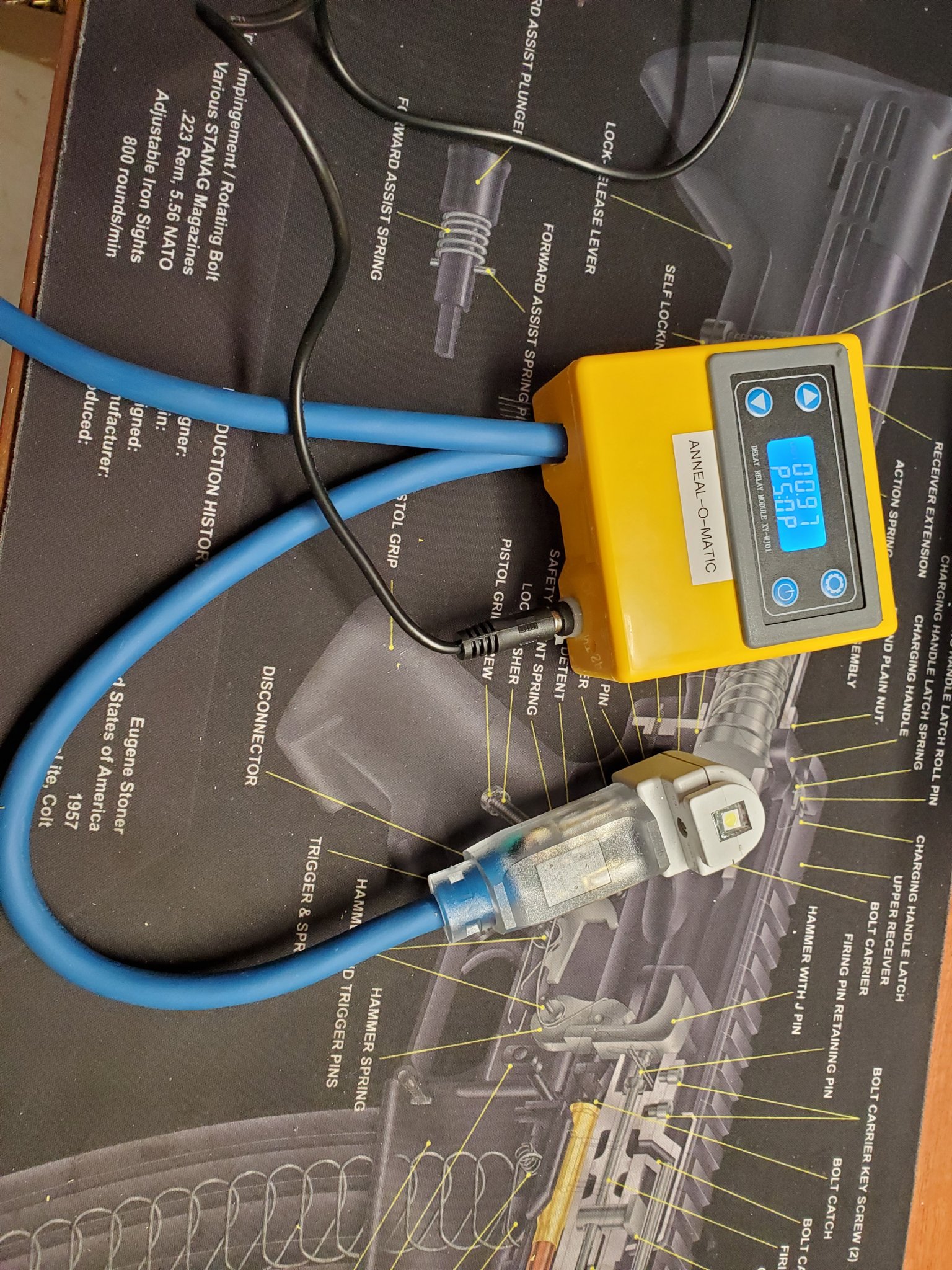

Very nice jobI built a sliding plate for the amp annealer and amp-mate.

It slides on T-Track on table rollers so I can move it out of the way when not in use.

JosephView attachment 7518084View attachment 7518085

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do in the reloading room today?

- Thread starter Kisssofdeath

- Start date

If you don't mind, what does a setup like that cost? I really like it.

And, NO,not asking for a friend. FM

And, NO,not asking for a friend. FM

If you don't mind, what does a setup like that cost? I really like it.

And, NO,not asking for a friend. FM

The amp annealer 1395.00

The amp mate. 350.00

The case feeder with plate 300.00

Each pilot 20.00 each

That’s about it. I think

Joseph

I made a removeable weight that fits the slot in the fore-end below the barrel. I also stitched together a quick adjustbale rifle sling using 1.25" webbing and Grovtec HD QD swivels/flushcups.

Any results to report? I have plenty of 400’s, but no 450’s. I really hoping you had good results!Running a primer comparison test with a 6BR. Left, Rem 7.5, right CCI 400.

View attachment 7335538

Past data showed excellent results with CCI BR 4's, they are all gone. Plenty of 7.5 and 400's on hand, looking for accuracy results without adding another component to the to the inventory. Burning H322, again, plenty on hand.

I cleaned out from under the bench today, found a small fortune in dropped small rifle primers, think I’ll be able to afford that section of land we were thinking about buying!

Was the weight for recoil reduction? Balance on the bag? Both? Have you shot with it yet?I made a removeable weight that fits the slot in the fore-end below the barrel. I also stitched together a quick adjustbale rifle sling using 1.25" webbing and Grovtec HD QD swivels/flushcups.

Since I have no desire to use up precious primers at this time, I took every die off the Dillon 550 toolheads, and both T-7 turrets, and broke them all down and cleaned them until they are perfect. Little bit of carb cleaner, some Hoppes, light oil, and about a hundred Qtips, and done. It wasn't a ton of setups, just .308, 6.5, .223 X2, and 9mm. Felt good to have everything shining like new. I was worried about any hidden rust, but found not a spec of rust in any die or thread. It's nice to know they are all cleaned up and protected until this mess gets better. Cleaned the 550 and T-7 as well, although they were not bad at all since I clean them after every loading session. Just some light dust removal. The bench is clean and clear at this time.

finished 100 6.5 x47 rounds. Now on to prepping 500 6 dasher pieces of brass for reloading next.

picked a bad time in history to start but I am almost ready to put a space together just to start reloading got my fingers crossed it goes well

Yesterday I cleaned, sized, check case lenght, inspected, and cleaned primer pockets on my LC/06 brass I have been playing with necking down to 6.5/06 instead of necking up 25/06 brass and that works well.

All 20 of them and they are looking and shooting fine so far.

Today I will charge them, seat bullets, measure, and be ready to try them at 1000 when it is warm enough to hang out on that hill in the cold wind.

I might clean off the bench a bit too but that is not a big priority to me. That is MY space and I will do what I want with it.

I admire pictures of all of you guys with the clean sanitary benches but mine is smaller, has been in almost daily use for 35 years, and has everything I need to load many different rounds that I shoot and I know where each and every thing is. I wish I had more space, but I don't. I lack storabe space.

It is not dirty or unclean and to many may look like a mess, but, I know where each and every thing I need is located.

Things are stacked in the order that I will need them and within an arm's reach.

And,, NO, I am not posting pictures of my bench. I don't know how to post pictures and will probably never learn how to do that as I am retarded as to how to do that and don't really care to learn that new skill.

All 20 of them and they are looking and shooting fine so far.

Today I will charge them, seat bullets, measure, and be ready to try them at 1000 when it is warm enough to hang out on that hill in the cold wind.

I might clean off the bench a bit too but that is not a big priority to me. That is MY space and I will do what I want with it.

I admire pictures of all of you guys with the clean sanitary benches but mine is smaller, has been in almost daily use for 35 years, and has everything I need to load many different rounds that I shoot and I know where each and every thing is. I wish I had more space, but I don't. I lack storabe space.

It is not dirty or unclean and to many may look like a mess, but, I know where each and every thing I need is located.

Things are stacked in the order that I will need them and within an arm's reach.

And,, NO, I am not posting pictures of my bench. I don't know how to post pictures and will probably never learn how to do that as I am retarded as to how to do that and don't really care to learn that new skill.

For the local long range steel matches, there's no penalty for heavy rifles. They're always supported somehow, off bags, or bipod/tripod, and more mass reduces recoil. The balance point doesn't really matter, so long as it's not too out of whack.Was the weight for recoil reduction? Balance on the bag? Both? Have you shot with it yet?

I have shot it. It balances a bit in front of the mag well. It has a long, heavy barrel and it's a little nose-heavy, so I'll probably drill out the stock under the butt-pad, and add another lump of lead. Again, other than having to lug around a heavy rifle, there's no reason not to make it even heavier.

My rifle is heavy too, somewhat, and has a nice brake on it, I hate recoil.

I don't have to carry it very far but could tote it a ways if I had too.

I don't have to carry it very far but could tote it a ways if I had too.

I finished off my Mil. 06 to 6.5 and have fireformed them all. 20. Rds.

It all went well and felt good so I hope weather let's me play at the top of the hill out to 1000. -- I get cold quick. That is a factor.

If it doesn't I will go to 600 range down out of the wind somewhat and give it a go there. Nice steel at 600. and I paint em.

We have a speedometr, LabRadar, and it would be neat to use it but it is cold as fuck up there so I don't wanting my Partner in Crime getting his fingers too cold. There is a better day for that.

As hard as it to do, Everybody think of something that makes YOU, Happy. It is everywhere for me. FM

It all went well and felt good so I hope weather let's me play at the top of the hill out to 1000. -- I get cold quick. That is a factor.

If it doesn't I will go to 600 range down out of the wind somewhat and give it a go there. Nice steel at 600. and I paint em.

We have a speedometr, LabRadar, and it would be neat to use it but it is cold as fuck up there so I don't wanting my Partner in Crime getting his fingers too cold. There is a better day for that.

As hard as it to do, Everybody think of something that makes YOU, Happy. It is everywhere for me. FM

That many? Or so few that you have to make sure you didn't lose one?just counting my primer stock..... again.....

I had a temper tantrum! Turns out that my brand new Redding #2 kept sticking at about 1/10 grain from even. Once I figured it out, I had to dump and reload 50 rounds, of different ammo... Well I found out why it was sticking, the tip end of the beam was touching the scale on the left, so I stupidly though that if I touched the end of beam against the belt sander it would provide some clearance, turns out that worked just fine, but the level of the scale was so far off it was un-usable, that's when I had a tantrum!! Aaarg ... Thats a $100 bill I'll never get back.... my fault though, should have thought that through before doing anything....

Been too long since I got much done.

300 PRC

Expander mandrel through the brass followed by a light chamfer. Dropped some RL26 in the case and seated some old 208 Amax on top to get through barrel speed up.

300 PRC

Expander mandrel through the brass followed by a light chamfer. Dropped some RL26 in the case and seated some old 208 Amax on top to get through barrel speed up.

Attachments

Stocked up on some freedom powder and new brass. Got my induction annealer timer wired up. Now just waiting on the heater.

Thanks to all you guys here I had to spend a bunch of money and try loading some precision ammo on the 550. Last few weeks I’ve been gathering things I needed. I got a cpl armonov toolheads also polished up my shellplate and waiting for a new inline stand to get it all set back up. Will be starting some load development on a 223 when it’s back together. I have a healthy stock of 77smk varget and 8208 to start playing with. I think I settled on my first run I’ll size on the MEC than prep brass. It’ll go to the Dillon for mandrel powder and seat. Wish me luck.

I got to shoot my 6.5/06 with the LC 06 brass with the LabRadar chingadero this morning.

We had a bit of trouble getting the speedometer to work right but using my usual dope I knew they were pretty fast and going high.

I lowered the elev. and got hits and dialed more windage in. Going too fast. I will lower charge.5 gr. accurate but I want some barrel life too.

Carlos,I like your bench. Busy with various.

We had a bit of trouble getting the speedometer to work right but using my usual dope I knew they were pretty fast and going high.

I lowered the elev. and got hits and dialed more windage in. Going too fast. I will lower charge.5 gr. accurate but I want some barrel life too.

Carlos,I like your bench. Busy with various.

Getting an old colleague into long range shooting and reloading. He spent a shit load of money lately getting everything recommended but he hasn't set up his bench yet. He's coming to my place today for a tutorial on brass prep. Add another one to the ranks.

Yesterday, I spent time on detail-cleaning a factory rifle. It was full of desert dust and grit clinging to various oily surfaces after the last year's worth of plinking, match-shooting and varmint hunting. While it was apart, I took the oportunity to stone the sear. Annoyingly, it still feels gritty before the break. At least it's all clean now.

I finally got all of my precision and finalizing work inside, pretty happy with it. Not being in the garage the temperature is now controlled inside and the A&D FX120i responds much better now. Not to mention the dust has cut down drastically. It's also nice being warm in the winter, that little buddy heater could only do so much.

OK nice flex with your 8lbs of N570I finally got all of my precision and finalizing work inside, pretty happy with it. Not being in the garage the temperature is now controlled inside and the A&D FX120i responds much better now. Not to mention the dust has cut down drastically. It's also nice being warm in the winter, that little buddy heater could only do so much.

View attachment 7531527

I swear it’s always thereOK nice flex with your 8lbs of N570

I didn’t even take a picture of the mystery cabinet below the bench

Took my RPR down to nuts and bolts for a cleaning and color change....

The irony is that he doesn't have any primers to light it. It's just expensive, rarified Finnish fertilizer.OK nice flex with your 8lbs of N570

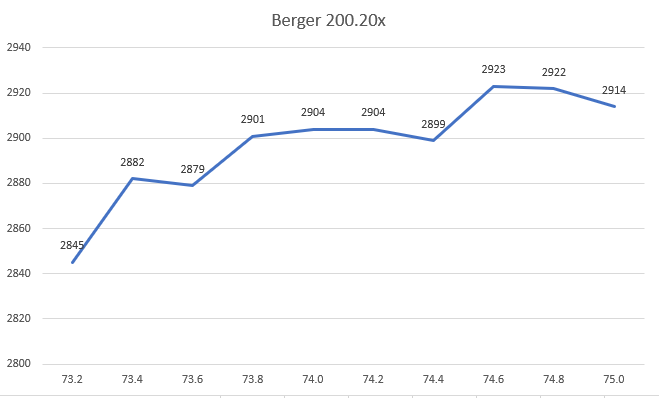

What did I do? I downloaded data from my ladder test yesterday with 300-WM cases, Accurate MagPro powder, and Berger 200.20x bullets. It showed two really nice flat-spots (73.8-74.2 and 74.6-74.8) that I built deep-dive 5-round groups to accuracy-test on the next nice range day. I also built one more grain of ladder testing above 75.0 to start looking for pressure signs. Used my new QuickLoad software to formulate the tests ... that's pretty cool too. Test rifle is a MPA 300WMBA.

Really getting into this handloading stuff ... it is VERY addictive. My wife hasn't seen me since I got my reloading press ... she think "Calipers" are a vegetable.

Really getting into this handloading stuff ... it is VERY addictive. My wife hasn't seen me since I got my reloading press ... she think "Calipers" are a vegetable.

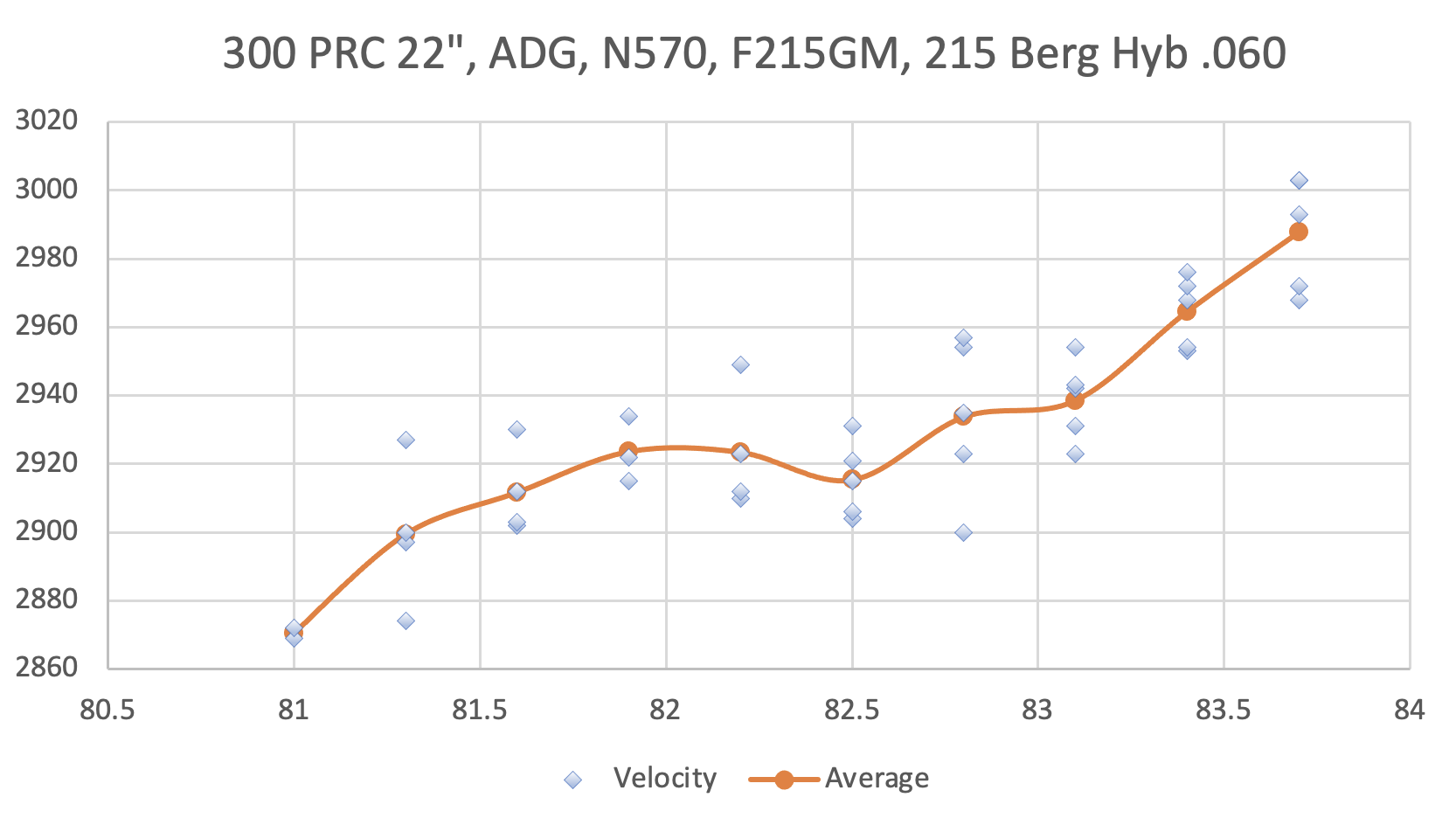

Inspired by rustyinbend I decided to analyze my ladder as well early this morning before work. The shot count was at 60 when I started this and ended at 110.

I'm under the theory from Adam MacDonald at AutoTrickler...

- Group size is primarily dependent on seating depth (jump)

- Velocity SD is primarily dependent on the powder charge

- Group shape is a statistical illusion. Size is all that matters.

I'm very tempted to do the test again to get more data points on once fired brass. But for now, it looks like a nice node at 82.0 grains. Onto seating depth...

I'm under the theory from Adam MacDonald at AutoTrickler...

- Group size is primarily dependent on seating depth (jump)

- Velocity SD is primarily dependent on the powder charge

- Group shape is a statistical illusion. Size is all that matters.

I'm very tempted to do the test again to get more data points on once fired brass. But for now, it looks like a nice node at 82.0 grains. Onto seating depth...

Good stuff. only comment is don't ignore the 2-shot flat spot around 83gr. Maybe build for that too.Inspired by rustyinbend I decided to analyze my ladder as well early this morning before work. The shot count was at 60 when I started this and ended at 110.

I'm under the theory from Adam MacDonald at AutoTrickler...

- Group size is primarily dependent on seating depth (jump)

- Velocity SD is primarily dependent on the powder charge

- Group shape is a statistical illusion. Size is all that matters.

I'm very tempted to do the test again to get more data points on once fired brass. But for now, it looks like a nice node at 82.0 grains. Onto seating depth...

And you're absolutely right ... group size matters.

Thanks, I did see some pressure around 83.1 but I'm not sure if it's too much to worry about it. The ejector swipes happen on my dummy rounds but ejector marks, half moons, (please correct me if my language is wrong) started to show. Not sure if it's because virgin brass needed to be fire formed to better fit the chamber or not.

This is 83.1 then 83.4 respectively, definitely going to start a separate thread.

This is 83.1 then 83.4 respectively, definitely going to start a separate thread.

Primers are flat and an ejector mark. Brass won’t last very long running it that hot.Thanks, I did see some pressure around 83.1 but I'm not sure if it's too much to worry about it. The ejector swipes happen on my dummy rounds but ejector marks, half moons, (please correct me if my language is wrong) started to show. Not sure if it's because virgin brass needed to be fire formed to better fit the chamber or not.

This is 83.1 then 83.4 respectively, definitely going to start a separate thread.

View attachment 7531915

I've been taught that once you see the ejector circle ... it's time to stop.Thanks, I did see some pressure around 83.1 but I'm not sure if it's too much to worry about it. The ejector swipes happen on my dummy rounds but ejector marks, half moons, (please correct me if my language is wrong) started to show. Not sure if it's because virgin brass needed to be fire formed to better fit the chamber or not.

This is 83.1 then 83.4 respectively, definitely going to start a separate thread.

BTW ... I always do my testing with brass that's been fired. It takes the "New Brass Bloat Factor" out of the equation.

Primers are flat and an ejector mark. Brass won’t last very long running it that hot.

For comparison's sake here's 81.0 and 81.3 along with an unfired primer.

BTW ... I always do my testing with brass that's been fired. It takes the "New Brass Bloat Factor" out of the equation.

Going to run the test again to eliminate this factor, thanks for that insight.

Last edited:

If you keep running that much powder...you are going to blow those primer pockets out...I can show you a partial 5 gallon bucket of ADG 300PRC brass if you don't believe me....I'd rather not...that is WAY down stairs and it is my lazy day.

Do you use the electric trimmer to vibrate the brass to get more powder in?

I'm about to load up some 245gr Berger EOL's....and slap in some converted 375 Ruger to 300PRC....probably shoot Saturday....Going to spin my old barrel on to give this 300-375 brass its first firing.

I'm about to load up some 245gr Berger EOL's....and slap in some converted 375 Ruger to 300PRC....probably shoot Saturday....Going to spin my old barrel on to give this 300-375 brass its first firing.

If it fits it ships.I'm sure you'll love this one, N570 86.0 grains for some pressure testing, little vibration lovin' tonight. I think it might be at capacity?

View attachment 7533091

de primed 400 rounds by hand lol and cleaned the primer pockets again by hand but only 3100 left to go god help me lol

can see i am going to have to automate at least this part as soon as I can .

can see i am going to have to automate at least this part as soon as I can .

Not a fucking thing, can’t find srp. May resort to standing at an intersection with a cardboard sign.