Hawkhills on pretty much everything anymore. Great quality and short lead times. I run 219 bore on all 22 cal, 237 bore on all 6mms.@406shootist

What brand barrel?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

22GT load data

- Thread starter Krob95

- Start date

That’s really discouraging news. The question is will you do it again or go back the 6GT?Barrel life update:

Started shedding jackets with 1250 rounds on it 2 weeks ago. Confirmed with both 90SMK and Berger 85.5 LRHT. She gone.

Bore scope showed significant carbon retention around the shoulder/neck junction and into the leade.

Ran some Iosso patches through it and it unsurprisingly revealed some of the worst carnage I’ve ever seen. There were essentially no lands left in the throat, jagged edges where the lands remained in tact, and had significant fire cracking present 6-8” beyond the chamber. When I say it was torched it was TORCHED.

Interestingly enough, it shot well right up to that point. But once it started going, it fell off a cliff.

Notes of interest:

- Brux 28” - 1:6.5 twist - .218 bore diameter

- steady diet of 3120-3150fps over the life of the barrel

- adjusted the load after cleaning to see if slower speeds would keep the jackets together with no such luck

I would say a variety of factors contributed to this barrel being pretty short-lived. Between the speeds/firing intervals, twist rate, bore size, etc. I’m somewhat surprised it lasted as long as it did. That said, I have no idea how guys are getting 2k plus out of these things shooting anywhere near normal speeds. I just don’t see it.

Haven’t decided if I’m going to replace it and keep going or sell off the components and go a different direction. I would change a number of factors if I were to do it over again.

Another falls victim to the .22GT. 88gr ELD-M at 3080fps. No exit wound but DRT. About 300 yards. Couldn’t get an exact range due to tall blowing wheat and terraces, but took best guess for multiple readings and used 1.0 mils for 330 yards.

John

John

Thank you for posting this. I can’t imagine the SMK bearing surface would cause significantly Higher psi. It’s odd my brass has all cratered primers at 34/35gr h4350 or Whatever im using. Stupid AI.It's a burn rate and pressure curve issue, not just fill. Fill is more of a guideline; you don't want to use a powder that leaves the case too empty as it might have inconsistent ignition, nor do you want a powder that's so compressed it results in inconsistent seating depths, and crunching the crap out of the powder with a heavily compressed load can break it down into smaller pieces which will alter the surface area of the kernels and can change the burn rate characteristics which can result in weird pressure spikes or increased SD/ES.

For instance, from the tables above 38.16gr of 4955 is 102% fill, yields 59.4ksi pressure and 3072 fps, and it isn't fully burned by the time the bullet leaves the barrel. Even if you altered the density of 4955 to make it more dense per grain (so you could physically pack more in the case) but maintained the same burn characteristics and overall energy content per grain of powder you still couldn't safely put more in the case to reach a higher velocity because it would be at max pressure; the burn characteristics of 4955 just aren't ideal for that case and bullet combo, it hits max pressure before achieving your targeted velocity.

On the other hand, if you use RL16 and adjust the charge to the same 59.4ksi target pressure it takes 35.76gr of RL16 which is 95.8% fill but QL comes back with 3158fps.

4955 is slower than RL16 based on Hodgdon's burn rate chart (RL16 is #129, while 4955 is #145.) Based on the QL data the 4955 burn characteristics aren't ideal for the 22GT even with 90s, so even with a near max pressure load of 4955 the estimated velocity is slower than the more ideal powders at the same or even lower pressures.

Oddly enough, at the same target pressure of 59.4ksi QL estimates the fastest powder for 90s in the 22GT would be RL26; using 41.6gr which is a 101% fill it's estimating 3250fps at the same 59.4ksi pressure as 4955 and RL16 above. What's kind of odd is RL26 is even slower on the burn rate chart than 4955 (RL26 is #157) but obviously the burn and pressure characteristics are different as the estimated velocity with RL26 is much higher. RL26 really seems to be the speed king in many loads that use heavy for caliber bullets, provided there's enough case capacity for it.

QL allows you to quickly "test" a bunch of powders in your case/bullet combo by specifying a target pressure and max fill percentage and it returns results sorted in order of velocity. I usually like to have it run that powder database test around 52.5ksi and 105% max fill. I haven't messed with Gordon's reloading tool but I'm guessing it would have a similar feature.

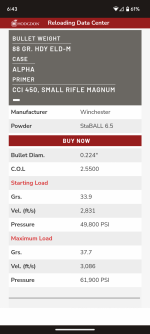

As mentioned earlier I don't have the dimensions for the 88 ELDM, but here's what QL shows for a 90 VLD @ 2.6" with H4350 in a 26" barrel which should be close...

View attachment 8114632

Thank you for posting this. I can’t imagine the SMK bearing surface would cause significantly Higher psi. It’s odd my brass has all cratered primers at 34/35gr h4350 or Whatever im using. Stupid AI.

Pretty sure we are running identical guns/loads and mine did the same thing - cratered primers, but no other real pressure signs.

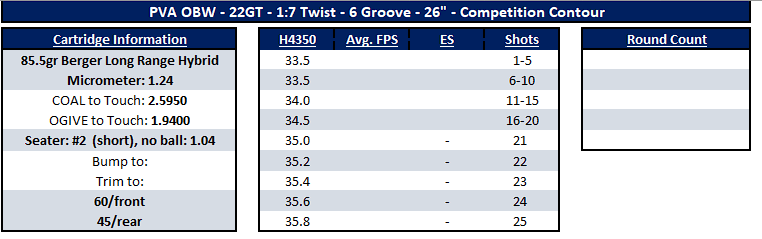

Barrel in hand so I decided it was time to load up the first 25 rounds. Waiting on my ACC Elite to arrive before I can go shoot.

Still cant figure out my pressure issue. I think a carbon ring is forming. 34g H4350 behind 88 eldm. running right at 2950 in my 24" barrel. I hit about 50-60 rounds and start getting significant pressure. Anyone else running into this after so few rounds? Thanks.

Still cant figure out my pressure issue. I think a carbon ring is forming. 34g H4350 behind 88 eldm. running right at 2950 in my 24" barrel. I hit about 50-60 rounds and start getting significant pressure. Anyone else running into this after so few rounds? Thanks.

I don't plan on going to extended round counts with this before cleaning. Carbon rings are a PITA to get out so I'm hoping to stay ahead of them. It should easily go 120+ from a clean barrel even with a fairly dirty powder. Did have something similar happen in my 6GT, didn't show pressure but speed started climbing & it was indeed a carbon ring building up.

Good scrubbing with a little iosso in the throat took care of it. I also switched to Bore tech eliminator and it has never reoccurred +5-600 rounds later.

Last time out with the 22GT I fired 80 rounds fire forming virgin Alpha brass. 37.5g 6.5 Staball & 88 eldm speed was 3040 from a 24" barrel on a Tika. The 6.5 Staball is the dirtiest powder I've tried.

I have limited experience with StaBall, but I think all the Alliant powders I've used 15.5, 16, 19 and 23 are just as dirty if not dirtier than Staball. I have learned that you do not go extended intervals of cleaning with them or you will be sorry.The 6.5 Staball is the dirtiest powder I've tried.

I am using a Giraud I just use the 6gt holder and it works just fine. I do the same with the 22 creedmoor and use 6 creedmoor holder.

@S3th , still running H4350 and 85.5s?

Yeah. I just competed in my first match with it. Rounds 60-120, and barrel sped up around 125fps on dope.

What load and speed are you at now?

I just shot my first few yesterday so I could get a feel for it and see what speeds I’m getting. I am at 35 grains of 4955 and 88s. Only 20 rounds so far and it’s about 2865 fps. I want to save my other powders until the barrel gets 150 rounds on it or so. Then I’ll likely use H4831SC.

I just shot my first few yesterday so I could get a feel for it and see what speeds I’m getting. I am at 35 grains of 4955 and 88s. Only 20 rounds so far and it’s about 2865 fps. I want to save my other powders until the barrel gets 150 rounds on it or so. Then I’ll likely use H4831SC.

What load and speed are you at now?

I just shot my first few yesterday so I could get a feel for it and see what speeds I’m getting. I am at 35 grains of 4955 and 88s. Only 20 rounds so far and it’s about 2865 fps. I want to save my other powders until the barrel gets 150 rounds on it or so. Then I’ll likely use H4831SC.

I am running 35.0 at 3,125 according to Kestrel. That’s a big jump up from the 2,959 in the initial testing. Now that the barrel is sped up, I’m going to do one more load development run.

The whole rifle is new so my opinion is not fully formed. I will say, coming from a 6.5CM going 2,745, I need more practice. Misses are harder to see and the bullet gets to the target noticeably faster. Overall, I am fan with no regrets. Ask me again after a few more matches and 500+ rounds. I'm sure the misses and time of flight will be less of an issue.How did you like it during the match? Are you running a brake, what kind and size?

I think that seeing hits on plates at closer distances for sure will be difficult at the speeds you are pushing. Even near 3000 fps isn’t that much slower. I know I can tell a difference in my 6GT loads of 2830 and 2940. I’m harder pressed to see which way a plate wiggles with the faster node if I can even tell. It’s something I just expect with the 22. Time will tell.

How far did you have to shoot and did you have issues knowing if you hit the plate? ROs have issues?

How far did you have to shoot and did you have issues knowing if you hit the plate? ROs have issues?

BTW, I am runnin a 6.5mm PVA Jet4 Brake.

Easily moves steel. The match I shot yesterday had overgrown grass so everyone had issues seeing splash.Any issues seeing hits at distance? ROs have problems seeing impacts?

I'm not sure what your definition of really deep in the case is. But here's the math.

From the base of the 22GT to the neck shoulder juncture is 1.43". To the end of the chamber is 1.73". So the neck of the chamber is .3" long. The transition is usually about .015, and using a standard .120" GT freebore that gives you .435" to seat the bullet and jump it.

The bearing surface is .361 on the 85.5gr Hybrid. So if you were to perfectly line up the bearing surface boat tail juncture of the bullet to the neck shoulder juncture of the case (which still isn't perfectly accurate as the case juncture has a bit of radius) you would be jumping approximately .075". I say approximately because the ogive will actually contact the lands a little sooner than that.

But even with a .120" freebore, you can still jump .060" with nothing but the .166" boattail section of the bullet in the case. And if you have to go a little deeper that doesn't mean anything. I've shot that bullet and the 88gr ELDM in a .050" freebore 22BR and 22 Dasher. They were lasers. There are reasons to seat the bullet out in to the neck and get it out of the case, but every load doesnt have to be that way. Seating the bullet out is optional. Most often not even necessary.

I'm currently using the standard .120 freebore on my 6GT and running long ass 115gr DTACs. They are seated a little in to the case, but that doesn't hurt anything. This is last Wednesday getting ready for the PRS Pro Series Lead Farm Barrel Burner. This is 20 rounds at 1000 yards testing bullet BC. I got a .310 G7 BC and 5" of vertical dispersion.

I know this post is almost a year old but I have a couple questions for you. Naked or coated DTACs, what powder, what jump?

Wow, those must have been pretty deep in the case. I have a new barrel and was thinking about using my DTACs but they are coated, but they take more powder to get the same speed. I might not be able to get enough powder in there with them that deep. Thanks for the info.

For those using virgin GAP brass and 88 ELDMs. I sized down the neck and then ran a carbide turning mandrel though the neck. I'm getting marks/indentations on the bullets when I seat them with my Forster micrometer die. I'm wondering if the necks are too hard from the additional sizing procedures and causing the issue or if these bullets are really soft in the nose where the seater touches? The bullets don't seem to seat any harder than other bullets.

Last edited:

When I sized down the GAP brass I got great e.s. and s.d. numbers, but couldn't get anything to group worth a dam. I too came to the conclusion that the necks had become too hard and that they should probably be annealed. Switching to Alpha brass solved my problems.For those using virgin GAP brass and 88 ELDMs. I sized down the neck and then ran a carbide turning mandrel though the neck. I'm getting marks/indentations on the bullets when I seat them with my Forster micrometer die. I'm wondering if the necks are too hard from the additional sizing procedures and causing the issue or if these bullets are really soft in the nose where the seater touches? The bullets don't seem to seat any harder than other bullets.View attachment 8154771

I will anneal once I get all my brass fired once. My numbers aren’t horrible, but groups are just okay. I honestly think that once I anneal the brass neck tension will be more consistent and groups will shrink.When I sized down the GAP brass I got great e.s. and s.d. numbers, but couldn't get anything to group worth a dam. I too came to the conclusion that the necks had become too hard and that they should probably be annealed. Switching to Alpha brass solved my problems.

I normally run Alpha brass, but since I have seen so many burn out 22GT barrels quickly I really didn’t want to spend the money on Alpha this time.

Been working with StaBALL 6.5 and 90 SMK. SD’s are in the mid-high 20’s with charges in the low-mid 37gn range. I upped the charge to 37.8-38gn and noticed a huge improvement in the numbers. 38gn averaged 3107 fps with an SD of 14. There were zero signs of pressure. I’m not going any higher but has anyone noticed an improvement on higher StaBALL 6.5 charges?

The 90 SMK were 20 thou off.

Edited to add that I shoot suppressed. As of this post my barrel has right under 300 rounds. The attached picture is cleaning after 81 rounds of suppressed. 5 wet patches and 5 dry. StaBALL 6.5 is dirty but a different kind of dirty. The carbon is soft and easy to clean.

The 90 SMK were 20 thou off.

Edited to add that I shoot suppressed. As of this post my barrel has right under 300 rounds. The attached picture is cleaning after 81 rounds of suppressed. 5 wet patches and 5 dry. StaBALL 6.5 is dirty but a different kind of dirty. The carbon is soft and easy to clean.

Attachments

I’ve read over and over again that StaBall needs to be on the upper end to give good ES/SD.

Started barrel break-in on Mon with 88 ELDM's seated 30 thou off, finding pressure limits with Staball6.5.

Started at 34gr and went up to 38gr in 1gr increments (5 @ each). Found a sticky bolt at 38 (didn't shoot all 5).

Cleaned after each batch of 5 and noticed the same as @021411 , it was dirty but cleaned easily.

None of the groups were under an inch (100yds) and I'd probably wager they all were over 1.5in. Didn't bother measuring since nothing was even promising.

Didn't bother chrono'ing since most people say not to worry about load development during barrel break-in. Does that sentiment extend to component elimination as well? Obviously I haven't tried different seating depths and I realize 1gr increments is a lot, but I'm tempted to scrap the 88 ELDM/Staball6.5 combo altogether.

I think I've seen too many of the alleged/amazing "First/Second/Third group from my new barrel!" pics that it was a bit disappointing.

"STFU and break in your barrel, it's too early to tell anything"? Or ditch the bullet/powder combo already?

Thanks guys

Bryan

Started at 34gr and went up to 38gr in 1gr increments (5 @ each). Found a sticky bolt at 38 (didn't shoot all 5).

Cleaned after each batch of 5 and noticed the same as @021411 , it was dirty but cleaned easily.

None of the groups were under an inch (100yds) and I'd probably wager they all were over 1.5in. Didn't bother measuring since nothing was even promising.

Didn't bother chrono'ing since most people say not to worry about load development during barrel break-in. Does that sentiment extend to component elimination as well? Obviously I haven't tried different seating depths and I realize 1gr increments is a lot, but I'm tempted to scrap the 88 ELDM/Staball6.5 combo altogether.

I think I've seen too many of the alleged/amazing "First/Second/Third group from my new barrel!" pics that it was a bit disappointing.

"STFU and break in your barrel, it's too early to tell anything"? Or ditch the bullet/powder combo already?

Thanks guys

Bryan

Seat them 88s around 20 or 55 off. I've found the 88s, 109s, 140s all like these jumps. Velocity nodes for the 22gt with the 90s is 3000-3030 & 3090-3120. Stabal doesn't really stabilize until you get the pressure up.Started barrel break-in on Mon with 88 ELDM's seated 30 thou off, finding pressure limits with Staball6.5.

Started at 34gr and went up to 38gr in 1gr increments (5 @ each). Found a sticky bolt at 38 (didn't shoot all 5).

Cleaned after each batch of 5 and noticed the same as @021411 , it was dirty but cleaned easily.

None of the groups were under an inch (100yds) and I'd probably wager they all were over 1.5in. Didn't bother measuring since nothing was even promising.

Didn't bother chrono'ing since most people say not to worry about load development during barrel break-in. Does that sentiment extend to component elimination as well? Obviously I haven't tried different seating depths and I realize 1gr increments is a lot, but I'm tempted to scrap the 88 ELDM/Staball6.5 combo altogether.

I think I've seen too many of the alleged/amazing "First/Second/Third group from my new barrel!" pics that it was a bit disappointing.

"STFU and break in your barrel, it's too early to tell anything"? Or ditch the bullet/powder combo already?

Thanks guys

Bryan

My fire form/barrel break in loads. Virgin Alpha brass .222 mandrel, 37.5 gr 6.5 Staball, 88 eldm -.023 jump 2.546/1.980, old Wolf SR magnum primers. 3040 was speed with very few rounds on the 24" barrel. For the hell of it I shot a 20 round group of these at 100 early march at around 40 degrees. It was hang firing, but still put all 20 into just over an inch.Started barrel break-in on Mon with 88 ELDM's seated 30 thou off, finding pressure limits with Staball6.5.

Started at 34gr and went up to 38gr in 1gr increments (5 @ each). Found a sticky bolt at 38 (didn't shoot all 5).

Cleaned after each batch of 5 and noticed the same as @021411 , it was dirty but cleaned easily.

None of the groups were under an inch (100yds) and I'd probably wager they all were over 1.5in. Didn't bother measuring since nothing was even promising.

Didn't bother chrono'ing since most people say not to worry about load development during barrel break-in. Does that sentiment extend to component elimination as well? Obviously I haven't tried different seating depths and I realize 1gr increments is a lot, but I'm tempted to scrap the 88 ELDM/Staball6.5 combo altogether.

I think I've seen too many of the alleged/amazing "First/Second/Third group from my new barrel!" pics that it was a bit disappointing.

"STFU and break in your barrel, it's too early to tell anything"? Or ditch the bullet/powder combo already?

Thanks guys

Bryan

Shot the last 20 of these last weekend in 80 degree temps and no hang fires. Didn't have magneto on it but it was 2.8 mil @600

Now that barrel should be sped up & I have 200 cases I'm going to see how it does with RL 15.5 & a few different primers.

Thanks guys, kinda sounds like they'll shoot from the get-go if they're going to at all. I'll try seating them further out and try some smaller increments between 36.5-37.5

If that doesn't work, on to my stash of H4350. Really hope the 88's work simply due to the lower cost. "Babe, a new caliber makes total sense, look how much less the bullets are!"

If that doesn't work, on to my stash of H4350. Really hope the 88's work simply due to the lower cost. "Babe, a new caliber makes total sense, look how much less the bullets are!"

With lower 37gn charge weights I would get occasional hang fires. Once I upped the charge the hang fires went away.

I hit the range this morning to confirm my findings from the previous session. My barrel likes 38gn of StaBALL 6.5 and the 90 SMK. I loaded some with a 10 thou jump and they were shooting really nice. The MV averaged 3103 with SD of 9. ES was 24.

I have a 1/7 22” Preferred Barrel Blanks barrel chambered by Fisher T&C with an Omega 30.

I hit the range this morning to confirm my findings from the previous session. My barrel likes 38gn of StaBALL 6.5 and the 90 SMK. I loaded some with a 10 thou jump and they were shooting really nice. The MV averaged 3103 with SD of 9. ES was 24.

I have a 1/7 22” Preferred Barrel Blanks barrel chambered by Fisher T&C with an Omega 30.

Last edited:

That's fast for a 22"! I may need to experiment with slower powders. My 36.0gr H4350 load at 3120 from a 26" barrel shows psi at times.With lower 37gn charge weights I would get occasional hang fires. Once I upped the charge the hang fires went away.

I hit the range this morning to confirm my findings from the previous session. My barrel likes 38gn of StaBALL 6.5 and the 90 SMK. I loaded some with a 10 thou jump and they were shooting really nice. The MV averaged 3103 with SD of 9. ES was 24.

I have a 1/7 22” Preferred Barrel Blanks barrel chambered by Fisher T&C with an Omega 30.

Now that barrel should be sped up & I have 200 cases I'm going to see how it does with RL 15.5 & a few different primers.

Only testing will tell, but I think it’s going to be too fast of powder. Have you ran it through GRT or Quick Load?

@browning442 is running 15.5 with great success in his 22" barrel, fast with 85.5 Bergers.Only testing will tell, but I think it’s going to be too fast of powder. Have you ran it through GRT or Quick Load?

Yes - running 85.5s around 3240-3250 in a 22” barrel, RL15.5. No pressure at 80 degrees today. Shilen 7.5 twist

I want to give it a try cause it out performed expectations in my 6.5 Creedmoore with 130's.Only testing will tell, but I think it’s going to be too fast of powder. Have you ran it through GRT or Quick Load?

For the 22 GT with 15.5, I'm not planning to test any projectiles over the 85.5 Bergers. For 77 - 85.5's it should be pretty good as per @browning442 results.

RL 15.5 is a little odd, in that it reaches peak pressure slowly & yet burns out fast. The model below with 77RDF's doesn't reach peak until almost 4" bullet travel.

Not sure if it'll be any better than H4350, RL 16, or N555 in the 22GT? Based on my experience with it so far in the Creedmoor it is the ideal powder for short barrels if you want complete burn along with good speed & medium weight class projectiles.

Since you are running lighter bullets that should help. Are these estimated or actual values from GRT?

That’s GRT’s estimate. I built the case and those 2 bullets in the model. Won’t know for sure till I shoot it and true the powder model.Since you are running lighter bullets that should help. Are these estimated or actual values from GRT?

For 6.5 C the GRT estimate was within 20fps using Their RL5.5 model.

I’ve only ever had one from scratch initial estimated close in GRT. After the first firing and I can input accurate case volume, powder temp, FPS and such, it’s damn close.

Most of the time my initial estimate about 70-100 fps faster than what I actually get. Once I have that and use the OBT function and it adjusts the powder parameters it’s off to the races.

Keep us informed, I’d love to know how it goes.

Most of the time my initial estimate about 70-100 fps faster than what I actually get. Once I have that and use the OBT function and it adjusts the powder parameters it’s off to the races.

Keep us informed, I’d love to know how it goes.

Finally got the StaBALL 6.5 out into the heat to see how stable it is.

The previous session was 82 degF and resulted an avg MV of 3103. Yesterday was 95 degF. The ammo was pretty warm even sitting in the shade. I saw an avg MV of 3134. The SD actually dropped a little to 7 from the previous 9. Still no pressure signs.

The previous session was 82 degF and resulted an avg MV of 3103. Yesterday was 95 degF. The ammo was pretty warm even sitting in the shade. I saw an avg MV of 3134. The SD actually dropped a little to 7 from the previous 9. Still no pressure signs.

Well what do you know. 90 SMK at 1.979” CBTO which is a 20 thou jump for me fits in the MDT Dasher/BR mag. The tip of the bullet is about 2 cunt hairs or so away from the binder plate. Going to give it a whirl and see how they work out tonight. With that said I have absolutely zero issues with the MDT Poly Metal mags. They work 100%.

Do you have the short 120fb or longer 170fb reamer?Well what do you know. 90 SMK at 1.979” CBTO which is a 20 thou jump for me fits in the MDT Dasher/BR mag. The tip of the bullet is about 2 cunt hairs or so away from the binder plate. Going to give it a whirl and see how they work out tonight. With that said I have absolutely zero issues with the MDT Poly Metal mags. They work 100%.View attachment 8173210

0.169Do you have the short 120fb or longer 170fb reamer?

For those using virgin GAP brass and 88 ELDMs. I sized down the neck and then ran a carbide turning mandrel though the neck. I'm getting marks/indentations on the bullets when I seat them with my Forster micrometer die. I'm wondering if the necks are too hard from the additional sizing procedures and causing the issue or if these bullets are really soft in the nose where the seater touches? The bullets don't seem to seat any harder than other bullets.View attachment 8154771

A quick update. After loading more rounds I noticed my seating pressure was in fact considerably higher seating these bullets and not consistent on the press handle. I annealed with the code of my sacrificial brass and still was deforming bullets and very inconsistent seating depths.

I went with my gut feeling that the necks were too hard and not annealed properly. After playing around with annealer settings I have come up with a good setting that allows me to seat bullets consistently, without bullet deformation and consistent handle pressure.

I chased my tail for a bit, but I believe I’m on the right track now.

Similar threads

- Replies

- 16

- Views

- 341

- Replies

- 1

- Views

- 290