@Chipster697:

Yes, it has also been a learning curve for me as well, as the excitement from the market hype has given way to the reality of its capabilities. Expectations drive satisfaction or disappointment, which is likely a central issue with this.

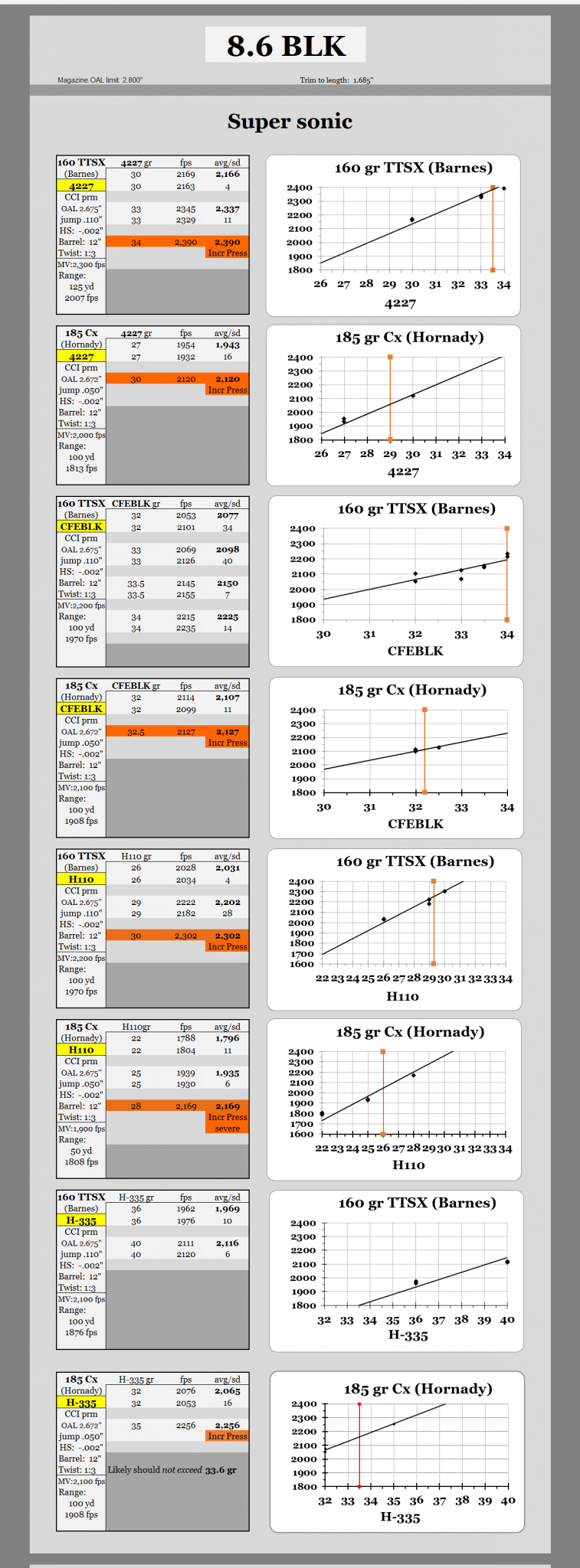

I have posted a fair amount of load data, both super and subsonic data, from a 12" 1:3" twist barrel. Recently, I have loaded a final batch of rounds to supplement the earlier data, and I would like to wrap this phase up for now. I do have a 16" barrel that I will develop loads for and will publish when available.

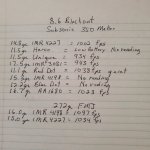

In short, I agree with your assessment that this caliber, in the 1:3" twist configuration is mostly a subsonic round. The subsonic performance is interesting, and I have achieved ~ MOA performance at 100 and 300 yards. With the Porq Chop, the gun is impressively quiet. For load development, the 300 gr SMK, and Maker 300 gr and 350 gr projectiles work well.

For super-sonic applications, (again, with the 1:3" twist), the performance and the latitude of available projectiles is discouraging. Bearing in mind, that projectile selection is limited to solid copper or bonded. Barnes TSX/TTSX projectiles need ~1,800 fps to function, which is near the muzzle velocity for the heavier options (185 gr, 210 gr), and limits effective use to ~100 yards. The Barnes 160 gr muzzle velocity is a bit higher, probably reaching out to 150 yards or so. Another attractive option is the Maker 220 gr option which is likely the best all-around supersonic option, designed to function in the 1,500 - 1,900 fps envelope, extending the range a bit further. To directly address your question, I would start with the Barnes 160gr projectile for a velocity (only) best case design, and increase weight from that point.

Regarding barrels and twist rate . . . I personally only have experience with Q barrels, and have been satisfied. I have read too much about other brand barrels not performing satisfactorily and would not consider as a viable option. Another manufacturer, Mos-Tec (

https://mos-tek.com/) is worth considering, as they offer additional twist rates of 1:5", and 1:6", which allows for wider projectile selection and much higher muzzle velocities.

Regarding powders . . . The data I have generated is with H110, CFEBLK, H4227, A1680, and H335 (too slow). Any of the first four powders are fine, with H110 being efficient (least powder weight for velocity), however, at this point, I favor H4227 (slightly). Overall, pressure limits will be reached with all of the four. A powder I haven't tested yet is H4198, which looks interesting.

Summary . . .

I have come to accept that with the 1:3" twist, subsonic performance out to 300 yards, and supersonic performance is reliable to 100 - 150 yards. Slowing the barrel twist to 1:5" - 1:6.5" will greatly increase the super-sonic performance and projectile latitude.

With The Fix, which is what I own, I plan to use the 6.5 CM barrel if I need to reach out beyond the capability of the 8.6 barrel, or alternatively, one could opt for the .308 to fill the gap between 8.6 and 6.5.

Best of luck with your efforts . . .