Ever tried Blue Dot? It is by far the most accurate powder I have tried for 10mm.I made a pressure work up with 800-x for my 10mm. Was using aa #9, but got tired of 14 grains per pull.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do in the reloading room today?

- Thread starter Kisssofdeath

- Start date

- Nov 3, 2010

- 10,522

- 23,055

Who makes the side linkage? I'm looking at some for my co-ax rebuild. I think I'd prefer one that dont have a point jutting into the side clearance like some others.Cut the front shield in half and drilled a hole in the side shield for the Autotrickler. Loaded up 100 rds of 6BR for next weekends match.

View attachment 7556467

View attachment 7556469

View attachment 7556470

Who makes the side linkage? I'm looking at some for my co-ax rebuild. I think I'd prefer one that dont have a point jutting into the side clearance like some others.

Just started loading for 10mm and aa#9 and 800-x was all I could get. I’ll keep blue dot in mind once the world gets its head out of its ass.Ever tried Blue Dot? It is by far the most accurate powder I have tried for 10mm.

I never joined FB - is there a website or other contact info for the manufacturer?

Thanks in Advance - those look pretty cool. Do you like them?

Try this email, if he doesn’t respond I’ll reach out to him on Facebook. I really like them, and better than the other options. More open and you have more access. It is an excellent upgrade and only $65I never joined FB - is there a website or other contact info for the manufacturer?

Thanks in Advance - those look pretty cool. Do you like them?

[email protected]

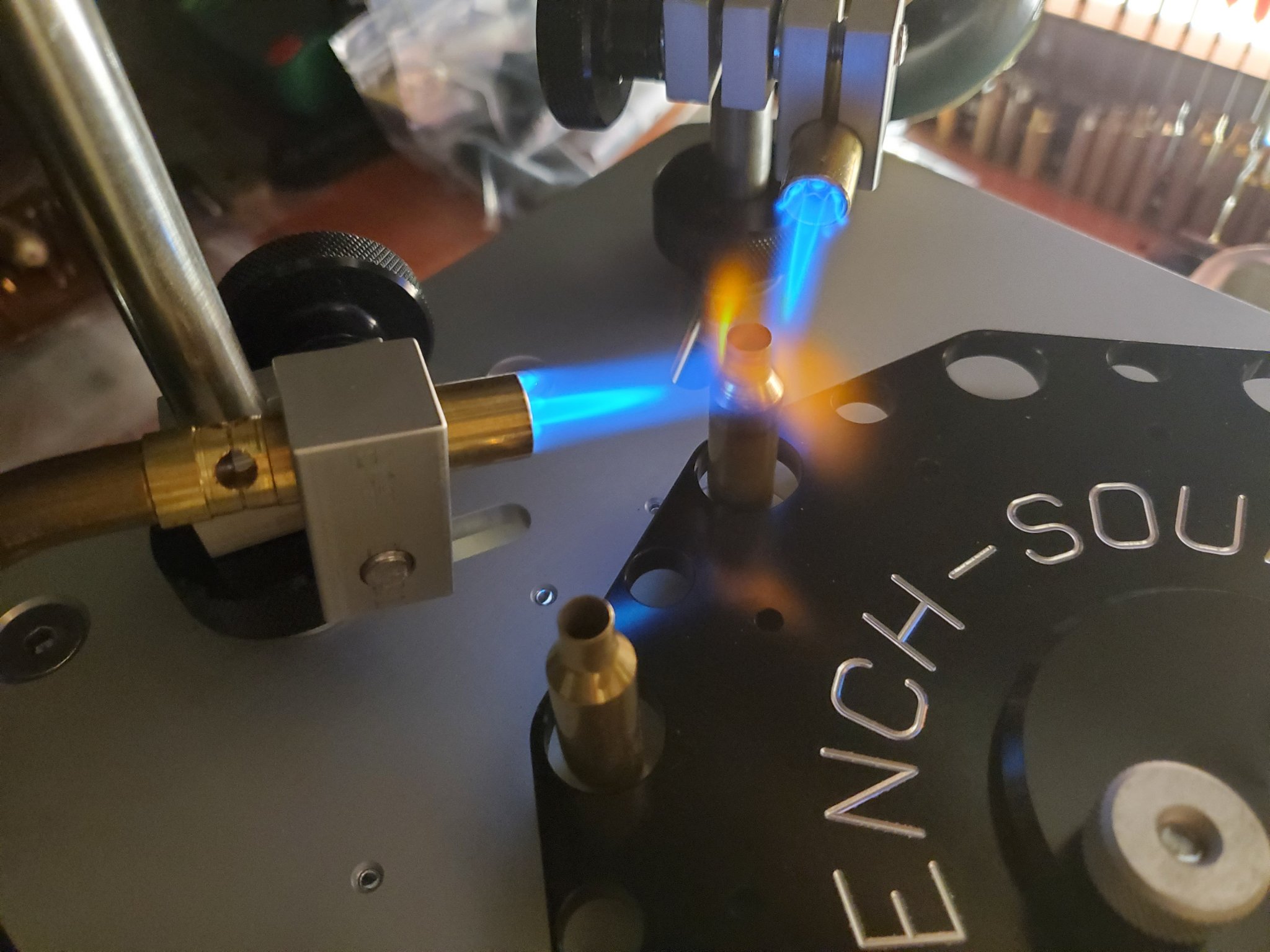

Tried out ny new Bench Source annealer (thanks to a solid member here). Prob did close to 700 cases of various calibers. Wish I had done this years ago...

Ran my first batch loading with the 550. Brass was sized on my Mec than prepped. Dillons setup with an Armonov toolhead with 21st Mandrel, Dillon Powder Die, Redding Micro seater. Powder was thrown on a chargemaster. Ran 30 rounds and to they turned out very consistst at about +- .0005 CBTO. Hopefully I’ll get to empty them tomorrow and pin down this load data.

Overall I am pleased with the first run. Besides forgetting to close the drain on my chargemaster went smooth. I took my time to go through them as not to Ed up. I’m used to running pistol stuff on Dillon so obviously workflow a little different. I also checked every round with comparator as it came off the press just to get some baselines. I think a few tweaks to the press and it’ll definitely be a step in the right direction.

went smooth. I took my time to go through them as not to Ed up. I’m used to running pistol stuff on Dillon so obviously workflow a little different. I also checked every round with comparator as it came off the press just to get some baselines. I think a few tweaks to the press and it’ll definitely be a step in the right direction.

Overall I am pleased with the first run. Besides forgetting to close the drain on my chargemaster

The Chargemaster Drain. Glad I'm not alone.Ran my first batch loading with the 550. Brass was sized on my Mec than prepped. Dillons setup with an Armonov toolhead with 21st Mandrel, Dillon Powder Die, Redding Micro seater. Powder was thrown on a chargemaster. Ran 30 rounds and to they turned out very consistst at about +- .0005 CBTO. Hopefully I’ll get to empty them tomorrow and pin down this load data.

Overall I am pleased with the first run. Besides forgetting to close the drain on my chargemasterwent smooth. I took my time to go through them as not to Ed up. I’m used to running pistol stuff on Dillon so obviously workflow a little different. I also checked every round with comparator as it came off the press just to get some baselines. I think a few tweaks to the press and it’ll definitely be a step in the right direction. View attachment 7562531

Yeah it was sad to see that varget going everywhere. Luckily caught it pretty quick.The Chargemaster Drain. Glad I'm not alone.

Between that and spending like half hr looking for one damn primer that rolled away last week.

Just finished loading up a couple of thousand dollars worth (200 rounds  ) of 300 WinMag target ammo, I should be good for awhile.

) of 300 WinMag target ammo, I should be good for awhile.

$2K at least!Just finished loading up a couple of thousand dollars worth (200 rounds) of 300 WinMag target ammo, I should be good for awhile.

View attachment 7566061

Is the piece of equipment in the background for belts?

Is the piece of equipment in the background for belts?

Yes, https://www.snipershide.com/shootin...the-reloading-room-today.6949295/post-8919945

Last edited:

I did nothing, just busy with some stuff

I hear ya Will. I spent most of the day finishing-up on removing about 400 yards of barb wire fencing and posts! Putting up ne fence will be a “cakewalk” compared to removing!

Counted to make sure I had enough 6.5x47 ammo for the Accuracy International Long Range match coming up in a couple weeks.

I

I made 50 rounds of 223 before my daughter found me. We than took a ride so she could take a nap and then played with every toy in the playroom. Was a good day with my baby.

If you don’t mind me asking what’s the ruler for?

I made 50 rounds of 223 before my daughter found me. We than took a ride so she could take a nap and then played with every toy in the playroom. Was a good day with my baby.

- Nov 3, 2010

- 10,522

- 23,055

Started getting things ready for a 22 match next weekend, but then it got canceled today so fuck it

Reloading related

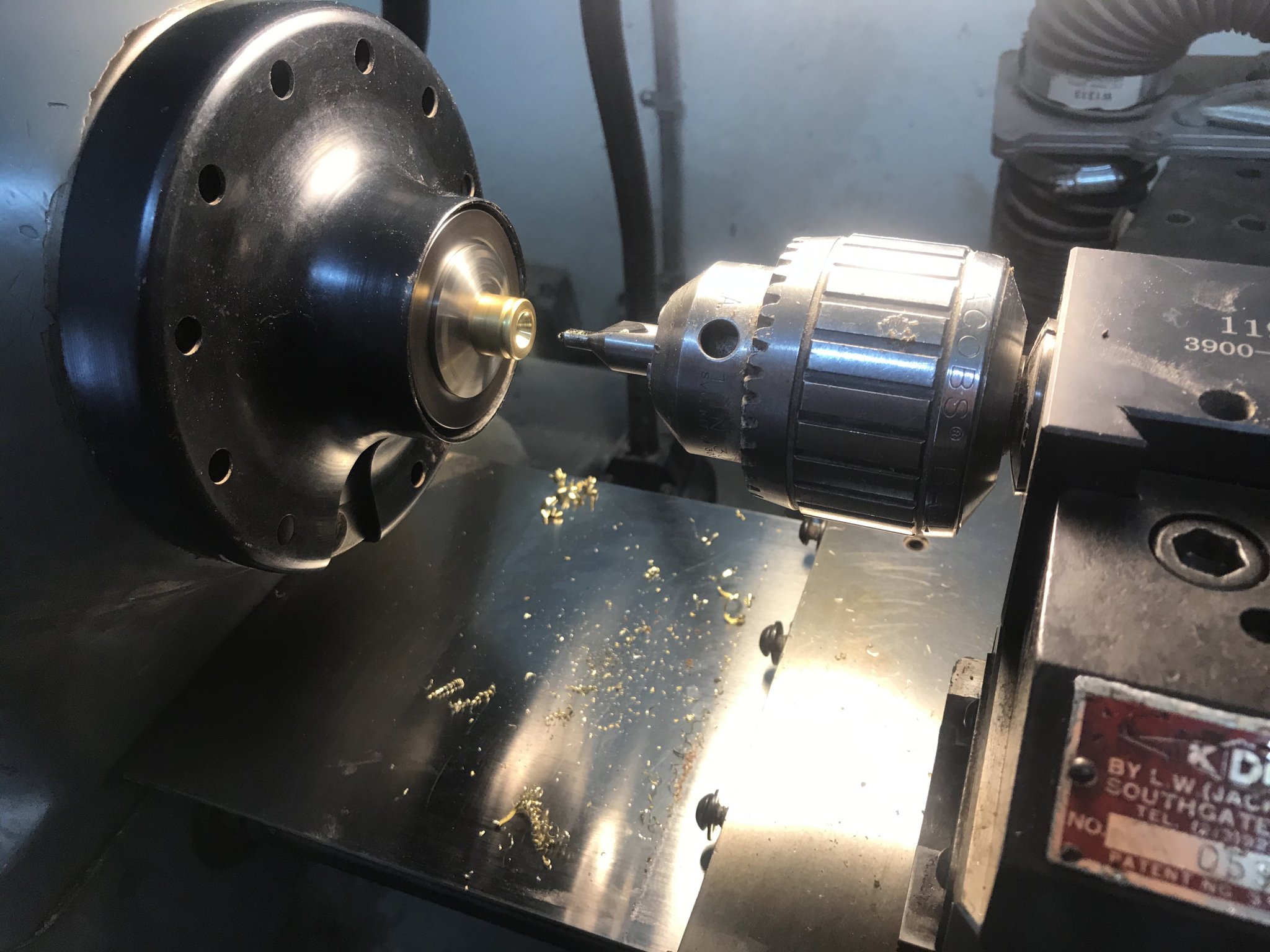

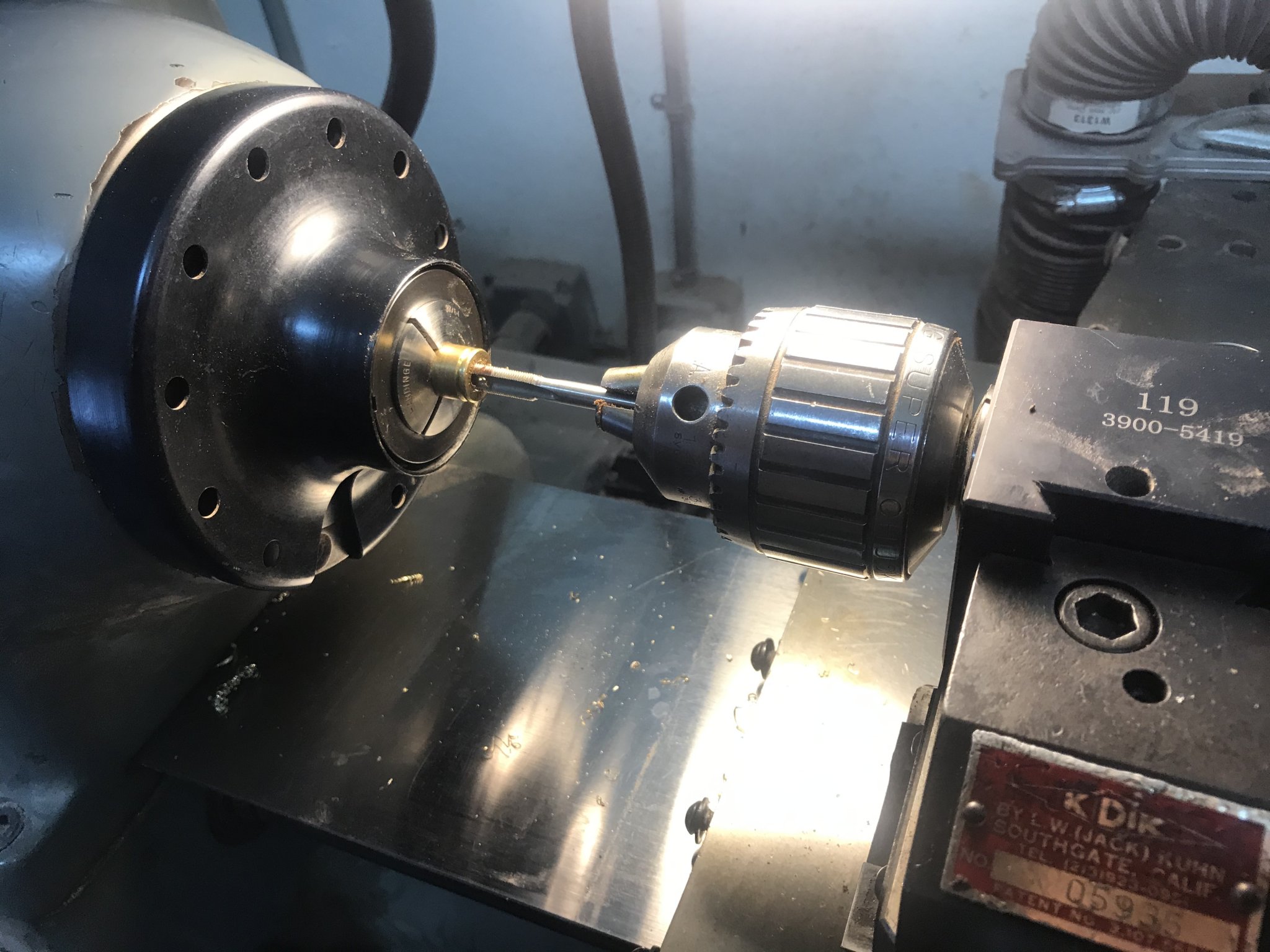

I made a 338 Norma magnum modified case for a buddy.

I made a 338 Norma magnum modified case for a buddy.

Yep, me too. So much fun...

Loaded some 6.5 Creedmoor ammo to test my new box of Barnes 145 gr. Match Burner bullets.

When I finished loading I checked the rounds CBTO length consistency. All were within .001". Then I checked for bullet concentricity. All came in at .001" or less. Perfect! Quite proud of myself.

As I was cleaning up, I removed my Forster Ultra-Micrometer seating die from my Co-Ax press and went to put it in its hole in the 6.5 Creedmoor section of my die shelf. Then I discovered....my 6.5 Creedmoor seating die was already in it's hole! I quickly checked the tiny shallow engraving on the die's floating sleeve (the only spot on the die where there's any indication of what cartidge it's for). I had loaded my new 6.5 ammo with my .308 seating die!

Can't argue with the results, though. Very consistent ammo - just loaded with the wrong die. I can only hope the proper seater works as well.

I promptly got out the label maker and labelled those two similar dies.

When I finished loading I checked the rounds CBTO length consistency. All were within .001". Then I checked for bullet concentricity. All came in at .001" or less. Perfect! Quite proud of myself.

As I was cleaning up, I removed my Forster Ultra-Micrometer seating die from my Co-Ax press and went to put it in its hole in the 6.5 Creedmoor section of my die shelf. Then I discovered....my 6.5 Creedmoor seating die was already in it's hole! I quickly checked the tiny shallow engraving on the die's floating sleeve (the only spot on the die where there's any indication of what cartidge it's for). I had loaded my new 6.5 ammo with my .308 seating die!

Can't argue with the results, though. Very consistent ammo - just loaded with the wrong die. I can only hope the proper seater works as well.

I promptly got out the label maker and labelled those two similar dies.

Built some 300-PRC ladder tests to (a) look for velocity nodes on bigger charges with my 220gr Berger Hybrids, and (b) figure out if lighter 200.20x Berger Hybrids could perform well in my 300-PRC since I've got "thousands" of them (for my 300-WM).

I've discovered that reloading is excellent "Quarantine Therapy".

I've discovered that reloading is excellent "Quarantine Therapy".

If you don’t mind me asking what’s the ruler for?

I sort bulk range brass that is swept up from relatively clean floors mostly.

Facing case mouths tward yourself helps spot 22lr stuck in there and case diameter.

You pull the yardstick towards you and that lines the length up.

That makes for easier identification.

The line of sorted cases can then be shoved along the ruler into a container.

This hepls get out any grit, staples and easy to spot crushed necks.

The 3 lb tubs are 9mm.

Did brass prep yesterday. Had 300 blackout I needed to get processed. Prepped some Peterson 308 brass for new load for my FN. I have a couple thounds 223 I need to finish tumbling today, then start processing it.

Regarding "tumbling" ... I've totally thrown out the whole "steel media" thing, and tumble after decapping with my Frankford Arsenal wet tumbler, using only hot water and FA's Instaclean Brass Cleaning Packets. Then I tumble once more after sizing to remove lube and give everything one more cleaning. VERY happy with the result. Super clean cases ... even primer pockets get clean ... and no need to wrestle with those stupid steel pins getting caught everywhere.Did brass prep yesterday. Had 300 blackout I needed to get processed. Prepped some Peterson 308 brass for new load for my FN. I have a couple thounds 223 I need to finish tumbling today, then start processing it.

So easy ... just drop in a packet and tumble for an hour, and then maybe 90 minutes in the brass dryer (also from FA). It only took me a couple of times using steel media to know that was NOT for me.

Anybody want to buy 10 lbs of tiny steel pins?

I’m still using walnut or corncob, can’t remember which one. But all this talk about brass juice and wet tumbling has me intrigued.

Super easy ... throw dirty brass into the wet tumbler with cleaning packet and hot water ... tumble for an hour or two ... drain ... rinse ... dry ... DONE.I’m still using walnut or corncob, can’t remember which one. But all this talk about brass juice and wet tumbling has me intrigued.

The whole "corn-cob mess" and/or "steel media nightmare" is so "2010's". LOL

I go back on forth if I want to try wet tumbling but I keep telling myself I don’t want the extra hassle of having to dry them. I like to be able to tumble and get right to work.

I'm a dry tumble guy.

Pet bedding wallnut media.

Small enough to pass through flash holes. It is dusty when you get it.

A mix of mineral spirits and car wax squirted into the media and ran for 5 minutes, no more dust.

The brass comes out clean, dry and serviceable with a super thin protective wax coating.

The media just poors out unless you used too much mineral spirits and need to run it longer to get it to flash off.

Pistol brass just gets the one run and rifle gets done after sizing / working for the second run just prior to loading.

I don't get where the mess is I just worked 500 + in my house with another 500 + still tumbling.

PS. I threw out corn cob media first time I used it.

Pet bedding wallnut media.

Small enough to pass through flash holes. It is dusty when you get it.

A mix of mineral spirits and car wax squirted into the media and ran for 5 minutes, no more dust.

The brass comes out clean, dry and serviceable with a super thin protective wax coating.

The media just poors out unless you used too much mineral spirits and need to run it longer to get it to flash off.

Pistol brass just gets the one run and rifle gets done after sizing / working for the second run just prior to loading.

I don't get where the mess is I just worked 500 + in my house with another 500 + still tumbling.

PS. I threw out corn cob media first time I used it.

A little revolver loading today (.357mag).

Tried to find something that some else needed more than me.......Still looking.

https://www.amazon.com/Milliard-Citric-Acid-Pound-NON-GMO/dp/B01DKRP1GMSuper easy ... throw dirty brass into the wet tumbler with cleaning packet and hot water ... tumble for an hour or two ... drain ... rinse ... dry ... DONE.

The whole "corn-cob mess" and/or "steel media nightmare" is so "2010's". LOL

scoop of that to replace the cleaning packet. Wayyy cheaper and that 10# will last you forever

Got the framing done for the new bench. Sick of using an old desk.

Planning on being there a while I see. Good for you !!!Got the framing done for the new bench. Sick of using an old desk. View attachment 7575898

Well until my wife gives me the ok to get outa this state... So yeah gonna be here a while.Planning on being there a while I see. Good for you !!!

I hope so, I’m pleased with how it’s coming out. It’s got some weight I probably don’t even need to screw to the wall but gonna just in case. Next up is the top and some shelving. Always something.That is strong enough to hold engine blocks.

Should last you.

Used up the last bit of RL17. Usually load on a 650 with a Hornady powder measure, but for the last 1/8 (or less) of a pound the powder measure is too inconsistent. Used the 650 more like a single stage press. 3 or 4 kernels for each 0.1 in charge weight

Finally got to try out a couple top end products I bought.

1st the CPS primer seater! Diggin it!

2nd Area 419 funnel system, who knew you could enjoy a funnel?!

Staball, and 140gr Hornady BTHP OCW test this weekend.

8-10 more weeks for my V3...

1st the CPS primer seater! Diggin it!

2nd Area 419 funnel system, who knew you could enjoy a funnel?!

Staball, and 140gr Hornady BTHP OCW test this weekend.

8-10 more weeks for my V3...