Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maggie’s The Welding and Metalworking Thread

- Thread starter bogeybrown

- Start date

Damn gents, those are some motivational projects. I knew @sirhrmechanic would have some militaria to drool over but I can't wrap my head around that trailer that @Geno C. fabbed. With today's steel prices a lot of the "normal" backyard projects are basically cheaper to buy, which sucks. I can't imagine doing that riveted trailer in today's market.

@timesublime , do we even want to ask how sick of a deal you got on a full rod oven?

@Snipe260 , @oneshot86 has talked to me about the mobile rig. He used to make a nice living with one down in FL. I'm a ways from being good enough to show up on "any" job and being able to handle it, but it's in the mental pipeline. Also, down here just about every other person is, was, or knows a welder so there's a fair bit of competition to do it commercially. However, momma is on board with the idea of working towards a pipeliner rig and 5th wheel so we can go on the road. We're looking at doing a pipefitting program together while I continue to build my welding skills. It's a long shot at this point, but she's excited about having an even bigger truck with lots of machines on it regardless.

@Sean the Nailer , you couldn't have summed it up better. I've put the word out to all my buddies with machines that I am donating as much time as I can possibly make available to anyone working on backyard and side commercial projects. If they come through I should be working on a number of smokers and cooking trailers, and another guy has offered to start teaching me stick and TIG pipe on his drops from an XRay job he's working on.

All in all I've been pretty fucking frustrated with the class I'm in and all the things they've consciously decided I don't need to know. I have never before asked how to do so many things only to be told that I "won't need to know that". It's fucking ludicrous. The instructor that runs the Fitting program has seen my frustration and has been awesome answering the questions that others dismiss. He's even extended me an invitation out to his personal shop on the weekends to work with him which was a huge and apparently very rare honor for a beginner-level student.

when you get edumacatered up, ill let you use one of my mobile machines, prolly the 280 NT for your truck if you want, till you get your own machine, itll take the edge off of buying shit right at first...

in the mean time, you can come pick up and borrow my dial arc 300, leads, tig torch, water cooler, what ever you need that im not using.

hook that bitch up in your garage and practice like a mofo

nothing like bribeing a dude to come drink beer, naw, nelson is a good dude and a friend...

when you get edumacatered up, ill let you use one of my mobile machines, prolly the 280 NT for your truck if you want, till you get your own machine, itll take the edge off of buying shit right at first...

in the mean time, you can come pick up and borrow my dial arc 300, leads, tig torch, water cooler, what ever you need that im not using.

hook that bitch up in your garage and practice like a mofo

nothing like bribeing a dude to come drink beer, naw, nelson is a good dude and a friend...

Damn brother, I'm fucking choked up at such an amazing offer. If you have a "spare" Trailblazer maybe think of what I can offer in trade for it?

Either way, be dreaming up a project for me to come down and help on once I'm finished with school (mid August). My skills ain't there yet, but I'll burn rods until the machine needs a break.

You're the best, my friend. I'm looking forward to the next trip down, hopefully with momma.

Bogey, you've been granted 'next level' opportunities (plural) for SURE. You're a good man, Oneshot!

im not interested in selling anything, but if im not using them, kinda reckless to let shit just sit around, have at it, and it will give you the time to by right

I started by going to Brazosport College in a machnist/millwright program. I went to a shop in town that I hoped to work for, and they wouldn't even let me leave a resume. Then I met the nephew of the machine shop foreman in a class, and he was impressed with what I could do on a machine already. I got an interview, got the job, and the company paid for the rest of the classes for my associate's degree. I had classes at night in the middle of my shift, and about half the time I was allowed to stay clocked-in.Looking to get into "Machining", basically what I would need to know in order to build a rifle. Chamber, Thread, etc. Pretty much lathe work, maybe some milling.

Been trying to look at local VoTech Programs, not really having any luck.

Could anyone please advise how & where you got your education & training?

When I left (because I was moving) I was making $28.10 an hour. Cost of living is super low here in Texas, so I was living good.

Any more questions?

im not interested in selling anything, but if im not using them, kinda reckless to let shit just sit around, have at it, and it will give you the time to by right

Fair enough, I'll get you liquored up on Natty Light and keep working on a deal.

In all seriousness, I think I remember you saying you occasionally came across the welding/generators at fair prices. If you spot one let me know. Or if you change your mind I've got silly gun stuff to offer in trade.

I'm not seeing it. Did the tongue crack by the gussett?

Can't see crap on the phone.

Okay,

What do you want in trade for that GMC pickup or Suburban that's sitting there behind you? Rebecca would love that.

It's a '58, right?

Can't see crap on the phone.

Okay,

What do you want in trade for that GMC pickup or Suburban that's sitting there behind you? Rebecca would love that.

It's a '58, right?

Last edited:

Lol, so the hitch was wore enough that it came unhooked at 60mph. Guy drug it about a half mile because you can't see or feel it behind the first trailer. It drive the inner part of the jack through the top of the upper part. Had to cut it out and weld in a new one. Couldn't be a simple bolt on job like most are...

Now that '58 gmc will never leave. It's my father in laws and his dad bought it brand new. It was what he remembers growing up. I finally got him to get it out of the mothballs and get it running 2 years ago. Now I have to keep after him to get the brakes fixed. It's cool as hell! Not in show room shape but easily fixed to look close. It shows a few dings and corner rust. Me buying the 57 ford really got a little fire under him with this one since I drive mine every day I can

Now that '58 gmc will never leave. It's my father in laws and his dad bought it brand new. It was what he remembers growing up. I finally got him to get it out of the mothballs and get it running 2 years ago. Now I have to keep after him to get the brakes fixed. It's cool as hell! Not in show room shape but easily fixed to look close. It shows a few dings and corner rust. Me buying the 57 ford really got a little fire under him with this one since I drive mine every day I can

Had to slap together a couple hitch handles. Curved factory ones get the the way and my in laws' broke.

Wanted to try a flat bottom on the RPR. Still need to blend a couple welds and lighten it up where I can. Think I'm gonna shoot it for a bit first, though. No sense in making it purdy if I decide not to run it.

Lol, so the hitch was wore enough that it came unhooked at 60mph. Guy drug it about a half mile because you can't see or feel it behind the first trailer. It drive the inner part of the jack through the top of the upper part. Had to cut it out and weld in a new one. Couldn't be a simple bolt on job like most are...

Had something similar happen last fall except single trailer and after dark. First I knew something was wrong was when I saw sparks, then when I started to slow down trailer starts going perpendicular to the road down the other lane trying to pass the truck. Stomped on the gas to straighten up and when I came to a stop I was about 100 yards away from the trailer which was setting in the middle of a line on 81 with no lights.

Bogey take full advantage of that instructors offer.

I can't believe the class is wasting time teaching you how to make crap welds on improperly prepared material. Plus instructors should be willing to answer RELEVANT questions.

I can't believe the class is wasting time teaching you how to make crap welds on improperly prepared material. Plus instructors should be willing to answer RELEVANT questions.

Back in High School I was the best arc welder in my class and debatable in the entire school. Oxy-acetelyn on the other hand I wasn't as good. Had a bad habit of not turning the gas off the right way and always got that loud ass pop that scared the hell out of the class and pissed off my teacher.

I build junk with metal from the scrap pile out of necessity.

Attachments

-

E1BA9A73-D2F9-451C-992A-9188CC6BE54C.jpeg407.9 KB · Views: 368

E1BA9A73-D2F9-451C-992A-9188CC6BE54C.jpeg407.9 KB · Views: 368 -

BE925189-7571-486B-BFAA-1C0B54DB1BF2.jpeg400.8 KB · Views: 358

BE925189-7571-486B-BFAA-1C0B54DB1BF2.jpeg400.8 KB · Views: 358 -

D435D982-55D7-49F3-ADC0-9B1048C70382.jpeg430.1 KB · Views: 364

D435D982-55D7-49F3-ADC0-9B1048C70382.jpeg430.1 KB · Views: 364 -

4E4A587E-E449-437D-8C74-71F4D521F895.jpeg418.8 KB · Views: 348

4E4A587E-E449-437D-8C74-71F4D521F895.jpeg418.8 KB · Views: 348 -

A3B147EA-F65E-42A9-A031-73B5A23CA764.jpeg421.9 KB · Views: 362

A3B147EA-F65E-42A9-A031-73B5A23CA764.jpeg421.9 KB · Views: 362 -

AD533EF0-346F-4E90-BE6D-2AB9F232FB6E.jpeg410.1 KB · Views: 361

AD533EF0-346F-4E90-BE6D-2AB9F232FB6E.jpeg410.1 KB · Views: 361 -

E9BFA607-CC6C-4BFC-95CD-1C4E0B65CCD7.jpeg297.4 KB · Views: 360

E9BFA607-CC6C-4BFC-95CD-1C4E0B65CCD7.jpeg297.4 KB · Views: 360 -

0FBA2207-CEB6-45A4-86E2-9C447CD41AD3.jpeg184.1 KB · Views: 388

0FBA2207-CEB6-45A4-86E2-9C447CD41AD3.jpeg184.1 KB · Views: 388 -

45F82C1D-824B-4AB0-AFFD-62C60E373F69.jpeg500.6 KB · Views: 349

45F82C1D-824B-4AB0-AFFD-62C60E373F69.jpeg500.6 KB · Views: 349

If you mean the first pic in his first post, it sure looks like a calf puller to me.@McNamara, that device with the come-a-long on it.... wassat?

Bogey take full advantage of that instructors offer.

I can't believe the class is wasting time teaching you how to make crap welds on improperly prepared material. Plus instructors should be willing to answer RELEVANT questions.

Oh I'm definitely taking him up on it.

The school is run through the State as a job-skills development / career placement initiative. They are geared toward teaching the bare minimum skills in the time they have in order to get you hired on to the shipyards, which have traditionally been the big employers.

We recently had to "declare" if we were going to test for the shipyard or not. If so, you spend the rest of the school practicing for that test. If not, you work on a slightly different program with a tiny bit more flexibility. However, their mindset is still that of what you'll be welding every day as a beginning welder in a shipyard. Here's what's killing me, out of 15 of us, only 3-4 want to go to the shipyard; the rest want to learn general fab and pipe.

Here's some examples of what I've been told in the past few weeks:

Me: can you show me how to run a downhill 6010

Instructor/s: we don't want you running 6010 downhill, you won't need to do that

Me: I've been running fillets on T-joints (inside corners), would it be okay to set up a corner joint to work on outside corner welds

Instructor/s: nah, pretty much all you'll be welding are "T"s and V-grooves

Me: can we work on some other fit-ups like lap joints or square butts (we only do V so far)

Them: nah, those aren't good joints to begin with and you won't need to be able to do those

We've even been told that as Welders it's not important for us to be good on cutting equipment, because the Fitters handle that.

I know I'm being pissy. This school is a great opportunity. I had to compete heavily for a slot and it's conducted free of charge through the State. The instructors are all highly experienced guys from the Yards who could be making big checks with a whip in their hands but they've chosen to teach at a State School instead. The equipment is top-notch and all they ask is that we not waste materials because it's tax-payer funded and they legitimately give a shit that we're not wasting what's granted to us.

For the young guys it's a huge opportunity (I'm the oldest guy in my class). It's run like an actual job with a time clock and zero tolerance for absence or tardiness. They keep a permanent record of every minute you miss to be shared with potential employers. So the "kids" are learning valuable skills aside from welding. For some of us of older guys it's a great way to learn/develop a new skill while still working during the day. The "disconnect" for me is from having attended and taught so many courses over the past 25 years or so, I've never run into such a predetermined limit on what you can learn.

Either way, I realize how many people applied and were passed over for me to get a slot and I am determined to complete the course with a perfect attendance record and get everything I can from it. I watch hours of instructional videos to fill in gaps, and donate my time to everyone I know who has a machine and a project to work on. I WILL get good at this, one way or another.

Who knows that a "weldor" is the person doing the welding, whereas, a "welder" is the machine, generator, transformer, piece of electrical or Oxy/acetelene equipment that lets the "weldor" do what he or she does?

An OLD term not used a lot today but in years past it is correct. FM

An OLD term not used a lot today but in years past it is correct. FM

Who knows that a "weldor" is the person doing the welding, whereas, a "welder" is the machine, generator, transformer, piece of electrical or Oxy/acetelene equipment that lets the "weldor" do what he or she does?

An OLD term not used a lot today but in years past it is correct. FM

I recently ran across that distinction in an older book I bought to study up. I thought it made sense.

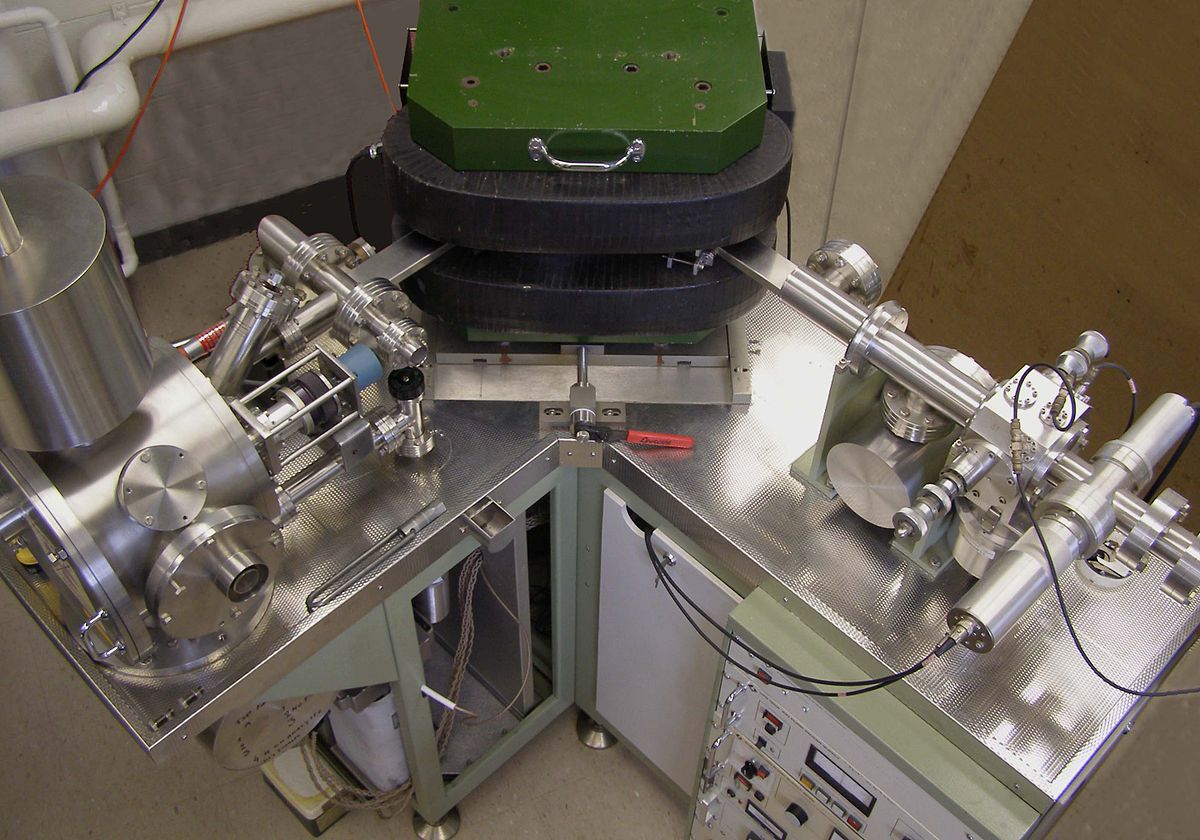

I learned something new at work. Our mechanical and manufacturing guys decided on using the Friction Stir welding process to seal an enclosure that we fill with Helium.

There are some online videos which show this process.

There are some online videos which show this process.

Last edited:

Is that a Tilt-a-whirl?View attachment 6919848View attachment 6919849So we had a little mishap on the way home yesterday. So much for the day off. We cut out the old hitch and welded in a new one.

These days my big projects are done in a group with plenty of enthusiastic beginner welders so they do the easy stuff and we have a couple certified welders for anything that needs an engineer sign off.

I wind up working in design, detail stuff like storage racks, making sure the mechanical assemblies don't suck and introducing "new" techniques and materials to the group.

My small projects happen when I line up enough gunsmithing tasks and hammer them out over night when I can get the shop to myself.

Once upon a time I did short run and prototype fabrication for various tech companies and race car stuff. Before that I worked in research and got to play with some very exotic materials. When I was in highschool I fooled around with steam engines, cars, Tesla coils and potato guns.

I had one quarter of "formal" student machine shop training. Everything else self taught or on the job.

I needed too much education to pursue research work, fabrication was fun but didn't pay the bills so I wound up doing something else. It is a well developed hobby for me.

As a kid I was gopher in a machine shop that repaired heavy construction equipment and built all kinds of steel equipment for pipeline construction. So I got some basic metalworking and welding instruction, but mostly I helped with setup. In school, I learned quite a bit about design and manufacture of high vacuum instrumentation, things like mass spectrometers and X-ray spectrometers. These are made from stainless and my welding skills were inadequate so rather than wasting the expensive stainless, I worked more on the machining end and let the experts do the welding. This continued when I went into industry, except that the people I worked with were exceptionally skilled, so there was no way I was going to screw up the projects. So the pictures I'm attaching are just examples of the scientific equipment, not instruments I worked on.

I'm not carnival folk so I'm not sure on the names of your amusements.Really? You're joking right?!

I was the same with the lab equipment. Once I knew what the staff welder liked, I prepared all the joints and clamped it up for him. We got all of our stuff done quicker because he didn't have to interpret drawings or attempt impossible welds called out by graduate students.

After the first pass it was helium leak detector time and occasionally we had to go back over a pinhole or two but usually only when we were using special alloys.

Hi,

@TripleBull

Is that first picture the International Space Station Coffee maker and the second picture the International Space Station Paninni maker?

Sincerely,

Theis

@TripleBull

Is that first picture the International Space Station Coffee maker and the second picture the International Space Station Paninni maker?

Sincerely,

Theis

Not carnie folk?! Doubt you could hack it ? the tilt a whirl is Americans number 1 ride. Should be easy to spot. And just a hint. It looks nothing like the pictureI'm not carnival folk so I'm not sure on the names of your amusements.

I was the same with the lab equipment. Once I knew what the staff welder liked, I prepared all the joints and clamped it up for him. We got all of our stuff done quicker because he didn't have to interpret drawings or attempt impossible welds called out by graduate students.

After the first pass it was helium leak detector time and occasionally we had to go back over a pinhole or two but usually only when we were using special alloys.

This past week we had a guest instructor pop into the school and he motivated the hell out of us. This guy is in his early 30's and is a a true "Golden Arm" badass of a welder and teacher. We flocked to him like pigeons on popcorn and he got a lot of us over some individual hurdles we'd each been having. It's amazing how one dude with a true love of what he does, and passing it on to others, can motivate you to be better.

Personally I'd been struggling to figure out why my welds consistently broke down at the same place on every plate. I asked him for some help and he spotted it in about 15 seconds: I was setting my hands on fire at the same place on every one of my vertical passes, causing my arc length to increase as I was trying to keep my hands out of the fire.

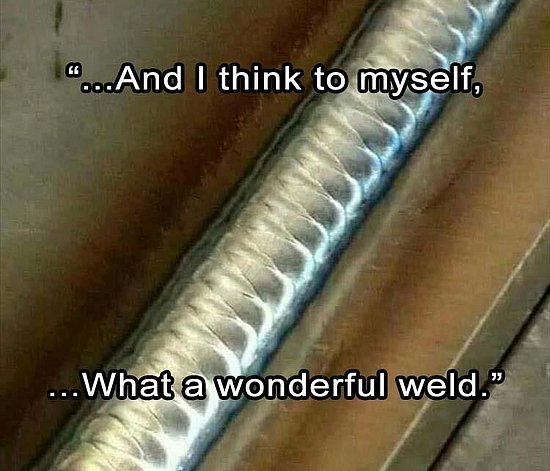

Here's an example of what I was dealing with:

You can see where the bead goes from good to shit at the bottom of the picture (plate is upside down) just from me not being able to keep my hands in position as the rod burned down.

Man I wish this guy could've stuck around, but he's off on a hugely lucrative new job this weekend until the beginning of October. We did exchange numbers though, and he's offered to let me come help him on some of his side jobs and at his shop once he's back in town. I continue to be humbled by the generous spirit of guys willing to share their time and knowledge with an old guy just starting out.

Personally I'd been struggling to figure out why my welds consistently broke down at the same place on every plate. I asked him for some help and he spotted it in about 15 seconds: I was setting my hands on fire at the same place on every one of my vertical passes, causing my arc length to increase as I was trying to keep my hands out of the fire.

Here's an example of what I was dealing with:

You can see where the bead goes from good to shit at the bottom of the picture (plate is upside down) just from me not being able to keep my hands in position as the rod burned down.

Man I wish this guy could've stuck around, but he's off on a hugely lucrative new job this weekend until the beginning of October. We did exchange numbers though, and he's offered to let me come help him on some of his side jobs and at his shop once he's back in town. I continue to be humbled by the generous spirit of guys willing to share their time and knowledge with an old guy just starting out.

After a few months your hands will toughen up and deal with the heat better.

Since you are essentially beating the metal to conform to your will, power comes in handy but the best welders and fabricators will combine that with a good amount of finesse.

You might want to try some of the heavily insulated MIG gloves.

Since you are essentially beating the metal to conform to your will, power comes in handy but the best welders and fabricators will combine that with a good amount of finesse.

You might want to try some of the heavily insulated MIG gloves.

Bogeybrown what plate test are you working on?

If I were going to test for the shipyard I'd be working on 3G with backing strap on 3/8" plate both Stick 7018 and Flux Core with 6010 root.

Because I'm on my own program I'm working on V-groove open butt, no backer, 5/8"- 1" plate 6010 root and 7018 fill and cap (and some variations thereof) in all positions as well as some FCAW. I can actually go from 3/8 - 1" , but if they're gonna allow me and furnish me essentially unlimited coupons, I'm welding the thickest stuff I can possibly practice on.

I should've mentioned that my flat and horizontal was going well, bUt my hand position in vertical was causing me to burn my hands, especially having to burn rods down to the numbers with a 1" thick plate.

Thin is a good thing to learn, if you're not working at a ship yard, building bridges, skyscrapers or heavy equipment, 3/8" will be a really big weldment.

With TIG, thin makes you learn how to go fast.

Real hot dogs can TIG weld aluminum cans together.

The best I can claim is that I'm pretty good at chasing holes.

With TIG, thin makes you learn how to go fast.

Real hot dogs can TIG weld aluminum cans together.

The best I can claim is that I'm pretty good at chasing holes.

Seems like your on the right path, I have my 6g for structural. Iv been working on my 6g for process pipe but that 6010 open root has been kicking my butt. Keep up the good work.

Haven't done alot of welding outside school and minor projects around the house on a crappy harbor freight welder.

I did learn that my BAD ASS underarmour gear that was bitching and brand new and like 300 bucks...... Likes to melt when it gets hit with splatter when arc welding.... Still have the scars

I did learn that my BAD ASS underarmour gear that was bitching and brand new and like 300 bucks...... Likes to melt when it gets hit with splatter when arc welding.... Still have the scars

Similar threads

- Replies

- 0

- Views

- 565

- Replies

- 15

- Views

- 2K

- Replies

- 13

- Views

- 2K

Precision Rifle Gear

Tango Innovations FIRE4000 WMLRF Initial Impressions

- Replies

- 346

- Views

- 28K