Yes, I have the 360 and the girls are both the GenII action. I really can’t say right now as I haven’t even chambered a round in the 360. But I really do enjoy it while dry firing it. I have now owned every iteration of the V-22 repeater and I can honestly say that I could not choose between them, they are all excellent. On top of that I have owned SO many other of the very best rimfire rifles made and for a repeater my choice is 100% the V-22…Looks like dad’s is the only 360. Which do you prefer?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vudoo Gun Works V-22 Rimfire Bolt Action

- Thread starter RAVAGE88

- Start date

Great looking rifles. Did you modify the cheek pieces on the Bravos or are those after market?

Alright just got my 360…what do y’all use to clean that itty bitty bore diameter…

@Harry_19 Yes, I made a thread about it.

www.snipershide.com

www.snipershide.com

Ultimate KRG Bravo upgrade

After spending about 6 months with two Vudoo V-22's in the KRG Bravo chassis that I built for my daughters I have personally grown to love the Bravo. So much so that I have sold all my other chassis and stocks. In this time I have added the weighted spacer in the butt for balance and the...

Call Bore Tech. They will hook you up. A cleaning jag, nylon brushes, a bore guide, and a rod of the proper length - that’s what you need along with some sort of cleaner (they sell rimfire blend, which works well for me). There was a coupon for 10% off that came with my barreled action.Alright just got my 360…what do y’all use to clean that itty bitty bore diameter…

Watch Mike’s video on YouTube about how to clean using the bore guide, and to minimize potential damage to the crown.

I like the C4 better than the Rimfire blend for what it's worth...

I bought a 40x bore guide and machined a groove in the top to clear the anti rotation pin, works great.Alright just got my 360…what do y’all use to clean that itty bitty bore diameter…

I felt the need to post something here regarding the outstanding customer service I received last week from Greg and Jay at Vudoo Gunworks. It seems I have one of the rare Three 60's that has sporadic ejection problems. I've been in contact with Greg at Vudoo, and it happened that I was passing through St. George, UT last week. I asked if I could stop in so he could have a look at the issue as well as help me with a couple of other things I was seeing. In addition to the weird ejection problem, I was having problems with feeding if my mag was touching anything. I also have seen a little bit of the "first shot flier" problem. Not bad, but anything is noticeable when a gun groups this well. Anyway, after giving the specifics to Greg he asked me to stop by the shop on my way through.

When I got there Greg was waiting for me and asked me to grab my gun and come to the shop. We went directly to the bench of Jay, who while young, is clearly already a craftsman. Greg told me that it's not uncommon for the mag catch in the Bravo chassis to not work quite right, so he had Jay fab one up ahead of time for me. Note that this is for a gun that I put together, with an action from Mile High and a Bravo from KRG. This isn't a Vudoo-assembled rifle, yet they were taking time out of their day to help me out with a problem that they didn't create and they couldn't control.

While Jay was working on my chassis, Greg grabbed a borescope and looked at my chamber. I also showed him some targets with examples of groups where the first round was outside of the rest of the shots. This only would happen if the rifle had been sitting for more than a few minutes. If I shoot two consecutive five-shot groups from one magazine, the second group is always very tight. Or, if shooting a ten-round group, the first round would be outside the group and the rest would be where they should be. Greg looked at my crown too, and it was good. He suggested the carbon ring in my chamber is likely causing my problems and gave me a detailed description of cleaning procedures and discussed the idea of "good" fouling vs. "bad" fouling. Since getting home from this visit I see that Greg has a video on youtube about cleaning a Vudoo.

After this I got a complete tour of the shop from start to finish, and it's quite impressive. I've worked in aerospace machine shops and have inspected machine shops for my company's clients, and this one is a good one. These rifles are expensive because corners aren't cut in manufacturing, and the results show this.

After the tour, we got back to Jay who had installed the new mag catch, test-fired the gun with my magazine, then modified a couple more magazines for me to try to see if they would fix the erratic ejection issue. In his tests at the bullet trap he found that whatever he had done seemed to help a bit, but may not completely solve the problem. I was told that they're still investigating this issue in-house and they'd notify me when they get it completely figured out. This is OK with me, as I'm not competing with the rifle at this time and the ejection is basically an inconvenience, not something that will cost me points. I should note that they had previously offered to let me send the rifle to them for a thorough evaluation, but left that decision up to me.

I've seen the posts @RAVAGE88 has made on this forum, and the help he has provided to people here, and was always impressed. But what Greg and Jay (and everyone else I met) did for me was way beyond what I expected. I thanked both guys before I left, but I think a public thank you is in order for the way they treated me. Outstanding work, Vudoo Gunworks!

When I got there Greg was waiting for me and asked me to grab my gun and come to the shop. We went directly to the bench of Jay, who while young, is clearly already a craftsman. Greg told me that it's not uncommon for the mag catch in the Bravo chassis to not work quite right, so he had Jay fab one up ahead of time for me. Note that this is for a gun that I put together, with an action from Mile High and a Bravo from KRG. This isn't a Vudoo-assembled rifle, yet they were taking time out of their day to help me out with a problem that they didn't create and they couldn't control.

While Jay was working on my chassis, Greg grabbed a borescope and looked at my chamber. I also showed him some targets with examples of groups where the first round was outside of the rest of the shots. This only would happen if the rifle had been sitting for more than a few minutes. If I shoot two consecutive five-shot groups from one magazine, the second group is always very tight. Or, if shooting a ten-round group, the first round would be outside the group and the rest would be where they should be. Greg looked at my crown too, and it was good. He suggested the carbon ring in my chamber is likely causing my problems and gave me a detailed description of cleaning procedures and discussed the idea of "good" fouling vs. "bad" fouling. Since getting home from this visit I see that Greg has a video on youtube about cleaning a Vudoo.

After this I got a complete tour of the shop from start to finish, and it's quite impressive. I've worked in aerospace machine shops and have inspected machine shops for my company's clients, and this one is a good one. These rifles are expensive because corners aren't cut in manufacturing, and the results show this.

After the tour, we got back to Jay who had installed the new mag catch, test-fired the gun with my magazine, then modified a couple more magazines for me to try to see if they would fix the erratic ejection issue. In his tests at the bullet trap he found that whatever he had done seemed to help a bit, but may not completely solve the problem. I was told that they're still investigating this issue in-house and they'd notify me when they get it completely figured out. This is OK with me, as I'm not competing with the rifle at this time and the ejection is basically an inconvenience, not something that will cost me points. I should note that they had previously offered to let me send the rifle to them for a thorough evaluation, but left that decision up to me.

I've seen the posts @RAVAGE88 has made on this forum, and the help he has provided to people here, and was always impressed. But what Greg and Jay (and everyone else I met) did for me was way beyond what I expected. I thanked both guys before I left, but I think a public thank you is in order for the way they treated me. Outstanding work, Vudoo Gunworks!

4-40x3/16"Does anyone know the screw size and type for the Vudoo bore guide from Bore Tech? I somehow managed to lose the screw.

Thank you! Any idea what kind of head is it? Looks too tall to be a pan head. Trying to find a replacement on Fastenal but I can't really find one that matches.4-40x3/16"

View attachment 7700182

That's a good question, hopefully @RAVAGE88 will chime in to confirm. This is the closest thing I could find on McMaster:Thank you! Any idea what kind of head is it? Looks too tall to be a pan head. Trying to find a replacement on Fastenal but I can't really find one that matches.

High-Profile Narrow Fillister Head Phillips Screw

Thank you! Any idea what kind of head is it? Looks too tall to be a pan head. Trying to find a replacement on Fastenal but I can't really find one that matches.

Why not just call bore-tech?

Bore-Tech didn't design it, Mike Bush did...that doesn't mean Bore-Tech wouldn't know...but @RAVAGE88 is the engineer.Why not just call bore-tech?

i have a 60 moa base, I have the same specs on my ETR. I have about 31 +/- up and i can zero 25yd. Zero issues on my end for clarity or anything of that natureVudoo with 40 moa base and athlon cronus 4-29 Mounted with 1.125” nightforce rings. Zeroed at 50 yards, able to dial almost 25 mils of the cronus’s useable 32 mils. That means I’m leaving a little over 7 mils. 7 mils x 3.47 moa = 24.3 moa. So if I add another 20 moa to the base that adds 5.76 mils elevation. 7-5.76 = 1.24 mils left over if I switch out to a 60moa base.

This will let me roughly dial about 30.5 mils elevation with the cronus on a 60moa base with 1.125 rings and a 50 yard zero. My dilemma is : am I getting out of the scopes sweet spot of optical clarity with that much movement to the edge limits? @koshkin

I just saw this. I doubt there is much of a difference. What length did you finish yours at?I spoke to benchmark. Curious how the 15t does compared to their 16t. Mine is going to be a 16t 3 groove

I just saw this. I doubt there is much of a difference. What length did you finish yours at?

I went with 22"

Let's compare notes when you get it runningI went with 22"

Gave them a call and they confirmed the dia/size/length. They ended up just sending a replacement screw for free instead of having me track down the specific one. Very pleased with their CS, no wonder VGW decided to work with them to make the bore guides.Why not just call bore-tech?

Well I got my new 360 finally! It took about 5 months from when I placed my order. I have an NRL22X match tomorrow so I didn't want to swap all my competition gear around but I did get a Xylo chassis the other day and I have an old Razor HD AMG to throw it together. Top is the new Vudoo 360, bottom is my current comp rig, a Gen 1.2

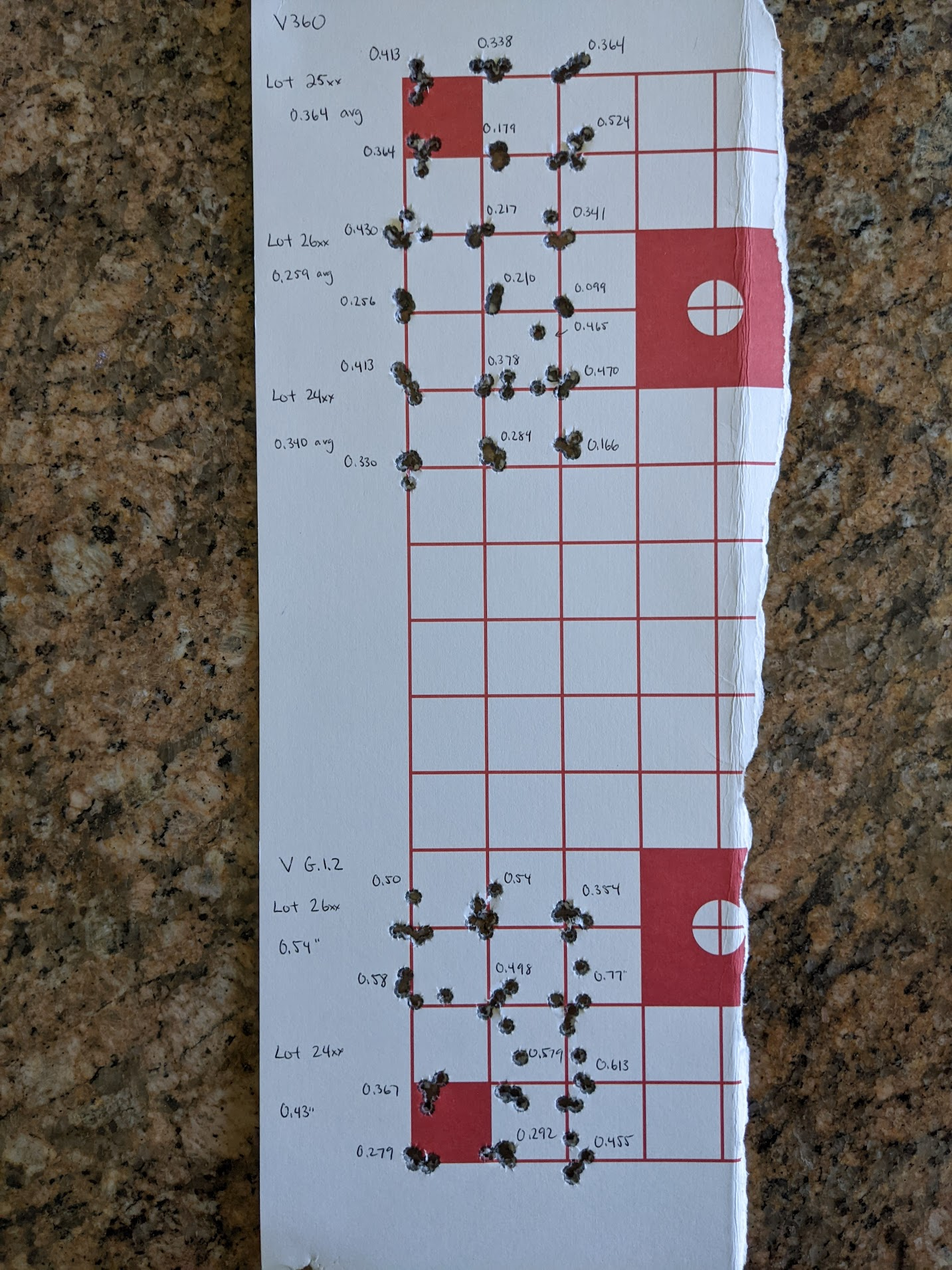

Took 3 rounds to zero the new Vudoo, and went off and did 3 6x5's at 50 yards with 3 lots of Center-X. I then did 2 more 6x5's with with my old Vudoo. The results weren't great, and I thought my trusty old Vudoo would've done a lot better as I generally do groups in the .25-2.7" but it was kind of a mess today. Shot in prone, breezy and next to a guy with an AR and a brake. Good news is the new Peltor LEP-200's did fantastic. I didn't have to double up and they were super comfy.

A little over 100 rounds on the new 360, and happy to say zero feeding or extraction issues. With the ARC Xylo, the magazine well is super tight. 2 of my poly mags fit, but 1 of them wouldn't free drop. The 15-round aluminum fit, but the 12-round I had to manually pull out. The one that wouldn't fit was .8mm thicker. The aluminum mag I can't seem to figure out where it's rubbing as I measured different areas and they all seemed to be the same dimensions.

The bolt lift, I have to say for a 3-lug felt exactly the same heaviness as my 2-lug so it felt. Action is smoother as well even though it's brand new compared to my 10K round Gen 1.2.

I don't think I'll go out and spend any significant time on groups again though. I'll most likely just send my 360 to Lapua like I did my Gen 1.2 and just continue comps. All my groups are good enough to hit the 1/4" kyl at 50 yards, and the vertical stringing probably was just me.

Took 3 rounds to zero the new Vudoo, and went off and did 3 6x5's at 50 yards with 3 lots of Center-X. I then did 2 more 6x5's with with my old Vudoo. The results weren't great, and I thought my trusty old Vudoo would've done a lot better as I generally do groups in the .25-2.7" but it was kind of a mess today. Shot in prone, breezy and next to a guy with an AR and a brake. Good news is the new Peltor LEP-200's did fantastic. I didn't have to double up and they were super comfy.

A little over 100 rounds on the new 360, and happy to say zero feeding or extraction issues. With the ARC Xylo, the magazine well is super tight. 2 of my poly mags fit, but 1 of them wouldn't free drop. The 15-round aluminum fit, but the 12-round I had to manually pull out. The one that wouldn't fit was .8mm thicker. The aluminum mag I can't seem to figure out where it's rubbing as I measured different areas and they all seemed to be the same dimensions.

The bolt lift, I have to say for a 3-lug felt exactly the same heaviness as my 2-lug so it felt. Action is smoother as well even though it's brand new compared to my 10K round Gen 1.2.

I don't think I'll go out and spend any significant time on groups again though. I'll most likely just send my 360 to Lapua like I did my Gen 1.2 and just continue comps. All my groups are good enough to hit the 1/4" kyl at 50 yards, and the vertical stringing probably was just me.

I'll most likely just send my 360 to Lapua like I did my Gen 1.2

I plan to do that with mine, but just FYI, Mike Bush told me that he suggests not sending it off until you have at least 1000 rounds through it. I'm about 2/3 there

I plan to do that with mine, but just FYI, Mike Bush told me that he suggests not sending it off until you have at least 1000 rounds through it...

Yeh I won't send it for a while. I have a case of my 24xx and 26xx that looks to shoot well enough and will hold me over for quite some time. I might invest in a case of Midas+ if it shows significant 100yd groups just so I have some slightly tighter ammo for engaging the 300+ yard targets.

I like the Xylo chassis, littlepod.

It's one of my favorites and about the only one I know of that is constructed of superior 7075 T-6 aluminum.

Looks like you've attached a 419 barricade stop to your ARCA rail which is the best looking on the market.

The XLR chassis is excellent too though; two great-looking rifles, congratulations.

It's one of my favorites and about the only one I know of that is constructed of superior 7075 T-6 aluminum.

Looks like you've attached a 419 barricade stop to your ARCA rail which is the best looking on the market.

The XLR chassis is excellent too though; two great-looking rifles, congratulations.

I like the Xylo chassis, littlepod.

It's one of my favorites and about the only one I know of that is constructed of superior 7075 T-6 aluminum.

Looks like you've attached a 419 barricade stop to your ARCA rail which is the best looking on the market.

The XLR chassis is excellent too though; two great-looking rifles, congratulations.

Thanks! I do like the Xylo chassis a lot. I personally like to support my rifles on top of the fore-end which is why I really like the XLR Envy Pro so much. I'm hoping I can find someone to CAD up something that can go ontop of the ARC.

The barricade stop is there, but the mag has absolutely no movement in the way the Xylo is engineered, so I think I can just get rid of it, but it still looks pretty nice with it on.

I would have to leave it on, if it were my rifle, as I think it looks cool.The barricade stop is there, but the mag has absolutely no movement in the way the Xylo is engineered, so I think I can just get rid of it, but it still looks pretty nice with it on.

Looks matter too, lol.

It's killing me to hear about & see all the new Three 60 builds here - my Three 60 action and all the parts for the build are sitting out in the shop, just waiting for me to get time to finish replacing the spindle bearings on the JET lathe so I can get this baby up & running before winter! Keep it up guys - this is exactly the sort of motivation I need to get fall drilling & harvesting done so I can get the lathe finished.

I really wish that barricade stop was closer to the magazine.Vudoo in a Vision Chassis

I really wish that barricade stop was closer to the magazine.

+1

With it that far out, and the weight of that rifle, to get it to balance in front of the mag well it's going to be a 20+lb rifle.

I believe the KRG design and the AI designs for their fore-end are much closer to the mag.

Quick question that I’m struggling to get a good answer to. Which MOA base should I order with my Vudoo 360? I want to mainly be shooting at 50-100 yards, but I want the capability to be going up to 500 yards. I will be using a ZCO 5-27 optic. I’ve got every answer you can get. Just looking for some confirmation from anyone that might be running this optic.

Also, any recommendation on which ZCO reticle is ideal, or doesn’t it really matter?

Thanks in advance!

Also, any recommendation on which ZCO reticle is ideal, or doesn’t it really matter?

Thanks in advance!

Added a V360 this week, no time to shoot yet, all torqued up for next weekend...

50moa in my opinion. You could go 60 but 50 works great.Quick question that I’m struggling to get a good answer to. Which MOA base should I order with my Vudoo 360? I want to mainly be shooting at 50-100 yards, but I want the capability to be going up to 500 yards. I will be using a ZCO 5-27 optic. I’ve got every answer you can get. Just looking for some confirmation from anyone that might be running this optic.

Also, any recommendation on which ZCO reticle is ideal, or doesn’t it really matter?

Thanks in advance!

It will likely need some internal and/or external weights up front to better balance on a bag, especially with the typical shorter barrels on a 22. But it doesn’t mean you can’t get it to balance where you want it, just might end up being heavier like you said.+1

With it that far out, and the weight of that rifle, to get it to balance in front of the mag well it's going to be a 20+lb rifle.

I believe the KRG design and the AI designs for their fore-end are much closer to the mag.

The material in front of the magwell stiffens the center section considerably, so any loading of the forend or recoil doesn’t flex the center section and where the recoil lug contacts the chassis. Obviously less of a concern for recoil with a 22 haha. The new Spuhr chassis has done something very similar to their center section…

Get 20 MOA. It's the most versatile at ranges under 150 yd. If you want more scope tilt, install your scope with Burris Tactical Signature rings. You can add or subtract up to 40 more MOA.Quick question that I’m struggling to get a good answer to. Which MOA base should I order with my Vudoo 360? I want to mainly be shooting at 50-100 yards, but I want the capability to be going up to 500 yards. I will be using a ZCO 5-27 optic. I’ve got every answer you can get. Just looking for some confirmation from anyone that might be running this optic.

Also, any recommendation on which ZCO reticle is ideal, or doesn’t it really matter?

Thanks in advance!

I will be using either ARC M10 rings or the ARC M-brace mount. I was hoping to settle on a base that could accomplish both of my objectives without having to swap rings on and off.Get 20 MOA. It's the most versatile at ranges under 150 yd. If you want more scope tilt, install your scope with Burris Tactical Signature rings. You can add or subtract up to 40 more MOA.

I will be using either ARC M10 rings or the ARC M-brace mount. I was hoping to settle on a base that could accomplish both of my objectives without having to swap rings on and off.

If you're paying for a ZCO, get a 50moa rail. You won't have any optical clarity degredation and have a whole 30mils to dial up. A lot people with ZCOs are running 50moa rails (including myself)

I have some minor feeding issues with my Vudoo. It's a complete rifle in a Bravo chassis.

Sometimes the bolt doesn't feed a round. Instead it goes over the round, puts a big dent on the round, and then it get stuck.

I'm doing my best to load the mag correctly (watched the video).

This happens typically once for every 2 mags.

I'm using the standard 10 round poly mag with Center X.

Sometimes the bolt doesn't feed a round. Instead it goes over the round, puts a big dent on the round, and then it get stuck.

I'm doing my best to load the mag correctly (watched the video).

This happens typically once for every 2 mags.

I'm using the standard 10 round poly mag with Center X.

I have some minor feeding issues with my Vudoo. It's a complete rifle in a Bravo chassis.

Sometimes the bolt doesn't feed a round. Instead it goes over the round, puts a big dent on the round, and then it get stuck.

I'm doing my best to load the mag correctly (watched the video).

This happens typically once for every 2 mags.

I'm using the standard 10 round poly mag with Center X.

Did you buy it from them? If so, then they should try to fix it.

Otherwise, if the bolt is going over the round, then the mag isn't sitting high enough, or you're short stroking the bolt (not pulling far enough back before pushing forward meaning the bolt misses the rim on the round and starts catching it after the rim which will push the round forward, sandwich it and dent it.

I finally ordered a Vudoo barred action. The wait is going to suck!

Yup, and the arrival will not suck, not at all in anyway. Mine must be near ... decided last December, had the budget in place and ordered in April, any time I reckon.I finally ordered a Vudoo barred action. The wait is going to suck!

Yup, and the arrival will not suck, not at all in anyway. Mine must be near ... decided last December, had the budget in place and ordered in April, any time I reckon.

What did you order? Full rifle or barreled action? My order in April was originally slated to be done in early August, but I changed it to a custom barrel which wasn't going to have delivery until mid Sept so I just got my 360.

Full rifle, I suspect the Flavio Fare trigger is the sticking point, also I'm in Canada so customs might take a while. I wish I had got it before the snow flew(too late now) but I'll shoot it daily all winter anyway. This rifle is so special to me I'd wait two years for it if I had to.What did you order? Full rifle or barreled action? My order in April was originally slated to be done in early August, but I changed it to a custom barrel which wasn't going to have delivery until mid Sept so I just got my 360.

I'll call Vudoo on Monday, but hoping to maybe get it figured out this weekend but my bolt release won't work on the new 360. It worked fine as I put the bolt in, but went and shot a few hundred rounds and came home and I can't get the bolt release to work at all. Pushing on it as hard as I can and it won't push in.

Any suggestions?

Any suggestions?

Use compressed air to blow around it in case there is some debris stuck in there somewhere.I'll call Vudoo on Monday, but hoping to maybe get it figured out this weekend but my bolt release won't work on the new 360. It worked fine as I put the bolt in, but went and shot a few hundred rounds and came home and I can't get the bolt release to work at all. Pushing on it as hard as I can and it won't push in.

Any suggestions?

Make sure you're not bringing the bolt all the way back against the bolt release prior to pushing the bolt release. There's a feature that locks the two together to eliminate a moment of force that can bounce the release out of the way when you run the bolt hard.I'll call Vudoo on Monday, but hoping to maybe get it figured out this weekend but my bolt release won't work on the new 360. It worked fine as I put the bolt in, but went and shot a few hundred rounds and came home and I can't get the bolt release to work at all. Pushing on it as hard as I can and it won't push in.

Any suggestions?

MB

Make sure you're not bringing the bolt all the way back against the bolt release prior to pushing the bolt release. There's a feature that locks the two together to eliminate a moment of force that can bounce the release out of the way when you run the bolt hard.

MB

The 1/16" screw was super tight. I was worried my little 1/16" allen key was going to break but I got it to turn. About 1 revolution out revolution out, the bolt stop started working again. I turned 1/4 turn and it got a little gritty, so I backed it out again until the bolt stop was smooth and springy.

300 rounds down the rifle now and I'm giving it a cleaning and will try to get my dope dialed in for it tomorrow. 22" Benchmark is chronoing at 1055. I wanted to confirm to see if it slowed down that much and ran my Center-X in my friend's custom 24" Benchmark CZ 457 and it looks right. Eley Tenex ammo though out of his CZ shoots at 1090, so it looks like if I want my ammo to be more in the 1090 range I'll have to shoot the hotter Eley stuff.

| Lot# | 26xx | 24xx | 24xx | 25xx | 26xx CZ |

| 1055 | 1051 | 1049 | 1062 | 1042 | |

| 1074 | 1053 | 1061 | 1059 | 1038 | |

| 1065 | 1063 | 1063 | 1062 | 1030 | |

| 1043 | 1057 | 1050 | 1055 | 1039 | |

| 1055 | 1057 | 1058 | 1058 | 1041 | |

| 1044 | 1055 | 1054 | 1056 | 1033 | |

| 1051 | 1036 | 1050 | 1070 | 1035 | |

| 1050 | 1046 | 1051 | 1059 | 1060 | |

| 1048 | 1048 | 1049 | 1059 | 1034 | |

| 1057 | 1054 | 1045 | 1073 | 1041 | |

| 1068 | 1068 | 1054 | |||

| AVG | 1055.454545 | 1052 | 1054.363636 | 1060.636364 | 1039.3 |

| STDEV | 9.933414683 | 7.40870359 | 7.159227993 | 5.971142726 | 8.273787256 |

| ES | 31 | 27 | 23 | 19 | 30 |

50 yd groups were all relatively good a lot better than the first outing. Need to stretch it to 100/200 to see which Lot# works the best. Sadly I don't have any more 25xx, but I have 1.5 cases of 24xx and 1 case of 26xx. Rifle isn't threaded so no quick way for an ATS/EC tuner, so I'll probably have to send it in to Lapua.

I have like 7500 rounds through my Gen 1.2 and it is slick and feeds really smoothly. The 360 cycles really cleanly while dry firing, but picking up rounds into the chamber is not as smooth as my Gen 1.2.

Hey guys, I have a new Three60. I've got about 350 rounds down it so far. At what point are you guys doing serious chrony work and testing? I dont wanna start now if im wasting my time until 1000rds or so?

Similar threads

- Replies

- 14

- Views

- 2K

- Replies

- 2

- Views

- 2K

- Replies

- 4

- Views

- 1K

- Replies

- 3

- Views

- 916