So I completed a test with 6.5 Twist and 350 Maker bullets.

They do indeed open up in the 6.5 twist. But it may be delayed a bit when compared to the 3 twist.

You can adjust the velocity up to 1600 fps to get some real power, with the muzzle device attached and good accurscy, in the 6.5 twist....not limited to 1050 fps as in the 3 twist.

Accuracy, the 3 twist is horrible...group sizes were 3 and 1/3 times larger with the 3 twist with the 350 gr Maker. Some even greater, like 6 and 1/2 times larger!

Reminded me why I gave up on the Faxon rough barreled 3 twist. It just as waste of ammo.

I enjoyed the AR platform, but will do no more shooting with this barrel.

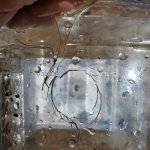

The 6.5 twist and 350 gr Makerl...looking through the back, as the bullet expanded in this jug of water.

Exit wound in wet paper shows expanded bullet with petals still present.

These 350 Maker were not caught in full bloom. They open up and had a huge cavity in a burned log, then lose the petals and penetrate for ever,.. it seems. Stopped it with armor plate, glanced off the plate, and dug into the ground. Took a shovel to find it.

How fast they open is adjustabe by velocity to only 1050 fps with the 3 twist. But do not open at around 750 or maybe 800 fps depending on medium impacted. Steel would be different, gravel was different...so it depends...

I'm only testing these and do not plan to hunt with the 8.6 Blackout.

The performance varies, and is somewhat adjustable, but it's a close range bullet as the velocity changes the performance changes.

So if ya find a velocity and range it works good in, on the animal you hunt, keep your range limited.

Not that it won't kill if it doesn't expand, but works a lot better if it does.

I bought 5 boxes of these 350 Maker bullets and fired almost 2 boxes on testing. Is it a good hunting bullet? Who knows? I haven't killed anything with it.

But it will penetrate, after the petals break off...

And the accuracy of the Faxon 3 twist ...if ya aim at a hogs head and hit him in the lower jaw at 70 yds...that is about my accuracy with the Faxon 3 twist barrel, so expanding won't kill him....but the 6.5 twist will put the bullet very close to where you aim, 350 Maker, or almost any other, in subsonic mode, plus you have excellent supersonic capabilities with any lead bullet guaranteed to dump a hog, economically.

After today the Faxon 3 twist is definitely retired...I have better things to do, than waste ammo, with this horribly inaccurate barrel.

But if you love your 3 twist, keep on using it. Other brands might be a bit more accurate.

They do indeed open up in the 6.5 twist. But it may be delayed a bit when compared to the 3 twist.

You can adjust the velocity up to 1600 fps to get some real power, with the muzzle device attached and good accurscy, in the 6.5 twist....not limited to 1050 fps as in the 3 twist.

Accuracy, the 3 twist is horrible...group sizes were 3 and 1/3 times larger with the 3 twist with the 350 gr Maker. Some even greater, like 6 and 1/2 times larger!

Reminded me why I gave up on the Faxon rough barreled 3 twist. It just as waste of ammo.

I enjoyed the AR platform, but will do no more shooting with this barrel.

The 6.5 twist and 350 gr Makerl...looking through the back, as the bullet expanded in this jug of water.

Exit wound in wet paper shows expanded bullet with petals still present.

These 350 Maker were not caught in full bloom. They open up and had a huge cavity in a burned log, then lose the petals and penetrate for ever,.. it seems. Stopped it with armor plate, glanced off the plate, and dug into the ground. Took a shovel to find it.

How fast they open is adjustabe by velocity to only 1050 fps with the 3 twist. But do not open at around 750 or maybe 800 fps depending on medium impacted. Steel would be different, gravel was different...so it depends...

I'm only testing these and do not plan to hunt with the 8.6 Blackout.

The performance varies, and is somewhat adjustable, but it's a close range bullet as the velocity changes the performance changes.

So if ya find a velocity and range it works good in, on the animal you hunt, keep your range limited.

Not that it won't kill if it doesn't expand, but works a lot better if it does.

I bought 5 boxes of these 350 Maker bullets and fired almost 2 boxes on testing. Is it a good hunting bullet? Who knows? I haven't killed anything with it.

But it will penetrate, after the petals break off...

And the accuracy of the Faxon 3 twist ...if ya aim at a hogs head and hit him in the lower jaw at 70 yds...that is about my accuracy with the Faxon 3 twist barrel, so expanding won't kill him....but the 6.5 twist will put the bullet very close to where you aim, 350 Maker, or almost any other, in subsonic mode, plus you have excellent supersonic capabilities with any lead bullet guaranteed to dump a hog, economically.

After today the Faxon 3 twist is definitely retired...I have better things to do, than waste ammo, with this horribly inaccurate barrel.

But if you love your 3 twist, keep on using it. Other brands might be a bit more accurate.