PVA OWB, .219, 1:7tw, 26", 6grooveWhat barrel?? Length? .218 or .219 bore? Twist?

28.5gr Varget virgin brass during 1st firing with with 88 ELD I was at 2966....

29.1gr Varget with 90smk I'm at 2999

28" Mullerworks 4gr 1:7

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.22 br

- Thread starter Dai Bando

- Start date

219 bore drops pressure a LOT vs a 218. Put more powder in that case and you'll get the speed you desire.PVA OWB, .219, 1:7tw, 26", 6groove

What brand brass?Just finished putting 200 rounds through my barrel (speeding up and fire forming) so I ran a pressure test with Varget and 88gr ELDMs (shots 196-200).

Virgin Brass firing...

27.0 - 2,758

27.5 - 2,792

28.0 - 2,835

28.5 - 2,874

29.0 - 2,928

This is significantly slower than I would have thought after reading this thread.

PVA OWB, .219, 1:7tw, 26", 6groove

Gotcha I'm 2" longer and .218 bore

I run the same barrel on my 22bra. It shoots great 90 smk at 3040 with 30.0 of 4166. I’d say your barrel is running on about the same curve as mine considering the difference in the two cartridges.I wonder how high (grains) I should go or just run around 2,900.

28” Brux 22BRA

30.0gr Varget with 85.5 LRHTs gives me around 3050fps. Same charge with the 88s was averaging about 25-30fps slower.

30.5gr with the 85s was around 3105fps. No pressure but didn’t bother to go up any further.

Again not a 1:1 comparison, but close enough to say the 29-30gr charge weight range is a pretty safe bet.

30.0gr Varget with 85.5 LRHTs gives me around 3050fps. Same charge with the 88s was averaging about 25-30fps slower.

30.5gr with the 85s was around 3105fps. No pressure but didn’t bother to go up any further.

Again not a 1:1 comparison, but close enough to say the 29-30gr charge weight range is a pretty safe bet.

Anyone tested XBR 8208 in the 22 BR or GT?

My 223 Ackley is pushing the 88 ELD-M at 2800 FPS with 24.5 grs of 8208. Great practice load.

With 6mm bergers being so expensive and hard to find I’m considering building a 22BR or GT for local matches.

My 223 Ackley is pushing the 88 ELD-M at 2800 FPS with 24.5 grs of 8208. Great practice load.

With 6mm bergers being so expensive and hard to find I’m considering building a 22BR or GT for local matches.

You happen to know if yours is a .218 or .219 bore?28” Brux 22BRA

30.0gr Varget with 85.5 LRHTs gives me around 3050fps. Same charge with the 88s was averaging about 25-30fps slower.

30.5gr with the 85s was around 3105fps. No pressure but didn’t bother to go up any further.

Again not a 1:1 comparison, but close enough to say the 29-30gr charge weight range is a pretty safe bet.

What is everyone bumping? 1.0660" here; fireformed is 1.0680" (curious on chamber differences)

Those number are not exact...they are reference point numbers only so they won't be comparable from person to person....

While I don't have a BR and my case is less over-all capacity, seating the bullet out further gives me close to same as loaded capacity...... as I shoot same charge weights as guys on here with pretty much same velocities.I wonder how high (grains) I should go or just run around 2,900.

My new barrel I chambered in 22 GI is also a .219 bore like the previous barrel. And shoots in the high 1's and 2's with my old barrels 29 gr varget load but at 50- 60 fps less even though new barrel 3" longer.

I bumped charge up 6 tenths to get back on the 2990 node and is much more consistent

And shoots smaller.

As long as you don't see pressure I would pour the powder to it to get the 2990 node....

.218 boreYou happen to know if yours is a .218 or .219 bore?

Got out today to play with some 80's over H4895. IDK why I didnt test H4895 first, its my go to 6BR powder with super low SD's, higher velocity per charge weight than Varget and is super accurate.

Loaded up 28.0-30.5gr in 0.5gr increments with both Berger 80 VLD and newer pointed 80 SMK. The 80SMK shot awesome, just like they did in my 220TB with Varget. No pressure at 30.5gr primers looks great, bolt feels great so not sure how much higher I can go but over 3230 @ 30.5gr.... SD's were all 5 or less across all the charge weights. Really like this H4895 / 80 SMK combo...

The VLD didnt shoot so great but not terrible. Because I have 0.100" freebore, the 80 SMK were jumping 0.060" and that still only had half the neck engaging the bullet bearing surface. 80 VLD also had half the neck engaging the bullet bearing surface but that was 0.008" off the lands...

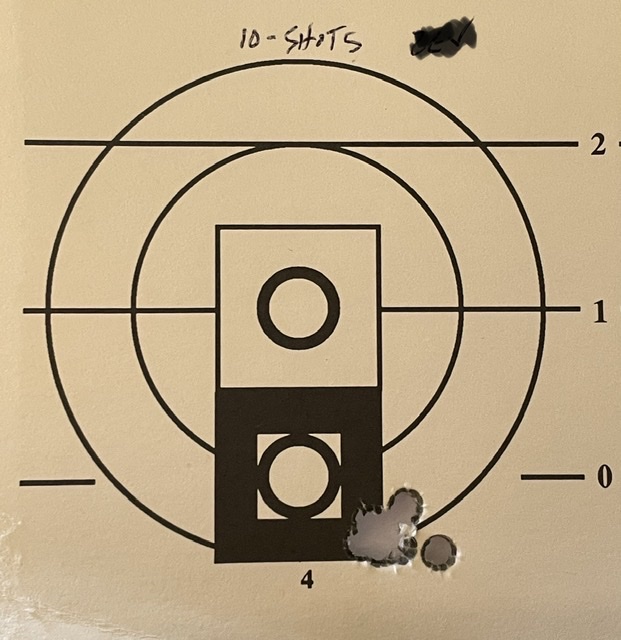

80 SMK - H4895 OCW @ 200yd

80 VLD - H4895 OCW @ 200yd

Loaded up 28.0-30.5gr in 0.5gr increments with both Berger 80 VLD and newer pointed 80 SMK. The 80SMK shot awesome, just like they did in my 220TB with Varget. No pressure at 30.5gr primers looks great, bolt feels great so not sure how much higher I can go but over 3230 @ 30.5gr.... SD's were all 5 or less across all the charge weights. Really like this H4895 / 80 SMK combo...

The VLD didnt shoot so great but not terrible. Because I have 0.100" freebore, the 80 SMK were jumping 0.060" and that still only had half the neck engaging the bullet bearing surface. 80 VLD also had half the neck engaging the bullet bearing surface but that was 0.008" off the lands...

80 SMK - H4895 OCW @ 200yd

80 VLD - H4895 OCW @ 200yd

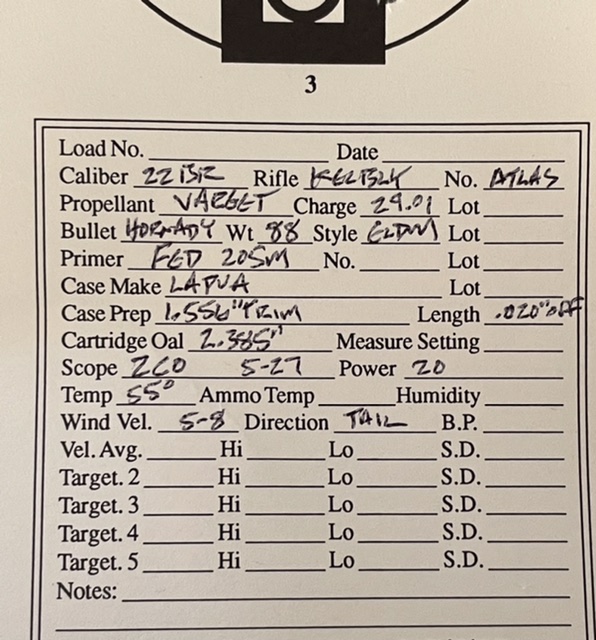

Okay, here is more data on my PVA OBW 22BR...

Lapua 6BR brass; 88gr ELDM

In the last update, I spoke about 29.0gr of Varget producinging 2,928fps (one shot in a pressure test; 29.0 being the highest). With 200 rounds on the barrel, I cleaned it as best as I could with no borescope.

First, 5 shots were 29.0gr Varget jumping 0.040" - avg. 2,885fps w/ SD of 24 and ES of 63 (could this be due to the barrel being clean? not really concerned)

(could this be due to the barrel being clean? not really concerned)

The next 5 shots were a pressure test from 29.2-30.0:

29.2- 2,918

29.4- 2,932

29.6- 2,950

29.8- 2,966

30.0- 2,990

Then I followed up with 5x shots with 29.2, 29.4, and 29.6 as I thought these would have put me around 2,950-3,000. I did not Magnetospeed these; that will be next. All 5x groupings were between .3-.5 moa. I will likely do a greater test here as I started to have bolt face smear at 30.0.

Lapua 6BR brass; 88gr ELDM

In the last update, I spoke about 29.0gr of Varget producinging 2,928fps (one shot in a pressure test; 29.0 being the highest). With 200 rounds on the barrel, I cleaned it as best as I could with no borescope.

First, 5 shots were 29.0gr Varget jumping 0.040" - avg. 2,885fps w/ SD of 24 and ES of 63

The next 5 shots were a pressure test from 29.2-30.0:

29.2- 2,918

29.4- 2,932

29.6- 2,950

29.8- 2,966

30.0- 2,990

Then I followed up with 5x shots with 29.2, 29.4, and 29.6 as I thought these would have put me around 2,950-3,000. I did not Magnetospeed these; that will be next. All 5x groupings were between .3-.5 moa. I will likely do a greater test here as I started to have bolt face smear at 30.0.

For sure the ES is from cleaning.

This is reason for fouling shots before any testing or shooting for consistency.

Some rifles will increase 80+ fps in first couple shots on a clean bore.

My chrono data over many years on clean barrels tells me the complete opposite..... 80fps swing because of a clean bore? High SD's?? Not in my experience.

The 7 twist on my rifle now with 29 gr Varget /88ELDM will be 2880-90's on first clean cold bore shot by 3 or 4th will be high 2930's low 2940's until I clean again....

Each barrel is different but the 1st shot on a completely clean barrel almost always is lower velocity maybe not 80 which is upper end I have seen....

Each barrel is different but the 1st shot on a completely clean barrel almost always is lower velocity maybe not 80 which is upper end I have seen....

I've seen swings like that from a good cleaning several times. Not unusual at all but doesn't happen with every barrel. Goes back to normal after a handful of rounds.My chrono data over many years on clean barrels tells me the complete opposite..... 80fps swing because of a clean bore? High SD's?? Not in my experience.

I went back to the reloading table and wanted to recheck my components, etc. I think I may have been crushing my primers 8 thou... which could be the driver of my low velocities. As I fired the last 225 rounds, the recoil impulse/firing pin to ignition felt weird.

Throwing this out there in case someone else is looking. I’m not sure who else would be shooting 8208 or 77gr projectiles in a 22BR, but I have a ton of these components on hand for 223 and figured I would try to use them for fireforming 22BRA in lieu of Varget, Hybrids, etc.

Barrel specs:

- 28” Brux 1:6.5 twist 22BRA

- Virgin Lapua 6BR brass, necked down with a .249 bushing (false shoulder method)

- 27.0gr 8208

- 77gr SMK seated to 1.858” base to ogive

~3000-3050fps (didn’t actually chrono but this is what the Kestrel told me)

This is a GREAT FF load. No pressure to speak of and super light recoil. It piled 10 rounds into a single hole while zeroing and was very consistent out to 700 yards.

Given the cost and availability of components, I figured there could be a lot more of this coming. Also need to disclose that it’s not a perfect 1:1 comparison given true BR vs. fireforming to BRA, but the data should be similar.

Barrel specs:

- 28” Brux 1:6.5 twist 22BRA

- Virgin Lapua 6BR brass, necked down with a .249 bushing (false shoulder method)

- 27.0gr 8208

- 77gr SMK seated to 1.858” base to ogive

~3000-3050fps (didn’t actually chrono but this is what the Kestrel told me)

This is a GREAT FF load. No pressure to speak of and super light recoil. It piled 10 rounds into a single hole while zeroing and was very consistent out to 700 yards.

Given the cost and availability of components, I figured there could be a lot more of this coming. Also need to disclose that it’s not a perfect 1:1 comparison given true BR vs. fireforming to BRA, but the data should be similar.

First, 5 shots were 29.0gr Varget jumping 0.040" - avg. 2,885fps w/ SD of 24 and ES of 63(could this be due to the barrel being clean? not really concerned)

Reshot this load and was 8 SD 20 ES.

Really great pricing on 90gr SMK

10off556 for 10% off

www.rmrbullets.com

www.rmrbullets.com

10off556 for 10% off

.224 90 Gr. Sierra Match King Hollow Point Boat Tail Bullets *NEW* | RMR Bullets

These beautiful, sleek SMKs are the bullets to use for reaching out there with your Valkyrie, 22 Nosler, .22 Grendel, .22 Creedmoor, etc. Brand new factory firsts! These will not be loadable in .223 Rem/ 5.56 at magazine length but if you want to single feed them they will work. BC info: .563 @ 2080

www.rmrbullets.com

www.rmrbullets.com

Got out to shoot the rest of the 80SMK rounds I had loaded up. 29.5gr H4895, 80SMK......3154

It was windy as hell as you can see in the below video clip. I was banging some steel but decided to shoot 2 groups on paper at 400yds. I was trying to time the luls to shoot these groups. Worked for the one group at 0.178moa..... but the second group not so much.

These little 80SMK really hammer, super accurate but definitely dont buck the wind like my 90smk load does...

It was windy as hell as you can see in the below video clip. I was banging some steel but decided to shoot 2 groups on paper at 400yds. I was trying to time the luls to shoot these groups. Worked for the one group at 0.178moa..... but the second group not so much.

These little 80SMK really hammer, super accurate but definitely dont buck the wind like my 90smk load does...

Here is my result with 22BR. OBW 1:7 barrel, .130” fb, .248” bushing, .220“ mandrel. 20 shot ES 25, SD 7.

Only problem, it was my shooting buddy who shot that 10-shot group. I need to up my game.

Only problem, it was my shooting buddy who shot that 10-shot group. I need to up my game.

FYI and for search keywords...

22BR w/ 88gr ELDMs

Zeus

Manners TCS

MDT BR Mag

I was initially having feeding issues; cases were rising on release and jamming into the top of the action. I was able to adjust the front of the mag lips ever so slightly and now have zero feeding issues.

22BR w/ 88gr ELDMs

Zeus

Manners TCS

MDT BR Mag

I was initially having feeding issues; cases were rising on release and jamming into the top of the action. I was able to adjust the front of the mag lips ever so slightly and now have zero feeding issues.

What have people seen with respect to collapsing shoulders when necking down 6BR brass? Got a new Forster FL die and ran a few pieces of new Lapua through, bulged/collapsed all three shoulders and saw significant belling of the case neck mouth too.

Sent the die off to get honed to 0.247” (talked to them on the phone, they said they’ll hone more than their order form says, they just don’t recommend it). Hoping that’ll fix it (I’m necking down something like 30 thou with the raw die, the honing should make that more like 20 thou), but just wondering if I’m gonna need a step-down die. Really don’t want one, since I’m not running a bushing die.

@Birddog6424 you said you neck down in one step, what OD are you going to when you do, and using what die setup?

Update on this for anyone in a similar situation: Got the Forster die back, and tried it out with a good dose of One Shot on a piece of 6BR Lapua range brass I picked outta the grass a couple weeks back. Didn't fully collapse the shoulder, but still bubbled it a bit. Googled sizing down 6BR, landed on the following site: www.6mmbr.com/22br.html

They mentioned chamfering the case mouth before sizing down, so I gave that a whirl. Worked like a charm, I'm about halfway through my 500-case batch and haven't lost a piece yet. So: 0.247" die neck, plenty of One Shot, and inside/outside chamfer is the ticket. The inside's only really for bullet seating and to try to minimize how much brass residue the nitride mandrel picks up, just the outer chamfer is needed for smooth neck-down.

Quick question for the pros

I'm thinking about eventually moving from 204R to 22BR for Yotes. Right now I have a HS DBM Gen 2 for 223. Max coal is approx 2.43in which is perfect for those 75 eld-m/SMK80.

Can I simply open the feedlips and be able to feed the 22BR ? Seems like I would work better than getting a 308SA magazine with a spacer/stop. AFAIK HS doesn't make a dedicated BR magazine. I'd rather not convert to a different BDM/wyatt box.

Here's a pic for reference.

Yes I know it's a retarded choice for a DBM, I was mislead into taking a Manners UC into that dbl inlet rather than M5.

I'm thinking about eventually moving from 204R to 22BR for Yotes. Right now I have a HS DBM Gen 2 for 223. Max coal is approx 2.43in which is perfect for those 75 eld-m/SMK80.

Can I simply open the feedlips and be able to feed the 22BR ? Seems like I would work better than getting a 308SA magazine with a spacer/stop. AFAIK HS doesn't make a dedicated BR magazine. I'd rather not convert to a different BDM/wyatt box.

Here's a pic for reference.

Yes I know it's a retarded choice for a DBM, I was mislead into taking a Manners UC into that dbl inlet rather than M5.

Attachments

Can't speak to how well the feed lips will work for you, but I can tell you that with 0.130 FB and the 88gr ELD-M jumping 0.050", my COAL is 2.305". You should be good to go from a COAL standpoint unless you go for the 95gr SMK or something, but I bet even that would be fine, sounds like you have like 0.125" to play with beyond my COAL.Quick question for the pros

I'm thinking about eventually moving from 204R to 22BR for Yotes. Right now I have a HS DBM Gen 2 for 223. Max coal is approx 2.43in which is perfect for those 75 eld-m/SMK80.

Can I simply open the feedlips and be able to feed the 22BR ? Seems like I would work better than getting a 308SA magazine with a spacer/stop. AFAIK HS doesn't make a dedicated BR magazine. I'd rather not convert to a different BDM/wyatt box.

Here's a pic for reference.

Yes I know it's a retarded choice for a DBM, I was mislead into taking a Manners UC into that dbl inlet rather than M5.

I think I could also weld a lip on the follower to bias the rounds up and with a bit of chamfer in the barrel, I think it could feed reliably. I also think the BRs do better with CRF than pushfeed and I still have a Nuke 1.1 with a 308BF so I might also do that rather than use my Defiance.Can't speak to how well the feed lips will work for you, but I can tell you that with 0.130 FB and the 88gr ELD-M jumping 0.050", my COAL is 2.305". You should be good to go from a COAL standpoint unless you go for the 95gr SMK or something, but I bet even that would be fine, sounds like you have like 0.125" to play with beyond my COAL.

Personnally im runing the 95gr and got a COAL of 2.355 when im barrely jammed in the land.

Thoses bullets are not usual as they need a good twist to stabilise them, Im runing a Gain twist benchmark 6.75 to 6.25.

Curious about you guys, what is your barrel life for PRS style of shooting ? Just something to dig around, about 1k they still Hammer no issue.

Thoses bullets are not usual as they need a good twist to stabilise them, Im runing a Gain twist benchmark 6.75 to 6.25.

Curious about you guys, what is your barrel life for PRS style of shooting ? Just something to dig around, about 1k they still Hammer no issue.

Personnally im runing the 95gr and got a COAL of 2.355 when im barrely jammed in the land.

Thoses bullets are not usual as they need a good twist to stabilise them, Im runing a Gain twist benchmark 6.75 to 6.25.

Curious about you guys, what is your barrel life for PRS style of shooting ? Just something to dig around, about 1k they still Hammer no issue.

Why are you jamming those?

You’ll get between 2500 and 3000 rounds. That’s what I’ve had in my last one with 85.5’s

If i get 2500 ill be happy.Why are you jamming those?

You’ll get between 2500 and 3000 rounds. That’s what I’ve had in my last one with 85.5’s

I jam because i get really good accuracy there.

Should not be an issue.If i get 2500 ill be happy.

I jam because i get really good accuracy there.

You haven’t found accuracy out in the 0.070" jump?

To be True I havent test much the OAL. Someone told me to jam it at 0.010, I did it, first group was 1/4moa on 5 shots, so I stopped there. From a day to an other I always get half moa or better so why chasing for better, the rifle have win every PRS matches yet with this.

But if you tell me I should try jumping that much I might give it a try sometime just to see.

But if you tell me I should try jumping that much I might give it a try sometime just to see.

Doing a seating depth test is always worth it. Most of the time there’s some nice spots from 0.050" down to 0.090".To be True I havent test much the OAL. Someone told me to jam it at 0.010, I did it, first group was 1/4moa on 5 shots, so I stopped there. From a day to an other I always get half moa or better so why chasing for better, the rifle have win every PRS matches yet with this.

But if you tell me I should try jumping that much I might give it a try sometime just to see.

Good luck with your next matches

I just finished processing some 22 BR cases, and was looking here for some 80 SMK loads. I was reading on the 22 BR forum on Accurate Shooter and see where the only load listed with the 80 SMK was 31.5 H 4350 with a listed speed of 3150.

I see where a member here is using 29.5 H 4895 with the 80 SMK and it's going 3150.

After seeing the H 4895 data, I'm thinking the 4350 is on the show side for a 22BR & 80 SMK's ?

My Bbl. has a 1-8 twist and I was able to collect a bucket full of the SMk's from an estate sale.. My range only goes out to 600 , I figure I'll stop there with the 22 BR 80 SMK/ 75 A Max.

I see where a member here is using 29.5 H 4895 with the 80 SMK and it's going 3150.

After seeing the H 4895 data, I'm thinking the 4350 is on the show side for a 22BR & 80 SMK's ?

My Bbl. has a 1-8 twist and I was able to collect a bucket full of the SMk's from an estate sale.. My range only goes out to 600 , I figure I'll stop there with the 22 BR 80 SMK/ 75 A Max.

Yes H4350 is slow for the 22br but useable. I use varget for heavies(85.5 and up) and I'm sure h4895 will work fine with 75/80s especially in shorter barrels.I just finished processing some 22 BR cases, and was looking here for some 80 SMK loads. I was reading on the 22 BR forum on Accurate Shooter and see where the only load listed with the 80 SMK was 31.5 H 4350 with a listed speed of 3150.

I see where a member here is using 29.5 H 4895 with the 80 SMK and it's going 3150.

After seeing the H 4895 data, I'm thinking the 4350 is on the show side for a 22BR & 80 SMK's ?

My Bbl. has a 1-8 twist and I was able to collect a bucket full of the SMk's from an estate sale.. My range only goes out to 600 , I figure I'll stop there with the 22 BR 80 SMK/ 75 A Max.

26" "bull" contour, Set this up for the grand daughters . Zero recoil and set it up as a single shot to teach them some long range skills

I'd try varget too if you can get some.26" "bull" contour, Set this up for the grand daughters . Zero recoil and set it up as a single shot to teach them some long range skills

Man idk how you guys are having such good luck with varget.

28-29 gr

88 eldm or Berger 85.5

2935-2975 fps

I get sticky bolt lift, expanded case webs (have to use small base die or they won’t chamber) and flat primers with some having extrusion around the firing pin.

I need to pin gauge the bore dia. to confirm its .219, but that’s all I can think of.

28-29 gr

88 eldm or Berger 85.5

2935-2975 fps

I get sticky bolt lift, expanded case webs (have to use small base die or they won’t chamber) and flat primers with some having extrusion around the firing pin.

I need to pin gauge the bore dia. to confirm its .219, but that’s all I can think of.

This is exactly what I was getting in a 20" barrel. And why I switched to a 22 Creed

Not what I wanted to hear. Maybe I’ll convert it to 22 dasher if I can’t find any 4166 (I get good speed and low pressure with it, but I only have 3#.)

Man idk how you guys are having such good luck with varget.

28-29 gr

88 eldm or Berger 85.5

2935-2975 fps

I get sticky bolt lift, expanded case webs (have to use small base die or they won’t chamber) and flat primers with some having extrusion around the firing pin.

I need to pin gauge the bore dia. to confirm its .219, but that’s all I can think of.

While I run a different caliber I get same performance as guys on here running 22 BR....

Many things or combinations of could be causing you pressure/velocity issue.

What brass you running... I know Peterson 6 BR is several grains less capacity vs Lapua.

How many rounds on your barrel?

I have .218 and .219 bore barrels chambered with same reamer..... .218 (25")takes 29 gr varget for 3000 fps.,219 (28") takes 29.6 gr of varget to reach 3000 fps.

The .218 bore took 180 rds to speed up to that velocity.... it shot great at 28.5 gr/2930's , 180 rnds in was 2960 , redeveloped load ....29.0 gr at 3000 consistent .2's

While I run a different caliber I get same performance as guys on here running 22 BR....

Many things or combinations of could be causing you pressure/velocity issue.

What brass you running... I know Peterson 6 BR is several grains less capacity vs Lapua.

How many rounds on your barrel?

I have .218 and .219 bore barrels chambered with same reamer..... .218 (25")takes 29 gr varget for 3000 fps.,219 (28") takes 29.6 gr of varget to reach 3000 fps.

The .218 bore took 180 rds to speed up to that velocity.... it shot great at 28.5 gr/2930's , 180 rnds in was 2960 , redeveloped load ....29.0 gr at 3000 consistent .2's

Lapua Brass

Cci 450s

500 rounds on the barrel

Bullets are .020 from lands

Barrel definitely sped up around 200 rounds

How much neck clearance , donut in brass, freebore of chamber?

.006 neck clearance

.100 fb

No donut (bullet is not seated bast neck shoulder junction).

I will check for carbon ring tonight, but it has done this since new.

Does it shoot good?

Checking the bore would be the next step I would take. If no carbon build up in throat and first few inches of barrel then inspection of bore for diameter is needed.

Sounds like size die is not sizing brass enough? If case cannot expand at all this will make pressure higher ... expanding case act like a shock absorber ...same as water on rnd or in chamber causes an over pressure condition on upper end loads.

Checking the bore would be the next step I would take. If no carbon build up in throat and first few inches of barrel then inspection of bore for diameter is needed.

Sounds like size die is not sizing brass enough? If case cannot expand at all this will make pressure higher ... expanding case act like a shock absorber ...same as water on rnd or in chamber causes an over pressure condition on upper end loads.

Does it shoot good?

Checking the bore would be the next step I would take. If no carbon build up in throat and first few inches of barrel then inspection of bore for diameter is needed.

Sounds like size die is not sizing brass enough? If case cannot expand at all this will make pressure higher ... expanding case act like a shock absorber ...same as water on rnd or in chamber causes an over pressure condition on upper end loads.

Hammers with 4166 at 2975 and RL 16 (slow, but I haven’t done much load dev).

The sizing die works fine for the 4166 and Rl16 cases.

The barrel shoots great with other powders no complaints, I just wanted to find a way to make varget work because I have a lot of it. After hearing the loads/velocity everyone is getting here, it’s making me scratch my head. Maybe I have a hot lot of Varget.

Similar threads

Reloading Equipment

WTS .. Seating dies BR,Dasher , Creed

- Replies

- 3

- Views

- 550