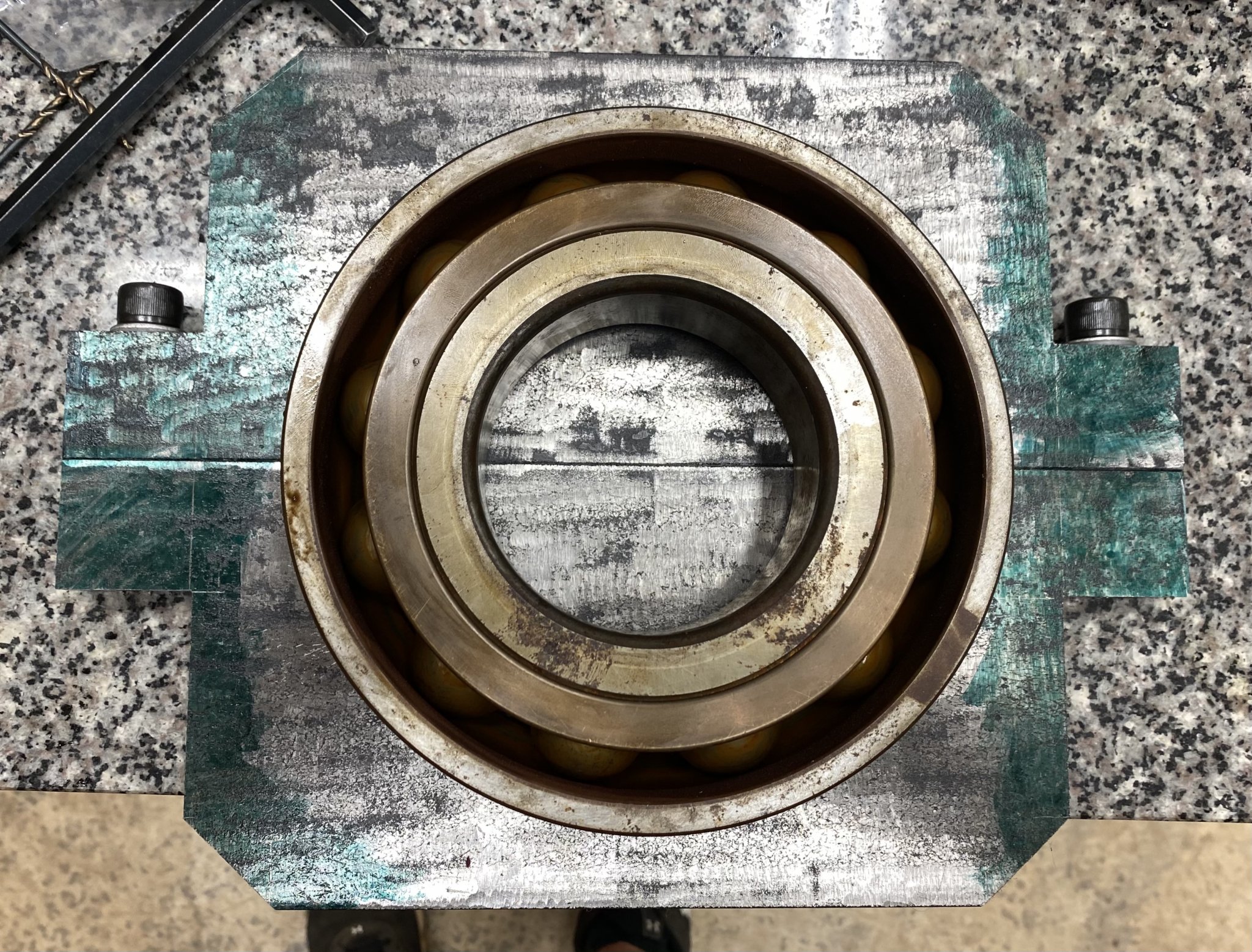

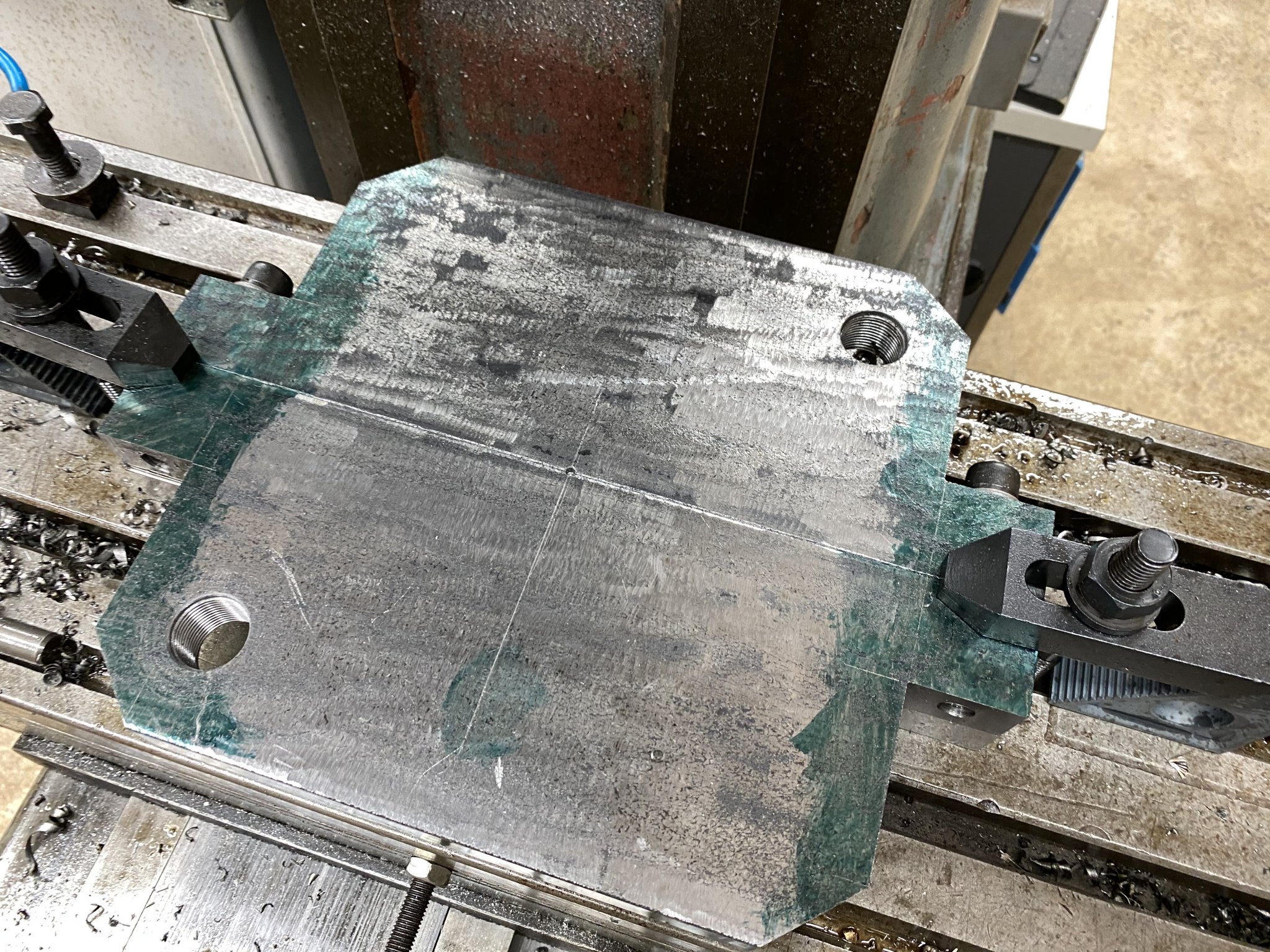

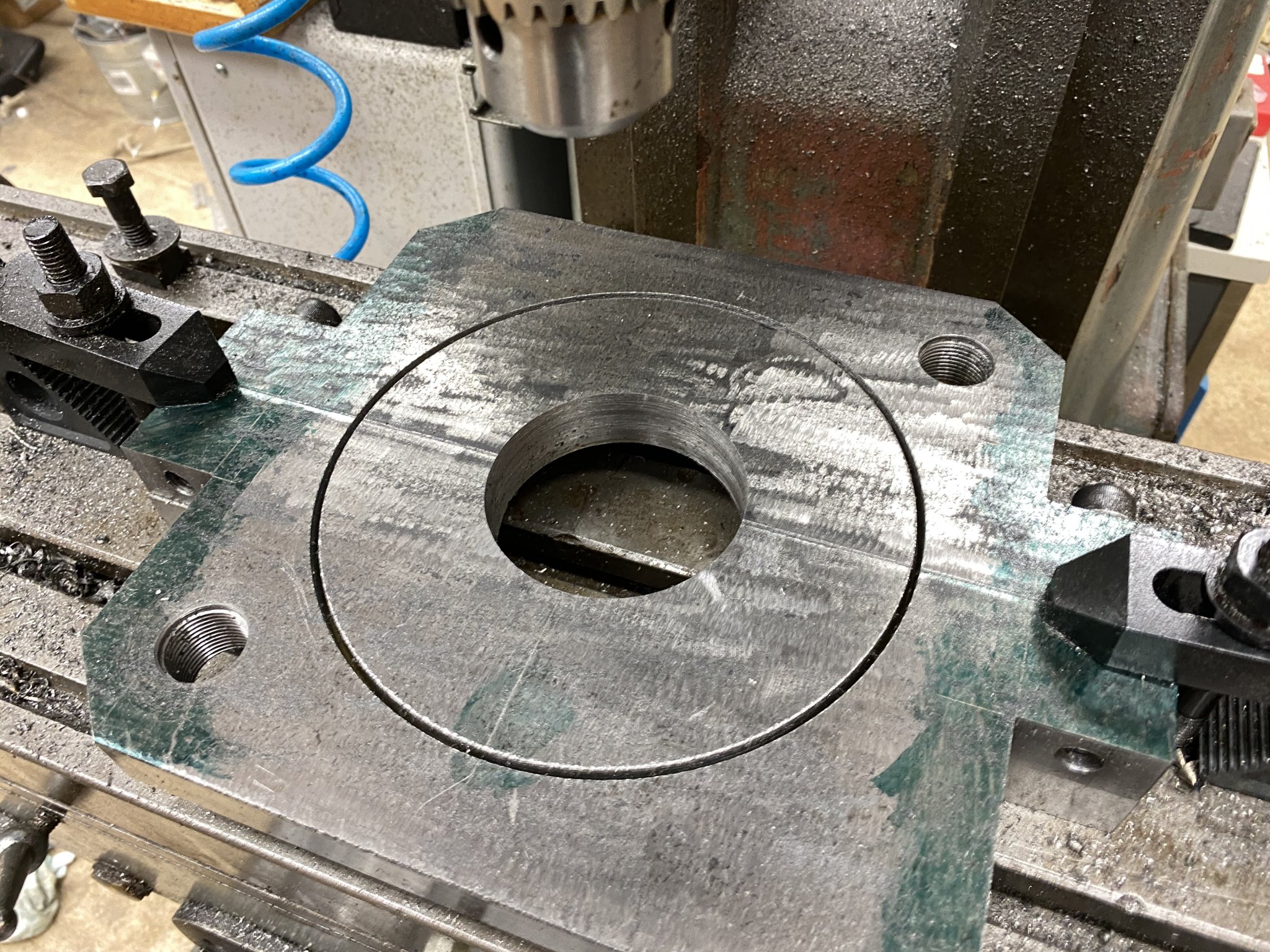

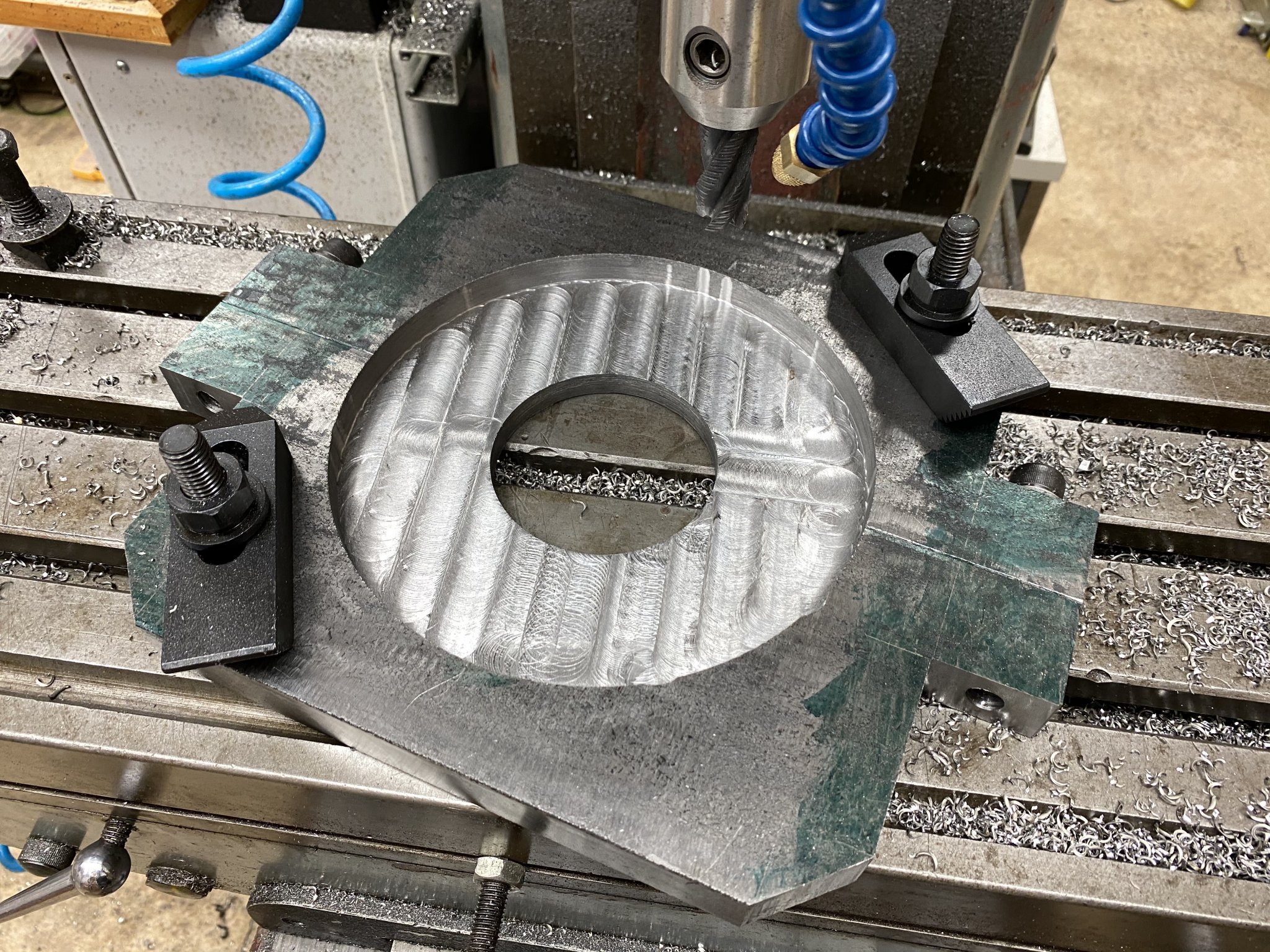

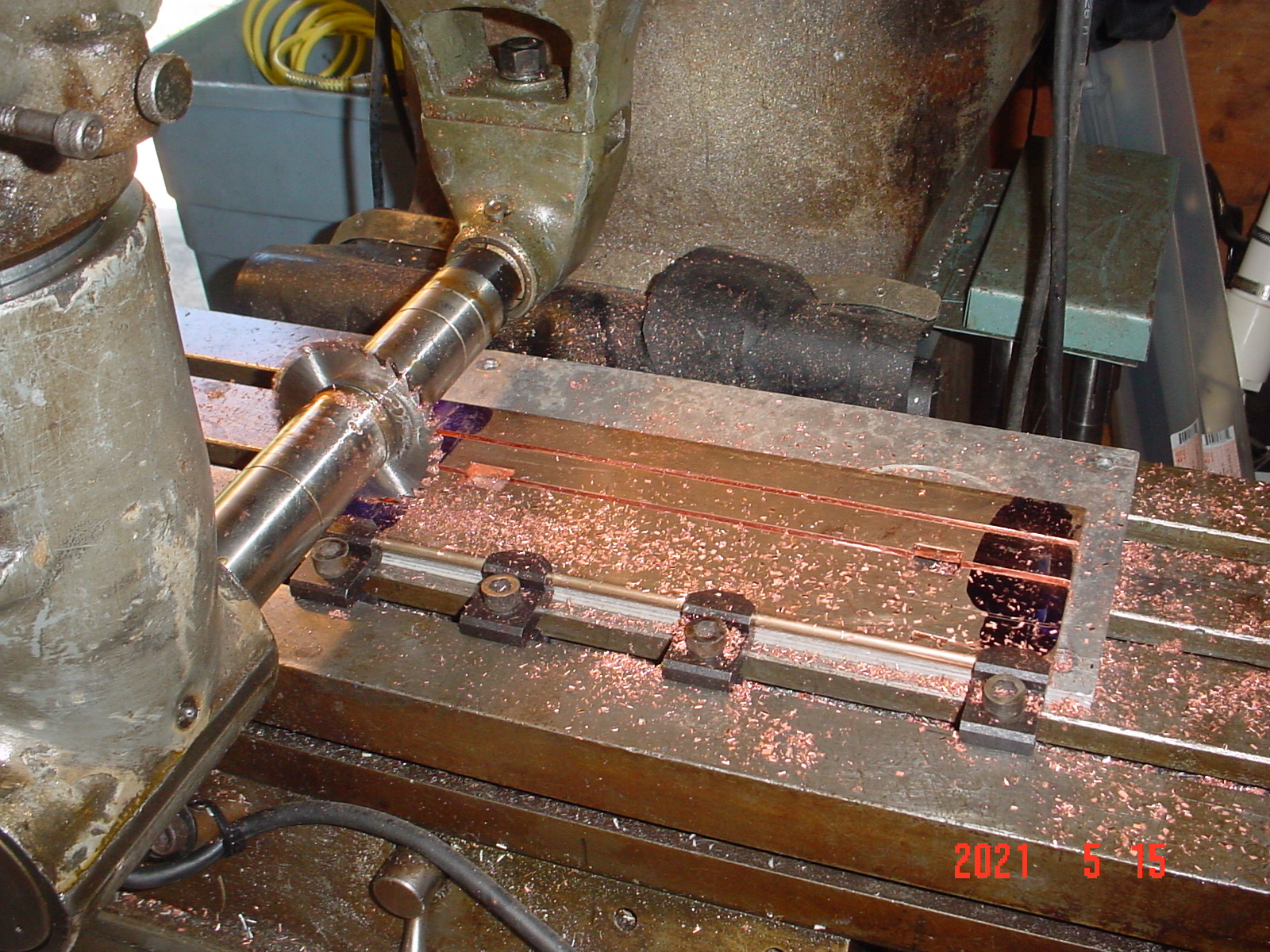

Bearing puller plates I’m making for a local commercial hvac company. Small one they used earlier in the year and I’m just finishing up the big one now. Big bearing is 7-1/2” plates are 13”x10”.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maggie’s The Welding and Metalworking Thread

- Thread starter bogeybrown

- Start date

I don't know if I have posted anything of the 64 Impala SS I've been resting for a guy, but this is my latest metal work. This was the quarter panel test fit, the driver's side quarter is already done.

Damn, there is some time in that. Nicely done.View attachment 7689516 Three passes of Hastelloy overlay to resurface a manway. About 3/8" of buildup.

PITA!!

I had about 7 hours today in fab/welding the sliders for my K30. Decided to incorporate the front cab mount into the slider. Came out pretty trick. And the transfer case is rebuilt and ready to mount the magnum box & paint. Couple more Sundays and I can wheel the frame out for blasting and Steel-It. The fun part begins.

Attachments

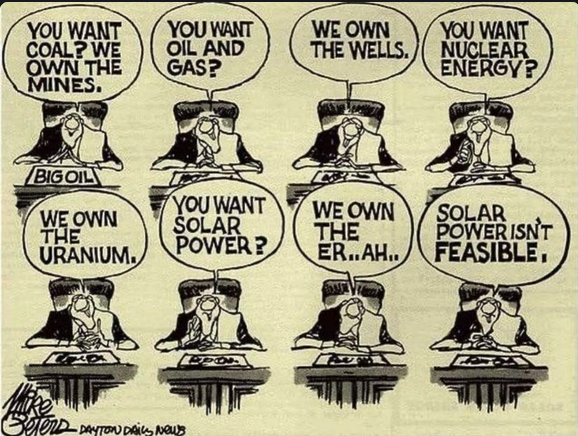

Did a solar project here over the Winter.

Found a place in the yard that gets the most Sun, ordered 210 ft. of Schedule-40

galvanized 1-1/2” pipe to make the frame for the solar panels.

Used the fence post auger w/ extensions to bore the holes for the concrete piers.

Built the frame, mounted the panels, ran conduit & cable 200 ft to the building w/ the electronics.

Made some buss bar from copper flat bar for connecting the batteries.

Found a place in the yard that gets the most Sun, ordered 210 ft. of Schedule-40

galvanized 1-1/2” pipe to make the frame for the solar panels.

Used the fence post auger w/ extensions to bore the holes for the concrete piers.

Built the frame, mounted the panels, ran conduit & cable 200 ft to the building w/ the electronics.

Made some buss bar from copper flat bar for connecting the batteries.

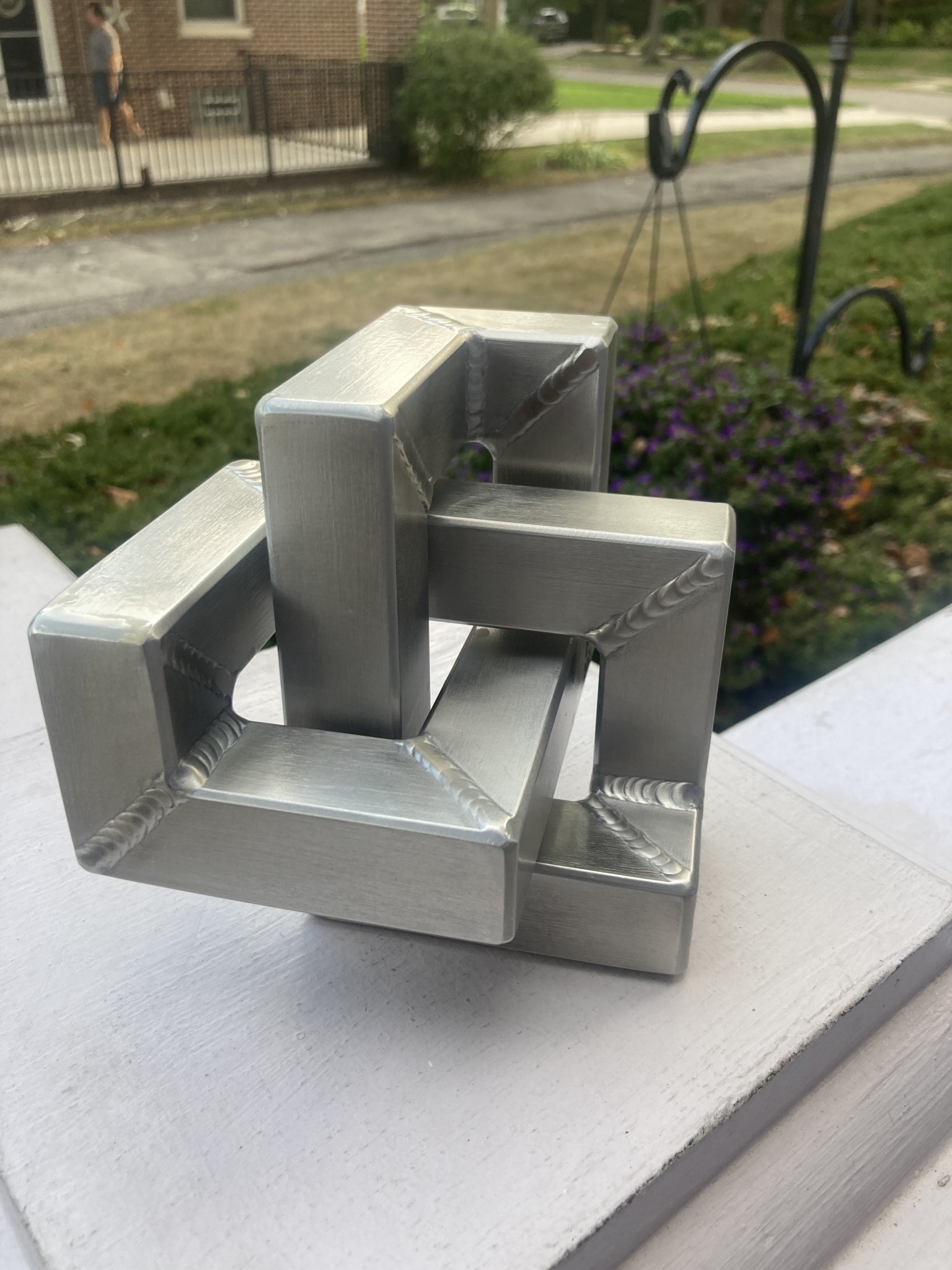

Buddy of mine, bored with retirement and out of projects has turned to artwork..

One does not “turn to” Artwork. One is an artist, or one is not.

Just because he earned a living as a welder does nothing make him any less of an artist than Picasso or Van Gogh or Henry Moore.

Good welders are artists no matter what they do to feed their families.

“Turning to Art” is simply a case of starting to weld to the print in their head… not the one some engineer hands them.

Beautiful work!

Sirhr

Just because he earned a living as a welder does nothing make him any less of an artist than Picasso or Van Gogh or Henry Moore.

Good welders are artists no matter what they do to feed their families.

“Turning to Art” is simply a case of starting to weld to the print in their head… not the one some engineer hands them.

Beautiful work!

Sirhr

More recent projects:

A receiver trueing chuck.

A 2 axis floating reamer holder/collet chuck

It takes ER20 collets. It floats both axially and radially, and the float feature can be locked by tightening the knurled ring, for rigid drilling/tapping:

Some lead molds, for a local business that makes leather saps.

A replacement speed range chart for my manual mill.

A magnetic quick detach adjustable cheekrest for my FN SPR.

I went through my lathe and replaced the spindle bearings with P5 Timkens, installed a new Siemens 3 phase motor, realigned the headstock.

While apart I added a slide-out chip tray, and powder coated the stand.

I cut the hole, and riveted in some support.

Then did some cleanup and powder coat.

A receiver trueing chuck.

A 2 axis floating reamer holder/collet chuck

It takes ER20 collets. It floats both axially and radially, and the float feature can be locked by tightening the knurled ring, for rigid drilling/tapping:

Some lead molds, for a local business that makes leather saps.

A replacement speed range chart for my manual mill.

A magnetic quick detach adjustable cheekrest for my FN SPR.

I went through my lathe and replaced the spindle bearings with P5 Timkens, installed a new Siemens 3 phase motor, realigned the headstock.

While apart I added a slide-out chip tray, and powder coated the stand.

I cut the hole, and riveted in some support.

Then did some cleanup and powder coat.

Last edited:

Been thinking about putting a staircase in my barn/office for a long time to access the loft. Finally had an excuse to put my drawings to metal with hunting season coming. I definitely went overkill on the materials. Still have to finish the wall railing and a post at the top of the stairs. Pretty stoked for my first crack at staircase. Had a structural engineer buddy come over and inspect - he laughed.

Can't post to many revealing pics, but this is what I have going on in the shop right now.

Its an 82mm (3.25" for us mericans) pneumatic artillery cannon for triggering avalanches. It shoots a 2.5 lb explosive payload with a range of 2500 meters.

I do lots of pressure vessels and stainless usually, but got rather excited when this project rolled in the door.

Really hope we get to test fire it

Its an 82mm (3.25" for us mericans) pneumatic artillery cannon for triggering avalanches. It shoots a 2.5 lb explosive payload with a range of 2500 meters.

I do lots of pressure vessels and stainless usually, but got rather excited when this project rolled in the door.

Really hope we get to test fire it

Attachments

Last edited:

Here’s a larger version I didn’t know he made

He’s a self taught welder and fab man

He’s a self taught welder and fab man

Planning the same for my Dodge 3500. WI had about 7 hours today in fab/welding the sliders for my K30. Decided to incorporate the front cab mount into the slider. Came out pretty trick. And the transfer case is rebuilt and ready to mount the magnum box & paint. Couple more Sundays and I can wheel the frame out for blasting and Steel-It. The fun part begins.

Planning the same on my Ram 3500. What gauge wall thickness did you use?

3/16”. Quarter wall would have been overkill.Planning the same on my Ram 3500. What gauge wall thickness did you use?

real cool...Can't post to many revealing pics, but this is what I have going on in the shop right now.

Its an 82mm (3.5" for us mericans) pneumatic artillery cannon for triggering avalanches. It shoots a 2.5 lb explosive payload with a range of 2500 meters.

I do lots of pressure vessels and stainless usually, but got rather excited when this project rolled in the door.

Really hope we get to test fire it

and why have you been hiding this from us and can we have the drawings

please

Oh trust me, I want one really bad too! The actual barrel is 12' long and the entire thing mounts on a 360° azimuth plate.real cool...

and why have you been hiding this from us and can we have the drawings

please

I'm an avid snowmobileererer and have lost a friend in an avalanche, so this one really scratches the itch... I have a pipe dream of mounting one of these on the back of a snowcat and doing avalanche mitigation in the popular backcountry riding spots.

But just like all good things in life, these bad boys ain't cheap! Plus I cant imagine the pile of paper work you have to do to get clearance to use one of these in the intended fashion.

Another new toy for the shop (assuming I can get it running again). First GovPlanet purchase. Fees/taxes add 25%  but otherwise easy pay/pickup vs old DRMO.

but otherwise easy pay/pickup vs old DRMO.

- Nov 3, 2010

- 10,541

- 23,113

Nothing super serious like you fellas are churning out. My youngest is carrying the flag for the opening ceremony of a small horse show. She wanted to use a wood flag pole, so I’m staining and adding a topper for her.

Had to help a coworker out yesterday. Seems Ford made some frame rail changes between 2011 and now, so his bed slide brackets didn’t fit his new F250. A little time on the waterjet, two bends on the press brake and a little rattle can.

View attachment 7706277View attachment 7706278View attachment 7706279View attachment 7706280

Great job! Why can't I have friends like you???????

My friends come to me for help.

Built the front of this pos. Has a 6.0 ls/4l80e swap, 4 link some day….

These bumpers i built. Kinda hard to see the finer parts of them, but eh they look decent in person. I only do it when i feel like it, no big shop or tools. 90% grinder, 8% welder and 2% skill. I borrowed a bender for round tube, i never took a class and never worked at a shop. The swinger works better than 95% on the market, just wish i had built it on the face of the bumper, double shear. It just uses a trailer spindle.

I made a mount, to install a vertical linear scale on my mills quill.

Here's the mount and scale mocked up after machining.

Here are the parts, fresh out of the oven. In Cerakote midnight bronze. (A mix of 75% burnt bronze and 25% graphite black)

Here's a better view of the color.

how to upload pictures to the internet

how to upload pictures to the internet

Here's the transfer bar, with the brass locking pin. The brass pin is driven by a setscrew, that passes through the bar at an angle.

Took a little time aligning the scale, but got it to under a thou, over a span of 5".

It uses 3mm setscrews, from the back to lock the scale down.

The lower mount

And, the finished product .

upload and share pictures

upload and share pictures

Here's the mount and scale mocked up after machining.

Here are the parts, fresh out of the oven. In Cerakote midnight bronze. (A mix of 75% burnt bronze and 25% graphite black)

Here's a better view of the color.

how to upload pictures to the internet

how to upload pictures to the internetHere's the transfer bar, with the brass locking pin. The brass pin is driven by a setscrew, that passes through the bar at an angle.

Took a little time aligning the scale, but got it to under a thou, over a span of 5".

It uses 3mm setscrews, from the back to lock the scale down.

The lower mount

And, the finished product .

upload and share pictures

upload and share picturesQuick project for today....

Needed a shotgun forend wrench for an upcoming project....

Being too cheap to spend $10 to buy one.....I decided to spend $15 on materials and $100 of my time and machined one up instead.

View attachment 7708854

View attachment 7708855

Fit is perfect, which is surprising considering I pulled all the dims out of my ass.

I've made a few of them during my time. I have a habit of eiither throwing them away or losing them, so I make one just about every time I need one.

Luckily, they aren't too difficult to make.

Last edited:

I am a backyard farm shop welder. I'm looking for beer, Copenhagen and a willingness to work with no complaints about the lack of pay. It usually works out because most of the time the help is somebody needing me to fab something for them.

They should be able to read a traditional vernier scale and a traditional micrometer. Before they are ever allowed to touch a digital one. Even though Digital micrometers and verniers are everywhere these days, understanding how the scales work is important. Batteries aren’t always available.question for yall...

1) for those of you that work in/ run a shop....what metrology skills would you like to see from new hires.

2) do any of yall have a text on Metrology that you particularly like.

ive been tasked with developing a new GD&T/ Metrology course...trying to get an industry perspective on what yall are looking for.

They also should be able to use Gage blocks and standards in order to check The settings And the zeros.

That should be absolutely basic.

Unfortunately these days you probably even have to teach them how to use digital.

Sirhr

The new hotness going in the garage this week

Man, this could turn into a bitch session real quick. Couple things that stick out to me that are related to your question:question for yall...

1) for those of you that work in/ run a shop....what metrology skills would you like to see from new hires.

2) do any of yall have a text on Metrology that you particularly like.

ive been tasked with developing a new GD&T/ Metrology course...trying to get an industry perspective on what yall are looking for.

1. How to use a set of calipers. How much force to get an accurate measurement and the various ways they can be used. And when they shouldn’t.

2. How to read micrometers including the tenths

3. GD&T. All of it, with living examples.

3.a And while I’m at it, how to use concentricity callouts and when it shouldn’t be used. Seriously. Yup

3.b true position for holes. What the true implications of a 0.002” call out really is for the part and the machining. And then how to use the hole tolerance to push it into spec if needed. This is the more practical side of it all, but if they can think like that then they are saving money not bleeding it.

"The new hotness going in the garage this week"

How bout a pic of the two-tone Beauty in the background!!

How bout a pic of the two-tone Beauty in the background!!

If you can't run a grinder, tape measure, or broom, expect them to be thrown at you while being called lots of names.question for yall...

1) for those of you that work in/ run a shop....what metrology skills would you like to see from new hires.

2) do any of yall have a text on Metrology that you particularly like.

ive been tasked with developing a new GD&T/ Metrology course...trying to get an industry perspective on what yall are looking for.

Not my rules, I just follow them

And this... is the best thing yet!!!If you can't run a ... broom, expect them to be thrown at you while being called lots of names.

Because everyone cleans up.

Sirhr

Pretty much self taught myself, I work doing industrial maintenance and have access to a complete machine shop with several welders, and an endless supply of scrap steel. I need to get more time on the TIG.

Here are a few pics of things I've made: I am an artist, so I do like to make yard art, working on a steel fence, made my deer feeder and my bull-bar is a work in progress.

Here are a few pics of things I've made: I am an artist, so I do like to make yard art, working on a steel fence, made my deer feeder and my bull-bar is a work in progress.

Attachments

I guess these would be more relatable; some targets and my shooting bench. "One of these days" I have a deep ravine that runs down into a bottom that I want to set up my own 100yd range

Attachments

I need help troubleshooting a welder.

As previously stated, I'm pretty much self taught. After 6 or so years I'm getting to where I don't have to grind/paint near as much. At home I have a Lincoln tombstone and a Hobart handler 175 that I keep flux core wire in, because I do all my welding in the open. At work we have a Lincoln power mig 140c, that I too put in a roll of flux core just because our big Lincoln 255XT has started welding like shit.

It has 75/25 gas but everything lately is so porous it looks like the gas is turned off. Clean steel, good ground, windows/doors closed, new hose/gun. I've adjusted the gas pressure up and down with no effect. I'm thinking maybe the regulator has crapped out (has an older style double guage, not the flow type with a floating ball)?? Would anyone have advise they could offer? TIA

As previously stated, I'm pretty much self taught. After 6 or so years I'm getting to where I don't have to grind/paint near as much. At home I have a Lincoln tombstone and a Hobart handler 175 that I keep flux core wire in, because I do all my welding in the open. At work we have a Lincoln power mig 140c, that I too put in a roll of flux core just because our big Lincoln 255XT has started welding like shit.

It has 75/25 gas but everything lately is so porous it looks like the gas is turned off. Clean steel, good ground, windows/doors closed, new hose/gun. I've adjusted the gas pressure up and down with no effect. I'm thinking maybe the regulator has crapped out (has an older style double guage, not the flow type with a floating ball)?? Would anyone have advise they could offer? TIA

Check for flow at nozzle, check for Crack in line which would let air in or gas out.

Check for flow at nozzle, check for Crack in line which would let air in or gas ou

Don't see any cracks in the hose from regulator into machine (when I can, I'll pull the covers and have a look inside) I do hear gas coming out the gun when I pull the trigger, but I guess it could have air mixed?? Not everyone closes the tank valve, it doesn't appear to be leaking down any. If the tank were empty & pressure gauge was stuck, would the other still adjust up/down?Check for flow at nozzle, check for Crack in line which would let air in or gas out.

The target frames at the range where we shoot 1000 BR are falling apart and need to be replaced. Put together a prototype frame this weekend in the shop using 2" angle with clips to hold the 4x4 OSB backing for the targets. Welded it using my recently acquired Millermatic 255 and love the way it runs on pulse.

I need help troubleshooting a welder.

As previously stated, I'm pretty much self taught. After 6 or so years I'm getting to where I don't have to grind/paint near as much. At home I have a Lincoln tombstone and a Hobart handler 175 that I keep flux core wire in, because I do all my welding in the open. At work we have a Lincoln power mig 140c, that I too put in a roll of flux core just because our big Lincoln 255XT has started welding like shit.

It has 75/25 gas but everything lately is so porous it looks like the gas is turned off. Clean steel, good ground, windows/doors closed, new hose/gun. I've adjusted the gas pressure up and down with no effect. I'm thinking maybe the regulator has crapped out (has an older style double guage, not the flow type with a floating ball)?? Would anyone have advise they could offer? TIA

It's happened to me before onceThe gas may be contaminated and try a different cylinder if you have one on hand. Also check the o rings and seals at the power pin.

The target frames at the range where we shoot 1000 BR are falling apart and need to be replaced. Put together a prototype frame this weekend in the shop using 2" angle with clips to hold the 4x4 OSB backing for the targets. Welded it using my recently acquired Millermatic 255 and love the way it runs on pulse.

View attachment 7727961

How you like the pulse on the 255? You run 90/10? I have an indestructible 252 and run short arc with 75/25. Anything that I want less splatter I just TIG. Curious how you liking it as I havent had a chance to use one.

I definitely like the pulse feature on the 255. No splatter and produces very clean welds with little or no clean up. I am still tweaking the Arc Length and Arc Control to find the sweet spot for me. I am running it with C10 which works for short arc as well. The short arc function works well also and have run it with both C10 & C25. Have not tried aluminum or SS with it yet. When running pulse it sounds similar to AC TIG. Replaced the MDX gun with a Bernard with Centerfire consumables.How you like the pulse on the 255? You run 90/10? I have an indestructible 252 and run short arc with 75/25. Anything that I want less splatter I just TIG. Curious how you liking it as I havent had a chance to use one.

Finally getting my feet wet with this bad boy. Still have a lot to finish for the shop (3rd garage stall) to be complete though.

Also check the polarity if you were running solid wire before.I need help troubleshooting a welder.

As previously stated, I'm pretty much self taught. After 6 or so years I'm getting to where I don't have to grind/paint near as much. At home I have a Lincoln tombstone and a Hobart handler 175 that I keep flux core wire in, because I do all my welding in the open. At work we have a Lincoln power mig 140c, that I too put in a roll of flux core just because our big Lincoln 255XT has started welding like shit.

It has 75/25 gas but everything lately is so porous it looks like the gas is turned off. Clean steel, good ground, windows/doors closed, new hose/gun. I've adjusted the gas pressure up and down with no effect. I'm thinking maybe the regulator has crapped out (has an older style double guage, not the flow type with a floating ball)?? Would anyone have advise they could offer? TIA

I don't know enough to use the pulse, it used to weld great, we have 6-7 guys useing it. We have 1 certified welder on another shift, he isn't prone to sharing tips, but even he is aggravated with it. I will try a new tank when I go back to work.How you like the pulse on the 255? You run 90/10? I have an indestructible 252 and run short arc with 75/25. Anything that I want less splatter I just TIG. Curious how you liking it as I havent had a chance to use one.

Nice lathe. Have a Clausing 20" drill press in my shop and its a beast.The new hotness going in the garage this weekView attachment 7721926

Similar threads

- Replies

- 0

- Views

- 392

- Replies

- 13

- Views

- 1K

Precision Rifle Gear

Tango Innovations FIRE4000 WMLRF Initial Impressions

- Replies

- 298

- Views

- 14K

- Replies

- 33

- Views

- 4K

- Replies

- 4

- Views

- 1K