Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do in the reloading room today?

- Thread starter Kisssofdeath

- Start date

With that mini-split there over your charge thrower....are you concerned about airflow and a scale?Got the Inline Fab stuff mounted up and presses back set up. I have to wait until the floor is done in the old part (new playroom for kids) so my painter can come back and do touch up so I can't just set everything up yet but I'm trying to do what I can to limit how much there is to do after and get back in action. Slowly but surely.....

ups Delivered an 8 lb jug of Shooters World Match rifle. Going to start loading .308 again. When i look at what I used pay for RL15 I made the pig noise.

Not with it there but I couldn't put it or the scale anywhere else because I was worried about that. The fan on the new ones will run at 20% and with it pointed up, it doesn't mess with the scale. Of course you could always just turn it off while weighing and then cut it back on but I definitely heavily considered that whole phenomenon. It's about 6 feet out of being in line with the unit so the air blows past the scale mostly without "hitting it" even with the fan up more but if it's on a higher percentage speed it might effect it even with that placementWith that mini-split there over your charge thrower....are you concerned about airflow and a scale?

The biggest issue I have with ot is bulging when 147 gr bullets are seated.You love CBC brass and you just won’t admit it.

There’s nothing better than primers that are glued in and refuse to come out with a normal stroke of the press. It’s extra fun to have this happen when using a progressive press with automatic indexing.

CBC must have a hell of a wall thickness taper. They randomly bulge so much that either they won't chamber all the way or worse they chamber but lock the gun up something fierce.

I haven’t loaded any 147gr 9mm in their brass.

I just hate dealing with it in my XL650 because of their primer gluing nonsense.

At this point with the cost of primers reloading 9X19 is just about not worth it, especially if I factor in my time.

I just hate dealing with it in my XL650 because of their primer gluing nonsense.

At this point with the cost of primers reloading 9X19 is just about not worth it, especially if I factor in my time.

Aren't these things sorta like leased? You don't actually own them? Ridiculous!Too bad you spent your money on such a defective pile of crap.

Tell you what, I’ll do you big favor and take it off your hands so it doesn’t inconvenience you if you just send it to me.

LOL….

#jealous….

So, he can't send it to you without permission!!!!

147 gr suck . I quit loading them . Just my opinion but 124 gr. do whatever is necessary and 147 gr. don't do well out of MY pistols .I haven’t loaded any 147gr 9mm in their brass.

I just hate dealing with it in my XL650 because of their primer gluing nonsense.

At this point with the cost of primers reloading 9X19 is just about not worth it, especially if I factor in my time.

I also run a 550 ,650 setup and Don't glue any primers . Not sure what that's all about ,as I don't even lacquer seal primers , WHY ?

Beats me why CBC glues the primers in the pockets but they sure as hell do.147 gr suck . I quit loading them . Just my opinion but 124 gr. do whatever is necessary and 147 gr. don't do well out of MY pistols .

I also run a 550 ,650 setup and Don't glue any primers . Not sure what that's all about ,as I don't even lacquer seal primers , WHY ?

So when I go to resize/de-cap them in my 650 with Dillon dies the spring loaded de-cap pin doesn’t punch them all the way out I end up with a half in half out spent primer jamming the whole works.

I hate CBC ammo. It’s burner range ammo that is not worth picking up the brass.

Still figuring out the best place for everything. Here’s the latest setup:

Looking good.

I got this 14" double decker lazy susan that I like a lot for all my cleaning crap and such. It's sits in the corner and uses some space otherwise that wouldn't be used very well and keeps my bottles ans spray cans and all neat.. pretty useful and you can find em in all sizes and heights

I got my DAA mini case feeder running perfectly on the 550c. I hadn't adjusted the shuttle length and it was causing issues but after some messages ans pics exchanged with DAA guys, they pointed it out and I did so and now it works excellent. The magazine is fairly small but fills quickly. I think I'm going to rig up a dillon case feeder I have to feed it directly though. Doesn't seem like it would be hard to do. I can finally size my 223 brass and feed it doing so. I could of course also make a tool head to throw off press and seat on it while feeding it too and I probably will. Really glad to be able to finally crank out some quality brass quickly though for right now.

Looking good.

I got this 14" double decker lazy susan that I like a lot for all my cleaning crap and such. It's sits in the corner and uses some space otherwise that wouldn't be used very well and keeps my bottles ans spray cans and all neat.. pretty useful and you can find em in all sizes and heights

Once we finalize new shop, I think we are going with something similar to 2" butcher block. And definitely will be cutting in a track system.

Man I debated about the track system and went back and forth on it for a while. I ended up not doing it and going with 4 stations where I can swap out whatever I want with my qc work stations from inline fab.Once we finalize new shop, I think we are going with something similar to 2" butcher block. And definitely will be cutting in a track system.

I may still do a track in the other "desk" type area I have which will be the area dedicated to brass prep and measurement stuff I think. I wanted to use the space with some things in place and make sure I really did want to do it as planned and didn't have a change of heart after I used the space for a while.

The tracks are great but they collect a lot if powder and trash and that's why I went with the qc work stations instead. I can store various items and just put them on a qc plate (like a vise) and still have my areas of whole top clear.

You may be better off with tracks though since I guess you swap stuff and move more things around than I do but I'd at least thunk about setting up with multiple flush mount plates for qc work stations. If you have a good place to install a storage place for the qc plates with stuff mounted on them (which is heavy) then you could do that and only have 4 or 5 flush mount bases in your top vs tracks. It was by far the biggest struggle I had when setting up. I'm pretty happy with it so far.

Did a little puttering around the shop today after I got up from night shift... Swapped the aftermarket 3d printed case feeder over from my original Lee APP to the spank new Lee APP "Deluxe"  . Case feeder works, but the new setup still needs a little tuning to get everything dialed in. Not in the mood for that kind of fiddly $hit while I'm on nights, so onto the next project...

. Case feeder works, but the new setup still needs a little tuning to get everything dialed in. Not in the mood for that kind of fiddly $hit while I'm on nights, so onto the next project...

Pulled the dust cover (garbage bag) off the RL550B, and swapped it with the 419 Zero on the Inline Fab mount. Used to have it all set up and dialed in, but ended up stripping all the tool heads. So... time to start over. Dug through the stack of 308 dies... hmmm... feels like a Forster kind of day . Set up the first tool head with a Forster National Match F/L die, neck honed to 0.333". Lubed them up and ran 'em through. Drug the F/A tumbler and Dillon case separator out of storage, threw them in the rice for about an hour.

. Set up the first tool head with a Forster National Match F/L die, neck honed to 0.333". Lubed them up and ran 'em through. Drug the F/A tumbler and Dillon case separator out of storage, threw them in the rice for about an hour.

In the meantime, went looking for some powder and bullets. Figured this is a good opportunity to use up some odds-n-ends - some Nosler CC 168s & 175s, and some 175 RDF, and the odd pound of IMR 4064 I had floating around the powder stash. Got the AT4 calibrated for 4064... counting the days until the new Ingenuity starts shipping Set up the second tool head with a Lee decapper in station #1, Dillon powder die + MTM funnel in station #2, and Forster Ultra BR seater in station #3. Still need to set the seating depth at some point.

Set up the second tool head with a Lee decapper in station #1, Dillon powder die + MTM funnel in station #2, and Forster Ultra BR seater in station #3. Still need to set the seating depth at some point.

Hmmm... looks like I need to update the powder inventory - how much of what is in which storage tote. Not the most glamorous task... but it needs doing, so time to git'r dun.

Not as much fun as loading up a whole mess of ammo, but I have a general rule of no gun powder or power tools while I'm on night shift - the mental focus just ain't there.

Pulled the dust cover (garbage bag) off the RL550B, and swapped it with the 419 Zero on the Inline Fab mount. Used to have it all set up and dialed in, but ended up stripping all the tool heads. So... time to start over. Dug through the stack of 308 dies... hmmm... feels like a Forster kind of day

In the meantime, went looking for some powder and bullets. Figured this is a good opportunity to use up some odds-n-ends - some Nosler CC 168s & 175s, and some 175 RDF, and the odd pound of IMR 4064 I had floating around the powder stash. Got the AT4 calibrated for 4064... counting the days until the new Ingenuity starts shipping

Hmmm... looks like I need to update the powder inventory - how much of what is in which storage tote. Not the most glamorous task... but it needs doing, so time to git'r dun.

Not as much fun as loading up a whole mess of ammo, but I have a general rule of no gun powder or power tools while I'm on night shift - the mental focus just ain't there.

I'm not poor, and I'm reasonably organized. But this thread makes me feel like a homeless slob.

I understand this feeling very well.

Did nothing in the reloading room today other than move some stuff around so I would have room on the bench to mount a scope tomorrow morning over coffee. While I have the levels out, I'll go ahead and install the Hellfire Match on it, too.

Next project will be to get a 6.5CM ladder loaded over the weekend.

New Starline brass, Berger 140gr hybrids over SW 4350.

I have the Starline in both SRP & LRP. Thinking about running identical ladders with each.....all things equal except the primer size.

May be a goofball endeavor....but it will be cool to see the difference.

I'm able to replace the SRP much easier at this time....so there is some motivation.

I did take 200rds of brass from the front door upstairs to the loading room. Some 6GT brass for a project in the works.

Start night shift tomorrow as well. Zombie living for a few days.

Next four nights.

Sucks.....but it'll pay for components & new gear.

Next project will be to get a 6.5CM ladder loaded over the weekend.

New Starline brass, Berger 140gr hybrids over SW 4350.

I have the Starline in both SRP & LRP. Thinking about running identical ladders with each.....all things equal except the primer size.

May be a goofball endeavor....but it will be cool to see the difference.

I'm able to replace the SRP much easier at this time....so there is some motivation.

I did take 200rds of brass from the front door upstairs to the loading room. Some 6GT brass for a project in the works.

Did a little puttering around the shop today after I got up from night shift... Swapped the aftermarket 3d printed case feeder over from my original Lee APP to the spank new Lee APP "Deluxe". Case feeder works, but the new setup still needs a little tuning to get everything dialed in. Not in the mood for that kind of fiddly $hit while I'm on nights, so onto the next project...

Pulled the dust cover (garbage bag) off the RL550B, and swapped it with the 419 Zero on the Inline Fab mount. Used to have it all set up and dialed in, but ended up stripping all the tool heads. So... time to start over. Dug through the stack of 308 dies... hmmm... feels like a Forster kind of day. Set up the first tool head with a Forster National Match F/L die, neck honed to 0.333". Lubed them up and ran 'em through. Drug the F/A tumbler and Dillon case separator out of storage, threw them in the rice for about an hour.

In the meantime, went looking for some powder and bullets. Figured this is a good opportunity to use up some odds-n-ends - some Nosler CC 168s & 175s, and some 175 RDF, and the odd pound of IMR 4064 I had floating around the powder stash. Got the AT4 calibrated for 4064... counting the days until the new Ingenuity starts shippingSet up the second tool head with a Lee decapper in station #1, Dillon powder die + MTM funnel in station #2, and Forster Ultra BR seater in station #3. Still need to set the seating depth at some point.

Hmmm... looks like I need to update the powder inventory - how much of what is in which storage tote. Not the most glamorous task... but it needs doing, so time to git'r dun.

Not as much fun as loading up a whole mess of ammo, but I have a general rule of no gun powder or power tools while I'm on night shift - the mental focus just ain't there.

Start night shift tomorrow as well. Zombie living for a few days.

Next four nights.

Sucks.....but it'll pay for components & new gear.

Start night shift tomorrow as well. Zombie living for a few days.

Next four nights.

Sucks.....but it'll pay for components & new gear.

If I could go back to swing shift, I might never retire

As it is... the one good thing about a rotating 5 shift schedule is the seven straight days off every rotation.

If I could go back to swing shift, I might never retire

As it is... the one good thing about a rotating 5 shift schedule is the seven straight days off every rotation.

Heck yeah !!!!!

You said it.

I am wrapping up my 7-day off today.

This one sure went by quick....made a road trip for the first four days....seems like I've barely had time to get anything done around the house.

Let’s just say it was done in the reloading room/garage/every project room. Have incubated this task for some time now, but finally finished another more portable bench for our 1k range at the ranch. Old corian counter top material repurposed for shooting bench top, some pipe mounts from Urban Rifleman and a little labor yielded a somewhat heavy, but portable all weather bench.

I look at this picture and I begin to drool....

Precision gear that is well laid out.

Can you elaborate on the chair in the bottom left corner ? I've been using a chair that was already in the spare bedroom I'm slowly converting into a reloading room. I did grab a barstool from Amazon for the standing bench that'll hold the Dillons.

I asked the same thing a while back. It's a $600 chair. I ended up getting a $150.00 one that is pretty comfy and rolls nice and has a lot of height adjustment. I just couldn't spend that much on a chair but thats a sweet chair.I look at this picture and I begin to drool....

Precision gear that is well laid out.

Can you elaborate on the chair in the bottom left corner ? I've been using a chair that was already in the spare bedroom I'm slowly converting into a reloading room. I did grab a barstool from Amazon for the standing bench that'll hold the Dillons.

I started to set up my Dillon progressive for a quick run of 6GT today ... I've never loaded for the GT on the progressive, but thought what the hell ....

I started getting everything ready and setting up the dies and then found out I didn't have a Dillon powder funnel for 6GT! I started looking around to order a caliber conversion kit .. They were $100+ and I really already had everything but the funnel. Just about to place the order and thought to myself ... you have a lathe, why not just make one. I'm not a machinist by any stretch of the imagination, but this piece isn't necessarily a true precision job .... took about an hour with set up and then banged out 100 rounds pretty quickly. No waiting for a day or two for shipping.

I started getting everything ready and setting up the dies and then found out I didn't have a Dillon powder funnel for 6GT! I started looking around to order a caliber conversion kit .. They were $100+ and I really already had everything but the funnel. Just about to place the order and thought to myself ... you have a lathe, why not just make one. I'm not a machinist by any stretch of the imagination, but this piece isn't necessarily a true precision job .... took about an hour with set up and then banged out 100 rounds pretty quickly. No waiting for a day or two for shipping.

Rigged up my DAA mini case feeder for my dillon 550c to a dillon case feeder so I can feed cases with the dillon through the DAA set up. Honestly I'm not sure why DAA didn't just make a kit to work with the dillon case feeder while they were at it because it was pretty easy to do. I just went to lowes and got some reinforced hose and cpvc and fittings and away I went. I put a chamfer on the inside of the 1/2" cpvc piece I used which fit the dillon case feeder and ran the tube to the DAA set up and boom! Works like a champ. I ran 100 through to make sure it wouldn't hang up at all and it ran like a champ!

Wish I could upload videos here???? It says it needs some extension???

Wish I could upload videos here???? It says it needs some extension???

Last edited:

Whew.....words a dude hopes to never hear.Rigged up my DAA mini case feeder for my dillon 550c to a dillon case feeder so I can feed cases with the dillon through the DAA set up. Honestly I'm not sure why DAA didn't just make a kit to work with the dillon case feeder while they were at it because it was pretty easy to do. I just went to lowes and got some reinforced hose and cpvc and fittings and away I went. I put a chamfer on the inside of the 1/2" cpvc piece I used which fit the dillon case feeder and ran the tube to the DAA set up and boom! Works like a champ. I ran 100 through to make sure it wouldn't hang up at all and it ran like a champ!

Wish I could upload videos here???? It says it needs some extension???

Sorry. Juvenile humor is where I'm at.....getting ready for my 4th consecutive 13+ hour night shift.....running on limited sleep but pounding down two cups of killer coffee as I read this thread.

I'm currently working with my Co-Ax for load development. Once I'm dialed in on loads for specific guns/cartridges, I'll be setting up toolheads for my waiting 550C & XL750.

The 550C will have toolheads dedicated to .308 Win for my AR-10 and another for my M1A.

A setup like you describe sounds intriguing.

Can you post up some pics of it ????

Sorry man, my reply with pics didn't go through for some reason.Whew.....words a dude hopes to never hear.

Sorry. Juvenile humor is where I'm at.....getting ready for my 4th consecutive 13+ hour night shift.....running on limited sleep but pounding down two cups of killer coffee as I read this thread.

I'm currently working with my Co-Ax for load development. Once I'm dialed in on loads for specific guns/cartridges, I'll be setting up toolheads for my waiting 550C & XL750.

The 550C will have toolheads dedicated to .308 Win for my AR-10 and another for my M1A.

A setup like you describe sounds intriguing.

Can you post up some pics of it ????

This is basically a hose hooked up to 2 cpvc 1/2" couplings put together. I chamfered the inside of the couplings so the case wouldn't get hung up, similar to how the little plastic piece works for my amp mate to be fed.

I just measured the DAA piece where the magazine goes and hooked up the right size hose to it.

It works really well. I ran 100 pcs through without a single issue. I will now make a better stand out of metal pipe, but i wanted to use pvc to adjust the height easily while I was testing it all out and figuring out the heights.

It has to sit up high enough to feed into the DAA set up, which drops the case only when the orange tube goes up, it then shoves the case into the shell plate once its back down.

I took some pics of the handle all the way down and all the way up to show the difference in the DAA set up when that happens. Happy to answer any questions.

Here you go.

Attachments

Last edited:

Sorry man, my reply with pics didn't go through for some reason.

This is basically a hose hooked up to 2 cpvc 1/2" couplings put together. I chamfered the inside of the couplings so the case wouldn't get hung up, similar to how the little plastic piece works for my amp mate to be fed.

I just measured the DAA piece where the magazine goes and hooked up the right size hose to it.

It works really well. I ran 100 pcs through without a single issue. I will now make a better stand out of metal pipe, but i wanted to use pvc to adjust the height easily while I was testing it all out and figuring out the heights.

It has to sit up high enough to feed into the DAA set up, which drops the case only when the orange tube goes up, it then shoves the case into the shell plate once its back down.

I took some pics of the handle all the way down and all the way up to show the difference in the DAA set up when that happens. Happy to answer any questions.

Here you go.

That is cool.

Gotta be one highly efficient 550 right there.

Not gun related, but since I have limited space it's my workspace for other things as well. That is a twist lock thumb insert for a bowling ball.OK ... what is this? .... Some type of adapter?

Well, V4 arrived. It was pretty easy to set up. So far I'm liking it.

Cleaned and drying 1,000 .38 Special cases....drying now.

Annealed 100 6.5 CM (Starline SRP) & 46 .270 Win (Winchester) cases.

Didn't finish what I'd hope to finish, that's for sure. Watching some of the SB before calling it a night. Workweek will start early tomorrow.

Hopefully I'll get brass prep finished and can load the ladders for 6.5CM (two rifles) & .270 Win. I want to be ready to shoot them on my next day off.

Annealed 100 6.5 CM (Starline SRP) & 46 .270 Win (Winchester) cases.

Didn't finish what I'd hope to finish, that's for sure. Watching some of the SB before calling it a night. Workweek will start early tomorrow.

Hopefully I'll get brass prep finished and can load the ladders for 6.5CM (two rifles) & .270 Win. I want to be ready to shoot them on my next day off.

Last edited:

Do you like the 6000? I kind of want one. Reloading 9mm on a 4 hole Lee turet now.Adding an inline bullet feeder to the Pro 6000. A Double Alpha is on its way. Cast and powder coated a couple thousand 125TC 9mm's last week to wring it out.

Funny story now, that stretched a couple of weeks. Got some rounds loaded up for my 6br finally. Got to range one day and landed on 40 thou jump with 105gr vld target on top of 30gr of imr4895. Zeroed with a handful of rounds and chrono at 2855 so happy with those numbers. Load up 50 and a friend and I hit the range the following week and it's hammering.

Excited about the great range day I fire up the powder measure and load up another 100rds with the plan on getting to the range and practice. Head out there Friday ready to put in some work. Go straight to a spot where I know distance (625) and knocked out the center the previous week with the friend. Squeeze off first shot and I see splatter about 200 yards or so IN FRONT of target.

Thinking I messed up something in the 4dof app I reassess the numbers and go back again, same thing. I measure with reticle and I'm about 1-1.5 mil off. Wtf. I pack up and head home and clean barrel, confirm everything is torqued correctly, inspect mount for cracks or anything. Toss the magnetospeed on and fire off 5 rds in the backyard and yup...2315 is what I'm getting. Sigh of relief it isn't the rifle. Fire up the scale pull the bullets, remeasure charges....23.6. How!?! Then I remembered, FA intellidropper suggests warming up the scale for 15-20 min before loading. DOH!. Did NOT do that with these 100rds.

Load up the pulled bullet cases after resizing neck, and another 15rds of freshly primed cases and head back out. Back in business. Numbers match...on point. Cleaned a TYL on the last handful of rounds. Lesson learned, warm up the powder measure

Excited about the great range day I fire up the powder measure and load up another 100rds with the plan on getting to the range and practice. Head out there Friday ready to put in some work. Go straight to a spot where I know distance (625) and knocked out the center the previous week with the friend. Squeeze off first shot and I see splatter about 200 yards or so IN FRONT of target.

Thinking I messed up something in the 4dof app I reassess the numbers and go back again, same thing. I measure with reticle and I'm about 1-1.5 mil off. Wtf. I pack up and head home and clean barrel, confirm everything is torqued correctly, inspect mount for cracks or anything. Toss the magnetospeed on and fire off 5 rds in the backyard and yup...2315 is what I'm getting. Sigh of relief it isn't the rifle. Fire up the scale pull the bullets, remeasure charges....23.6. How!?! Then I remembered, FA intellidropper suggests warming up the scale for 15-20 min before loading. DOH!. Did NOT do that with these 100rds.

Load up the pulled bullet cases after resizing neck, and another 15rds of freshly primed cases and head back out. Back in business. Numbers match...on point. Cleaned a TYL on the last handful of rounds. Lesson learned, warm up the powder measure

Last edited:

Loaded 100 rounds of .308 for an upcoming PRS match. ARC Archimedes with X-Caliber 26" bbl.

Lapua Brass

Hornady 178 ELD-M

Alliant PP 2000-MR

CCI 200 primers

Lapua Brass

Hornady 178 ELD-M

Alliant PP 2000-MR

CCI 200 primers

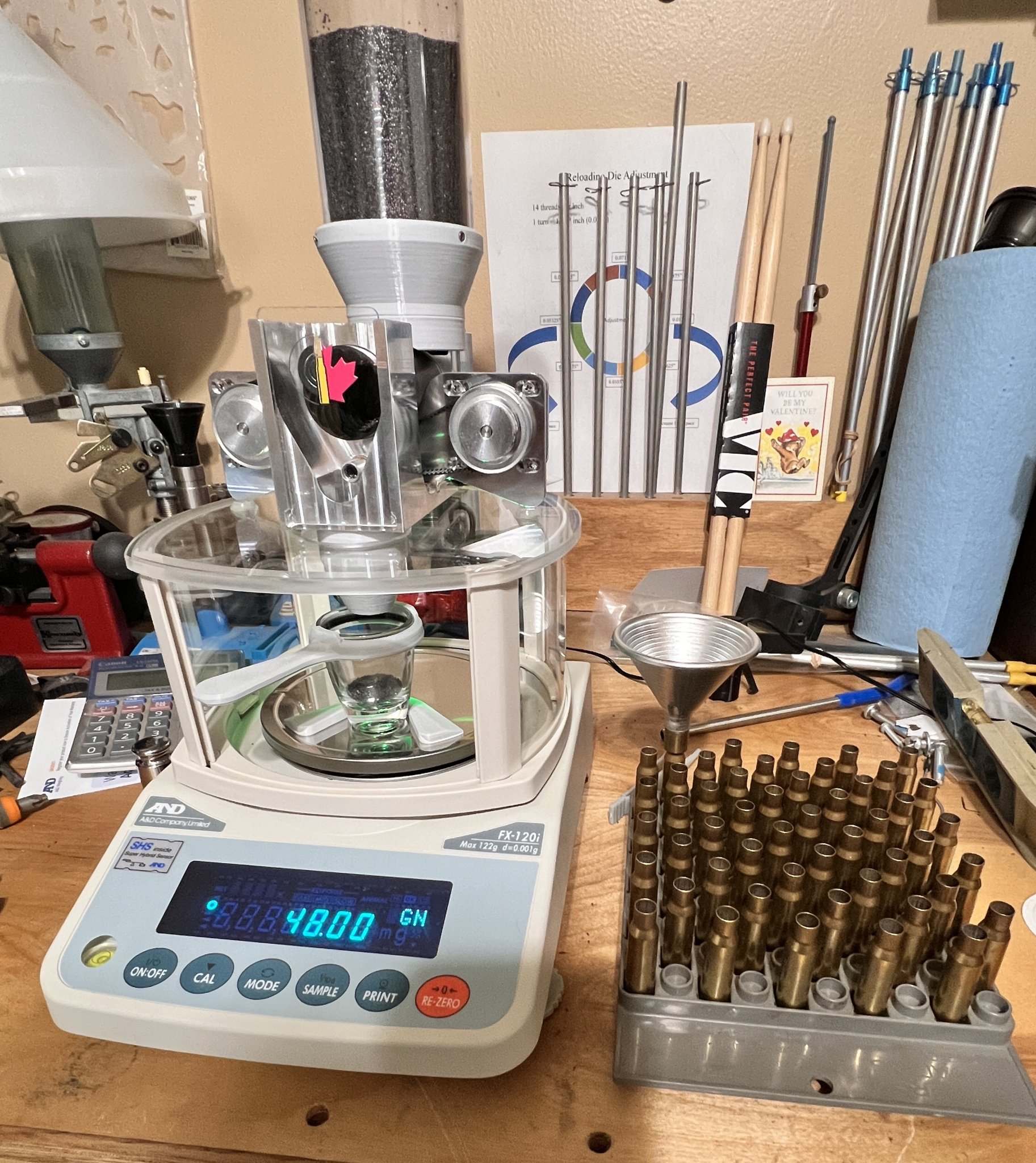

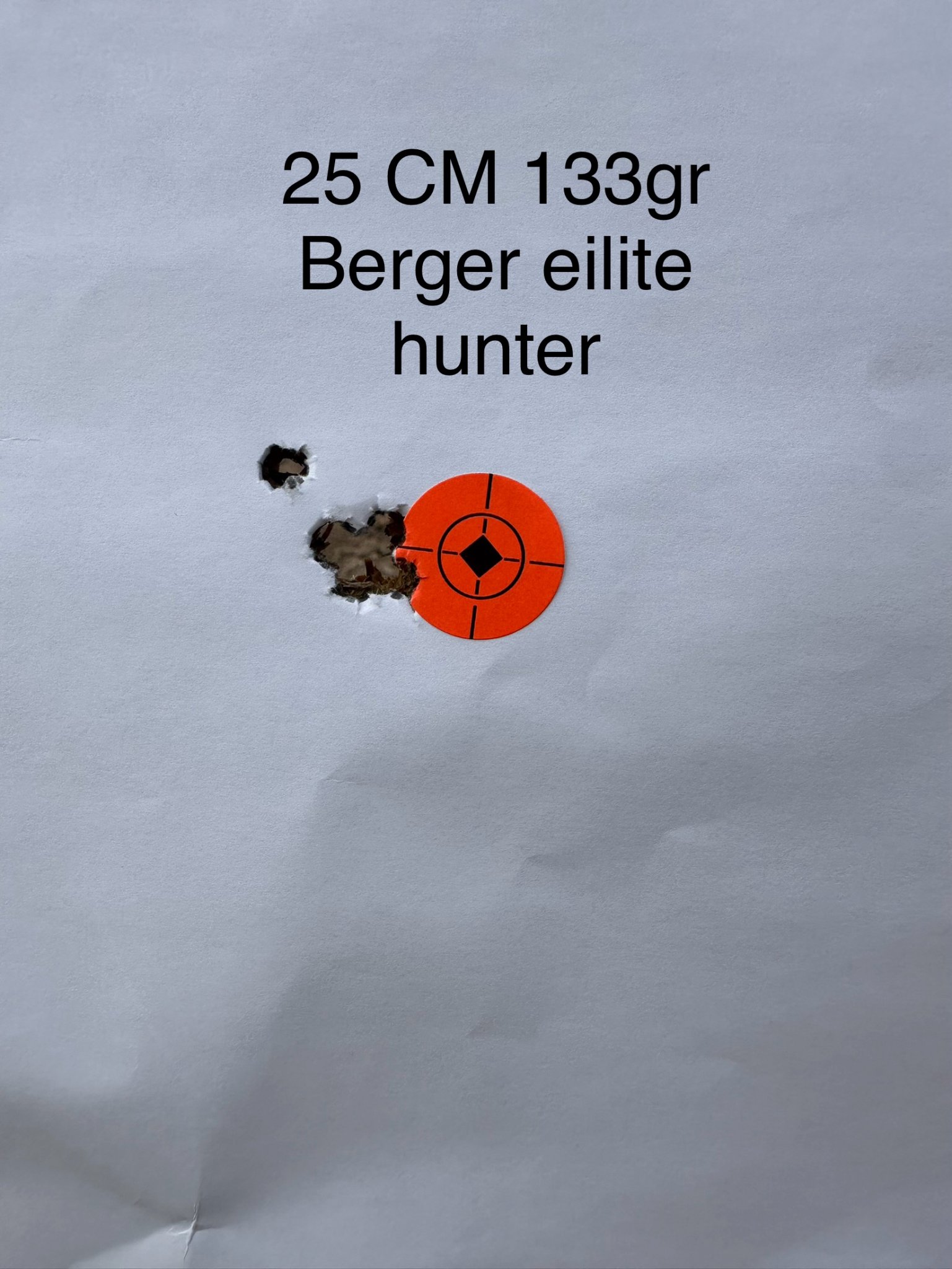

Worked on a 25cm load for customer. This was a 10 shot string with generic starting load and .030 jump. First shot was the high left. Then the next 9. SD was a bit disappointing at 11, but not a bad starting point.

Working on my aim. Flinging converted blackouts with a Dillon swager. The spring gimmick is awesome.

Finished up on the lathe . Fired #3 cartridges from each of My Rifles . That in itself took a while . Proceeded to measure chambers ,then bumped shoulders 0.003" ran on the concentric gauge and comparator base for case straightness . Took the Best out of the #3 ,chucked em in the lathe then drilled out primer pocket and final size hole using a 7.30 mm drill bit > I then using My lathe tapped 5/16"X36 for hornady OAL gauge . Finally got All of MY chambers dialed in and entered into the log . Put cases with one other properly sized case with slit neck and put them together in their individual zip baggies . Been meaning to do that forever and just never got around too doing every Rifle until today .

Just loaded 50rds of 338LM. 95.5gr of H1000/250gr Accubonds running 3032 out of 30" barrel. New barrel getting broke in, waiting for warmer weather before doing serious load development with 285 ELDM, throat/freebore was set for the 285 and to feed from 3.85CIP mags.

SAC did the work.

SAC did the work.

I can’t shake the desire for a .460Rem S&W revolver, just so I can shoot it with the alternative options of .454 and .45LC.Started brass prep and setting up dies for my 454 Casull.

I have absolutely no need for it, but I want it.

Sorry about the delay in response. I am very happy with the 6000. I added the UFO light (a must have in my opinion). I was using a Pro 1000 for the last 15 years. The extra stations and smoothness are a big upgrade.Do you like the 6000? I kind of want one. Reloading 9mm on a 4 hole Lee turet now.

Shane

Similar threads

- Replies

- 14

- Views

- 793