechanism is basically finished, though a lot more to go.

View attachment 7189627

View attachment 7189628

View attachment 7189630

Something to stay busy with when not vertically stacking rocks...

Cheers,

Sirhr

Beautiful..........

Miniature shells too? Please say yes cause that would be awesome and make me wish I could turn metal like that even more!!

Miniature shells too? Please say yes cause that would be awesome and make me wish I could turn metal like that even more!!

Of course!

sirhr

2 Nov. 2019

14 Nov. 2019

22 Nov. 2019

26 Nov. 2019

27 Nov. 2019

All the trusses:

Top cord, 4"X8"X 11 ga.

Bottom cord, 4"X4"X 11 ga.

King post, 4"X4"X 1/4"

Outter posts, 4"X4"X 11 ga.

Gussets, 4"X4"X 14 ga.

Columns, 4" round pipe 3/8" wall

Weld plates in the slab, 1/2" wity 5/8" rebar J-bolts.

Lots of welding this month...

Of course!

sirhr

Not just shells, but the aluminum limber 'trays' that carry them.

If you are going to go nuts... you might as well go completely nuts!

Cheers,

Sirhr

S

S Roche

Guest

Sirhr, you amaze me at the detail of your work. There are only a couple of things I wish I had the skill to do, this is 1 of them. Fine work Sir

how many oz of weight to balance that baby

I'm thinking that the one extra re-bar IS the balancing weight.

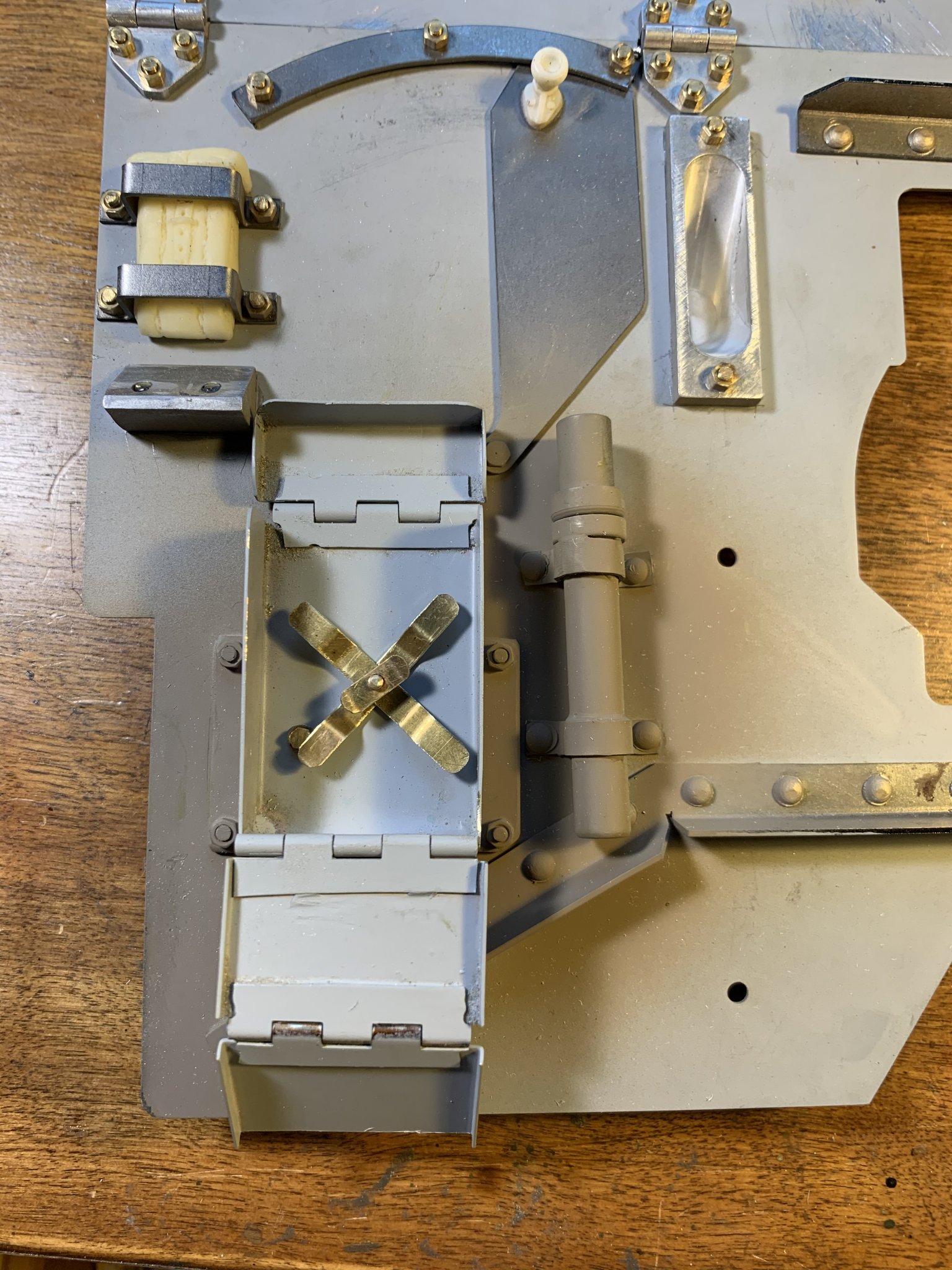

Got some more work done on the 25 Pdr miniature...

Limber/tool boxes from scratch including tiny little padlocks!

And the firing platform. All bucked rivets on the platform!

Lots of 8ba studs and nuts, too!

Cheers, Sirhr

Limber/tool boxes from scratch including tiny little padlocks!

And the firing platform. All bucked rivets on the platform!

Lots of 8ba studs and nuts, too!

Cheers, Sirhr

Some more model progress... Spent most of the day making this infernal little box out of brass sheet and doll-house-sized piano hinges. All soldered. 1/6th scale. Box tri-folds and is used to hold a towing cable.

Watch for scale showing it closed.

Here it is attached to the back of the gun shield. On the watch are some of the 10BA bolt/nuts used to hold things together. That and 8BA. Very small!!! At the bottom is one of the wood boxes that I made last weekend.

Here's the bolt and nut combo...

But small is fun. I engraved this up.... it's a replica of the presentation plate on the gun I am replicating. From the Sultan of Oman to the Brits at Woolrich, 1978.

Here is the box in place with the internals. This is used for nothing more than to hold a coiled cable in place. The inside has a hand wheel with a screw and the flat plate pieces are to hold the wire in place. Taking things to the extreme? Yeah. Why not!

That's all for today. Tomorrow I start to work on the T&E.

Cheers,

Sirhr

Watch for scale showing it closed.

Here it is attached to the back of the gun shield. On the watch are some of the 10BA bolt/nuts used to hold things together. That and 8BA. Very small!!! At the bottom is one of the wood boxes that I made last weekend.

Here's the bolt and nut combo...

But small is fun. I engraved this up.... it's a replica of the presentation plate on the gun I am replicating. From the Sultan of Oman to the Brits at Woolrich, 1978.

Here is the box in place with the internals. This is used for nothing more than to hold a coiled cable in place. The inside has a hand wheel with a screw and the flat plate pieces are to hold the wire in place. Taking things to the extreme? Yeah. Why not!

That's all for today. Tomorrow I start to work on the T&E.

Cheers,

Sirhr

Last edited:

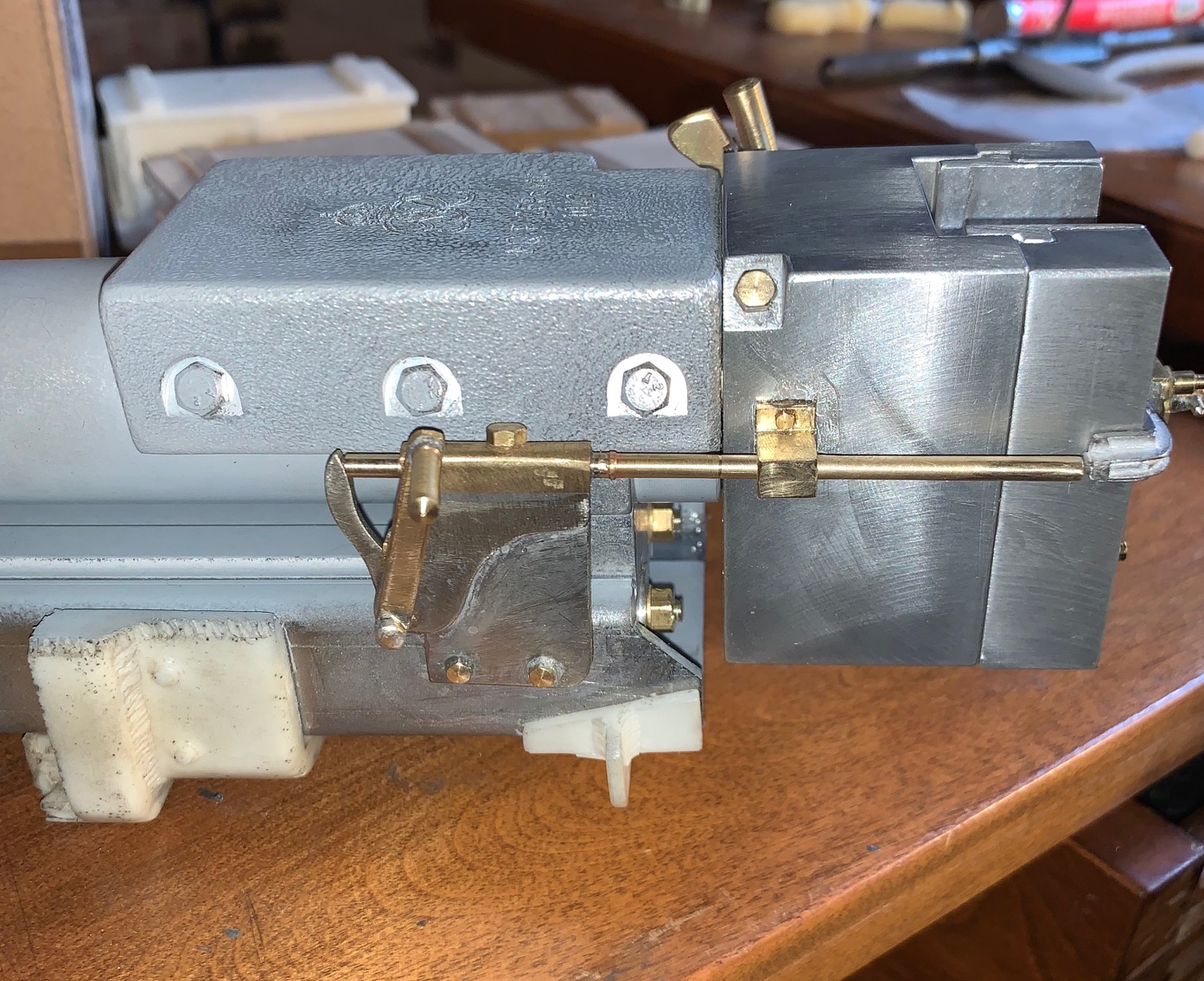

T&E done... coming together!

Sirhr

Thinking Bridget the Midget. Maybe it’s like Gunner with benefits...Fantastic, SirHR. If you're going to do a job, then by all means, do it well. And THAT you have done. Looking forward to seeing it all 'come together'. Who're you hiring to operate it?

You have a 1/6th of a person lined up already?

cheers, Sirhr

PS... no 3D printed parts at all. Some resin bits cast by a friend of mine. Everything else is files and mills and lathe.

It was the resin parts I thought may have been printed, have you tried that process? When do we get to see the finished project? Maybe we could use it as the signal cannon for the start of the party at Tucker's Pond???

Here's an interesting piece of machine work.

Complex threaded loose nut piece machined from a single part - photo - HomemadeTools.net

Complex threaded loose nut piece machined from a single part. Fullsize image: https://diqn32j8nouaz.cloudfront.net...t_fullsize.jpg Previously: https:/

www.homemadetools.net

Fantastic, SirHR. If you're going to do a job, then by all means, do it well. And THAT you have done. Looking forward to seeing it all 'come together'. Who're you hiring to operate it?

You have a 1/6th of a person lined up already?

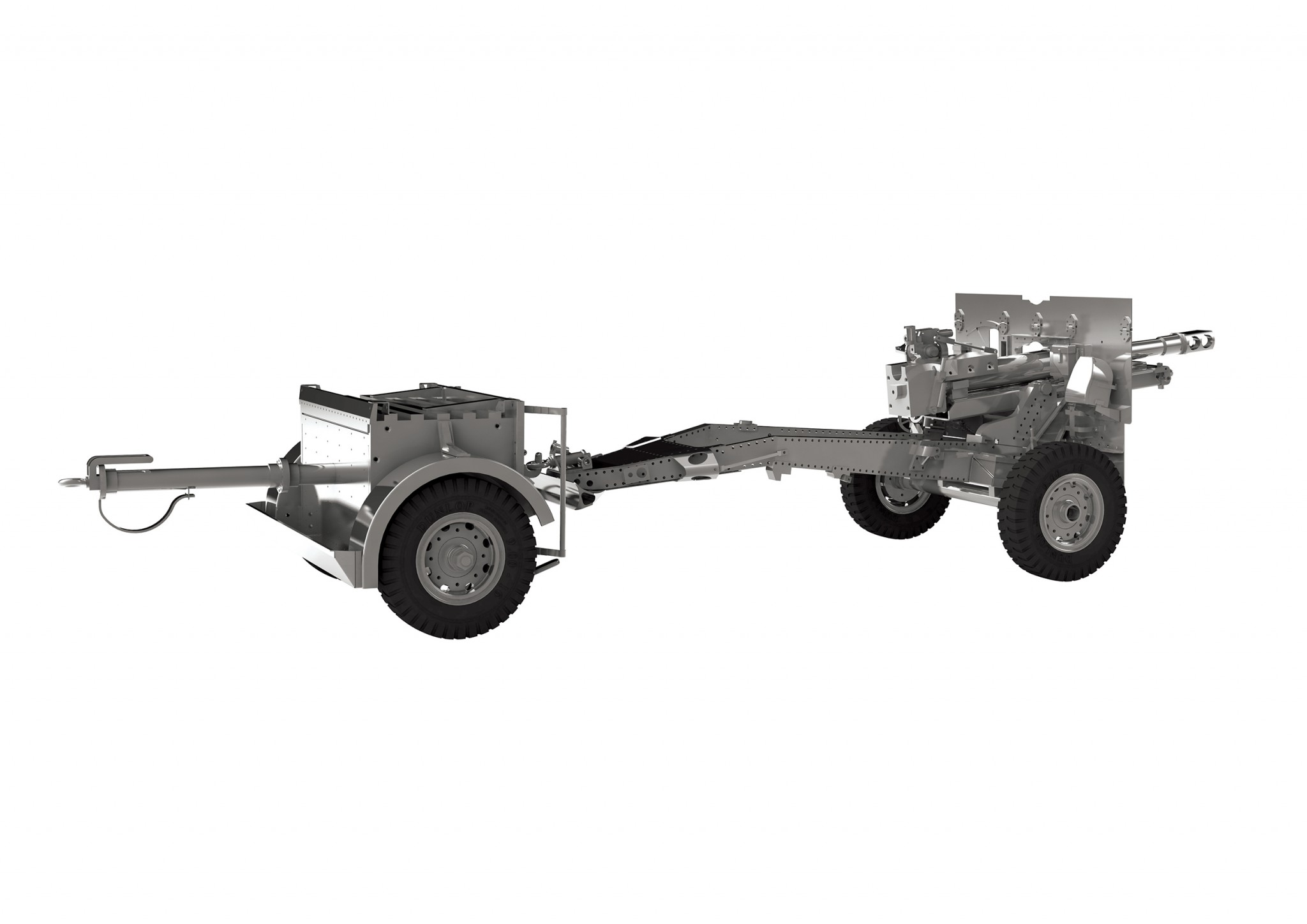

Major assemblies test fitted for the first time, except the firing table which is done, but working on the linkages. Still need about another day or so of machine work and small item fitting before it's time to prime (more) and paint.

Cheers,

Sirhr

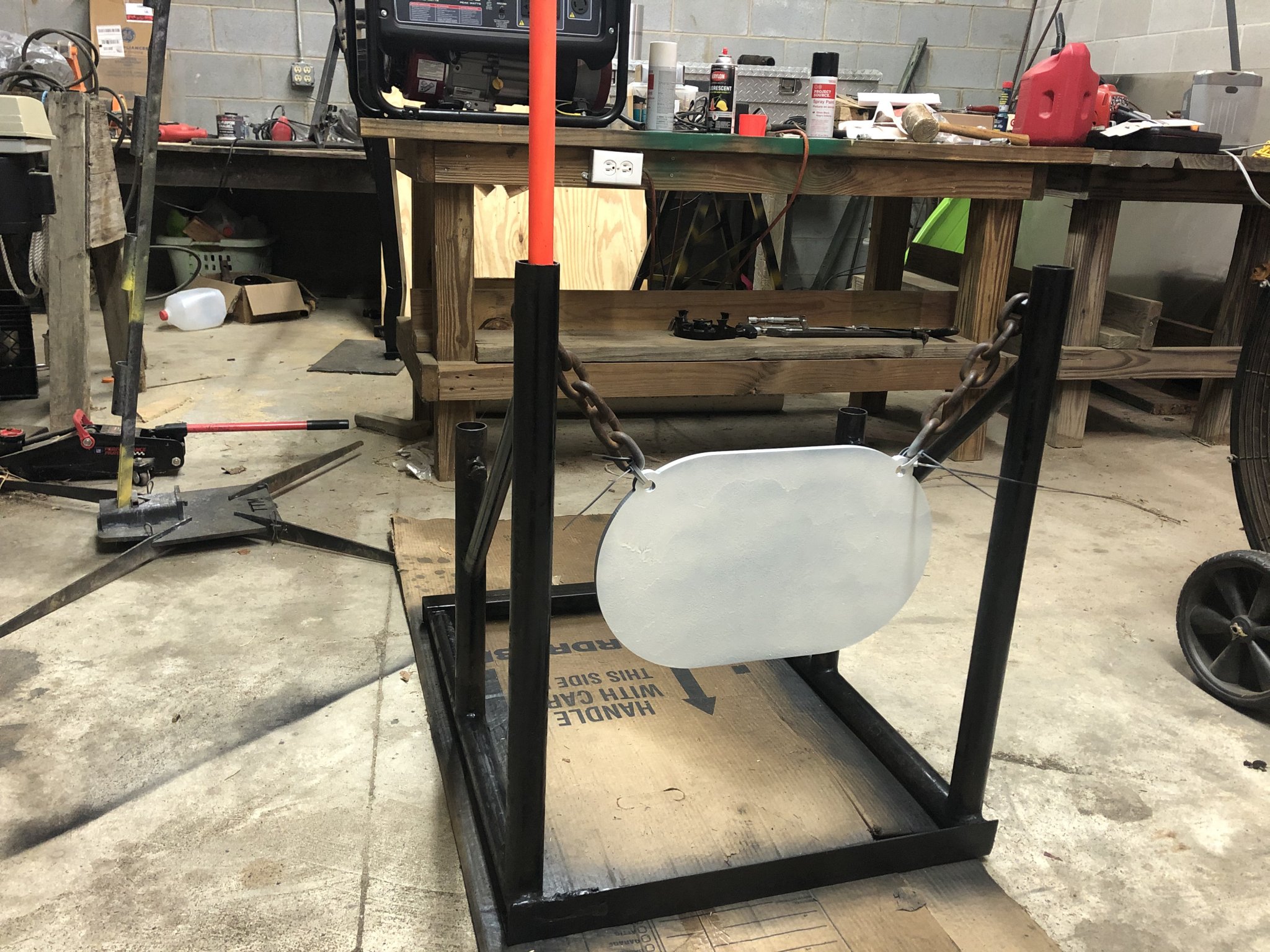

Well seeing @sirhrmechanic post makes mine look like the special olympics. Got bored last night and cut up some metal laying around the shop for a target hanger. Noting special but should hold it still(never mind the zip ties, I couldn’t find my large bolts to hold the target last night)

Will the handle with care sign be redundant when you replace the zip ties??? Looks good mate and your shop looks a bit tidier than mine at the moment.

That picture of the shop is like a magicians trick. All angles and trick shots because it’s a disaster. Never even noticed the handle with care part of the box! All remnants from the last military move I did.Will the handle with care sign be redundant when you replace the zip ties??? Looks good mate and your shop looks a bit tidier than mine at the moment.

Since I can't weld for crap... I think that's awesome!Well seeing @sirhrmechanic post makes mine look like the special olympics. Got bored last night and cut up some metal laying around the shop for a target hanger. Noting special but should hold it still(never mind the zip ties, I couldn’t find my large bolts to hold the target last night)View attachment 7210313View attachment 7210314

Cheers,

Sirhr

Not sure some of what I melt is considered welding either but it holds the metal together!Since I can't weld for crap... I think that's awesome!

Cheers,

Sirhr

Sirhr, are you thinking of adding the ammo limber??

Already built! I did that one first as kind of a warmup!

Got to do something when I'm not building guns, loading ammo, mowing fields and vertically stacking rocks!

Cheers,

Sirhr

Last edited:

That's because the A-T kits are awesome blank canvases! Some build them as out-of-the box RC kits. Others look at them as a great big opportunity to add 5x the parts and make everything work...Looks a hell of a lot better than the Armortek kit in my pic....

I'm friends with the owner of Armortek. It's an amazing company. And if you like models... these are the absolute ultimate. And I'm not even one of the really talented kitbashers. Marcus and Jeff and Dave Dibb take this stuff to a level that is simply amazing.

Cheers,

Sirhr

I know what you mean, I have been very tempted by this but at almost $8000 usd including all the extras and shipping to Australia....

I know what you mean, I have been very tempted by this but at almost $8000 usd including all the extras and shipping to Australia....

Their next kit is going to be “smaller and lighter...”. And less expensive. I don’t know exactly what yet. Close hold at the mother ship. But the trend has been to huge kits and they are looking to do a smaller one for us poors! ;-).

Personally, not so much into the tracks. The artillery is what I love and the base kits are not that expensive. But the big Tigers and the new Chieftain... are some serious investments!

cheers, sirhr

Last edited:

Already built! I did that one first as kind of a warmup!

View attachment 7210829

View attachment 7210838

View attachment 7210839

Got to do something when I'm not building guns, loading ammo, mowing fields and vertically stacking rocks!

Cheers,

Sirhr

Sirhr..........the attention to detail in what you do is just amazing..............you have some machining and fabricating skills that are probably the best I have ever seen.............

Anyone have to give up welding for health reasons? I'm having issues with my breathing and recently quit a mechanic position that I enjoyed because about a third of the time I welded. I'm debating on selling my welder, plasma cutter and all the related tools but I'm having a hard time with the thought of parting with them.

damn... I'm sorry to hear this. I too know what it's like to lose your career and it ain't an easy pill to swallow. Different kinda health reasons and cause, but....Anyone have to give up welding for health reasons? I'm having issues with my breathing and recently quit a mechanic position that I enjoyed because about a third of the time I welded. I'm debating on selling my welder, plasma cutter and all the related tools but I'm having a hard time with the thought of parting with them.

damn... I'm sorry to hear this. I too know what it's like to lose your career and it ain't an easy pill to swallow. Different kinda health reasons and cause, but....

Thanks, it's been bothering me for almost a year and decided that I don't want to make it worse. Giving up something that you are good at and enjoy is rather depressing.

@Bradu

Have you seen the doc?

Maybe see a good internal med doc to start. If no answers look at a pulmonologist.

There have been jobs I couldnt do (farming and tree nursery) as a kid, military as an adult all due to asthma.

Currently training for a marathon.....

There are usually other answers vs giving it up.

Having seen your work, that would really blow. Your good at it and seem to enjoy the challenge it holds.

All said, if the off-gassing of the fire/welding is causing it, best to stop while its hopefully reversible.

Take care

Have you seen the doc?

Maybe see a good internal med doc to start. If no answers look at a pulmonologist.

There have been jobs I couldnt do (farming and tree nursery) as a kid, military as an adult all due to asthma.

Currently training for a marathon.....

There are usually other answers vs giving it up.

Having seen your work, that would really blow. Your good at it and seem to enjoy the challenge it holds.

All said, if the off-gassing of the fire/welding is causing it, best to stop while its hopefully reversible.

Take care

@Bradu

Have you seen the doc?

Maybe see a good internal med doc to start. If no answers look at a pulmonologist.

There have been jobs I couldnt do (farming and tree nursery) as a kid, military as an adult all due to asthma.

Currently training for a marathon.....

There are usually other answers vs giving it up.

Having seen your work, that would really blow. Your good at it and seem to enjoy the challenge it holds.

All said, if the off-gassing of the fire/welding is causing it, best to stop while its hopefully reversible.

Take care

I normally see an internal medicine doctor and have been to see the pulmonologist twice so far with another appointment next week. I'm trying one more medication next week that just got approved by the insurance company, if this doesn't help I will probably see about going to the Mayo clinic to see if they can do anything to help. I had asthma as a kid and still take medicine for it but I don't think it is asthma. They insist that is what the problem is but everything they throw at it doesn't help. There are days I can't even walk my dog. I've wore a respirator for the last 4 or 5 years because I wanted to take care of myself after talking to some of the older welders out there.

Anyone here ever build a rocket stove? Got a hankering to build a small to medium scale, hopper fed, pellet burning version. And yes I know I can buy one already but where’s the fun in that. Looking at dimensions and scale from anyone that has. Trying to heat a small space maybe and doesn’t have to heat it all. Thanks

Similar threads

- Replies

- 0

- Views

- 570

- Replies

- 16

- Views

- 2K

- Replies

- 13

- Views

- 2K

Precision Rifle Gear

Tango Innovations FIRE4000 WMLRF Initial Impressions

- Replies

- 346

- Views

- 28K