I don’t anneal for the affects on group size per se. I anneal to extend the life of the brass. The fact that it’s in the exact same condition every time I reload it is a variable I now control.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Annealing Brass - Science vs Myths

- Thread starter stevenc23

- Start date

I wish people shot more.

Then academic discussions such as this would not be entirely academic. There would be a result-based portion of the discussion.

I'd like to shoot with the loudest voices in this thread at some point. I'd like an opportunity to see the results of their knowledge on target. Being this hostile with one another and jockeying for position in an imaginary hierarchy is not good for anyone.

Results. Results on target should be a more important part of this discussion than it ever is.

-----------

Follow on Instagram

Subscribe on YouTube

Then academic discussions such as this would not be entirely academic. There would be a result-based portion of the discussion.

I'd like to shoot with the loudest voices in this thread at some point. I'd like an opportunity to see the results of their knowledge on target. Being this hostile with one another and jockeying for position in an imaginary hierarchy is not good for anyone.

Results. Results on target should be a more important part of this discussion than it ever is.

-----------

Follow on Instagram

Subscribe on YouTube

No one said annealed is dead soft.According to who?

Are you referring to the fact that an AMP machine can do that? Or claiming that’s what they always do? Or what, and based on who’s data? Certainly not AMP’s.

If you pedantic geniuses are right, that annealing is only one thing, dead soft, and there is no in between, then there’s no reason to buy an AMP or any other annealer; just heat with a torch till it glows and call it done. That’d be fully annealed after all, and apparently your “ideal” condition.

Of course sooner or later you might figure out that there are situations where dead soft brass doesn’t work well. Something about semi autos, bullet setback, runout, that sort of thing.

You can prove that your fully annealed brass works well in some conditions. I wouldn’t even argue with that, and the idea that fully annealed is most consistent is right. No issues so far. But once you encounter conditions where that doesn’t hold a bullet adequately, it’s hard to claim that fully annealed is always best. It’s just not.

In fact, we did say exactly what it is, and that’s recrystallization.

According to who?

Are you referring to the fact that an AMP machine can do that? Or claiming that’s what they always do? Or what, and based on who’s data? Certainly not AMP’s.

If you pedantic geniuses are right, that annealing is only one thing, dead soft, and there is no in between, then there’s no reason to buy an AMP or any other annealer; just heat with a torch till it glows and call it done. That’d be fully annealed after all, and apparently your “ideal” condition.

Of course sooner or later you might figure out that there are situations where dead soft brass doesn’t work well. Something about semi autos, bullet setback, runout, that sort of thing.

You can prove that your fully annealed brass works well in some conditions. I wouldn’t even argue with that, and the idea that fully annealed is most consistent is right. No issues so far. But once you encounter conditions where that doesn’t hold a bullet adequately, it’s hard to claim that fully annealed is always best. It’s just not.

If it doesn’t hold a bullet properly, it’s not annealed.

It has started messing with the zinc content.

Again, this is all very, very simple. Annealing is a state in which there is recrystallization.

Before recrystallization, not much worth while happens. And if you heat long enough, you start melting things. That’s what’s happening when people say “over annealing.”

You just don’t understand what’s actually going on and making up your own idea.

Except that none of the data posted here or elsewhere supports your claims. Ignoring the reality of how most people use heat to PARTIALLY reduce the hardness of cartridge brass, but not dead soft, and refer to that as annealing, is just asinine. You’re either being so pedantic that it’s just stupid, or you’re flat out wrong. Which is it?

What’s happening here is you actually don’t understand what annealing is.

If it doesn’t hold a bullet properly, it’s not annealed.

It has started messing with the zinc content.

Again, this is all very, very simple. Annealing is a state in which there is recrystallization.

Before recrystallization, not much worth while happens. And if you heat long enough, you start melting things. That’s what’s happening when people say “over annealing.”

You just don’t understand what’s actually going on and making up your own idea.

What’s happening here is you actually don’t understand what annealing is.

No, what’s happening is your words don’t match reality. Whether they match what you’re thinking is the question; are you just complete crap at communicating or just full of crap? Or, as said earlier, so pedantic that it’s just stupidity? Do you even have a point, other than to argue about the definition of annealing?

No, what’s happening is your words don’t match reality. Whether they match what you’re thinking is the question; are you just complete crap at communicating or just full of crap? Or, as said earlier, so pedantic that it’s just stupidity? Do you even have a point, other than to argue about the definition of annealing?

Lol. Says the dude who thinks you can temper brass.

For anyone else reading this, I’ll briefly describe the process of heating brass and what happens.

When you apply heat to the brass you have three phases:

Recovery

Recrystallization

Grain growth

1: Recovery. As the brass is heating it enters a brief period where the brass can at *times* become slightly harder. Nothing incredibly substantial, but there have been instances of slight hardness increasing (and other than cold working and some ultrasonic methods is the only way brass hardness increases).

If you remove heat during the recovery process, you gain nothing at all and might as well not do it.

2: Recrystallization. You can Google this if you want a detailed explanation. But know this is the absolute *minimum* stage that needs to happen for annealing a brass case to actually do anything. As noted above, if you do *not* achieve recrystallization, you will *not* decrease hardness and may actually increase the hardness.

This is the really important stage.

3: Grain growth. Again, Google for more details. Once all the cold worked grains are consumed, recrystallization ends and grain growth begins. Then you get into recommended temps and times based on the copper and zinc content of the brass.

This is a very basic explanation, but for our purposes enough.

The key takeaways for anyone who wants to know more than “my brass shoots good”:

1: you *must* at a minimum get into recrystallization. If you do not, you have done nothing.

2: brass is either annealed or it’s not. If you do not enter recrystallization, it’s not annealed.

3: “under annealing” either doesn’t actually exist, or if you insist, means it never entered the recrystallization phase.

4: “over annealing” if we must use that term means

A: heat was allowed to travel into the case body and soften the body and head. This will render brass dangerous to use. If you suspect this happened, throw the brass away. It’s not worth it.

Or

B: the brass was heated enough to start melting zinc and/or copper. This is typically where you have issues with the neck being too soft. The brass still “looks” intact, but it started melting somewhere.

5: there is nothing else except these three stages. There is no tempering or “almost annealing” or getting it “kinda soft”. You either moved into recrystallization (and grain growth depending) or you didn’t.

If you use an AMP or another proven method, you likely don’t need to worry with any of this. But, if you want a better understanding, this is a start.

When you apply heat to the brass you have three phases:

Recovery

Recrystallization

Grain growth

1: Recovery. As the brass is heating it enters a brief period where the brass can at *times* become slightly harder. Nothing incredibly substantial, but there have been instances of slight hardness increasing (and other than cold working and some ultrasonic methods is the only way brass hardness increases).

If you remove heat during the recovery process, you gain nothing at all and might as well not do it.

2: Recrystallization. You can Google this if you want a detailed explanation. But know this is the absolute *minimum* stage that needs to happen for annealing a brass case to actually do anything. As noted above, if you do *not* achieve recrystallization, you will *not* decrease hardness and may actually increase the hardness.

This is the really important stage.

3: Grain growth. Again, Google for more details. Once all the cold worked grains are consumed, recrystallization ends and grain growth begins. Then you get into recommended temps and times based on the copper and zinc content of the brass.

This is a very basic explanation, but for our purposes enough.

The key takeaways for anyone who wants to know more than “my brass shoots good”:

1: you *must* at a minimum get into recrystallization. If you do not, you have done nothing.

2: brass is either annealed or it’s not. If you do not enter recrystallization, it’s not annealed.

3: “under annealing” either doesn’t actually exist, or if you insist, means it never entered the recrystallization phase.

4: “over annealing” if we must use that term means

A: heat was allowed to travel into the case body and soften the body and head. This will render brass dangerous to use. If you suspect this happened, throw the brass away. It’s not worth it.

Or

B: the brass was heated enough to start melting zinc and/or copper. This is typically where you have issues with the neck being too soft. The brass still “looks” intact, but it started melting somewhere.

5: there is nothing else except these three stages. There is no tempering or “almost annealing” or getting it “kinda soft”. You either moved into recrystallization (and grain growth depending) or you didn’t.

If you use an AMP or another proven method, you likely don’t need to worry with any of this. But, if you want a better understanding, this is a start.

Definition of annealing from the study.

Annealing -A heat treatment used to eliminate part or all of the effects of cold working.

"PART" being the key word.

Annealing -A heat treatment used to eliminate part or all of the effects of cold working.

"PART" being the key word.

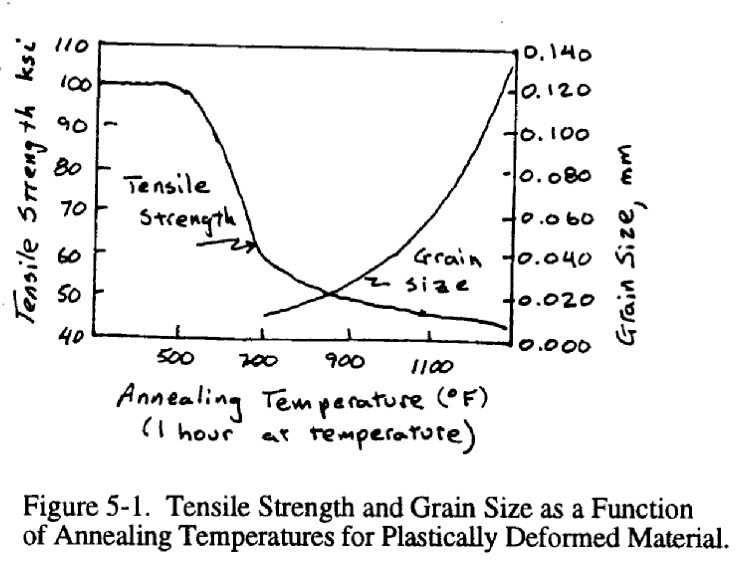

You can see from the chart, things start to change in the brass before recrystallization is reached. Then platuea somewhat after it starts.

You can see from the chart, things start to change in the brass before recrystallization is reached. Then platuea somewhat after it starts.

View attachment 7760074

See the screenshot from your link. The amount of change before recrystallization is not enough to matter and sometimes it gets slightly harder.

The rest I agree with. There is an entire range of hardness once recrystallization starts and all the way until melting.

Attachments

So like 90% annealed seems to be the goal?

Now that is beyond my knowledge.

I’ll chat up the AMP guys and see if it’s as simple as a %.

There it is. The number one trap of these academic discussions. People draw conclusions based on the numbers and theory.So like 90% annealed seems to be the goal?

You know the real goal of annealing? To extend the life of your brass, uniform the shoulders and necks, and to improve the results on your target.

That last part, is where the focus should be.

-----------

Follow on Instagram

Subscribe on YouTube

Last edited:

Also a good point.

The goal should be consistency. And then finding what works. And then back to consistently doing what works the exact same everytime.

Your goal could be brass life. It could be zero spring back. Etc etc.

Nothing will replace getting out there and *properly* testing.

But, I am always of them opinion that knowing the “why” and “how” behind it helps. But, that’s no substitute for doing it.

The goal should be consistency. And then finding what works. And then back to consistently doing what works the exact same everytime.

Your goal could be brass life. It could be zero spring back. Etc etc.

Nothing will replace getting out there and *properly* testing.

But, I am always of them opinion that knowing the “why” and “how” behind it helps. But, that’s no substitute for doing it.

I was actually being facetious in my oversimplification.There it is. The number one trap of these academic discussions. People draw conclusions based on the numbers and theory.

You know the real goal of annealing? To extend the life of your brass, uniform the shoulders and necks, and to improve the results on your target.

That last part, is where the focus should be.

-----------

Follow on Instagram

Subscribe on YouTube

Regardless one should aim for the right target for consistancy so yeah put a number on it. Amp aztec performs a test to find it. People use tempilaq and various other methods to find what process gets there.

That being said. What ever you call it, it would appear that there is indeed a goldilocks zone between not annealed and 100% annealed "dead soft". Not having the equipment to actually measure exact hardness we guess at that number.

I don't guess at anything.Not having the equipment to actually measure exact hardness we guess at that number.

I setup the annealer, shoot a test. Change the time on the annealer, shoot another test. ... and I continue doing this until I find the exact best performing setup. The target tells all.

However, I get that it's more fun for most shooters to just argue relentlessly in 500 post long threads because they can't shoot at their house. They have to drive to a range... so they don't get to test much of anything really. So disparaging one another when neither party has enough experience with testing the variable becomes the norm. Shout shout shout shout shout... with no one providing any targets or test results. lol

Y'all need Jesus. For real.

Keep in mind most are not as blessed as you.I don't guess at anything.

I setup the annealer, shoot a test. Change the time on the annealer, shoot another test. ... and I continue doing this until I find the exact best performing setup. The target tells all.

However, I get that it's more fun for most shooters to just argue relentlessly in 500 post long threads because they can't shoot at their house. They have to drive to a range... so they don't get to test much of anything really. So disparaging one another when neither party has enough experience with testing the variable becomes the norm. Shout shout shout shout shout... with no one providing any targets or test results. lol

Y'all need Jesus. For real.

What hardness have you arrived at as optimal?

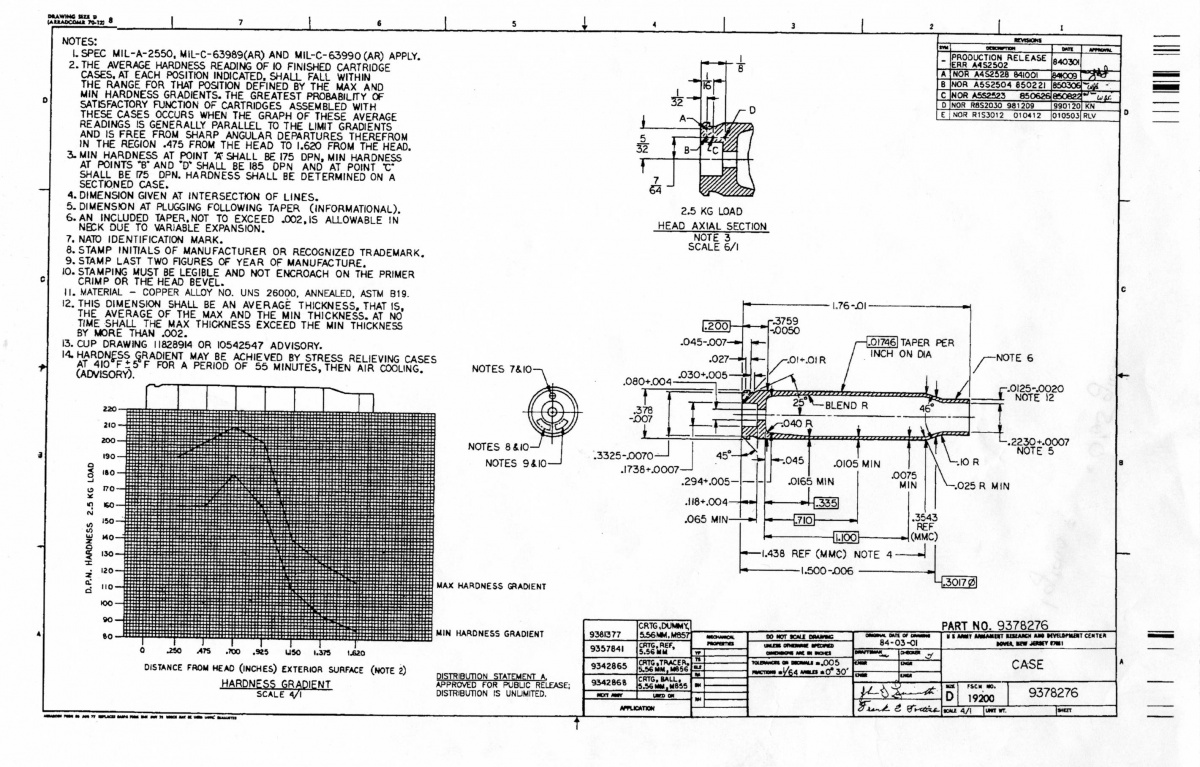

Here are general annealing numbers for mil-standard GI 5.56mm brass on the left and lower left (check the graphic showing hardness at distances from the case head). I'm sure there are drawings for all other .mil bottle-neck calibers -- I use this example because I seem to shoot more 5.56 than 7.62 and 338.

It seems (on GI cases) they are spec'ed to be soft from just below the shoulder and softest at mid-neck to the case mouth. Not saying Uncle is always right, but this shows what he's expecting. If you don't anneal you need to check how much resizing will work-harden your cases.

I anneal on a Ken Light:

It seems (on GI cases) they are spec'ed to be soft from just below the shoulder and softest at mid-neck to the case mouth. Not saying Uncle is always right, but this shows what he's expecting. If you don't anneal you need to check how much resizing will work-harden your cases.

I anneal on a Ken Light:

Last edited:

Sounds like "partially annealed." I.E "Recovery-A low-temperature annealing heat treatment designed to eliminate residual stresses introduced during deformation without reducing the strength of the cold worked material. Would help stop necks from cracking.Also in the definitions:

If you don’t get to recrystallization, you can’t reverse any of the cold working.

As you should be able to deduce from the temperature chart, from 500-700 degrees the tensile strength decreases rapidly before recrystallization begins.

I.E It looks like 675 would be a very bad temperature for recovery annealing if tensile strength reduction was a concern.

"The amount of change before recrystallization is not enough to matter and sometimes it gets slightly harder."

I am failing to find in the study where it says or represents this.

Last edited:

Perhaps this thread should be separated into 2 competing threads:

1- Based entirely on scientific studies and backed by labs with the requisite testing methods and confirmed results.

2- Based on purely experience based methods and proven with targets and ES reports.

We have two strongly entrenched camps and I see merit in both. In the meantime the tension in the thread is rising!

1- Based entirely on scientific studies and backed by labs with the requisite testing methods and confirmed results.

2- Based on purely experience based methods and proven with targets and ES reports.

We have two strongly entrenched camps and I see merit in both. In the meantime the tension in the thread is rising!

In the meantime the tension in the thread is rising!

Yes, this thread needs annealing…

Yes, this thread needs annealing…

Even a person that is an experienced reloader and metallurgist (camp 1) can examine an experienced reloader annealing (camp 2) and explain it in better detail than the reloader himself. The OP was close but he is not an experienced metallurgist with brass annealing for reloading. I think this guy can save us a lot of time if you have about 25 minutes to kill. It is not rocket science.Perhaps this thread should be separated into 2 competing threads:

1- Based entirely on scientific studies and backed by labs with the requisite testing methods and confirmed results.

2- Based on purely experience based methods and proven with targets and ES reports.

We have two strongly entrenched camps and I see merit in both. In the meantime the tension in the thread is rising!

Sounds like "partially annealed." I.E "Recovery-A low-temperature annealing heat treatment designed to eliminate residual stresses introduced during deformation without reducing the strength of the cold worked material. Would help stop necks from cracking.

As you should be able to deduce from the temperature chart, from 500-700 degrees the tensile strength decreases rapidly before recrystallization begins.

I.E It looks like 675 would be a very bad temperature for recovery annealing if tensile strength reduction was a concern.

"The amount of change before recrystallization is not enough to matter and sometimes it gets slightly harder."

I am failing to find in the study where it says or represents this.

So, in your link, which are you going with? The chart you’re interpreting (I haven’t taken much time to look at it yet), or the definitions and statements they make?

They specifically state recovery doesn’t have much effect on hardness.

Also, yes, the link you used doesn’t say it can harden slightly, but there are countless others who have this literature.

Sounds like "partially annealed." I.E "Recovery-A low-temperature annealing heat treatment designed to eliminate residual stresses introduced during deformation without reducing the strength of the cold worked material. Would help stop necks from cracking.

As you should be able to deduce from the temperature chart, from 500-700 degrees the tensile strength decreases rapidly before recrystallization begins.

I.E It looks like 675 would be a very bad temperature for recovery annealing if tensile strength reduction was a concern.

"The amount of change before recrystallization is not enough to matter and sometimes it gets slightly harder."

I am failing to find in the study where it says or represents this.

And to be fair, there is some literature out there that does seem to be at odds with one another on recovery.

This has some pretty good info as well:

Annealing of Metals: 3 Main Stages | Metallurgy

The three thermally active and overlapping stages during annealing are: 1. Recovery 2. Recrystallisation 3. Grain Growth. The first two stages of annealing are caused by the stored cold- worked energy. Grain growth, the third stage of annealing, occurs if annealing is continued after...

www.engineeringenotes.com

You should ask for your blessings and act on your faith to have any expectation of receiving the blessing. If more wanted to live out in the wide open and shoot out the window... they can.Keep in mind most are not as blessed as you.

What hardness have you arrived at as optimal?

I have no idea... I don't do hardness testing. I do target testing. A setting on the machine produces a result on the target. I adjust the machine until the target shows the best results. That's it.

Recovery-A low-temperature annealing heat treatment designed to eliminate residual stresses introduced during deformation without reducing the strength of the cold worked material

2. Rearrangement of dislocations, and in process some annihilation of them.

The relaxation processes, or the structural changes during recovery occur more, or less simultaneously throughout the deformed matrix. The first relaxation process starts at lower temperatures during annealing, which is followed by the second process at higher temperatures, but before the process of recrystallisation takes place.

At lower temperatures, the excess point defects, generated during the process of cold working, are annealed out, i.e., reduce their number to their equilibrium value in various ways. The most important point defect is a vacancy, which may have a finite mobility even at relatively low temperatures.

I am failing to see how this says there is only annealed and not annealed.

The chart is temp vs tensile strength. The chart would point to the reason you don't want the case heads getting too hot. You start to lose tensile strength quickly from 500-700 degrees.

2. Rearrangement of dislocations, and in process some annihilation of them.

The relaxation processes, or the structural changes during recovery occur more, or less simultaneously throughout the deformed matrix. The first relaxation process starts at lower temperatures during annealing, which is followed by the second process at higher temperatures, but before the process of recrystallisation takes place.

At lower temperatures, the excess point defects, generated during the process of cold working, are annealed out, i.e., reduce their number to their equilibrium value in various ways. The most important point defect is a vacancy, which may have a finite mobility even at relatively low temperatures.

I am failing to see how this says there is only annealed and not annealed.

The chart is temp vs tensile strength. The chart would point to the reason you don't want the case heads getting too hot. You start to lose tensile strength quickly from 500-700 degrees.

Its cause its too cold and dark up there in the arctic.You should ask for your blessings and act on your faith to have any expectation of receiving the blessing. If more wanted to live out in the wide open and shoot out the window... they can.

I have no idea... I don't do hardness testing. I do target testing. A setting on the machine produces a result on the target. I adjust the machine until the target shows the best results. That's it.

After reading all the discussion in this thread, I'm on the fence as to whether I "need" an AMP annealer or not. I'm currently using an Annealeeze flame annealer, but given all the seeming apparent complexities for a proper brass cartridge anneal I'm probably just going to get the AMP when they are back in stock and eliminate all doubt.

What is apparent to me from the last page or so is there is a target brass hardness at specific places on the cartridge. Whether this is a partial anneal or a full anneal is almost a moot point as AMP and the brass manufacturers specify a target hardness. The goal for reloaders seems to be to get a consistent neck tension and to prevent brass fatigue and cracking.

What is apparent to me from the last page or so is there is a target brass hardness at specific places on the cartridge. Whether this is a partial anneal or a full anneal is almost a moot point as AMP and the brass manufacturers specify a target hardness. The goal for reloaders seems to be to get a consistent neck tension and to prevent brass fatigue and cracking.

After reading all the discussion in this thread, I'm on the fence as to whether I "need" an AMP annealer or not. I'm currently using an Annealeeze flame annealer, but given all the seeming apparent complexities for a proper brass cartridge anneal I'm probably just going to get the AMP when they are back in stock and eliminate all doubt.

What is apparent to me from the last page or so is there is a target brass hardness at specific places on the cartridge. Whether this is a partial anneal or a full anneal is almost a moot point as AMP and the brass manufacturers specify a target hardness. The goal for reloaders seems to be to get a consistent neck tension and to prevent brass fatigue and cracking.

That’s pretty much in in nutshell.

If you watch the video above, you’ll see cases sitting in flame for 20sec and still have resistance when seating.

So, an “over anneal” is almost not possible unless you’re really trying.

I don't recall seeing any results on target.That’s pretty much in in nutshell.

If you watch the video above, you’ll see cases sitting in flame for 20sec and still have resistance when seating.

So, an “over anneal” is almost not possible unless you’re really trying.

There might be resistance enough to hold a bullet... but I'd bet dollars to pesos it won't shoot well.

For the purposes of accuracy and precision, you can certainly over-anneal.

Well I'm still somewhat a newb when it comes to reloading so I could very well be wrong, but a seating pressure of only 10 to 20 PSI would not give me a warm fuzzy especially if I'm shooting it in a semi-auto. It'd be interesting to run some of those "over" annealed rounds through a semi-auto and see if the bullets stayed put when chambering. I suppose if you hand fed every round in a bolt action it might work OK.That’s pretty much in in nutshell.

If you watch the video above, you’ll see cases sitting in flame for 20sec and still have resistance when seating.

So, an “over anneal” is almost not possible unless you’re really trying.

Last edited:

I’m going to make a slight distinction that I’m not sure anyone has made. Or maybe I missed it, I don’t knowI don't recall seeing any results on target.

There might be resistance enough to hold a bullet... but I'd bet dollars to pesos it won't shoot well.

For the purposes of accuracy and precision, you can certainly over-anneal.

If you were to change that one aspect of your entire process, newly fired case to loaded back into a chamber, you would probably see a different results. But you would not have optimized any other factors in the process to account for a different brass anneal(I know, everyone else. Spare me for now). Who knows, you could find something that makes your ammo better or your brass could end up lasting several more firings.

This next part isn’t directed at you, I’m just putting it out into the ether. It can also apply to lots of other scenarios in the firearms world

I find it very discouraging that even glancing in the direction of this sacred cow is met with screaming and insults. Just saying, “I’ve reloaded for a million years and this is or isn’t my process” doesn’t necessarily mean anything. I thought some new info would have been pondered for at least a few minutes

Sorry, I’ll take my little soap box and go home now

There is a third camp that choose not to anneal.I’m going to make a slight distinction that I’m not sure anyone has made. Or maybe I missed it, I don’t know

If you were to change that one aspect of your entire process, newly fired case to loaded back into a chamber, you would probably see a different results. But you would not have optimized any other factors in the process to account for a different brass anneal(I know, everyone else. Spare me for now). Who knows, you could find something that makes your ammo better or your brass could end up lasting several more firings.

This next part isn’t directed at you, I’m just putting it out into the ether. It can also apply to lots of other scenarios in the firearms world

I find it very discouraging that even glancing in the direction of this sacred cow is met with screaming and insults. Just saying, “I’ve reloaded for a million years and this is or isn’t my process” doesn’t necessarily mean anything. I thought some new info would have been pondered for at least a few minutes

Sorry, I’ll take my little soap box and go home now

They may benefit from the discussion tooThere is a third camp that choose not to anneal.

For them it is just more time suck.They may benefit from the discussion too

Is this where the discussion should turn into an argument and we call each other fucking retards?For them it is just more time suck.

But seriously, I totally understand that.

I don't recall seeing any results on target.

There might be resistance enough to hold a bullet... but I'd bet dollars to pesos it won't shoot well.

For the purposes of accuracy and precision, you can certainly over-anneal.

I've experienced exactly this first hand.

Used a 6 Dasher amp pilot to anneal 6BRA brass. The target did not show great results...

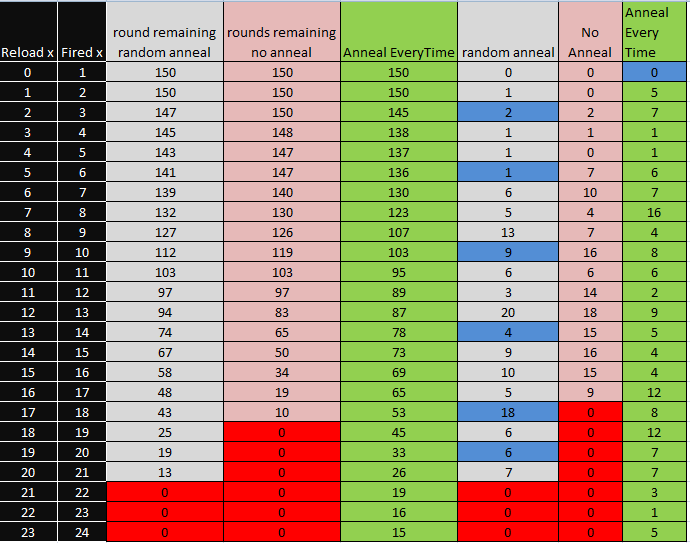

A fella on arfcom with the handle "Scorpius" did a brass longevity test using once-fired 5.56 range pick-up brass. He segregated into 150-case groups random annealed; not annealed; and annealed after every firing.

Here's his data graphically represented, starting with 150 cases in each of the three groups. The three columns on the right show how many cases he lost after each batch firing:

Here's his data graphically represented, starting with 150 cases in each of the three groups. The three columns on the right show how many cases he lost after each batch firing:

I don't recall seeing any results on target.

There might be resistance enough to hold a bullet... but I'd bet dollars to pesos it won't shoot well.

For the purposes of accuracy and precision, you can certainly over-anneal.

This is also a good point. I should have clarified.

There are many claims about annealing brass so soft it won’t hold a bullet. That is in fact pretty hard to do.

As far as on target….that’s a mixed bag. All things being equal (you didn’t change anything else except cook the brass for 20sec) it’s not going to shoot well.

However, if you then rework some other things (since neck tension is a sum of many things), you can at times bring things back in.

As you pointed out earlier, if you don’t anneal your next loading isn’t the same. The same would apply to “over annealing.” Once you change consistency of the softness of the brass, many times your entire neck tension needs to be reworked.

And as you made the good point, you need to get back on paper.

As with most things, all my testing points to “it depends” as there is almost never a 100% answer (within reason).

But I definitely agree. If shooter A has his process down to very consistent and good ammo…..but changes something like cooking your brass for 20sec, it’s almost never going shoot well comparatively.

My testing has show that as long as you don’t soften the case head, and the neck will hold a bullet, I can always bring the load back in “tune” via a rework.

What do you mean here when you say you can bring the load back in tune via a rework? Are you talking about work hardening the necks or re-developing a load?My testing has show that as long as you don’t soften the case head, and the neck will hold a bullet, I can always bring the load back in “tune” via a rework.

What do you mean here when you say you can bring the load back in tune via a rework? Are you talking about work hardening the necks or re-developing a load?

Change up your neck prep.

Since “neck tension” is a sum of many things, when you change one thing, you may have to change others to accommodate the original change.

Couple examples:

You decide to lube your necks when you hadn’t been before. With the decrease in friction, you may need to increase the interference fit.

You decide to anneal more than you have been. Maybe you need to increase interference fit or increase friction via no lube or a different lube.

Neck tension is a sliding scale. Sometimes you get lucky and it works the same after a change. Other times you have to slide the scale on something else.

The entire discussion about the case neck interior surface finish, neck thickness, and other prep... hinges on uniformity and correct dimensions.

The uniformity being key.

The simple version of what @Hoplite Arms Ammunition is saying:

So you can change the dimension or other variable, but if uniformity exists... then bullet seating depth, charge weight, or primer seating depth can be altered to come back into your node even though a variable was altered.

-----------

Follow on Instagram

Subscribe on YouTube

The uniformity being key.

The simple version of what @Hoplite Arms Ammunition is saying:

So you can change the dimension or other variable, but if uniformity exists... then bullet seating depth, charge weight, or primer seating depth can be altered to come back into your node even though a variable was altered.

-----------

Follow on Instagram

Subscribe on YouTube

Last edited:

A bench source with a swirl flame torch is the cheapest way to do it right.Orkan

I may have ,no I did, miss which set up so please forgive me. But which annealer set up would you recommend someone getting into that doesn’t have endless funds but wants to do it right?

An AMP is the easiest and best choice for a rookie, by far.

Similar threads

- Replies

- 9

- Views

- 740

- Replies

- 32

- Views

- 3K