Today I set up the lathe, collected all my tooling, tore apart a Howa 1500 and took some measurements, indicated in a replacement barrel, and threaded the metric tenon. I'll chamber/cut/crown and thread the muzzle tomorrow.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do in the reloading room today?

- Thread starter Kisssofdeath

- Start date

Today I mounted a new pattern vise to make use of its swivel jaws on the irregular shaped objects in out awesome hobby.

The frankford arsenal case prep center? If so how do you like it? Was just about to order one"Been avoiding trimming 850 6.5CM and 500 308 for weeks now. But the time has come.

"

With my slowly worsening carpal-tunnel sydrom, I may have to buy one of these things soon.

I did this.......... a forster coax mounted on a 4" inline fabrication riser.

It appears that you have a shorter handle on your press than the one that came with mine.I did this.......... a forster coax mounted on a 4" inline fabrication riser. View attachment 7510431

What are your thoughts on it?

"Been avoiding trimming 850 6.5CM and 500 308 for weeks now. But the time has come.

"

With my slowly worsening carpal-tunnel sydrom, I may have to buy one of these things soon.

Money well spent, why I waited decades to buy I am not sure.

The frankford arsenal case prep center? If so how do you like it? Was just about to order one

So my review of it, I’ve don’t about 1500 cases of 223 on mine, and if you have carpel tunnel then you should probably look elsewhere. I think I’m going to get the giraud triway trimmer. After 300 cases my hands hurt so bad I physically couldn’t do another one and I have young 27 y/o hands.

the triway would at least change it from a 3 step process to 1.

D

Deleted member 113831

Guest

That is a badass vice! Did you make the ways or just restore an original design?Today I mounted a new pattern vise to make use of its swivel jaws on the irregular shaped objects in out awesome hobby. View attachment 7510341

D

Deleted member 113831

Guest

I have the triway for 308, 223 and 300blk.So my review of it, I’ve don’t about 1500 cases of 223 on mine, and if you have carpel tunnel then you should probably look elsewhere. I think I’m going to get the giraud triway trimmer. After 300 cases my hands hurt so bad I physically couldn’t do another one and I have young 27 y/o hands.

the triway would at least change it from a 3 step process to 1.

I take a high speed drill and clamp it in a vice so the cutter is pointing up. I can do 1,000pcs of .223 in about 1 hour.

Yea 1000 pieces of 223 in the FA would take me probably 8 hours and my hands would need surgery after.I have the triway for 308, 223 and 300blk.

I take a high speed drill and clamp it in a vice so the cutter is pointing up. I can do 1,000pcs of .223 in about 1 hour.

D

Deleted member 113831

Guest

I had two 5 gallon buckets full to the top of winchester 223 brass, that had been languishing in my shed. I resized and trimmed it almost 15 years ago and hadn't touched it since.

I had never cleaned it, so it was still coated with resizing lube. So I dragged them out and began running all of it through the wet tumbler using 5/16 ceramic tumbling media instead of steel pins. I'm about 2/3rds done right now.

I had never cleaned it, so it was still coated with resizing lube. So I dragged them out and began running all of it through the wet tumbler using 5/16 ceramic tumbling media instead of steel pins. I'm about 2/3rds done right now.

I had two 5 gallon buckets full to the top of winchester 223 brass, that had been languishing in my shed. I resized and trimmed it almost 15 years ago and hadn't touched it since.

I had never cleaned it, so it was still coated with resizing lube. So I dragged them out and began running all of it through the wet tumbler using 5/16 ceramic tumbling media instead of steel pins. I'm about 2/3rds done right now.

what’s the purpose of the ceramic over SS?

For some reason wet tumbling with ss pins and citric acid doesn’t remove hornady one shot.

D

Deleted member 113831

Guest

The 223 is very easy on the hands. In a high speed drill the torque is very light. The 30 cal stuff is a little more difficult. I can't do as many of those or do them quite as fast, but still the cheapest and easiest solution I've found.Yea 1000 pieces of 223 in the FA would take me probably 8 hours and my hands would need surgery after.

As far as I'm concerned, it paid for itself the very first time I used it.

D

Deleted member 113831

Guest

It does just as good a job on the outside, it just doesn't get into the primer pockets, but I could care less about that. They get clean enough.what’s the purpose of the ceramic over SS?

For some reason wet tumbling with ss pins and citric acid doesn’t remove hornady one shot.

The ceramic doesn't get stuck in the flash holes or the inside of the case. It very easy to pick the cases out of it. I sacrifice an insignificant amount of cleaning ability for much more ease of use.

So my review of it, I’ve don’t about 1500 cases of 223 on mine, and if you have carpel tunnel then you should probably look elsewhere. I think I’m going to get the giraud triway trimmer. After 300 cases my hands hurt so bad I physically couldn’t do another one and I have young 27 y/o hands.

the triway would at least change it from a 3 step process to 1.

Trim it 2 might be another good option.

So my review of it, I’ve don’t about 1500 cases of 223 on mine, and if you have carpel tunnel then you should probably look elsewhere. I think I’m going to get the giraud triway trimmer. After 300 cases my hands hurt so bad I physically couldn’t do another one and I have young 27 y/o hands.

the triway would at least change it from a 3 step process to 1.

If your hands are like mine part of the problem is trying to hold something that small firmly enough.

Spark plug pliers are your friend. The black handled ones with the red tips (Lisle 52990).

Yes that is definitely the problem at least with the hand pain. Interesting idea.If your hands are like mine part of the problem is trying to hold something that small firmly enough.

Spark plug pliers are your friend. The black handled ones with the red tips (Lisle 52990).

the other half of the problem is also doing 3 steps instead of just once

Let's for the sake of argument you end up with thousands of pieces of quality range brass that is in specks but short of trim lenght.

What now?

Those 3 way trimmers dont do so well with that.

We made adapters to hold the lyman tools in a strait cordless screw driver.

What now?

Those 3 way trimmers dont do so well with that.

We made adapters to hold the lyman tools in a strait cordless screw driver.

Set it to the shorter cases so they're all the same.Let's for the sake of argument you end up with thousands of pieces of quality range brass that is in specks but short of trim lenght.

What now?

Those 3 way trimmers dont do so well with that.

We made adapters to hold the lyman tools in a strait cordless screw driver.

I use the forster classic with the 3-way and a drill.

That is a badass vice! Did you make the ways or just restore an original design?

no, they are on sale right now at Woodrcaft for $95, down from almost $150

Last edited:

D

Deleted member 113831

Guest

Huh?Let's for the sake of argument you end up with thousands of pieces of quality range brass that is in specks but short of trim lenght.

What now?

Those 3 way trimmers dont do so well with that.

We made adapters to hold the lyman tools in a strait cordless screw driver.

I've used my triway on literally thousands of range pickups. I set mine for 1.75" and go to it. If the neck on a piece is too short for the mouth to touch the cutter, then it is already good.

The problem showed up when I sorted out several hundred pieces of fc 223 (range brass) nice and clean.

It was all short of 1.75 but not very consistant.

I guess running it all shorter would have been an option but I was hoping it might make the cut next time if recovered.

I don't guess that will efect volume but maybe slightly on neck tension?

I use a mandrell and set all to 0.002 thousands.

I am open to any suggestions.

It was all short of 1.75 but not very consistant.

I guess running it all shorter would have been an option but I was hoping it might make the cut next time if recovered.

I don't guess that will efect volume but maybe slightly on neck tension?

I use a mandrell and set all to 0.002 thousands.

I am open to any suggestions.

If it didn’t need to be trimmed then I wouldn’t have touched it at all. These are AR rounds not F classes loads.The problem showed up when I sorted out several hundred pieces of fc 223 (range brass) nice and clean.

It was all short of 1.75 but not very consistant.

I guess running it all shorter would have been an option but I was hoping it might make the cut next time if recovered.

I don't guess that will efect volume but maybe slightly on neck tension?

I use a mandrell and set all to 0.002 thousands.

I am open to any suggestions.

If it didn’t need to be trimmed then I wouldn’t have touched it at all. These are AR rounds not F classes loads.

Well you have me on that.

I treat the ar rounds as if my life depended on them.

It's an exercise in futility with inexpensive bullets to hone skills with.

Well you have me on that.

I treat the ar rounds as if my life depended on them.

It's an exercise in futility with inexpensive bullets to hone skills with.

I don’t trim or charmer my bolt gun rounds every time. They only get trimmed when they get to max spec. Probably 6-7 loads inbetween each time they get trimmed and chamfered. No problem holding small groups.

you are putting too much effort into an AR load. Especially if you aren’t using match bullets

I haven't used it yet to be honest. That handle extends 8" off the yoke of the press. The press also came with the short forster handle. I might end up changing to it to shorten the throw. I'lll just have to see how it all feels once i begin using it.It appears that you have a shorter handle on your press than the one that came with mine.

What are your thoughts on it?

I found some 9mm 115 grain bullets yesterday and ordered some, but I have not been able to find much, if any, powder in stock for my various rifle applications. For the 9mm stuff I am planning on using some Unique that is normally allotted to my 20ga shotgun.Got powder today and bullets yesterday, probably enough to reload 2021 match season brass for 2022 match season lol.

After I posted my question, I went to my reloading room and noticed that your handle is the same length as mine...but never got around to amending my post/question.I haven't used it yet to be honest. That handle extends 8" off the yoke of the press. The press also came with the short forster handle. I might end up changing to it to shorten the throw. I'lll just have to see how it all feels once i begin using it.

Realized that about a month ago I must have accidentally thrown away my binder with data /records from the beginning when I was 16 to now... im 45 now!

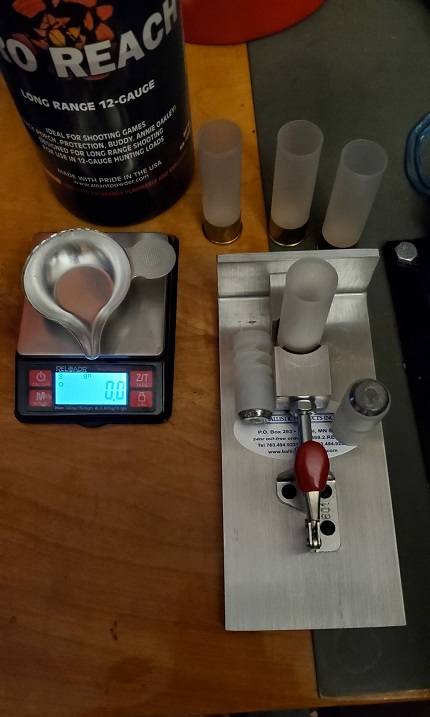

Not recent but the last thing I loaded was some Slugs.

I answered a phone call from my brother.

"I can't find H4350 for my 66 gr 140 gr NBT 7mmRM load. Can I substitute AA4350?"

I used Quickload and told him "Reduce to 65 gr for the same pressure and velocity. "

"I can't find H4350 for my 66 gr 140 gr NBT 7mmRM load. Can I substitute AA4350?"

I used Quickload and told him "Reduce to 65 gr for the same pressure and velocity. "

Finished up the Howa rebarrel job yesterday. Santa Claus will deliver this morning after coffee, and then weather permitting, it'll get zeroed then some load workup:

*Edit* Took a minute to run the bore cam down it just to QA my job before zero-ing. Looks pretty concentric at the lands, and has a good surface finish. I love Manson reamers.

*Edit* Took a minute to run the bore cam down it just to QA my job before zero-ing. Looks pretty concentric at the lands, and has a good surface finish. I love Manson reamers.

Last edited:

D

Deleted member 113831

Guest

AA4350 has been made by at least 2 different manufacturers. The older stuff was made by Lovex in the Czech Republic and the newer stuff (2009) has been made in the IMR plant in Canada.I answered a phone call from my brother.

"I can't find H4350 for my 66 gr 140 gr NBT 7mmRM load. Can I substitute AA4350?"

I used Quickload and told him "Reduce to 65 gr for the same pressure and velocity. "

The two jugs I have are Canadian and the burn rate is closer to 4831 than 4350.

You've really piqued my curiosity. Are these for hunting? Home defense? I reload for 12 and 20 ga but it's all 8's, 8.5's, and 7.5's - for clays. When I lived in a slug-only state, I could not stomach sitting down at the bench and squeezing off enough rounds to warrant reloading.Not recent but the last thing I loaded was some Slugs.

View attachment 7511252View attachment 7511253

Pumped out 1000 9mm 147gr on the Dillon, reorganized a few cabinets and then I cleaned and swept. I just cannot stand a disorganized work area and always budget 10 minutes at the end of a loading session for cleanup.

You've really piqued my curiosity. Are these for hunting? Home defense? I reload for 12 and 20 ga but it's all 8's, 8.5's, and 7.5's - for clays. When I lived in a slug-only state, I could not stomach sitting down at the bench and squeezing off enough rounds to warrant reloading.

Hunting. I shoot about 12 max at one sitting when I'm trying a load.

Ballistic Products for the tools, they also have load data. I'm using Slugs R Us for slugs and their published load data. Also Midway USA carries Lightfield slugs as a component. The hulls are hard to find right now, Grafs did have some.

Pro Reach and Herco in that order are my choice but Blue Dot showed well, definitely going work more on the Blue Dot.

I have a small bucket of .308 brass that needs trimming, so therefore I find any number of tasks to get through to further avoid trimming. Not that trimming is so bad, it's just not my favorite. Tonight's procrastination mission was to prep 200 pieces of new Lapua .308.

Run the necks over the mandrel, a quick inside chamfer, ready to go. Unfortunately, there are no more trimmer avoidance jobs. Next time at the bench, start making chips.

Praying all had a wonderful Christmas and a safe, productive 2021. C. S.

Run the necks over the mandrel, a quick inside chamfer, ready to go. Unfortunately, there are no more trimmer avoidance jobs. Next time at the bench, start making chips.

Praying all had a wonderful Christmas and a safe, productive 2021. C. S.

D

Deleted member 113831

Guest

I have 4 powders that get used for 223. I have Ramshot Xterminator, H335, Data 2230-C, WC844.

Depending on the information source, several of these can change places in burn rate order. I wanted to sort them out for my particular lots. I loaded 10 rounds of 55gn fmj's over 21gn of each powder and sorted them out by average velocity.

Depending on the information source, several of these can change places in burn rate order. I wanted to sort them out for my particular lots. I loaded 10 rounds of 55gn fmj's over 21gn of each powder and sorted them out by average velocity.

What did I do? Stared at my stuff ... wishing items on backorder would finally arrive.

put a shellplate bearing kit on the 550b, and a bearing guide for the primer system. also switched out the primer catch parts on the square deal to the newer style.

In the 90's I bought some bullet-making dies and made benchrest bullets for myself. When my job situation changed, I stopped shooting BR and put everything away. About 2005, I moved and brought all that crap with me. Since I don't shoot BR any more, I'm thinking about selling the dies (Simonson carbide 6mm) and presses (all RCBS, one each for squirt, core seat, and point up). So today I pulled out all the stuff, assembled the ejector frames on the presses, cleaned up everything, applied fresh lube, checked it all out, and took pictures. That took 7 hours, the presses were ... dirty.

In the process, I found an RCBS A-2 press that I bought from George Kelbly Sr back in the day. A-2s are steel. Heavy like boat anchor! Strong like ox! George was going to use the press for bullet-making so he replaced the shell-holder ram with a new part that he made. I want it to be a reloading press again so I need a shell-holder ram. If anyone on here has one, I'm in the market.

In the process, I found an RCBS A-2 press that I bought from George Kelbly Sr back in the day. A-2s are steel. Heavy like boat anchor! Strong like ox! George was going to use the press for bullet-making so he replaced the shell-holder ram with a new part that he made. I want it to be a reloading press again so I need a shell-holder ram. If anyone on here has one, I'm in the market.

Over the last few several days that have been cold and snowy, I used LC -76-Match brass to neck down for my 6.5/06.

Did 5 to start with and shot them for fire form and was happy, so I did the other 15. They take some trimming.

I stretched it out a long way as My Squaw knows to stay away from me when I am at my bench and makes no noise.

Silence is Golden and I am Rich.

Did 5 to start with and shot them for fire form and was happy, so I did the other 15. They take some trimming.

I stretched it out a long way as My Squaw knows to stay away from me when I am at my bench and makes no noise.

Silence is Golden and I am Rich.

Today finished stuffing 3 lbs of RL 16 into 6.5CM cases.

Threaded another muzzle today, and when finished, had a celebratory homebrew, and put the rifle back together. Hopefully a muzzle device won't affect the load/group/zero too much.

Neck turned 240 6BR cases for a new 6BRA that needs fire forming, neck turned 100 6BR cases and sized for new 22BR varmint rig, loaded all neck turned brass with R15 and various bullets in 6mm and .224 for range time. Sorted B to O 1000 Berger 108 BT's.

Attachments

Got the Zero fired up making some 500 mags today. This thing is smooth

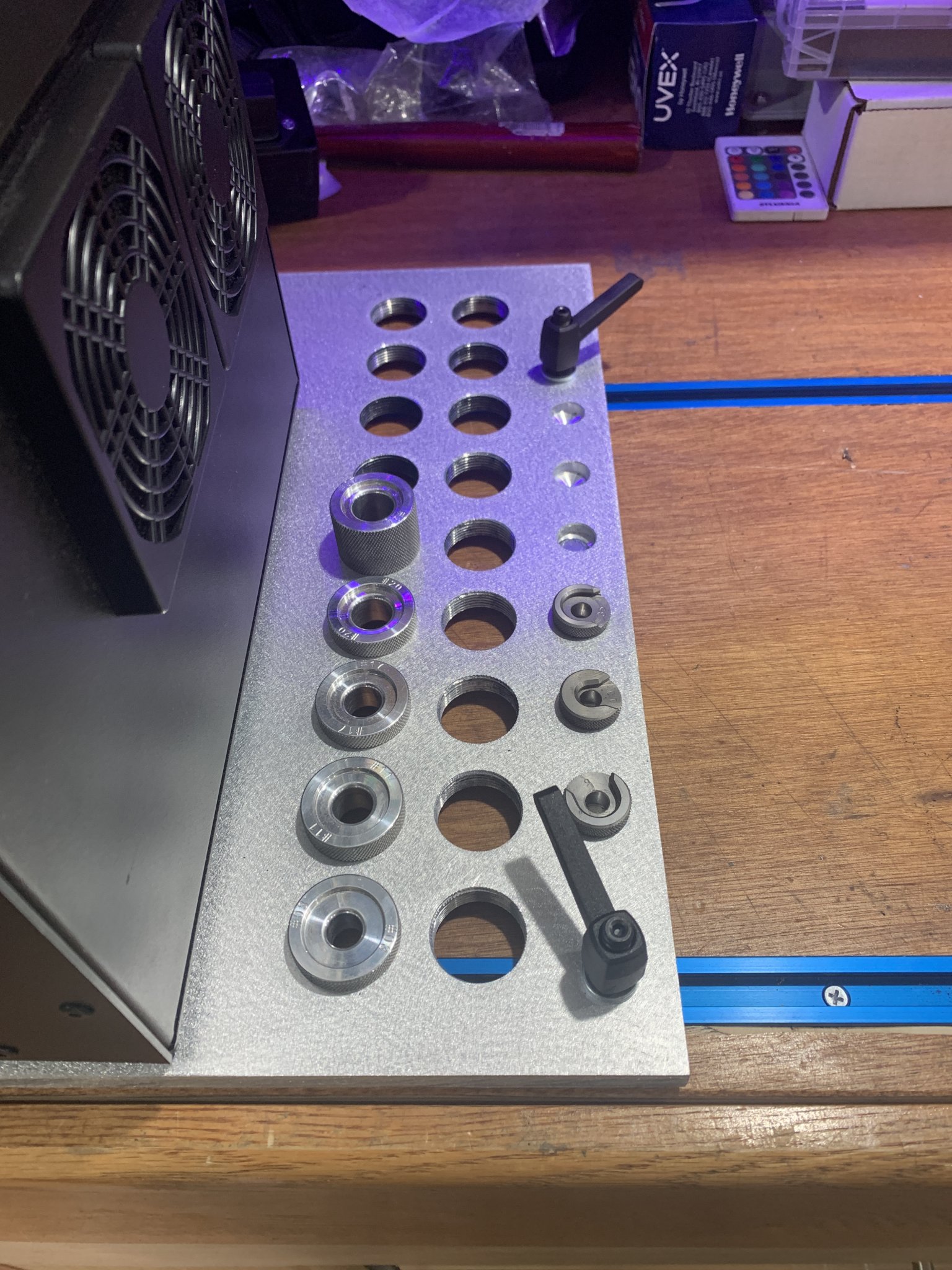

I built a sliding plate for the amp annealer and amp-mate.

It slides on T-Track on table rollers so I can move it out of the way when not in use.

Joseph

It slides on T-Track on table rollers so I can move it out of the way when not in use.

Joseph

![IMG_1126[1666].jpg](/shooting/data/attachments/702/702311-010a5753449d3e860b3ba7e0f4e5c053.jpg)

![IMG_1127[1667].jpg](/shooting/data/attachments/702/702312-48926c2c267d77db629acb119330628e.jpg)