I tested Alliant Unique up to 10.6. I think 10 grains gave small SDs, within 1 fps. I should’ve taken better notes, I think the bullet was a 300gr Lapua Scenar. I remember it being really quiet but not accurate. I didn’t play with seating depth at all to see if tuning it would improve accuracy. I ran a similar load on GRT, 14 grains of Unique with a 350 maker seated to where there wasn’t a lot of space and I think it said the load was dangerous.Re: 8.6 subsonic load development

Barrel: 12" 1:3" twist Q barrel for The Fix

Please pardon this simplistic approach, but as I get started into the process of load development for the 8.6 subsonic, I need to be able to visualize the percent case fill for different representative powders. I realize that the density charts provide the same information, but sometimes seeing is believing. My apologies to the more sophisticated reloaders with greater experience, but this exercise has helped me better understand some of these initial issues. I also thought this information might help others just starting out as well.

I envy @45- 90's ability to make what he wants with proper machine tools. I'm limited to hand tools and a drill press. Please give me a pass on the rough fabrication. The ID of the acrylic rod is very nearly (within a few percent) the same ID as the .338 case. The length of the acrylic rod represents the 'trim to' length of the 8.6 case. The two dimes are super-glued together and very closely represent the thickness of the shell base (after a little sanding to remove a few thousandths). The projectile is the Maker 350 gr and the 'O' ring maintains the OAL of 2.780" (chosen due to the magazine capacity is 2.800" and @45-90's data which has fixed OAL to the same length). As there is a dynamic relationship between seating depth and powder charge, I was thinking of starting out by 'fixing' as many variables as possible and just change one at a time.

The 350 gr projectile is likely the largest to be fired in this application, and thus represents a 'best case design' for case fill. The 300 gr and 250 gr projectiles get progressively shorter, if the OAL distance remains fixed. By the way, the distance for touching/seating at the lands for the Maker 350 gr and 300 gr projectiles measures ~ 2.880" (~.110" jump), and the SMK 300 gr touches/seats at around 2.820" (~.040" jump). For these heavy subsonics, several sources suggest a bullet jump of ~ 0.050" +/-, noting the SMK is pushing the suggested limit just a bit, but is commonly used and likely ok.

All powder charges are 14 gr. This is NOT a recommended charge weight, but only a way to compare the different powders, on a relative basis, for the percent case fill with the same projectile and same OAL.

The first images / powders, H110 and CFEBLK show quite a bit of air gap (or lower percent case fill).

- from prior experience, I have learned that H110 and CFEBLK performed better with filled / mildly compressed charges.

The third image is for Clays and is quite compressed.

- I have used Clays extensively in SASS shooting with low percentage case fills, and it has worked fine.

The fourth image is for Univeral Clays (slower than Clays), and has only a minimal air gap.

- I will be using a 12" 1:3 twist Q barrel and that barrel length might be enough for the majority of the powder to burn, but needs to be confirmed.

Next steps:

I will likely start with the Maker 350 gr and Clays powder. Previously in this thread, @45-90 jumped in with the fast pistol powder and suggested Clays as another reasonable consideration. Does anyone have any ballpark ideas for powder charge weights for the 350 gr projectile and Clays powder?

Thanks.

View attachment 8416539

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

8.6 Blk reloading info

- Thread starter unclemoak

- Start date

I tested Alliant Unique up to 10.6. I think 10 grains gave small SDs, within 1 fps. I should’ve taken better notes, I think the bullet was a 300gr Lapua Scenar. I remember it being really quiet but not accurate. I didn’t play with seating depth at all to see if tuning it would improve accuracy. I ran a similar load on GRT, 14 grains of Unique with a 350 maker seated to where there wasn’t a lot of space and I think it said the load was over pressured.Re: 8.6 subsonic load development

Barrel: 12" 1:3" twist Q barrel for The Fix

Please pardon this simplistic approach, but as I get started into the process of load development for the 8.6 subsonic, I need to be able to visualize the percent case fill for different representative powders. I realize that the density charts provide the same information, but sometimes seeing is believing. My apologies to the more sophisticated reloaders with greater experience, but this exercise has helped me better understand some of these initial issues. I also thought this information might help others just starting out as well.

I envy @45- 90's ability to make what he wants with proper machine tools. I'm limited to hand tools and a drill press. Please give me a pass on the rough fabrication. The ID of the acrylic rod is very nearly (within a few percent) the same ID as the .338 case. The length of the acrylic rod represents the 'trim to' length of the 8.6 case. The two dimes are super-glued together and very closely represent the thickness of the shell base (after a little sanding to remove a few thousandths). The projectile is the Maker 350 gr and the 'O' ring maintains the OAL of 2.780" (chosen due to the magazine capacity is 2.800" and @45-90's data which has fixed OAL to the same length). As there is a dynamic relationship between seating depth and powder charge, I was thinking of starting out by 'fixing' as many variables as possible and just change one at a time.

The 350 gr projectile is likely the largest to be fired in this application, and thus represents a 'best case design' for case fill. The 300 gr and 250 gr projectiles get progressively shorter, if the OAL distance remains fixed. By the way, the distance for touching/seating at the lands for the Maker 350 gr and 300 gr projectiles measures ~ 2.880" (~.110" jump), and the SMK 300 gr touches/seats at around 2.820" (~.040" jump). For these heavy subsonics, several sources suggest a bullet jump of ~ 0.050" +/-, noting the SMK is pushing the suggested limit just a bit, but is commonly used and likely ok.

All powder charges are 14 gr. This is NOT a recommended charge weight, but only a way to compare the different powders, on a relative basis, for the percent case fill with the same projectile and same OAL.

The first images / powders, H110 and CFEBLK show quite a bit of air gap (or lower percent case fill).

- from prior experience, I have learned that H110 and CFEBLK performed better with filled / mildly compressed charges.

The third image is for Clays and is quite compressed.

- I have used Clays extensively in SASS shooting with low percentage case fills, and it has worked fine.

The fourth image is for Univeral Clays (slower than Clays), and has only a minimal air gap.

- I will be using a 12" 1:3 twist Q barrel and that barrel length might be enough for the majority of the powder to burn, but needs to be confirmed.

Next steps:

I will likely start with the Maker 350 gr and Clays powder. Previously in this thread, @45-90 jumped in with the fast pistol powder and suggested Clays as another reasonable consideration. Does anyone have any ballpark ideas for powder charge weights for the 350 gr projectile and Clays powder?

Thanks.

View attachment 8416539

Last edited:

A .338 dia Maker 350 gr bullet 2.020" long.

A Winchester converted 6.5 CM cases 45.7 gr of H2O

Cartridge overall length 2.780" very important. Can not jam 10,000 psi pressure spike. Copper has double the start pressure over cup and core bullets, without jamming.

Do Not Exceed 1050 fps according to Maker, and for the 3 twist according to Maker.

12" barrel 8.6 Blackout

Clays

Start 8.1= 955 fps * danger do not go below 8.0 grs start pressure too high.

8.6 gr = 986 fps

9.0 gr =1010 fps here looks good IF velocity is correct, and approaching max load, and max velocity.

9.1 gr 1016 fps

9.2 gr 1022 fps definitely max for pressure for the case and bullet recommended maximum velocity.

This powder has good fill percentage, 100% burn, and good efficiency.

Will it get more consistent velocities?... Don't know, but the potential is there.

WARNING: I have Not fired this in my rifle, I do not have any Clays powder or Maker 350 gr bullets to try. This is for informational purposes only.

As always, test without muzzle devices attached to the 3 twist barrels, to make sure bullets will stay together and not damage muzzle devices or your face...and that the bullet actually exit the muzzle.

A Winchester converted 6.5 CM cases 45.7 gr of H2O

Cartridge overall length 2.780" very important. Can not jam 10,000 psi pressure spike. Copper has double the start pressure over cup and core bullets, without jamming.

Do Not Exceed 1050 fps according to Maker, and for the 3 twist according to Maker.

12" barrel 8.6 Blackout

Clays

Start 8.1= 955 fps * danger do not go below 8.0 grs start pressure too high.

8.6 gr = 986 fps

9.0 gr =1010 fps here looks good IF velocity is correct, and approaching max load, and max velocity.

9.1 gr 1016 fps

9.2 gr 1022 fps definitely max for pressure for the case and bullet recommended maximum velocity.

This powder has good fill percentage, 100% burn, and good efficiency.

Will it get more consistent velocities?... Don't know, but the potential is there.

WARNING: I have Not fired this in my rifle, I do not have any Clays powder or Maker 350 gr bullets to try. This is for informational purposes only.

As always, test without muzzle devices attached to the 3 twist barrels, to make sure bullets will stay together and not damage muzzle devices or your face...and that the bullet actually exit the muzzle.

Thanks for the info and notes of caution.

This evening I loaded 8 gr, 9 gr and 10 gr charges of Universal Clays (equivalent to Unique) with 300 gr and 350 gr Maker projectiles. This will be for initial velocity testing.

C.O.A.L. set to 2.780".

(There is still > ~.100" jump to engage the lands).

I'll plan to shoot the 9 gr charges first. I'll measure velocity with a LabRadar.

If the weather holds, I'll try to hit the range tomorrow.

Thanks for your input.

This evening I loaded 8 gr, 9 gr and 10 gr charges of Universal Clays (equivalent to Unique) with 300 gr and 350 gr Maker projectiles. This will be for initial velocity testing.

C.O.A.L. set to 2.780".

(There is still > ~.100" jump to engage the lands).

I'll plan to shoot the 9 gr charges first. I'll measure velocity with a LabRadar.

If the weather holds, I'll try to hit the range tomorrow.

Thanks for your input.

@wgranvilleb keep us posted! Very interested in this development. I also noticed you didn't include any spherical propellants in the discussion, say Accurate 1680 or the likes. Is this something you could get your hands on to compare against the other powder you've shown the visuals for in the acrylic cases? I have a feeling it may be a suitable middle ground between the two types you've shown so far

@fortify503, thanks for your note.

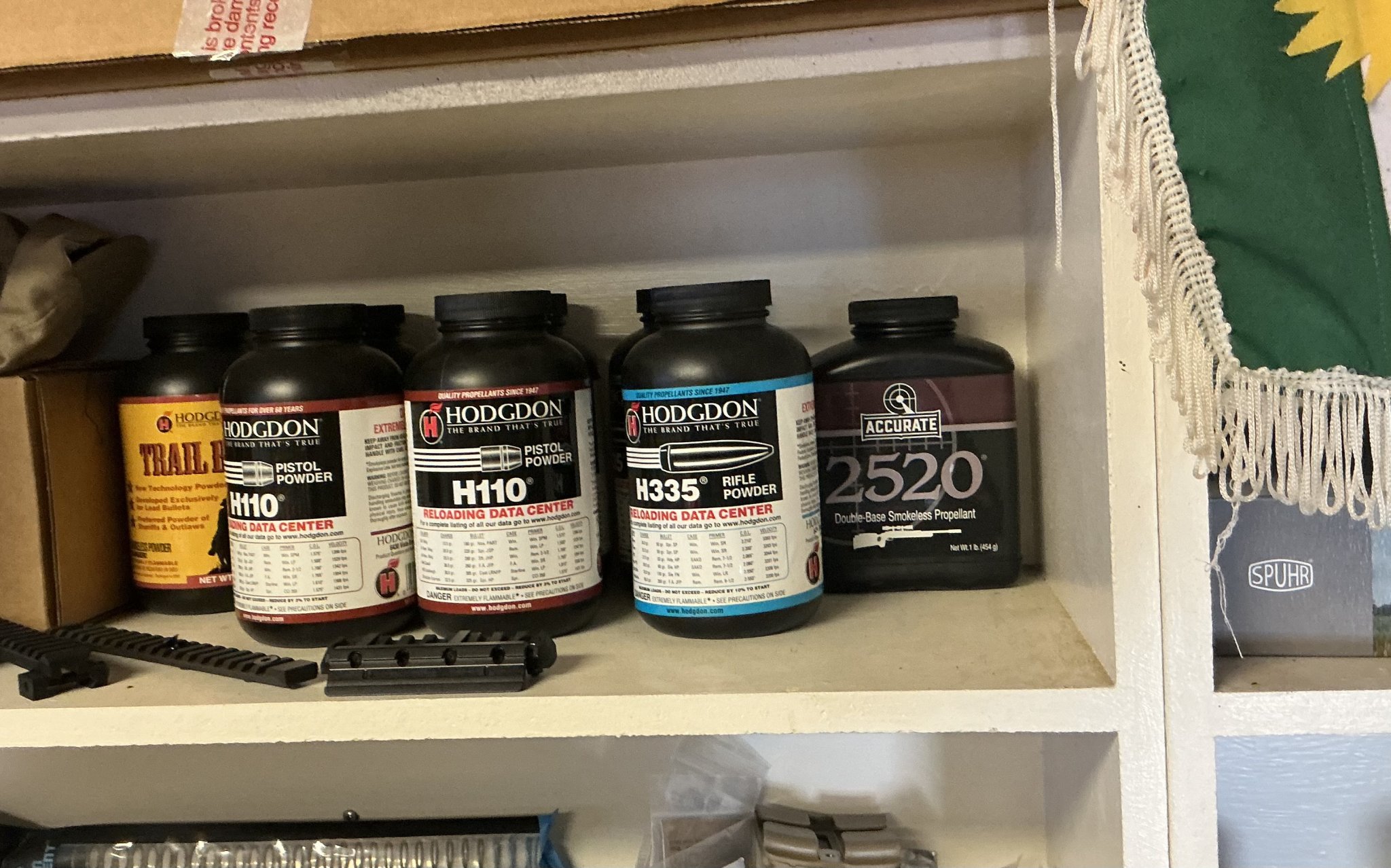

According to the Hodgon website, all three powders are 'spherical propellants'.

Judging from the density numbers, CFE BLK and H110 are similar, whereas Accurate 1680 is a fair amount more dense than the other two, thereby associated with even less case fill. The burn rates for the three are very similar. I'm not sure I'm following you as to how 1680 might function 'in a middle ground' as you put it.

Sorry, I don't have any 1680 on hand, but if you are willing to discretely send me a sample, I'll be happy to weigh and photograph it and add it to the collection. (PM me for address).

I haven't included 1680 so far since there is already a fair amount of information online regarding its use for 8.6 BO. My (original) intent was to find a way to use CFE BLK for both Super and Sub sonic loadings. I already have it onhand in quantity (loading for the .300 HAM'R) and wanted to take advantage of the CFE properties, since with 8.6 and 1:3 twist is generally used with solid copper or bonded projectiles. As a second powder choice, Hodgdon H110 was an interesting alternative as I also have an abundant supply onhand for .410 and hot .45 LC loads. Additionally, there is information online regarding H110 use with 8.6. (Caution with using AP 2020 Outdoors loads (from uTube) as a speciality projectile manufacturer has communicated privately that these loads are 'way over pressure', and likely unsafe). Both CFE BLK and H110 powders tend to favor high percent case fills which is another challenging aspect with the 8.6 Subs.

I guess we could start that 'charged' discussion regarding the use of case fillers (cream of wheat, dacron, dryer lint, even toilet paper). There is a fair amount of information online regarding potential downside of 'chamber ringing', however under certain circumstances fillers 'may' be ok. Somehow this still fits into the voodoo category from my perspective.

FYI . . . The information below is from the Hodgdon website:

CFE BLK contains our Copper Fouling Eraser ingredient, originally used in military propellant, which greatly deters copper fouling and contributes to longer periods of top accuracy with less barrel cleaning time.

Density of 60.93 lb/ft3

Density: 61.62 lb/ft3

Density: 96.76 lb/ft3

According to the Hodgon website, all three powders are 'spherical propellants'.

Judging from the density numbers, CFE BLK and H110 are similar, whereas Accurate 1680 is a fair amount more dense than the other two, thereby associated with even less case fill. The burn rates for the three are very similar. I'm not sure I'm following you as to how 1680 might function 'in a middle ground' as you put it.

Sorry, I don't have any 1680 on hand, but if you are willing to discretely send me a sample, I'll be happy to weigh and photograph it and add it to the collection. (PM me for address).

I haven't included 1680 so far since there is already a fair amount of information online regarding its use for 8.6 BO. My (original) intent was to find a way to use CFE BLK for both Super and Sub sonic loadings. I already have it onhand in quantity (loading for the .300 HAM'R) and wanted to take advantage of the CFE properties, since with 8.6 and 1:3 twist is generally used with solid copper or bonded projectiles. As a second powder choice, Hodgdon H110 was an interesting alternative as I also have an abundant supply onhand for .410 and hot .45 LC loads. Additionally, there is information online regarding H110 use with 8.6. (Caution with using AP 2020 Outdoors loads (from uTube) as a speciality projectile manufacturer has communicated privately that these loads are 'way over pressure', and likely unsafe). Both CFE BLK and H110 powders tend to favor high percent case fills which is another challenging aspect with the 8.6 Subs.

I guess we could start that 'charged' discussion regarding the use of case fillers (cream of wheat, dacron, dryer lint, even toilet paper). There is a fair amount of information online regarding potential downside of 'chamber ringing', however under certain circumstances fillers 'may' be ok. Somehow this still fits into the voodoo category from my perspective.

FYI . . . The information below is from the Hodgdon website:

Hodgdon CFE® BLK

This spherical propellant is designed expressly for the 300 Remington AAC Blackout cartridge and meters very accurately.CFE BLK contains our Copper Fouling Eraser ingredient, originally used in military propellant, which greatly deters copper fouling and contributes to longer periods of top accuracy with less barrel cleaning time.

Density of 60.93 lb/ft3

Hodgdon H110®

H110 is the spherical powder that screams "no wimps, please!", delivering top velocities with great accuracy in 44 Magnum, 454 Casull, 475 Linebaugh and the 460 and 500 S&W magnums. Silhouette shooters claim it is the most accurate 44 powder they have ever used. In addition, H110 is "the" choice for 410-bore shotgun.Density: 61.62 lb/ft3

Accurate 1680®

Accurate 1680 is an extremely fast burning, double-base, spherical rifle powder that is well suited for large capacity, high performance handgun cartridges such as the 454 Casull, 460 S&W and 500 S&W. 1680 is also an excellent choice for the 22 Hornet and 7.62 x 39, as well as other low capacity rifle cartridges.Density: 96.76 lb/ft3

Follow-up from range testing:

Barrel / gun: 12" 1:3 twist Q barrel on The Fix

Powder: Universal Clays (1:1 similar to Unique)

Projectiles: Maker 350 gr

C.O.A.L.: 2.780"

Two rounds of Gorilla 342 gr fired initially:

- velocities (fps): 1046, 1013

Universal Clays:

- 9 grains: 840, 750, 829 fps

- 10 grains: 894, 901, 893 fps (flattened primers, no extractor marks)

- 12 grains: 1,000 fps (flattened primer, noticeable extractor mark and excessive bolt opening tension)

The testing was terminated after the first 12 grain shot, due to excessive bolt opening tension and other signs of over-pressure.

Summary:

Well, it seemed like a good idea at the time . . . just didn't pan out.

Too fast a powder for this heavy round. Building pressure way faster than velocity.

I guess I'll plan to drop back into the next powder burn rate bracket (CFE BLK, H110, 1680, Lil' Gun, etc) and build out from there. I'll plan to start with CFE BLK, and if anyone has any suggestions for starting points (subs, 350 gr), any info would be greatly appreciated.

As a sidebar note, there is no evidence of carbon or copper barrel fouling.

Barrel / gun: 12" 1:3 twist Q barrel on The Fix

Powder: Universal Clays (1:1 similar to Unique)

Projectiles: Maker 350 gr

C.O.A.L.: 2.780"

Two rounds of Gorilla 342 gr fired initially:

- velocities (fps): 1046, 1013

Universal Clays:

- 9 grains: 840, 750, 829 fps

- 10 grains: 894, 901, 893 fps (flattened primers, no extractor marks)

- 12 grains: 1,000 fps (flattened primer, noticeable extractor mark and excessive bolt opening tension)

The testing was terminated after the first 12 grain shot, due to excessive bolt opening tension and other signs of over-pressure.

Summary:

Well, it seemed like a good idea at the time . . . just didn't pan out.

Too fast a powder for this heavy round. Building pressure way faster than velocity.

I guess I'll plan to drop back into the next powder burn rate bracket (CFE BLK, H110, 1680, Lil' Gun, etc) and build out from there. I'll plan to start with CFE BLK, and if anyone has any suggestions for starting points (subs, 350 gr), any info would be greatly appreciated.

As a sidebar note, there is no evidence of carbon or copper barrel fouling.

Last edited:

Try 16.8 to 17.2 gr CFE BLK, be cautious not to push them much past 1,000 fps, they can start to open in flight.Follow-up from range testing:

Barrel / gun: 12" 1:3 twist Q barrel on The Fix

Powder: Universal Clays (1:1 similar to Unique)

Projectiles: Maker 350 gr

C.O.A.L.: 2.178"

Two rounds of Gorilla 342 gr fired initially:

- velocities (fps): 1046, 1013

Universal Clays:

- 9 grains: 840, 750, 829 fps

- 10 grains: 894, 901, 893 fps (flattened primers, no extractor marks)

- 12 grains: 1,000 fps (flattened primer, noticeable extractor mark and excessive bolt opening tension)

The testing was terminated after the first 12 grain shot, due to excessive bolt opening tension and other signs of over-pressure.

Summary:

Well, it seemed like a good idea at the time . . . just didn't pan out.

Too fast a powder for this heavy round. Building pressure way faster than velocity.

I guess I'll plan to drop back into the next powder burn rate bracket (CFE BLK, H110, 1680, Lil' Gun, etc) and build out from there. I'll plan to start with CFE BLK, and if anyone has any suggestions for starting points (subs, 350 gr), any info would be greatly appreciated.

As a sidebar note, there is no evidence of carbon or copper barrel fouling.

The pressure was as predicted, but velocity a bit too low. The 10 gr load velocities appear consistent at 900 fps but a bit past max pressure. Indicating good powder burn at too high pressure.Follow-up from range testing:

Barrel / gun: 12" 1:3 twist Q barrel on The Fix

Powder: Universal Clays (1:1 similar to Unique)

Projectiles: Maker 350 gr

C.O.A.L.: 2.780"

Two rounds of Gorilla 342 gr fired initially:

- velocities (fps): 1046, 1013

Universal Clays:

- 9 grains: 840, 750, 829 fps

- 10 grains: 894, 901, 893 fps (flattened primers, no extractor marks)

- 12 grains: 1,000 fps (flattened primer, noticeable extractor mark and excessive bolt opening tension)

The testing was terminated after the first 12 grain shot, due to excessive bolt opening tension and other signs of over-pressure.

Summary:

Well, it seemed like a good idea at the time . . . just didn't pan out.

Too fast a powder for this heavy round. Building pressure way faster than velocity.

I guess I'll plan to drop back into the next powder burn rate bracket (CFE BLK, H110, 1680, Lil' Gun, etc) and build out from there. I'll plan to start with CFE BLK, and if anyone has any suggestions for starting points (subs, 350 gr), any info would be greatly appreciated.

As a sidebar note, there is no evidence of carbon or copper barrel fouling.

Plus acceptable accuracy needs to be attained.

Good test, but not meeting tbe criteria.

Try some other powders.

If using the same 350 gr Maker bullet, and COAL. Plus 12" barrel.

Important*... these are not to be shot over 1050 fps according to the manufacturer in the 3 twist.

I just checked the bullet stability calculator and I can shoot these with complete stability in the 6.5 twist...even went to zero elevation, -30° below and 750 fps. Plus I could probably run them at high velocity also. The 6.5 twist advantage.

Back to the predicted load data..

These will be predicated the 1100fps level do not start there for bullet safety

H110 14.0 GR 56.6% fill =1111 fps

LilGun 13.5 GR 56.3% fill= 1125 fps

H4227 14.0 GR 66.3% fill= 1105 fps

H4198 15.8 GR 72.9% fill= 1115 fps

CFE BLK 18.0 GR 73.5% fill 1111 fps ...

....but CFE has unburned powder at 87% burned meaning inconsistent velocities, but short range accuracy may be acceptable.

3 good possibilities may be as follows:

IMR 4227 14.5 GR fill 68.7% = 1134 fps

Plus 99.34 % of powder is burned

IMR 4198 15.0 GR 72.5% fill = 1107 fps

97% of powder burned

Vit N110 13.3 GR 68% fill= 1139 fps

100% powder burned.

One may never achieve excellence with this case with subs as it has too much powder capacity, and the Faxon 3 twist makes it worse. But use what ya have to see if any of these powders make a difference.

Powder burns efficiently and completely at the high pressures it was designed for. Low pressures and short barrels hinder that process. With inconsistent velocities and unburned powder.

I may try some of those bullets in the 6.5 twist without the muzzle brake, to see how fast they will go.

My personal best 8.6 sub load is 15.8 gr IMR 4198 with a 300 gr Berger 2.880" COAL (center feed mag, will take 2.990" cartridges)

I also run it at 2000 fps.

This is my sub accuracy load for that bullet with single digit S/ D over 10 shots and accurate.

But it's a long barreled 6.5 twist...

Not what many are using...so may not be much help...but I scrapped our the 3 twist Faxon for a quality 6.5 twist, with excellent results...keep the 3 twist if ya like em, don't matter to me...it's just my long road of exploration with the 8.6 Blackout. And I like it now. Maybe some of the information will help...loads are always for informational purposes. Work up slowly, without the muzzle device, to make sure they stay below the 1050 fps for 3 twist as recommended by the manufacturer...

Have fun...

Attachments

So I just visited the Maker bullet site for the 350 gr 338 expanding ....thinking of trying a few.

It now says KEEP UNDER 1000 FPS!..

Their ONE load data is 15.9 gr of 296/ H110.

Probably should be running these 900 to 950 fps Max to be safe with the 8.6 3 twist.

It now says KEEP UNDER 1000 FPS!..

Their ONE load data is 15.9 gr of 296/ H110.

Probably should be running these 900 to 950 fps Max to be safe with the 8.6 3 twist.

@45-90, thanks for the feedback and all of the great information.

Regarding projectile:

I started with the 350 gr thinking that would be the heaviest in class. Maybe the Maker design is not the best for load development. I do have 300 gr SMK on the shelf which might be better for now. I will look around for other 350 gr options that will work for 1:3.

Regarding powder:

I have several onhand that you mentioned, CFE BLK, H110, IMR 4227, IMR 4198.

Next steps:

Q 12" 1:3

COAL: 2.780"

300 gr SMK

Powders as above to bracket velocities.

Regarding projectile:

I started with the 350 gr thinking that would be the heaviest in class. Maybe the Maker design is not the best for load development. I do have 300 gr SMK on the shelf which might be better for now. I will look around for other 350 gr options that will work for 1:3.

Regarding powder:

I have several onhand that you mentioned, CFE BLK, H110, IMR 4227, IMR 4198.

Next steps:

Q 12" 1:3

COAL: 2.780"

300 gr SMK

Powders as above to bracket velocities.

That's my bad, It looked like H110 and CFE Black were also flake powders by the looks of them in the picture.@fortify503, thanks for your note.

According to the Hodgon website, all three powders are 'spherical propellants'.

Judging from the density numbers, CFE BLK and H110 are similar, whereas Accurate 1680 is a fair amount more dense than the other two, thereby associated with even less case fill. The burn rates for the three are very similar. I'm not sure I'm following you as to how 1680 might function 'in a middle ground' as you put it.

Sorry, I don't have any 1680 on hand, but if you are willing to discretely send me a sample, I'll be happy to weigh and photograph it and add it to the collection. (PM me for address).

I haven't included 1680 so far since there is already a fair amount of information online regarding its use for 8.6 BO. My (original) intent was to find a way to use CFE BLK for both Super and Sub sonic loadings. I already have it onhand in quantity (loading for the .300 HAM'R) and wanted to take advantage of the CFE properties, since with 8.6 and 1:3 twist is generally used with solid copper or bonded projectiles. As a second powder choice, Hodgdon H110 was an interesting alternative as I also have an abundant supply onhand for .410 and hot .45 LC loads. Additionally, there is information online regarding H110 use with 8.6. (Caution with using AP 2020 Outdoors loads (from uTube) as a speciality projectile manufacturer has communicated privately that these loads are 'way over pressure', and likely unsafe). Both CFE BLK and H110 powders tend to favor high percent case fills which is another challenging aspect with the 8.6 Subs.

I guess we could start that 'charged' discussion regarding the use of case fillers (cream of wheat, dacron, dryer lint, even toilet paper). There is a fair amount of information online regarding potential downside of 'chamber ringing', however under certain circumstances fillers 'may' be ok. Somehow this still fits into the voodoo category from my perspective.

FYI . . . The information below is from the Hodgdon website:

Hodgdon CFE® BLK

This spherical propellant is designed expressly for the 300 Remington AAC Blackout cartridge and meters very accurately.

CFE BLK contains our Copper Fouling Eraser ingredient, originally used in military propellant, which greatly deters copper fouling and contributes to longer periods of top accuracy with less barrel cleaning time.

Density of 60.93 lb/ft3

Hodgdon H110®

H110 is the spherical powder that screams "no wimps, please!", delivering top velocities with great accuracy in 44 Magnum, 454 Casull, 475 Linebaugh and the 460 and 500 S&W magnums. Silhouette shooters claim it is the most accurate 44 powder they have ever used. In addition, H110 is "the" choice for 410-bore shotgun.

Density: 61.62 lb/ft3

Accurate 1680®

Accurate 1680 is an extremely fast burning, double-base, spherical rifle powder that is well suited for large capacity, high performance handgun cartridges such as the 454 Casull, 460 S&W and 500 S&W. 1680 is also an excellent choice for the 22 Hornet and 7.62 x 39, as well as other low capacity rifle cartridges.

Density: 96.76 lb/ft3

Was hoping the Clays panned out for you...There might be hope for some stick powders maybe with lower burn rate than the Clays but similar in ability to fill more case compared to spherical??

Around 15.0 gr H110 and 16.0 gr CFE BLK will get you in the ballpark with a 12" barrel.@45-90, thanks for the feedback and all of the great information.

Regarding projectile:

I started with the 350 gr thinking that would be the heaviest in class. Maybe the Maker design is not the best for load development. I do have 300 gr SMK on the shelf which might be better for now. I will look around for other 350 gr options that will work for 1:3.

Regarding powder:

I have several onhand that you mentioned, CFE BLK, H110, IMR 4227, IMR 4198.

Next steps:

Q 12" 1:3

COAL: 2.780"

300 gr SMK

Powders as above to bracket velocities.

@45-90:So I just visited the Maker bullet site for the 350 gr 338 expanding ....thinking of trying a few.

It now says KEEP UNDER 1000 FPS!..

Their ONE load data is 15.9 gr of 296/ H110.

Probably should be running these 900 to 950 fps Max to be safe with the 8.6 3 twist.

Well, it's even a little more confusing than that.

Under the description in the list of items in the product category, it states 1000 fps, however, when one opens the particular item description (for the 350 gr), it states 1050 fps. I have sent a note to Paul asking for clarification, and I'll report back after I hear from him.

They are on at least V3 of these bullets. The last ones I received could be pushed a little faster.@45-90:

Well, it's even a little more confusing than that.

Under the description in the list of items in the product category, it states 1000 fps, however, when one opens the particular item description (for the 350 gr), it states 1050 fps. I have sent a note to Paul asking for clarification, and I'll report back after I hear from him.

Yes, I noticed the differences, and it's very confusing.@45-90:

Well, it's even a little more confusing than that.

Under the description in the list of items in the product category, it states 1000 fps, however, when one opens the particular item description (for the 350 gr), it states 1050 fps. I have sent a note to Paul asking for clarification, and I'll report back after I hear from him.

Is it the new version, that can handle 50 fps more, or the new version that handles 50 fps less?

Making a target velocity at 900 fps to 950 fps for a safety margin for velocity variations.

By the way, I ordered some to try in my 6.5 twist... in theory they are still way over stablized, according to the twist rate stabilizer calculator.

And the 1000 fps limit "may" be able to be exceeded, to the max velocity..."If" dependent on centrifical force, of the 3 twist.

First use their exact load to see what that does, then it’s off to the races.

Yet, another experiment.

And the 1000 fps limit "may" be able to be exceeded, to the max velocity..."If" dependent on centrifical force, of the 3 twist.

First use their exact load to see what that does, then it’s off to the races.

Yet, another experiment.

Yes, acknowledged. One would think that a decrease in rotational energy might allow for a marginal increase in translational energy (velocity).

A few weeks ago, I did the math to see to what extent the 1:3 twist (rotational energy) contributes to the overall projectile energy (translational energy + rotational energy). Interestingly, the rotational component contributes only a little more than an additional 5%. I was surprised and can only assume that what is seen in the many gel block tests reflects the 'shear' force interactions with tissue (viscosity), which is not explained by the energy math alone.

I have reached out to Lehigh Defense suggesting projectile development (solid copper) that might mimic their XP/XD lines of projectiles, which would fully exploit this high rotational property. An XD style projectile in a heavy subsonic should be crazy devastating and I am speculating the wound channel it will create in a gel block will be impressive. We'll see what they develop.

They also have two other lines of projectiles that are a little more 'classical', one being the Extreme Chaos (fragmenting) technology, and the other being a Maximum Expansion technology. None are commercially available at the moment, but development is underway and prototypes might be released in the near future.

Anyway, for now, with the Maker projectiles, I would think you might safely pick-up a little extra velocity with the 1:6.5 twist barrel. However, from the math alone, you're likely looking at 3%-ish. When I hear from Paul, I'll post in the thread.

A few weeks ago, I did the math to see to what extent the 1:3 twist (rotational energy) contributes to the overall projectile energy (translational energy + rotational energy). Interestingly, the rotational component contributes only a little more than an additional 5%. I was surprised and can only assume that what is seen in the many gel block tests reflects the 'shear' force interactions with tissue (viscosity), which is not explained by the energy math alone.

I have reached out to Lehigh Defense suggesting projectile development (solid copper) that might mimic their XP/XD lines of projectiles, which would fully exploit this high rotational property. An XD style projectile in a heavy subsonic should be crazy devastating and I am speculating the wound channel it will create in a gel block will be impressive. We'll see what they develop.

They also have two other lines of projectiles that are a little more 'classical', one being the Extreme Chaos (fragmenting) technology, and the other being a Maximum Expansion technology. None are commercially available at the moment, but development is underway and prototypes might be released in the near future.

Anyway, for now, with the Maker projectiles, I would think you might safely pick-up a little extra velocity with the 1:6.5 twist barrel. However, from the math alone, you're likely looking at 3%-ish. When I hear from Paul, I'll post in the thread.

The Maker bullets are on the way...so soon as they get here I will load some up.Yes, acknowledged. One would think that a decrease in rotational energy might allow for a marginal increase in translational energy (velocity).

A few weeks ago, I did the math to see to what extent the 1:3 twist (rotational energy) contributes to the overall projectile energy (translational energy + rotational energy). Interestingly, the rotational component contributes only a little more than an additional 5%. I was surprised and can only assume that what is seen in the many gel block tests reflects the 'shear' force interactions with tissue (viscosity), which is not explained by the energy math alone.

I have reached out to Lehigh Defense suggesting projectile development (solid copper) that might mimic their XP/XD lines of projectiles, which would fully exploit this high rotational property. An XD style projectile in a heavy subsonic should be crazy devastating and I am speculating the wound channel it will create in a gel block will be impressive. We'll see what they develop.

They also have two other lines of projectiles that are a little more 'classical', one being the Extreme Chaos (fragmenting) technology, and the other being a Maximum Expansion technology. None are commercially available at the moment, but development is underway and prototypes might be released in the near future.

Anyway, for now, with the Maker projectiles, I would think you might safely pick-up a little extra velocity with the 1:6.5 twist barrel. However, from the math alone, you're likely looking at 3%-ish. When I hear from Paul, I'll post in the thread.

Take off muzzle device and see what happens with speed and twist rate.

But check their only listed load for accuracy and velocity first.

It will be interesting as I can add 1000 fps to lead core bullets and they do not blow up in the 6.5 twist.

Which appears to be dependent on RPM of the projectile.

So 2000 fps which will not be attainable, with 350 grs, but might be safe in a lesser twist barrel.

I will run them at 1500 fps to 1700 fps for accuracy and max velocity, see what happens, as the velocity increases.

I have serious doubts about the gel test vs flesh, as the FBI does not consider the clear gel to be valid.

Its just a visual, in a consistent medium, animals have hide, bone, flesh, and a variety

of tough connective tissue.

Bullets stop rotation, break up, tumble, change coarse.

Ya can't put your finger in a bear and dig out a bullet.

Energy input is exact and can not be destroyed, but changed.

So any energy used to impart spin, must be subtracted from muzzle velocity, as energy used from the exact powder charge.

So it it cost 20 fps to spin a bullet faster than a slower twist...the slower twist will be 20 fps faster in muzzle velocity than the fast twist.

So the energy would always be an equal amount applied on the target.

The question is how the equal energy is applied,.. larger wound, less penetration.

Sharp pieces of bullet would cut easier than dull pieces, but that is more random in performance.

Does a bullet that makes 4 turns through a game animal instead of 2 have any more killing power, ...its random as to how & where the arteries and blood vessel are located with respect to bullet rotation, as the bullet strikes, and how resilient those body parts are, plus any rotation can stop instantly, petals break off, bullet goes way off coarse, sometimes 90°, or tumbles.

I find a lot of random bullet performance when shooting big game, with any bullet.

They all seem to kill over time, but it boils down to what has worked for you individually... and subsonic adds a whole new barrier to modern bullet performance.

So any new manufacturering ideas and sharing information may help in the subsonic endeavor, if there is a profit in promoting it, so far there are quite a number of bullets to be tested for various calibers, with alot of mixed reviews.

So I'll just report on what my testing shows, useful or not,...it gives me something usually fun, to do.

As I do not plan on any subsonic hunting, big heavy bullets at high 338 magnum velocity are my style for that..at close range... so a 8.6 sub could also work here. Or the old bow and arrow for stealthy times.

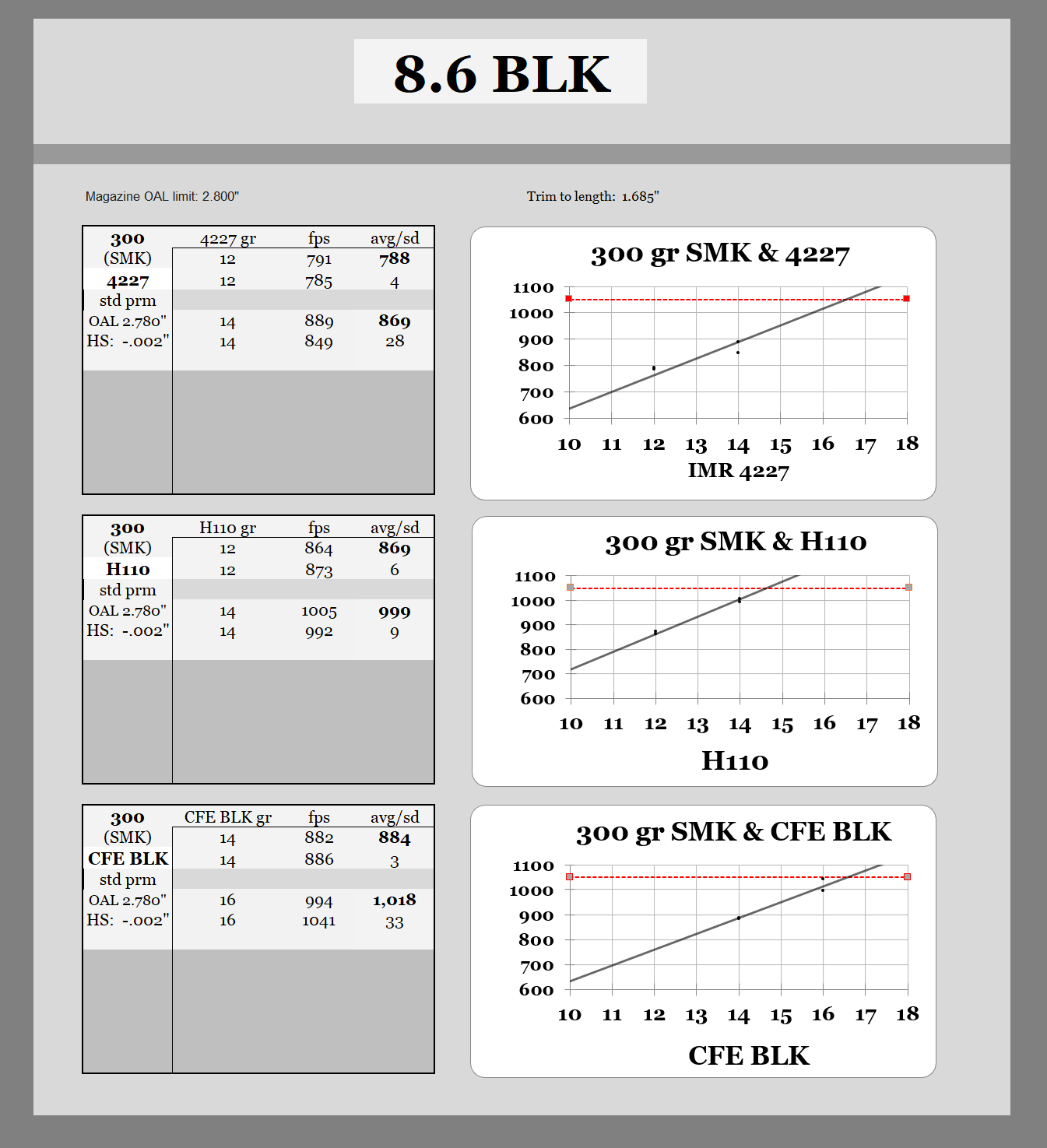

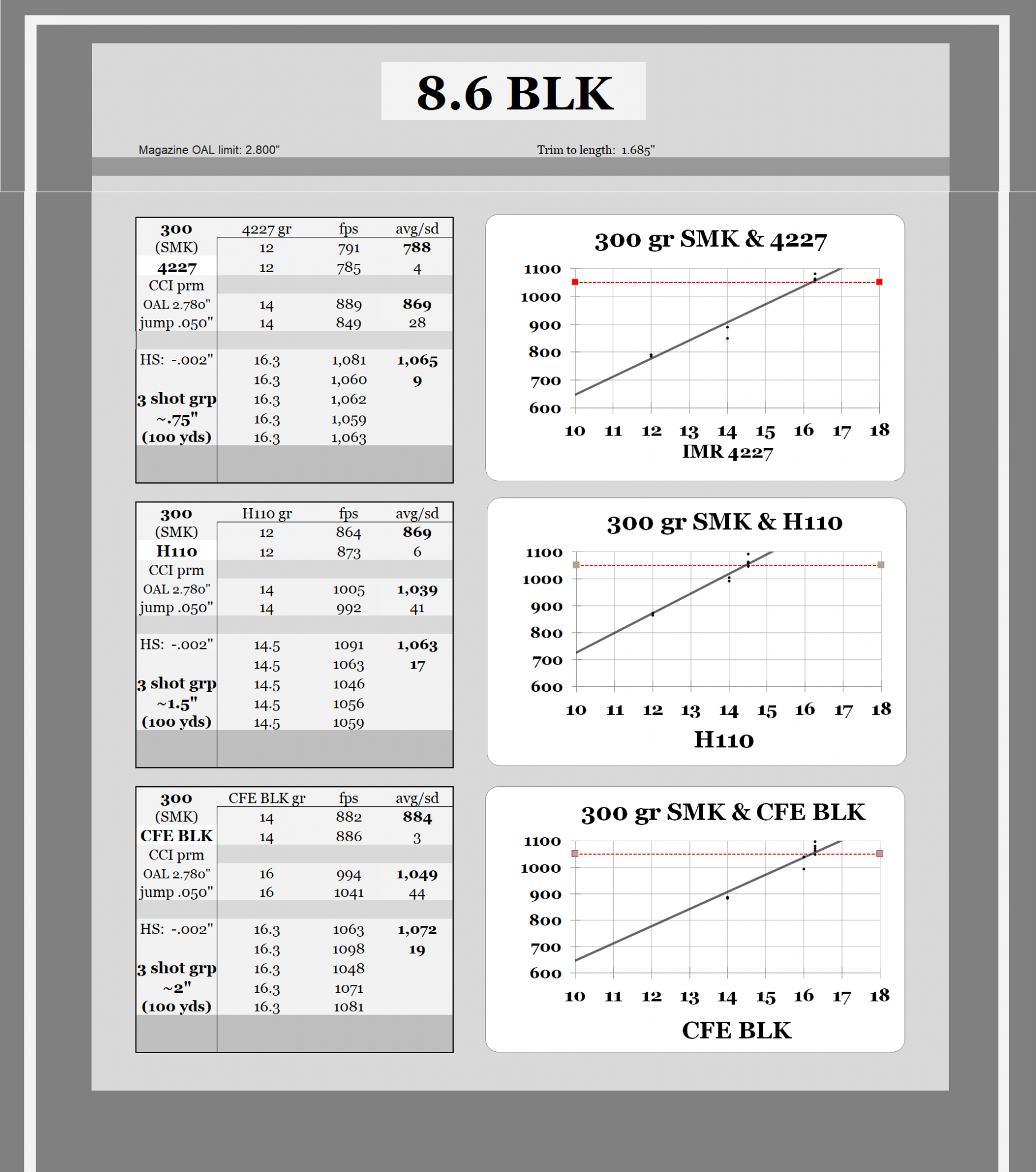

Tested three powders (CFE BLK, H110, 4227) today for velocity (only) using 300 gr SMK.

Rifle: The Fix (bolt)

Barrel: Q, LLC 12" 1:3" twist

OAL: 2.780" HS: - .002"

Primer: Standard large rifle

Rifle: The Fix (bolt)

Barrel: Q, LLC 12" 1:3" twist

OAL: 2.780" HS: - .002"

Primer: Standard large rifle

Last edited:

Re: 8.6 BLK - initial attempt at Supersonic loads

The Fix, 12" 1:3 barrel

Hornady 185 gr Cx

CFE BLK

OAL: 2.700" HS: -.002"

I set-up two charge weights, 32 gr and 35 gr of CFE BLK.

I started with the 32 gr and recorded a velocity of 2,132 fps.

HOWEVER, signs of over-pressure with a flattened primer and difficult to open bolt. No extractor marks.

I aborted after this first shot.

Time to go back to the drawing board. I would like to use CFE BLK, but it appears pressure is building faster than velocity.

Using any powder, what are reasonable expectations for maximum velocity with the 185 gr round and safe pressures?

Thoughts?

The Fix, 12" 1:3 barrel

Hornady 185 gr Cx

CFE BLK

OAL: 2.700" HS: -.002"

I set-up two charge weights, 32 gr and 35 gr of CFE BLK.

I started with the 32 gr and recorded a velocity of 2,132 fps.

HOWEVER, signs of over-pressure with a flattened primer and difficult to open bolt. No extractor marks.

I aborted after this first shot.

Time to go back to the drawing board. I would like to use CFE BLK, but it appears pressure is building faster than velocity.

Using any powder, what are reasonable expectations for maximum velocity with the 185 gr round and safe pressures?

Thoughts?

For the 300 gr SMK with your gun and data, the H110 loads shows good promise with low velocity S/D in both test samples.Re: 8.6 BLK - initial attempt at Supersonic loads

The Fix, 12" 1:3 barrel

Hornady 185 gr Cx

CFE BLK

OAL: 2.700" HS: -.002"

I set-up two charge weights, 32 gr and 35 gr of CFE BLK.

I started with the 32 gr and recorded a velocity of 2,132 fps.

HOWEVER, signs of over-pressure with a flattened primer and difficult to open bolt. No extractor marks.

I aborted after this first shot.

Time to go back to the drawing board. I would like to use CFE BLK, but it appears pressure is building faster than velocity.

Using any powder, what are reasonable expectations for maximum velocity with the 185 gr round and safe pressures?

Thoughts?

If the accuracy is there. The 4227 appears next, or maybe better with further testing, but it seemed to get worse as velocity goes above 800 fps...interesting.

CFE BLK is not a good candidate for low velocity S/ D as it never achieves full burn rate of the powder charge...even on many supers.

For the 185 gr CX something seems off, as pressure seems high, for the powder.

Being all copper I always jump them .050" as recommended for many yrs and accuracy is good there too...usually

If ya don't jump them a huge pressure spike comes in play early.

Not shooting the 185 gr CX, a newer alloy is stated to be involved...So how's that affect pressure?

Hornady states the bullet needs 2000 fps impact speed to be effective.

Not leaving much room in a 12" barrel, for effective range.

I believe you may get to 2100 - 2150 fps but it's a short range proposition, for proper bullet performance of 2000 fps impact velocity.

A sub load would be more reliable if that's all the velocity there is available.

W 296, H110, RL7, 10X, 4227, are all around 2100 fps, and burn up100% of tbe powder, or close to it in 12".

Hybrid cases help a bit with velocity in bolt guns. And the Barnes 160 gr may give a bit more velocity, but I do not know it’s impact restrictions, in game.

Barnes 160 gr TTSX in a conventional slower twist threshold is 1,800 fps for 1.7x expansion. For 2x expansion, add approximately 100-200 fps. Faster twist barrels drop the threshold at both the top and bottom end, but Barnes won't say how much, but they do lose petals at the top end.

What primers did you use? And just to confirm the bolt lift is difficult compared to other supersonic ammo? Some Fix guns have tension with any supers, even lower pressure ones. Guys buy the longer bolt handles Q has available to help that.Re: 8.6 BLK - initial attempt at Supersonic loads

The Fix, 12" 1:3 barrel

Hornady 185 gr Cx

CFE BLK

OAL: 2.700" HS: -.002"

I set-up two charge weights, 32 gr and 35 gr of CFE BLK.

I started with the 32 gr and recorded a velocity of 2,132 fps.

HOWEVER, signs of over-pressure with a flattened primer and difficult to open bolt. No extractor marks.

I aborted after this first shot.

Time to go back to the drawing board. I would like to use CFE BLK, but it appears pressure is building faster than velocity.

Using any powder, what are reasonable expectations for maximum velocity with the 185 gr round and safe pressures?

Thoughts?

Barnes claims a higher BC for comparable 185 gr copper than the Hornady CX.

One could chronograph lower velocity loads say 2000 fps to 1800 fps shoot them at close range, then catch them in water jugs or some medium of choice to see how much expansion they have or don't have.

All I do is give information on what I've shot and tested..or some QL information to help.

This is my 160 gr Barnes load, for the 6.5 twist barrel at almost 2800 fps ave. They mushroomed up at that velocity as expected, at close range.

So 2400fps + might be possible in a 12", maybe 2500 with hybrid cases, to extend the 8.6 range....with careful reloading, and some bullet performance testing.

One could chronograph lower velocity loads say 2000 fps to 1800 fps shoot them at close range, then catch them in water jugs or some medium of choice to see how much expansion they have or don't have.

All I do is give information on what I've shot and tested..or some QL information to help.

This is my 160 gr Barnes load, for the 6.5 twist barrel at almost 2800 fps ave. They mushroomed up at that velocity as expected, at close range.

So 2400fps + might be possible in a 12", maybe 2500 with hybrid cases, to extend the 8.6 range....with careful reloading, and some bullet performance testing.

Attachments

@45-90:

Thanks for your comments and insights.

For the subs with CFE BLK, if you think the increased SDV with the higher charges is due to unburnt powder, maybe consider using a magnum primer?

Earlier in the thread, I believe you mentioned using H335 for 165 gr Barnes for some impressive velocities.

Bearing in mind I'm using the 12" 1:3, what charges might be a reasonable starting point?

With regards to your comments regarding the 185 gr Cx experience, I agree, that's not what I was expecting.

I'll double check my jump distance as a starting point. If off, I'll plan to adjust to .050" and try another shot or two.

For subs, I'll plan to shoot some groups of each of the above powders to see if there are any significant accuracy differences. I'll report back with the results, probably early next week.

@tom12.7:

Thanks for your comments.

I am using CCI standard rifle primers.

The bolt was 'really stiff' and more than I typically experience.

Thanks for your comments and insights.

For the subs with CFE BLK, if you think the increased SDV with the higher charges is due to unburnt powder, maybe consider using a magnum primer?

Earlier in the thread, I believe you mentioned using H335 for 165 gr Barnes for some impressive velocities.

Bearing in mind I'm using the 12" 1:3, what charges might be a reasonable starting point?

With regards to your comments regarding the 185 gr Cx experience, I agree, that's not what I was expecting.

I'll double check my jump distance as a starting point. If off, I'll plan to adjust to .050" and try another shot or two.

For subs, I'll plan to shoot some groups of each of the above powders to see if there are any significant accuracy differences. I'll report back with the results, probably early next week.

@tom12.7:

Thanks for your comments.

I am using CCI standard rifle primers.

The bolt was 'really stiff' and more than I typically experience.

Magnum can primers help with some hard to ignite powders...but CFEBLK is probably not one...but I have not tried them...so an experiment may be in order.

Hard bolt lift means STOP!

figure out why...usually too high pressure.

Annealing cases can actually help with hard bolt lift because the hard brass on the shoulder springs back a couple of thousandths and not necessarily immediately, and when fired stay put, and not retract.

Cartridge case overall length, needs trimmed, excess can spike pressures.

Necks need to be turned, into the shoulder, as brass has flowed into the case shoulder junction and does not have enough clearance in that area release the bullet... common in wildcats and cartridges made from other calibers, like 8.6 Blackout. This will definitely spike pressures really high.

.050" jump to rifling on all copper bullets....far as I know no exceptions.

Or you will have an immediate high pressure spike... these can be 8,000 to 10,000 psi spikes with no benefit to velocity.

The bullet must start to move and add more continuous volume to as the powder burns...it's milliseconds, but the bullet must have no extra impedance at that instant.

Or it turns into a hand grenade, in your face, if impedance is too much.

Copper bullets have double the start pressure to begin with and must be taken into account, as pointed out in many handloading manuals, but so lump them together and that is not correct.

To run the 160 gr Barnes TTSXFB 338 in 8.6 Blackout.

All of the above must be addressed.

The bullet must be free to travel other than neck tension and a slight crimp if desired.

It needs min of .050" jump to the rifling.

160 gr Barnes.

Case capacity 45.7 gr H2O ...adjust for different capacity

12" barrel... no way to account for twist.

.050" off lands very important.

2.700" COAL adjust powder if shorter COAL.

58,740 psi max pressure wildcat status

What I use for brass cases, and 65,000 psi for hybrid cases...it has never blown a primer with pressure but velocities are sometimes off quite a bit.

Use at your own risk, ...it's a guesstimate.

What works for me may not for you.

Different rifles, twists & chambers, plus loading practices, make it all difficult to predict.

Work up slow. Stiff bolt lift STOP.

But any rifle should take the starting load..

Or something Is Wrong elsewhere, in the brass, case capacity, or loading practices.

Live and learn, just don't blow your face off.

"Any change" in the data changes the outcome.

39.0 gr H335 93.4 % fill = 2142 fps 42,871psi start load.

40 gr H335 95.8 % fill = 2202 fps

41 gr H335 98.2% fill = 2263 fps

42 gr H335 100.6% fill = 2325 fps 53,647 psi

43 gr H335 103% fill = 2388 fps 57,953 psi right at maximum.

43.2 gr H335 103.4% fill = 2401 fps 58,865 psi. Slightly over pressure.

Hard bolt lift means STOP!

figure out why...usually too high pressure.

Annealing cases can actually help with hard bolt lift because the hard brass on the shoulder springs back a couple of thousandths and not necessarily immediately, and when fired stay put, and not retract.

Cartridge case overall length, needs trimmed, excess can spike pressures.

Necks need to be turned, into the shoulder, as brass has flowed into the case shoulder junction and does not have enough clearance in that area release the bullet... common in wildcats and cartridges made from other calibers, like 8.6 Blackout. This will definitely spike pressures really high.

.050" jump to rifling on all copper bullets....far as I know no exceptions.

Or you will have an immediate high pressure spike... these can be 8,000 to 10,000 psi spikes with no benefit to velocity.

The bullet must start to move and add more continuous volume to as the powder burns...it's milliseconds, but the bullet must have no extra impedance at that instant.

Or it turns into a hand grenade, in your face, if impedance is too much.

Copper bullets have double the start pressure to begin with and must be taken into account, as pointed out in many handloading manuals, but so lump them together and that is not correct.

To run the 160 gr Barnes TTSXFB 338 in 8.6 Blackout.

All of the above must be addressed.

The bullet must be free to travel other than neck tension and a slight crimp if desired.

It needs min of .050" jump to the rifling.

160 gr Barnes.

Case capacity 45.7 gr H2O ...adjust for different capacity

12" barrel... no way to account for twist.

.050" off lands very important.

2.700" COAL adjust powder if shorter COAL.

58,740 psi max pressure wildcat status

What I use for brass cases, and 65,000 psi for hybrid cases...it has never blown a primer with pressure but velocities are sometimes off quite a bit.

Use at your own risk, ...it's a guesstimate.

What works for me may not for you.

Different rifles, twists & chambers, plus loading practices, make it all difficult to predict.

Work up slow. Stiff bolt lift STOP.

But any rifle should take the starting load..

Or something Is Wrong elsewhere, in the brass, case capacity, or loading practices.

Live and learn, just don't blow your face off.

"Any change" in the data changes the outcome.

39.0 gr H335 93.4 % fill = 2142 fps 42,871psi start load.

40 gr H335 95.8 % fill = 2202 fps

41 gr H335 98.2% fill = 2263 fps

42 gr H335 100.6% fill = 2325 fps 53,647 psi

43 gr H335 103% fill = 2388 fps 57,953 psi right at maximum.

43.2 gr H335 103.4% fill = 2401 fps 58,865 psi. Slightly over pressure.

@45-90:

Thank you for your thorough reply . . . all important points and greatly appreciated.

Process:

Very nice walk-through of the steps and considerations throughout the process.

Consistency and safety are the primary concerns.

Bullet jump (for solid copper):

Always >= 0.050" (noted)

Primers:

Regarding the suggestion for magnum primers, this came from noting Wilson's use of magnum primers for his 300 HAM'R, which I reload. It's a .30 round (90 gr - 150 gr range) based on a .223 case, with velocities at/approaching the 2,400 fps range. It is also a situation of a 'case capacity limited' cartridge. He landed on CFE BLK as the preferred powder and A1680 as a close second, and recommended magnum primers.

Powder H338 (and Barnes 160 gr TTSX):

Thanks for the charge ladder. I'll plan to start at the lower end and correlate.

Powder considerations / overview:

Just for the purposes of brainstorming . . .

I am assuming a general rule of thumb is the slower the powder the greater the amount needed to maintain velocity. Meaning as one moves down the burn rate chart, the powder charge increases for a desired velocity. . . until some practical limit is reached.

From the H335 charge ladder presented, it does appear that the percent case fill and pressure are reasonably well-mated (maybe still just a touch too fast???). As a sidebar note, the obtained velocity of at/just under 2,400 fps is approximately that of the .300 HAM'R whose performance was designed to mimic the classic .30-30 (using 125 gr - 150 gr projectiles).

However, just to take things one step further . . . and again, initially, just for brainstorming purposes . . . could one consider an even slower powder than H335, say H4895, which has pushed .30 projectiles for years, at higher velocities, albeit with greater case capacity and longer barrels? I realize H4895 might seem too slow, but is it 'possible' from a case capacity standpoint? Burn efficiency might be improved marginally with magnum primers.

This thinking is to set a 'bracket' limit for the slowest powder that could be considered (presumably limited primarily by case capacity and secondarily to barrel length) . . . theoretically, what might be the slowest powder that could be used? Pushing the 160 gr projectile would represent a 'best case' for available case capacity.

Thoughts / suggestions?

Thank you for your thorough reply . . . all important points and greatly appreciated.

Process:

Very nice walk-through of the steps and considerations throughout the process.

Consistency and safety are the primary concerns.

Bullet jump (for solid copper):

Always >= 0.050" (noted)

Primers:

Regarding the suggestion for magnum primers, this came from noting Wilson's use of magnum primers for his 300 HAM'R, which I reload. It's a .30 round (90 gr - 150 gr range) based on a .223 case, with velocities at/approaching the 2,400 fps range. It is also a situation of a 'case capacity limited' cartridge. He landed on CFE BLK as the preferred powder and A1680 as a close second, and recommended magnum primers.

Powder H338 (and Barnes 160 gr TTSX):

Thanks for the charge ladder. I'll plan to start at the lower end and correlate.

Powder considerations / overview:

Just for the purposes of brainstorming . . .

I am assuming a general rule of thumb is the slower the powder the greater the amount needed to maintain velocity. Meaning as one moves down the burn rate chart, the powder charge increases for a desired velocity. . . until some practical limit is reached.

From the H335 charge ladder presented, it does appear that the percent case fill and pressure are reasonably well-mated (maybe still just a touch too fast???). As a sidebar note, the obtained velocity of at/just under 2,400 fps is approximately that of the .300 HAM'R whose performance was designed to mimic the classic .30-30 (using 125 gr - 150 gr projectiles).

However, just to take things one step further . . . and again, initially, just for brainstorming purposes . . . could one consider an even slower powder than H335, say H4895, which has pushed .30 projectiles for years, at higher velocities, albeit with greater case capacity and longer barrels? I realize H4895 might seem too slow, but is it 'possible' from a case capacity standpoint? Burn efficiency might be improved marginally with magnum primers.

This thinking is to set a 'bracket' limit for the slowest powder that could be considered (presumably limited primarily by case capacity and secondarily to barrel length) . . . theoretically, what might be the slowest powder that could be used? Pushing the 160 gr projectile would represent a 'best case' for available case capacity.

Thoughts / suggestions?

Last edited:

Man, that was a long read.

So I'm going to experiment with 300SMKs subsonic out of a 16” 1:6.5 bolt gun, but with no inclusion in QL yet and a general lack of published data, what powder would be a good starting point?

My collection of fast powders is pretty limited, but would any of these suffice?

So I'm going to experiment with 300SMKs subsonic out of a 16” 1:6.5 bolt gun, but with no inclusion in QL yet and a general lack of published data, what powder would be a good starting point?

My collection of fast powders is pretty limited, but would any of these suffice?

H110 is probably your best bet to get started.

My charts are for 12" 1:3 barrel.

@45-90 has more experience.

My charts are for 12" 1:3 barrel.

@45-90 has more experience.

Yep, H110 is the better sub powder, the others are pretty slow for that, and make better super loads.H110 is probably your best bet to get started.

My charts are for 12" 1:3 barrel.

@45-90 has more experience.

There is a slow powder detonation phenomenon, whereby too much air space causes the powder to detonate...rather than burn. Look it up!

Try 14.0 gr to 14.5 gr H110 behind the 300 gr SMK at 2.780" COAL for 16" barrel.

Trail Boss velocity too low, and must absolutely Not compress it when loading it, as it breaks the little donuts and changes the burn speed.

Try 14.0 gr to 14.5 gr H110 behind the 300 gr SMK at 2.780" COAL for 16" barrel.

Thanks for that. I've done a lot of subs over the years, so the process isn't new, but this is the first time I'm doing it without QL or any published data. Funny, that TrailBoss stash is from quite a long time ago when I was using 10.5gr in .308WIN subs.

I've owned 3, 300 Ham'rs at one time...11.5" 16" and 18" settled on the 18".

One of the few places CFEBLK works, but only for the 150 grs below that 1680 gives better velocity and accuracy in my 18".

Powder burn rate charts are approximate, and many list powders in a different order....and not to be use for reloading, as the next particular powder on a particular list.

There are too many factors for consider, like chemistry and math equations of a particular powder burn under pressure.

I use slow powders in supers in 8.6 blackout but not for subs, such as RL 17, 4895, CFE 223, etc with 200 to 300 gr lead bullets for 6.5 Twist barrels... only, at 1900 to 2000 fps, for the 300 grs.

The detonation phenomenon is real, alot of air space in the case, with slow powders, can dismantle your gun, so I don't post such loads, cause so many are running 3 twist, and are limited to low velocity subs with lead bullets.

Most of my favorite 8.6, 6.5 twist loads are high velocity lead bullets...like cheap Speer 200 gr at 2611 fps or 225 Speer boat tail at 2481 fps using heavy doses of slow burning powders. Kill any game animal in North America, and get some extra range, out of the 8.6, plus shooting any subs.

Been messing with this cartridge since it first came out...changed things like barrel twist to suit me...others love their 3 twist...but there is another side to this cartridge and I have exposed that, for those who want both worlds, in lead and copper.

One of the few places CFEBLK works, but only for the 150 grs below that 1680 gives better velocity and accuracy in my 18".

Powder burn rate charts are approximate, and many list powders in a different order....and not to be use for reloading, as the next particular powder on a particular list.

There are too many factors for consider, like chemistry and math equations of a particular powder burn under pressure.

I use slow powders in supers in 8.6 blackout but not for subs, such as RL 17, 4895, CFE 223, etc with 200 to 300 gr lead bullets for 6.5 Twist barrels... only, at 1900 to 2000 fps, for the 300 grs.

The detonation phenomenon is real, alot of air space in the case, with slow powders, can dismantle your gun, so I don't post such loads, cause so many are running 3 twist, and are limited to low velocity subs with lead bullets.

Most of my favorite 8.6, 6.5 twist loads are high velocity lead bullets...like cheap Speer 200 gr at 2611 fps or 225 Speer boat tail at 2481 fps using heavy doses of slow burning powders. Kill any game animal in North America, and get some extra range, out of the 8.6, plus shooting any subs.

Been messing with this cartridge since it first came out...changed things like barrel twist to suit me...others love their 3 twist...but there is another side to this cartridge and I have exposed that, for those who want both worlds, in lead and copper.

The detonation phenomenon is real, alot of air space in the case, with slow powders, can dismantle your gun

Yup, case fill <80% can start to get a bit dicey.

Yep 10.5 gr of Trail Boss works great in 308 subs...I shot 175 SMK quite accurately with a variety of twist rates.Thanks for that. I've done a lot of subs over the years, so the process isn't new, but this is the first time I'm doing it without QL or any published data. Funny, that TrailBoss stash is from quite a long time ago when I was using 10.5gr in .308WIN subs.

I have both 3 twist and 6.5 twist in 8.6 Blackout.

IMO, the 3 twist is ridiculous and not needed.

You can shoot everything in a 6.5 twist at maximum velocities obtainable in a 8.6 Blackout without worrying about bullet blow up, destroying your muzzle devices and chronograph....not to mention some of the fragments could hit the shooter.

All copper bullets, are supposed to be safe at higher velocities in a 3 twist. But I found the 3 twist terribly inaccurate with copper bullets, working up loads, with the expensive copper bullets, was a waste.

For 3 twist lead bullets about 1000 fps max, some keep them at 900 fps with a suppressor.

I have abandoned the 3 twist, as I how no use for it.

It's very limited, inaccurate, and takes high velocity off the table, and expensive to shoot the all copper bullets that should be used with anything above 1000 fps.

Everything I now experiment with and load for is for 6.5 twist. It brings everything to the table that the limited 3 twist leaves behind and covers everything the 3 twist does...with much better accuracy.

Do yourself a favor and get a quality 6.5 twist. You're just wasting time and ammo with the 3 twist.

I have a bunch of test loads worked up for the 6.5 twist for lead bullets close to 338 Federal velocities, not possible with the 3 twist...and they are cheap to shoot. Plus sub and high velocity 300 gr SMK and 300 Berger.

I put a barrel on a trusted rifle. Barrel is 1:3 from Mostek. The amount of copper it picks up is insane, and accuracy... leaves some things to be desired. It's probably a 3 moa gun.

I have a McGowan barrel coming in 6.5" - It's been almost 6 months and they said it should take 5, so I expect to have it soon.

I ordered two barrel blanks for bolts from them at the same time, as I have finish reamers for both barrels, and plan on doing the gunsmithing myself.I put a barrel on a trusted rifle. Barrel is 1:3 from Mostek. The amount of copper it picks up is insane, and accuracy... leaves some things to be desired. It's probably a 3 moa gun.

I have a McGowan barrel coming in 6.5" - It's been almost 6 months and they said it should take 5, so I expect to have it soon.

View attachment 8420700

For the two Rem Varmit contour barrels of .338 6.5 twist and .510 10 twist, it took almost twice as long as they said.

But I did get 2 nice barrel blanks.

So their estimate of finish time was off, other than that, everything has been good.

Hope yours turns out well...I have tons of load data for the 6.5 twist, and some 350 gr bullets on the way to test.

Re: Follow-up with subsonic loadings

Gun: The Fix ; Barrel: 12" ; twist: 1:3"

Projectile: SMK 300 gr

COAL: 2.780" (jump: 0.050")

Sandbag rest, five shots/charge, group size via best 3/5

Summary:

First attempt for group size and only using a sandbag rest.

Decided to take the best 3 of 5 for group size and will retest at a later date with a better rest.

IMR 4227 had the tightest velocities with the least standard deviation and tightest group.

H110 and CFE BLK were roughly similar with velocity standard deviations and group sizes

Gun: The Fix ; Barrel: 12" ; twist: 1:3"

Projectile: SMK 300 gr

COAL: 2.780" (jump: 0.050")

Sandbag rest, five shots/charge, group size via best 3/5

Summary:

First attempt for group size and only using a sandbag rest.

Decided to take the best 3 of 5 for group size and will retest at a later date with a better rest.

IMR 4227 had the tightest velocities with the least standard deviation and tightest group.

H110 and CFE BLK were roughly similar with velocity standard deviations and group sizes

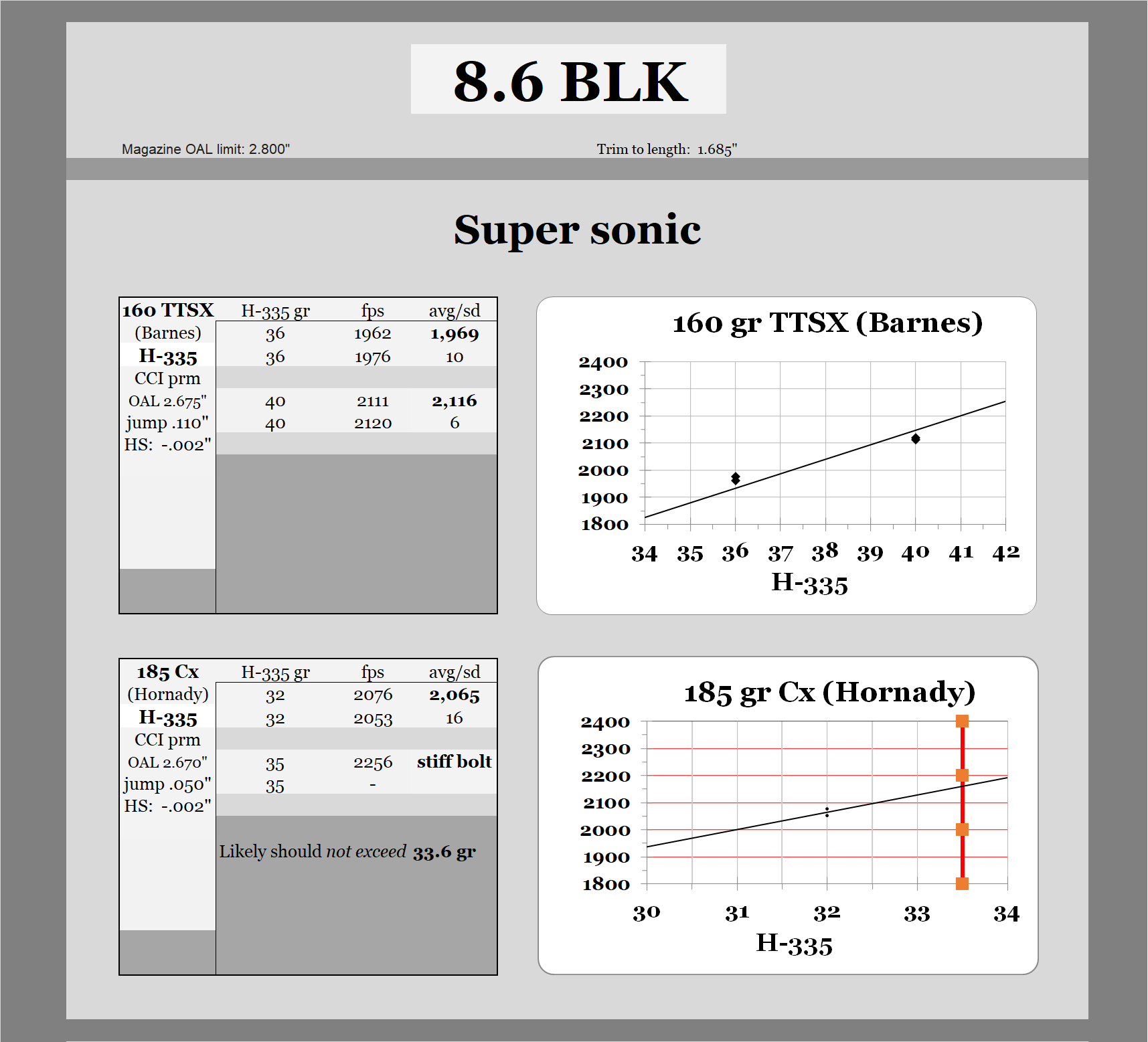

Re: Super sonic loadings - early experience

Gun: The Fix ; Barrel: 12" ; twist: 1:3"

Projectile: 160 gr TTSX (Barnes) ; 185 gr Cx (Hornady)

Powder: H-335

COAL: see below Jump: see below

160 gr TTSX:

OAL: 2.675" (established for projectile engagement of the case neck).

Jump: .110"

At 40 grains the primers were flattened, but no evidence of cratering, ejector marks, or changes with the bolt lift.

185 gr Cx:

OAL: 2.670"

Jump: .050"

Do NOT exceed 33.6 gr of H-335

(Note: COAL in this test of 2.675")

....................................................................................

Post by @45-90, earlier in this thread.

160 gr Barnes.

Case capacity 45.7 gr H2O ...adjust for different capacity

12" barrel... no way to account for twist.

.050" off lands very important.

2.700" COAL adjust powder if shorter COAL.

Stiff bolt lift STOP.

39.0 gr H335 93.4 % fill = 2142 fps 42,871psi start load.

40 gr H335 95.8 % fill = 2202 fps

41 gr H335 98.2% fill = 2263 fps

42 gr H335 100.6% fill = 2325 fps 53,647 psi

43 gr H335 103% fill = 2388 fps 57,953 psi right at maximum.

43.2 gr H335 103.4% fill = 2401 fps 58,865 psi. Slightly over pressure.

Gun: The Fix ; Barrel: 12" ; twist: 1:3"

Projectile: 160 gr TTSX (Barnes) ; 185 gr Cx (Hornady)

Powder: H-335

COAL: see below Jump: see below

160 gr TTSX:

OAL: 2.675" (established for projectile engagement of the case neck).

Jump: .110"

At 40 grains the primers were flattened, but no evidence of cratering, ejector marks, or changes with the bolt lift.

185 gr Cx:

OAL: 2.670"

Jump: .050"

Do NOT exceed 33.6 gr of H-335

(Note: COAL in this test of 2.675")

....................................................................................

Post by @45-90, earlier in this thread.

160 gr Barnes.

Case capacity 45.7 gr H2O ...adjust for different capacity

12" barrel... no way to account for twist.

.050" off lands very important.

2.700" COAL adjust powder if shorter COAL.

Stiff bolt lift STOP.

39.0 gr H335 93.4 % fill = 2142 fps 42,871psi start load.

40 gr H335 95.8 % fill = 2202 fps

41 gr H335 98.2% fill = 2263 fps

42 gr H335 100.6% fill = 2325 fps 53,647 psi

43 gr H335 103% fill = 2388 fps 57,953 psi right at maximum.

43.2 gr H335 103.4% fill = 2401 fps 58,865 psi. Slightly over pressure.

Last edited:

All my testing is done with the 6.5 twist...as I retired the 3 twist and was only a sub gun, and horrible inaccurate with somewhat high velocity copper, and most lead bullets...plus high velocity lead bullets were

out of the question.

I did notice the old 3 twist was never very fast with the 1680 load data provided by Faxon. And one load could not be reached, because of high pressure.

Your chamber and the 3 twist are way off, my 6.5 twist maximum charges, that I shoot in my gun.

I run 10% more powder with no pressure signs.

Is it the 3 twist?, its bore?, its chamber?

The Cases have slightly different capabilities, but this seem more extreme than that. Are they neck turned? Is there enough clearance in the neck to chamber fit?

Seems like a lot of difference when pressure maximum is reached.

Concerning, so much so, that any load data presented for tne 6.5 twist, should be at least 15% lower for the 3 twist.

One has to stop when pressure signs are present.

These will be your maximum loads regardless of what mine are.

More caution may be advisable for the 8.6 Blackout and twist/ chamber differences.

So if your happy with the velocity and accuracy, at these early max pressures, continue on.

If not, then something has to change.

So continue to work up slowly and start low, as the small capacity of the 8.6 case and and different rifling, chambers, and loading procedures, can get into a high pressure situation quickly.

out of the question.

I did notice the old 3 twist was never very fast with the 1680 load data provided by Faxon. And one load could not be reached, because of high pressure.

Your chamber and the 3 twist are way off, my 6.5 twist maximum charges, that I shoot in my gun.

I run 10% more powder with no pressure signs.

Is it the 3 twist?, its bore?, its chamber?

The Cases have slightly different capabilities, but this seem more extreme than that. Are they neck turned? Is there enough clearance in the neck to chamber fit?

Seems like a lot of difference when pressure maximum is reached.

Concerning, so much so, that any load data presented for tne 6.5 twist, should be at least 15% lower for the 3 twist.

One has to stop when pressure signs are present.

These will be your maximum loads regardless of what mine are.

More caution may be advisable for the 8.6 Blackout and twist/ chamber differences.

So if your happy with the velocity and accuracy, at these early max pressures, continue on.

If not, then something has to change.

So continue to work up slowly and start low, as the small capacity of the 8.6 case and and different rifling, chambers, and loading procedures, can get into a high pressure situation quickly.

@45-90 Thanks for your feedback.

Acknowledge the performance of the 3 twist and your 6.5 twist are different. I have wondered for a while if there might be a way to 'translate' the data for the 3 twist to the 6.5 twist and vice versa. Sounds like that relationship is (initially) evolving as a 15% charge reduction going from 6.5 to 3. That's a start.

The brass . . . I'm using Vairog from Milford Munitions. I have not neck turned as of yet. The trim length is ok. They fit in a Sheridan gauge. I shoulder bump ~ .002" - .003". I haven't measured the water volume yet. I use Hornady dies and anneal all brass after each firing. I don't know, maybe I'll try some of the Gorilla brass I have on hand as another data point.

Going back and reviewing your data for H335 / 42 gr charge for the 160 gr projectile producing 2,325 fps is more of what I had in mind. Is it possible / probable the 3 twist is the root cause for most of the discrepancy? The 185 gr data is also disappointing.

Honestly, I was hoping for more velocity than what I'm seeing to date. For the lighter super projectiles, I had hoped to see a bit more, more in line with the 2,325 fps proposed. The 2,100 fps velocity being achieved is beginning to remind me of the early optimistic days of 300 BO super load work-ups, only to be abandoned after significant effort due to low velocities. For me, the 300 HAM'R is the gun (for supers) that I was hoping the 300 BO would be. I hope this isn't a repeat performance.

So, to address your last paragraph . . . no, not happy with the results thus far . . . and agree, something needs to change. I am kind of stuck with the 12" 1:3 twist Q barrel for The Fix, so I need to make the best of it. The initial subsonic performance from this weekend seemed like a decent start with MOA / near MOA groups while getting use to the gun. However, it's the supers that are proving to be the challenge at this point. I don't know to what extent this is achievable with the 3 twist, but I would like to see ~2,300+ fps range with at least the light weight projectiles.

Acknowledge the performance of the 3 twist and your 6.5 twist are different. I have wondered for a while if there might be a way to 'translate' the data for the 3 twist to the 6.5 twist and vice versa. Sounds like that relationship is (initially) evolving as a 15% charge reduction going from 6.5 to 3. That's a start.

The brass . . . I'm using Vairog from Milford Munitions. I have not neck turned as of yet. The trim length is ok. They fit in a Sheridan gauge. I shoulder bump ~ .002" - .003". I haven't measured the water volume yet. I use Hornady dies and anneal all brass after each firing. I don't know, maybe I'll try some of the Gorilla brass I have on hand as another data point.

Going back and reviewing your data for H335 / 42 gr charge for the 160 gr projectile producing 2,325 fps is more of what I had in mind. Is it possible / probable the 3 twist is the root cause for most of the discrepancy? The 185 gr data is also disappointing.

Honestly, I was hoping for more velocity than what I'm seeing to date. For the lighter super projectiles, I had hoped to see a bit more, more in line with the 2,325 fps proposed. The 2,100 fps velocity being achieved is beginning to remind me of the early optimistic days of 300 BO super load work-ups, only to be abandoned after significant effort due to low velocities. For me, the 300 HAM'R is the gun (for supers) that I was hoping the 300 BO would be. I hope this isn't a repeat performance.

So, to address your last paragraph . . . no, not happy with the results thus far . . . and agree, something needs to change. I am kind of stuck with the 12" 1:3 twist Q barrel for The Fix, so I need to make the best of it. The initial subsonic performance from this weekend seemed like a decent start with MOA / near MOA groups while getting use to the gun. However, it's the supers that are proving to be the challenge at this point. I don't know to what extent this is achievable with the 3 twist, but I would like to see ~2,300+ fps range with at least the light weight projectiles.

Have you checked with a Sheridan gauge AFTER the projectile is in? Since they are made originally as 8.6, they should be OK without neck turning...@45-90 Thanks for your feedback.

Acknowledge the performance of the 3 twist and your 6.5 twist are different. I have wondered for a while if there might be a way to 'translate' the data for the 3 twist to the 6.5 twist and vice versa. Sounds like that relationship is (initially) evolving as a 15% charge reduction going from 6.5 to 3. That's a start.

The brass . . . I'm using Vairog from Milford Munitions. I have not neck turned as of yet. The trim length is ok. They fit in a Sheridan gauge. I shoulder bump ~ .002" - .003". I haven't measured the water volume yet. I use Hornady dies and anneal all brass after each firing. I don't know, maybe I'll try some of the Gorilla brass I have on hand as another data point.

Going back and reviewing your data for H335 / 42 gr charge for the 160 gr projectile producing 2,325 fps is more of what I had in mind. Is it possible / probable the 3 twist is the root cause for most of the discrepancy? The 185 gr data is also disappointing.