The AMPMate is so fascinating... It works like a charm. I don't know why I waited so long to buy it. The Dillon hopper is above the picture and I use a spring tube to just drop it in.Oh my, a real AMP Mate!

James is going to be jealous!

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

What did you do in the reloading room today?

- Thread starter Kisssofdeath

- Start date

Haven't touched it in months and still dialed to perfecto: couple hours + big blue press = lots of little blue bullets.

I swapped out the Rock chucker for the Lee turret tonight.

Going to shoot my second USPSA match tuesday night and I can see a large pile of 9mm getting eaten in the next few months.

Going to shoot my second USPSA match tuesday night and I can see a large pile of 9mm getting eaten in the next few months.

Shot some shtf bullets today.

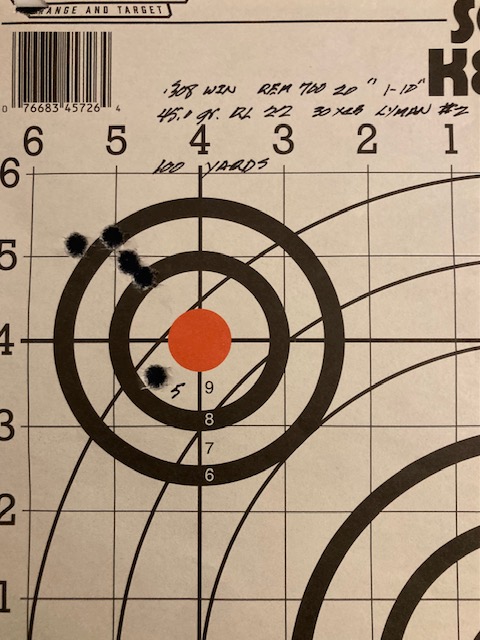

These are the 30XCB cast with Lyman #2 alloy, Hornady gas check, and LLA 2700+ lube loaded over 45.0 grs. of RL22. Remington case and Rem 9 1/2 primer. This load chronos at about 2300 fps.

The rifle is a G prefix Remington 700 SPS .308 Win with the barrel cut and crowned at 20” and it has a Timney Elite Hunter trigger set at 2 lbs. with no other changes.

I guess I should have culled the bullet in shot #5. The other 4 measure 0.859”

Here is the link to the bullet mould:

noebulletmolds.com

noebulletmolds.com

These are the 30XCB cast with Lyman #2 alloy, Hornady gas check, and LLA 2700+ lube loaded over 45.0 grs. of RL22. Remington case and Rem 9 1/2 primer. This load chronos at about 2300 fps.

The rifle is a G prefix Remington 700 SPS .308 Win with the barrel cut and crowned at 20” and it has a Timney Elite Hunter trigger set at 2 lbs. with no other changes.

I guess I should have culled the bullet in shot #5. The other 4 measure 0.859”

Here is the link to the bullet mould:

310-165-FN-H3 4 Cavity GC | NOE Bullet Moulds

Have you considered powder coating them instead of traditional lube? I stopped casting .30 cal bullets for the 06 and 30-30 long before PC became a thing so i haven't tried it myself but I understand its very effective in rifle bullets. I know I really like it on 9mm and .452 pistol bullets.Shot some shtf bullets today.

View attachment 7760022

These are the 30XCB cast with Lyman #2 alloy, Hornady gas check, and LLA 2700+ lube loaded over 45.0 grs. of RL22. Remington case and Rem 9 1/2 primer. This load chronos at about 2300 fps.

The rifle is a G prefix Remington 700 SPS .308 Win with the barrel cut and crowned at 20” and it has a Timney Elite Hunter trigger set at 2 lbs. with no other changes.

I guess I should have culled the bullet in shot #5. The other 4 measure 0.859”

Here is the link to the bullet mould:

310-165-FN-H3 4 Cavity GC | NOE Bullet Moulds

noebulletmolds.com

ShaKr

Got caught up on brass prep for my 6.5-CM AR-10 ... decapped, cleaned, annealed, sized, mandrelled, trimmed, and cleaned ... a few hundred twice-fired cases. Felt good to get this done. No better activity on a rainy day. Well ... "almost" no better activity.

Same here ... I shoot a LWRCI REPR MKII Elite in 6.5-CM with a Silencerco Chimera-300 suppressor. When I shoot this rifle with a muzzle brake and not suppressed it's super clean (cases and bolt carrier group) ... because it's a piston gas gun. But add the suppressor, and everything gets really dirty really fast, especially the cases. I wet-tumble on a Frankford Arsenal Platinum Series Rotary Tumbler using their Brass Cleaning Packs ... and even the ugliest brass comes out shiny and looking new ... even the primer pockets. It's a great cleaning alternative ... especially since I threw away the steel pins that made a mess and I realized were totally unnecessary.I did the same last night. Shot a gas gun match Saturday and reconditioned and prepped the 180 PCs of brass I shot. Those cases were nasty coming out of a suppressed gasser.

Nothing yet but I have some 338 edge brass I need to anneal and resize.

You'll be super-happy with the FA cleaning packs. I decap, and initially tumble for 90 minutes. Then do all my work ... I too use the Hornady One-Shot Case Lube spray ... and when I'm all done, I tumble for 60 minutes to get the lube off. Works great for me. Not a hint of leftover lube.I'm right there with you. Using the same tumbler although I haven't used their cleaning packs. I also stopped using steel pins to reduce the pinging on the necks. I have just been using Dawn and lemi shine. It generally works pretty good however it has a hard time with Hornady one shot lube. The mixture has to be just right in order for it to get the lube off and come out shiny. I ordered a 24 pack of the cleaning packs to give those a shot. How long are you letting them tumble for?

I like the work progres sheet on the binGot caught up on brass prep for my 6.5-CM AR-10 ... decapped, cleaned, annealed, sized, mandrelled, trimmed, and cleaned ... a few hundred twice-fired cases. Felt good to get this done. No better activity on a rainy day. Well ... "almost" no better activity.

View attachment 7760109

Cool checklist. May have to borrow that ideaGot caught up on brass prep for my 6.5-CM AR-10 ... decapped, cleaned, annealed, sized, mandrelled, trimmed, and cleaned ... a few hundred twice-fired cases. Felt good to get this done. No better activity on a rainy day. Well ... "almost" no better activity.

View attachment 7760109

For anyone that wants it, here's the Excel file (had to zip it to get it accepted as an attachment here). You're welcome to modify for your own stuff. The tags are sized for the 9"x6" Akro Bin #30237. These bins hold about 250 6.5-CM cases. Here's the Amazon link where I buy them.Cool checklist. May have to borrow that idea

Amazon product ASIN B00UBRV704

Attachments

Annealed some 6GT brass.

Man if I had ur reloading/gun budget I’d throw my money away. Beautiful setup there Sir!

Annealed some 6GT brass.

That doesn't suck. Only problem is I'd sit there and watch it all day, which would kinda defeat the purpose

Dillon Casefeeder.How big is the hopper?

Annealed some 6GT brass.

I hope you didn't strain any eye muscles watching that gadget anneal your brass.

HA! I was just about to ask if anyone with an amp mate actually saves time or do they all just sit there in a lump watching the whole time it runs.That doesn't suck. Only problem is I'd sit there and watch it all day, which would kinda defeat the purpose

First day I owned it. I watched it... For hours!HA! I was just about to ask if anyone with an amp mate actually saves time or do they all just sit there in a lump watching the whole time it runs.

I would reach out to Alex Findlay, he will make it right.My AmpMate just stopped working. Slowly deteriorated, getting more and more problematic until it just wasn't worth using after a while. It just sits in a corner. Wish I could send it back to Amp to be fixed or recalibrated

What wrong with it if you don't mind me asking?

Have you checked the ejector switch?I've spoken to him a number of times. I have swapped out USB cables. I have done firmware updates. I have readjusted heights and lengths

It will just randomly stop and I have to reset it

Over time, it doesn't get pressed correctly by the ejector arm. So what I do I add a piece of tape to press it easier (you can see it in my video closely). Or you can bend the arm.

Mine pooped out too.. I told him if he doesn't get back to moving that brass it's no dinner and he can sleep in the shed!

My AmpMate just stopped working. Slowly deteriorated, getting more and more problematic until it just wasn't worth using after a while. It just sits in a corner. Wish I could send it back to Amp to be fixed or recalibrated

Some people like PC and are quite successful with it. I have not tried it.Have you considered powder coating them instead of traditional lube? I stopped casting .30 cal bullets for the 06 and 30-30 long before PC became a thing so i haven't tried it myself but I understand its very effective in rifle bullets. I know I really like it on 9mm and .452 pistol bullets.

ShaKr

This is in a 12 twist .308. I also have a 17 twist. Shoot the same bullet. Both are Krieger barrels. Not sure what was up with the first shot here (It was 3 years ago). These loads are nowhere near max yet.

This is the 1-12” twist.

and this is the 1-17” twist .308. The goal with this one is 2700 fps.

Last edited:

Mine is hooked to a Dillon casefeeder. So far all of the problems come from the fucking casefeeder and my inability to stay within capacity limits. It'll rip through 2-3k cases in an hour while I do other things.Pics and info or you're making it up

Got caught up on brass prep for my 6.5-CM AR-10 ... decapped, cleaned, annealed, sized, mandrelled, trimmed, and cleaned ... a few hundred twice-fired cases. Felt good to get this done. No better activity on a rainy day. Well ... "almost" no better activity.

View attachment 7760109

I just totally stole that idea, few mins in word and I have a working set of labels that hopefully will make things easier to keep track of. Great idea man!

Today I rewired a dillon case feeder so it would go faster and keep up with this bugger.Set up my new rollsizer decapper. It's a pretty cool little machine for somebody who hates dirty ass primers around the press. And unlike most reloading gear, it actually works out of the box.

All this talk about Zero's and AMPMate's and rollsizer.com stuff has me wanting to throw some more money into the reloading room... except while I normally don't have cheap taste, what I have in mind is like $100 hahaha...

I'm thinking of getting one just for FL sizing and mandrel only.

Its ram lives right under station #1, so it's fully supported, the other stations not so much, but any of them would be fine for a mandrel die to live. The shell plates appear to be aluminum and honestly look nicer than what's on my Dillon.

Currently, I do both sizing and mandrel on my single stage, a pass for sizing, followed by a pass for the mandrel... and that means touching the brass 3-4 more times than I'd have to if I were to add the Lee to my routine. Then I could dedicate my single-stage for seating bullets (which is really the only thing I originally bought it for).

For precision stuff most of the time I normally only load 100 rounds at a time, so my current routine isn't too bad, but there are quite a few times (matches and such) where I end up loading 300 or more, and then it gets old quick.

Of course, I'll definitely end up spending as much or more than it costs pimping it out with Inline Fabrication stuff too... and I don't really have a good place to put it without getting another bench, but... behold the simplicity:

Anyone ever come across one of these?

Most of the videos I could find on them are of guys who went whole hog and attached every conceivable bell and whistle they could to turn it into some crappy, lame-ass impression of a Dillon 650/750, and that's NOT how I plan on using one. I plan to strip off all the unnecessary garbage and just use it as a simple auto-indexing two station press, IDK?

I'm thinking of getting one just for FL sizing and mandrel only.

Its ram lives right under station #1, so it's fully supported, the other stations not so much, but any of them would be fine for a mandrel die to live. The shell plates appear to be aluminum and honestly look nicer than what's on my Dillon.

Currently, I do both sizing and mandrel on my single stage, a pass for sizing, followed by a pass for the mandrel... and that means touching the brass 3-4 more times than I'd have to if I were to add the Lee to my routine. Then I could dedicate my single-stage for seating bullets (which is really the only thing I originally bought it for).

For precision stuff most of the time I normally only load 100 rounds at a time, so my current routine isn't too bad, but there are quite a few times (matches and such) where I end up loading 300 or more, and then it gets old quick.

Of course, I'll definitely end up spending as much or more than it costs pimping it out with Inline Fabrication stuff too... and I don't really have a good place to put it without getting another bench, but... behold the simplicity:

Anyone ever come across one of these?

Most of the videos I could find on them are of guys who went whole hog and attached every conceivable bell and whistle they could to turn it into some crappy, lame-ass impression of a Dillon 650/750, and that's NOT how I plan on using one. I plan to strip off all the unnecessary garbage and just use it as a simple auto-indexing two station press, IDK?

On the ghetto side of my reloading room I rigged together a Mr. Bulletfeeder and a Lee APP press. Now I can size 1200+ hi tek coated bullets per hour if I want to, which I really don't. But it works great.

Looking at the APP down the road for depriming 9mm and 5.56 prior to sending them to the 650.

It looks kinda chinsi. How tedious is the change over?

It looks kinda chinsi. How tedious is the change over?

It's easy. Seconds maybe. You just adjust the height. That's it.Looking at the APP down the road for depriming 9mm and 5.56 prior to sending them to the 650.

It looks kinda chinsi. How tedious is the change over?

Every video I've seen of it on the web makes it look really flimsy. I have mine on a Inline mount, and it is actually pretty stout. The little plastic pieces look like they will break, but so far no problems. I sized about 500 10 mm bullets a friend made for me, but he forgot to size them and I didn't want to look a gift horse in the mouth. It was easy as could be.Looking at the APP down the road for depriming 9mm and 5.56 prior to sending them to the 650.

It looks kinda chinsi. How tedious is the change over?

The tubes are a little loose in their mount, but a wrap of electrical tape firms it up a bit. The only other trick I've learned is that you have to set the jaws up first with one case (or bullet) in, but then you need to reset them once the stack is full, because the extra weight changes the amount of tension the grabbers have. Just a little.

I think it would work well for decapping. I use a rollsizer decapper, so I won't use it that way, but I will probably try to set it up with a Dillon casefeeder to give it a go and see how it would work. It shouldn't be too hard, it will just be an issue of making a transition from a dillon size tube to the app size. Chamfering the inside of the app tube should take care of feeding issues between the tubes.

Last edited:

guess my inner magpie just loved the pic of the shiny brass I finished cleaning 600 more of my own and shined them up till they sparkled in the room light .

I think it would work really well with one of those FW self centering decappers. The weird shellholders are going to have some more play than normal, but the self centering decapping die will counteract that. It wouldn't be that much of a pain to shove cases in the tube, or if you have kids you could just stick them up on the bench and let them play casefeeder.Ok. I'm convinced. I'm getting a Lee APP for Christmas.

IDK if I'll get a case feeder for it, or pimp it out too much, but even if the only thing I ever use it for is decapping, it'll be worth having.

I resized 15 cases out a 50 case box last night.

I’m a failure

I’m a failure

I resized 15 cases out a 50 case box last night.

I’m a failure

An addendum to this is that anybody using a Mr. Bulletfeeder who is having problems with it, which usually happens on the 1050 or Mk 7 as the toolhead moves rather than the shellplate, should look at mounting the MBF from a 3/4" pipe, either from the ceiling or the bench. It makes placement much easier, and the excellent Range Panda adapter sets it at a perfect 45 degree angle.On the ghetto side of my reloading room I rigged together a Mr. Bulletfeeder and a Lee APP press. Now I can size 1200+ hi tek coated bullets per hour if I want to, which I really don't. But it works great.

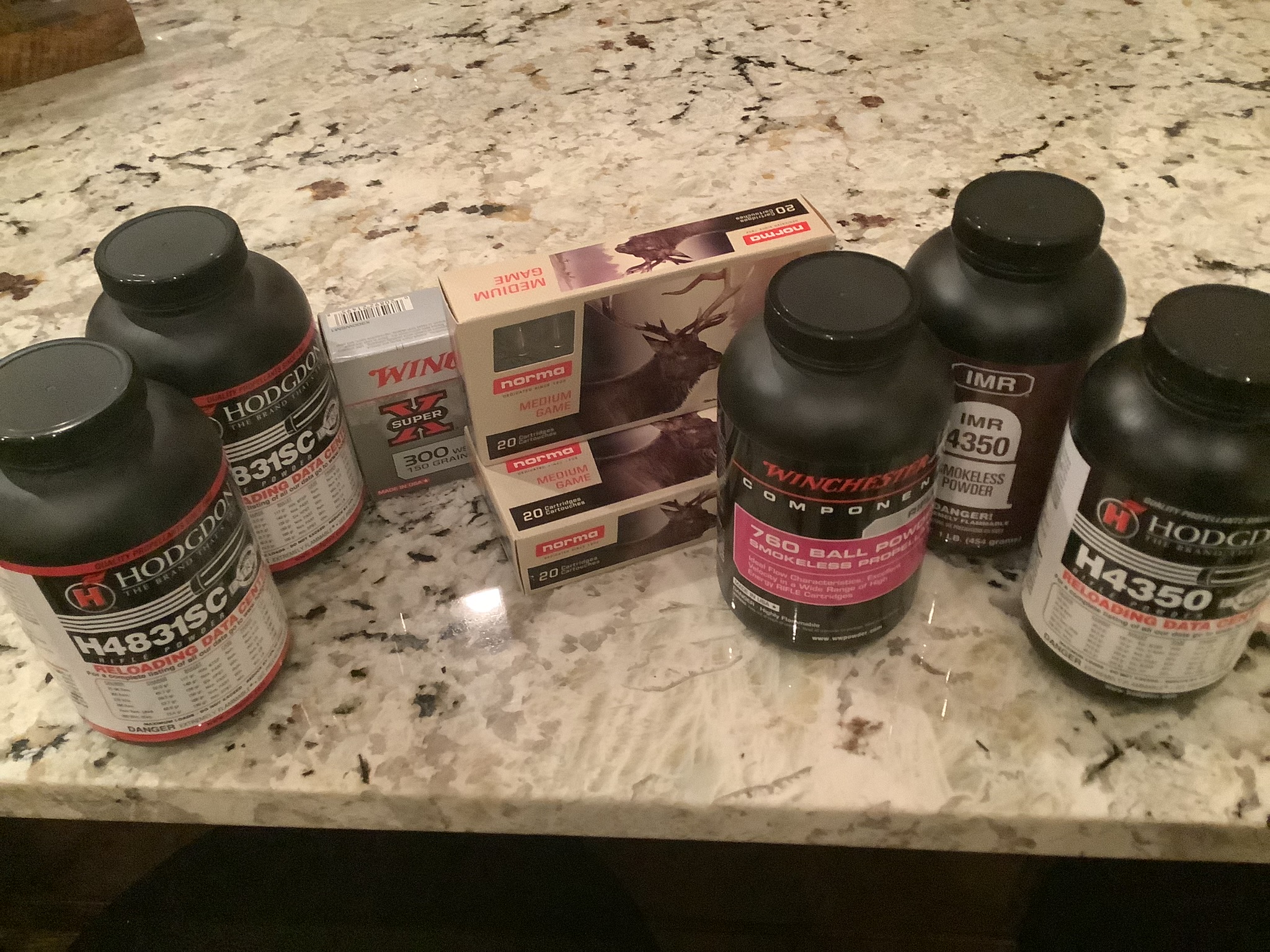

With my supply of 130 Bergers and Sierra’s drying up, after some good recommendations I got a supply in of the Norma Golden 130’s. Having the crud (a mild form of the flu not Covid) I have been working a bit slowly. Yesterday, I sized and cleaned 40 brand new Lapua cases in 6.5. Then after cleaning, I seated the primers after supper.

Today, I charged and seated the Norma bullets. However, for the first time, H4350 was used in the ladder test. These will be going in the MPA but the backstory involves the RPR.

When I purchased my RPR in 2017, IHMSA was defiantly on the wane in our area. The local club was holding 300 yard bench rest matches and I thought the RPR might work out in those matches. No one in our area was shooting the Creedmoor, so with no one to talk to I created loads using the powders I was familiar with, primarily IMR4350 and IMR4871. Nothing else on I had would work well with the Creedmoor. The accuracy was there but the velocities were very Poor. Then rechecking the newer manuals, I saw Superformance and gave it a try. Velocity in my rifle was not tops but good enough matching the factory load with factory listed bullet. So, all these years, I have been shooting Superformance with very good results and fine accuracy.

Never shot one of those bench rest matches (shooting paper is about as boring as shoveling ….) But got around enough folks shooting precision all of whom bragged on the results using H4350. So, I found a couple of pounds a month or so ago and am giving it a try.

Today, I charged and seated the Norma bullets. However, for the first time, H4350 was used in the ladder test. These will be going in the MPA but the backstory involves the RPR.

When I purchased my RPR in 2017, IHMSA was defiantly on the wane in our area. The local club was holding 300 yard bench rest matches and I thought the RPR might work out in those matches. No one in our area was shooting the Creedmoor, so with no one to talk to I created loads using the powders I was familiar with, primarily IMR4350 and IMR4871. Nothing else on I had would work well with the Creedmoor. The accuracy was there but the velocities were very Poor. Then rechecking the newer manuals, I saw Superformance and gave it a try. Velocity in my rifle was not tops but good enough matching the factory load with factory listed bullet. So, all these years, I have been shooting Superformance with very good results and fine accuracy.

Never shot one of those bench rest matches (shooting paper is about as boring as shoveling ….) But got around enough folks shooting precision all of whom bragged on the results using H4350. So, I found a couple of pounds a month or so ago and am giving it a try.

Out of shame

I finished sizing those edge cases and sized another 50 as well for penance.

I finished sizing those edge cases and sized another 50 as well for penance.

No actual work on the bench, but found some powder to reload 300WSM!

And some ammo too. Now if I could just find some LR primers!

And some ammo too. Now if I could just find some LR primers!

Loaded a bit of 308, sized 500 10mm bullets, decapped a few thousand 9mm cases. Tried to clean up but something got in the way.

Loaded 500 9mm's on the ole Lee pro 1000. Say what you want about Lee stuff, i shucked out 500 124gr berrys with 5.7gr of true blue @ 1.160" OAL in about an hour and a half with nary a hitch. Full ammo cans don't suck lol.

I got one last year and thought the same about the feeder for it. But when I had a couple hundred 38 spl to deprime I decided I didn't want to feed them all manually. If you have a 3D printer, check out https://castboolits.gunloads.com/showthread.php?354324-Making-that-Bullet-Collator for making your own case feeder/bullet feeder. Can use it for both brass or bullets. I printed/built two. One will be a case feeder on the APP and the other as bullet feeder for an XL650 w/Dillon Case feeder for pistol ammo. For the APP I have a 3/4" steel pipe as it's mount and then a spring routing brass to their attachments for the APP. The other cool part of their project is that they have interchangeable inserts for the APP which eliminate needing to adjust the bracket height when doing diff length brass.Ok. I'm convinced. I'm getting a Lee APP for Christmas.

IDK if I'll get a case feeder for it, or pimp it out too much, but even if the only thing I ever use it for is decapping, it'll be worth having.

600 loaded rounds of 9mm, over the last week. Everglades plated bullets shoot very well. I really like the Lee turret press. Auto drum and Inline fabrication reverse rotation kit makes this press way faster.

Should hold me for a few months.

Should hold me for a few months.