Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Any thoughts on structured barrels?

- Thread starter TriggerJerk!

- Start date

When you make some bold claims like Baker does, the burden is on the claimant to prove it. I already offered to do testing (if he supplies barrels and ammo) and we can see if his claims are bullshit or not.

Also why is int he a commercial supporter? Hell RIO/Fenix/Dave is and he makes shit in his shed. If he can afford it a guy peddling $1500 barrels sure as hell can.

For like the 8th time, that's not the only location we have. Also, you're probably the last guy that needs to be bringing up any rules or forum decor.

Not to mention, he hasn't attempted to sell anything.

The concept, like gain twist barrels has merit, they question becomes are you doing it right.

In my honest opinion, I think the best potential comes from a combination of both. A gain twist threading with a disruptive contour to break the harmonic wave.

If you gave me a choice, I want a Bartlein left hand gain twist with Chad Dixon at LRI doing the contour where it goes from large blocks to smaller hexes to grooves.

I think that barrels changes the game for the masses

In my honest opinion, I think the best potential comes from a combination of both. A gain twist threading with a disruptive contour to break the harmonic wave.

If you gave me a choice, I want a Bartlein left hand gain twist with Chad Dixon at LRI doing the contour where it goes from large blocks to smaller hexes to grooves.

I think that barrels changes the game for the masses

Absolutely agree with you. I will add that first types of fuel injection, be in mechanical or electric., it took time to mature. ABS was a dark art for years, now many motorbikes have, when early on i remember people saying it was impossible. Works well now.Regardless if said source is in fact moron.....it's a fair question. Structured barrels aren't all that new now. So, it's fair to assume if the advantage was large enough, people would be using them more at the top echelon of competition.

Not in any way saying they don't work. Just saying it's a valid question. And there could easily be valid reasons why they aren't being used more despite giving an advantage.

Structured barrels are not new, im aware of this. The benefits, if any, are still debated, much like tuners. However my current understanding of the whole thing is "yes there is a benefit, more research needs to be done". Yes benefit, so if people want to adapt to the technology, who am I to stop them or even complain ? Let people make their own decisions.

In time, with enough use, they may become main stream, who knows.

Absolutely agree with you. I will add that first types of fuel injection, be in mechanical or electric., it took time to mature. ABS was a dark art for years, now many motorbikes have, when early on i remember people saying it was impossible. Works well now.

Structured barrels are not new, im aware of this. The benefits, if any, are still debated, much like tuners. However my current understanding of the whole thing is "yes there is a benefit, more research needs to be done". Yes benefit, so if people want to adapt to the technology, who am I to stop them or even complain ? Let people make their own decisions.

In time, with enough use, they may become main stream, who knows.

Quite a bit different when comparing something that manufacturers have to incorporate before it gets to consumers and things a consumer can buy direct. Things that are noticeably better *and* readily available for consumers catch on much, much faster than something requires a manufacturer to buy into the technology and then utilize it before a consumer can buy it.

If we were talking about why a company like Ruger or Savage haven't started using the, I'd agree. But we are talking about a product that most every consumer in competitive rifle shooting has been aware of and the needle hasn't really moved yet.

LRI fluting is pretty cool, I have a hunting rifle with pattern X and a different rifle with the murder hornet on the way.The concept, like gain twist barrels has merit, they question becomes are you doing it right.

In my honest opinion, I think the best potential comes from a combination of both. A gain twist threading with a disruptive contour to break the harmonic wave.

If you gave me a choice, I want a Bartlein left hand gain twist with Chad Dixon at LRI doing the contour where it goes from large blocks to smaller hexes to grooves.

I think that barrels changes the game for the masses

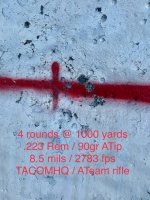

I have no real data to provide. This was the first 10 rounds out of a 6.5cm we chambered on a TacomHQ structured barrel. The customer supplied the structured barrel for the build. Can't say they do or don't do anything claimed. First two shots were the outliers. Then the next 8 in the group.

Hornady 140gr ELDM Factory ammo

Hornady 140gr ELDM Factory ammo

This response is to no one person. I will be to-the-point as I have waited for the appropriate time to outline the following, and given Rio Precision's post, this is as good as any.

First, a lot of people are citing facts, which is interesting in the field of science as the universe is only 14 billion years old, right?

Therefore, in spirit of setting the facts straight, I will start by saying our goal for Structured Barrels has been severely misinterpreted as we are not looking to improve a one-hole gun. How can we? Current methodologies yield great precision in way of 5-10 round counts. However, this is not our performance target. We are chasing the 15, 20, 25, 30+ round metric as groups open and become more unpredictable in there dispersion, which requires us to start asking new questions to the why and evaluating new variables.

I will ask, why do groups open up firing long strings? If your answer is heat, I will follow this up with how can an added 3-500% more surface area not improve stability?

Do you think the bore of any straight barrel is straight? Given the level of detail some persist to exercise, no.

Do you think the tapered bore or torque exerted on the barrel in the form of droop does not try to correct itself accelerating a bullet with 50,000 PSI?

Do you think there is zero energy loss within the surrounding system?

We appreciate ideas and methods throughout all engineering disciplines as there are often many analogous relationships applicable to other fields. It is for this reason we find it amusing so many gunsmiths challenge the concepts or examples proposed thus far as "bullshit science", and yet it is these very concepts, equations, programs, and simulations that drive modern structural engineering. For example, any gunsmith should appreciate the increased prevalence, advantage, and thereby the associated cost to asymmetric end mils to reduce vibration in the tool, dampening friction and thereby heat, and yielding a superior finish at higher feeds and speeds. Despite people ostracizing past examples, physics does not turn on at one moment, but off at another. This is the reason solutions found in one discipline often bear relevance to other disciplines.

The concepts proposed within our Structured Barrel How It Works was peer reviewed by several aeronautical engineers where we review axial stiffness, bending stiffness, natural frequencies, harmonics, temperature, moments of inertia ie second moment of area, etc. supplemented by a host of simulations and animations, some produced by Al Harral, whom performed engineering and structural analyses on complex systems at Lawrence Livermore National Laboratory, a top-level government R&D facility. To say this is all "bullshit science" is illogical and exhibits real bias - for virtually all facets of physics (except quantum) is interconnected, boasting equations that allow the end-user to navigate from one physics area to another.

Thus, vibration, temperature, friction, and energy are all related; you cannot affect one without affecting the other. The fact we do not understand groups past 15 rounds (our published work aims to give reason) is indicative there is more we do not yet understand, and I do not know why anyone would be so venomous in pursuing this answer. The world is filled with examples where the smallest things can have the greatest consequence at the macroscopic scale.

If you do not fully understand these concepts, we are not going to insult you by saying you are trying to sound smarter than you really are. The criticisms outlined in this forum have provided a good roadmap to ideas and things we can show, and for that - thank you. It is convenient to say "If it was so good why aren't more people using them?" because if enough people say the same thing, you have your current result. There is a human psychological element in this that is not being considered, as how many people want to spend "big" money and to be the first when they see no else using it? Sometimes, we get the impression people here think we are hiding behind not providing results. On the contrary, we are more than willing and look for challenges. We privately messaged DeathBeforeDismount looking to arrange a date and time after he noted receiving new camera equipment, but it was never acted on. Coastal Precision was scrutinized / discredited as being biased, and yet he was a major skeptic in the beginning. Under this condition, several people here exhibit a clear bias, so should their results be discredited if you evaluate them? Truthfully, I think we could post almost anything, and it will be picked a part by people whom never shot it. Look hard enough, you will always find something.

Cost is an interesting argument as the cost for a standard blank averages say $600, which includes material, one bore, and rifling. For a fully Structured Barrel, you get eight holes and a multitude of other machine work for $1,050. From our perspective, this is not too bad of a deal considering every barrel is customized for peak performance per customer parameters. When we are able to produce at higher volume and set standards, obviously cost will go down. Nevertheless, when buying a sports car, do you say, "Oh my God it is 4x of a sedan. Too expensive."? No. Cost and performance is never linear.

I will end by asking these simple questions. If harmonics did not matter:

1. Why do we all not shoot pencil barrels? Why is it largely accepted thicker barrels are higher performing than thin barrels? What is it about a thick barrel that is superior to that of a narrow profile? Since a Structured Barrel boasts the structural benefit of a thick barrel, but at a weight comparable to a standard barrel, are there any gains to be had?

2. Why do we free float barrels? Do you? Why? Why do we need +0.050" minimum clearance in a stock/chassis if the bullet has already left the muzzle? Why does vibration matter in a stock / chassis, but not a barrel? If your answer is recoil, how does a harmonically quieter barrel not help is this regard? If a Structured Barrel is more consistent staying on target during recoil, is there an advantage for pulling a follow up shot (let alone multiple people noting that can spot there own rounds).

3. If vibration moves exuberantly faster than a bullet, how much movement do you think can act on the system to induce error? If we know we need at least 0.050" in a stock/chassis, and 0.001" across 6" will yield a 0.6MOA difference at 100-yds, do you think we can find 50 millionths, or 1/100th of the 0.050" (correlates to 0.3MOA at 100-yds)?

Well funny you should ask, because we think we have a way to measure this movement spanning 0.002s. We have started more detailed planning.

4. Why do groups open firing 15, 20, 25, 30+ rounds?

To Drew, assuming you have read this, I want to say I have been impressed at your thorough consumption of the information we have posted, even if you are still a major critic, which is fine. It simply means we have more work to do. We wanted the information published about our barrels to be uniquely 3rd party. If anyone was to review our social media history, you will see we rarely posted about our own barrels for this reason up until recently.

Only a few months ago, scientists were convinced the universe was only 14 billion years old for decades. Drafting models of the early universe on this one assertion, and yet, Webb has effectively eviscerated this argument in mere months. Webb is a tool that provided the means to measure and study the universe in a way we never before could. Measuring barrel movement is analogous to this example. All FEA simulations point to one, undeniable fact - barrels move before the bullet exits the muzzle. To deny these analyses, denies their application and implementation in modern engineering. The small deviation, time, pressure, multi-axis, forces, etc. to date have been prohibiting to this study - and no, high speed camera cannot discern 50 millionths as this is lost within the pixels. We plan to show it. If it is there, us believing it is, this explains why groups open up erratically.

Thanks for reading

Jacob Baker

First, a lot of people are citing facts, which is interesting in the field of science as the universe is only 14 billion years old, right?

Therefore, in spirit of setting the facts straight, I will start by saying our goal for Structured Barrels has been severely misinterpreted as we are not looking to improve a one-hole gun. How can we? Current methodologies yield great precision in way of 5-10 round counts. However, this is not our performance target. We are chasing the 15, 20, 25, 30+ round metric as groups open and become more unpredictable in there dispersion, which requires us to start asking new questions to the why and evaluating new variables.

I will ask, why do groups open up firing long strings? If your answer is heat, I will follow this up with how can an added 3-500% more surface area not improve stability?

Do you think the bore of any straight barrel is straight? Given the level of detail some persist to exercise, no.

Do you think the tapered bore or torque exerted on the barrel in the form of droop does not try to correct itself accelerating a bullet with 50,000 PSI?

Do you think there is zero energy loss within the surrounding system?

We appreciate ideas and methods throughout all engineering disciplines as there are often many analogous relationships applicable to other fields. It is for this reason we find it amusing so many gunsmiths challenge the concepts or examples proposed thus far as "bullshit science", and yet it is these very concepts, equations, programs, and simulations that drive modern structural engineering. For example, any gunsmith should appreciate the increased prevalence, advantage, and thereby the associated cost to asymmetric end mils to reduce vibration in the tool, dampening friction and thereby heat, and yielding a superior finish at higher feeds and speeds. Despite people ostracizing past examples, physics does not turn on at one moment, but off at another. This is the reason solutions found in one discipline often bear relevance to other disciplines.

The concepts proposed within our Structured Barrel How It Works was peer reviewed by several aeronautical engineers where we review axial stiffness, bending stiffness, natural frequencies, harmonics, temperature, moments of inertia ie second moment of area, etc. supplemented by a host of simulations and animations, some produced by Al Harral, whom performed engineering and structural analyses on complex systems at Lawrence Livermore National Laboratory, a top-level government R&D facility. To say this is all "bullshit science" is illogical and exhibits real bias - for virtually all facets of physics (except quantum) is interconnected, boasting equations that allow the end-user to navigate from one physics area to another.

Thus, vibration, temperature, friction, and energy are all related; you cannot affect one without affecting the other. The fact we do not understand groups past 15 rounds (our published work aims to give reason) is indicative there is more we do not yet understand, and I do not know why anyone would be so venomous in pursuing this answer. The world is filled with examples where the smallest things can have the greatest consequence at the macroscopic scale.

If you do not fully understand these concepts, we are not going to insult you by saying you are trying to sound smarter than you really are. The criticisms outlined in this forum have provided a good roadmap to ideas and things we can show, and for that - thank you. It is convenient to say "If it was so good why aren't more people using them?" because if enough people say the same thing, you have your current result. There is a human psychological element in this that is not being considered, as how many people want to spend "big" money and to be the first when they see no else using it? Sometimes, we get the impression people here think we are hiding behind not providing results. On the contrary, we are more than willing and look for challenges. We privately messaged DeathBeforeDismount looking to arrange a date and time after he noted receiving new camera equipment, but it was never acted on. Coastal Precision was scrutinized / discredited as being biased, and yet he was a major skeptic in the beginning. Under this condition, several people here exhibit a clear bias, so should their results be discredited if you evaluate them? Truthfully, I think we could post almost anything, and it will be picked a part by people whom never shot it. Look hard enough, you will always find something.

Cost is an interesting argument as the cost for a standard blank averages say $600, which includes material, one bore, and rifling. For a fully Structured Barrel, you get eight holes and a multitude of other machine work for $1,050. From our perspective, this is not too bad of a deal considering every barrel is customized for peak performance per customer parameters. When we are able to produce at higher volume and set standards, obviously cost will go down. Nevertheless, when buying a sports car, do you say, "Oh my God it is 4x of a sedan. Too expensive."? No. Cost and performance is never linear.

I will end by asking these simple questions. If harmonics did not matter:

1. Why do we all not shoot pencil barrels? Why is it largely accepted thicker barrels are higher performing than thin barrels? What is it about a thick barrel that is superior to that of a narrow profile? Since a Structured Barrel boasts the structural benefit of a thick barrel, but at a weight comparable to a standard barrel, are there any gains to be had?

2. Why do we free float barrels? Do you? Why? Why do we need +0.050" minimum clearance in a stock/chassis if the bullet has already left the muzzle? Why does vibration matter in a stock / chassis, but not a barrel? If your answer is recoil, how does a harmonically quieter barrel not help is this regard? If a Structured Barrel is more consistent staying on target during recoil, is there an advantage for pulling a follow up shot (let alone multiple people noting that can spot there own rounds).

3. If vibration moves exuberantly faster than a bullet, how much movement do you think can act on the system to induce error? If we know we need at least 0.050" in a stock/chassis, and 0.001" across 6" will yield a 0.6MOA difference at 100-yds, do you think we can find 50 millionths, or 1/100th of the 0.050" (correlates to 0.3MOA at 100-yds)?

Well funny you should ask, because we think we have a way to measure this movement spanning 0.002s. We have started more detailed planning.

4. Why do groups open firing 15, 20, 25, 30+ rounds?

To Drew, assuming you have read this, I want to say I have been impressed at your thorough consumption of the information we have posted, even if you are still a major critic, which is fine. It simply means we have more work to do. We wanted the information published about our barrels to be uniquely 3rd party. If anyone was to review our social media history, you will see we rarely posted about our own barrels for this reason up until recently.

Only a few months ago, scientists were convinced the universe was only 14 billion years old for decades. Drafting models of the early universe on this one assertion, and yet, Webb has effectively eviscerated this argument in mere months. Webb is a tool that provided the means to measure and study the universe in a way we never before could. Measuring barrel movement is analogous to this example. All FEA simulations point to one, undeniable fact - barrels move before the bullet exits the muzzle. To deny these analyses, denies their application and implementation in modern engineering. The small deviation, time, pressure, multi-axis, forces, etc. to date have been prohibiting to this study - and no, high speed camera cannot discern 50 millionths as this is lost within the pixels. We plan to show it. If it is there, us believing it is, this explains why groups open up erratically.

Thanks for reading

Jacob Baker

Drew- show us your measurement that harmonics do not effect impact on target.Please show how harmonics are a driving factor in precision. Put up or shut up

A high speed camera shot with low density pixel vs required discrimination on an out of focus edge is not proof.

Show us your Tuner Test, extended round count, varying bullet weights, heat input... all you do is nay-say with not ONE piece of fact to back your wandering arguments.

Is the barrel:

Harmonically quieter - Yes

More rapid cooling- Yes

Less Mirage- Yes

Longer shot strings without group drift- 3rd party Yes.

Longer life- 3rd party Yes

Less overall muzzle movement- Yes

Tell me how I can stretch a alloy 1/2" bolt with only about 90ft lb of torque- then tell me the barrel does not see at least that force.

Please explain to me how a 45lb piece of D2 can be set into a motion of at least .003" of movement/growth (as in it expands and contracts .003" TIR) with only 120volts.

Please explain to me why hanging a weight off of a barrel will not only effect group position but also group size. WHY DIDN'T THE GROUP JUST DROP TO A NEW IMPACT POINT AND NOT CHANGE MOA VALUES.

PLUS you can't seem to READ. Show me where I ever said harmonics of the barrel is THE driving force for accuracy.

The only thing you can do is slander me and my company.

oral defamation, in which someone tells one or more persons an untruth about another, which untruth will harm the reputation of the person defamed. Slander is a civil wrong (tort) and can be the basis for a lawsuit.

Calling someone "snake oil salesman" and the company the same... time to test that theory (Tort)

Steel or CF?So .3 MOA 8 shot, 1.2 MOA 10 shot (ish)? That’s definitely a solid group, but not out of the norm for factory 6.5 from a good quality blank in my experience. 10 shot group from a Proof SS 6.5 barrel in my old AI AT (shooting factory Federal 140 TMK)View attachment 8311995

Barrel dimensions?

How many rounds down the tube?

Repeat with 3 other bullet weights and mfgs.

Repeat with 30-40rd groups.

How was the rifle supported? Bipod and rear bag...?

The answers you seek are in here.

Also:

“Please explain to me why hanging a weight off of a barrel will not only affect group position but also group size. WHY DIDN'T THE GROUP JUST DROP TO A NEW IMPACT POINT AND NOT CHANGE MOA VALUES.” MDT literally tested this and saw no change in group size

Also also: free floating is done so that the barrel is not deflected by pressure on the handguard/stock/forend, not because of “harmonics” nonsense

Last edited:

Funny how you can’t seem to read, but get pissed off when I ignore your false comparisons and misrepresentations. And I’ll do that when you do.Steel or CF?

Barrel dimensions?

How many rounds down the tube?

Repeat with 3 other bullet weights and mfgs.

Repeat with 30-40rd groups.

How was the rifle supported? Bipod and rear bag...?

As for your other questions, new barrel, bipod and rear bag.

I’ve actually decided to bring a product to market to completely harmonically deaden a barrel. It’s neva been done be4, we basically bed the entire barrel and fix it in place.

Here’s a pic of my prototype:

Here’s a pic of my prototype:

How many posts of results have we made that we produced?On their website Taccom claims that structured barrels provide the following advantages:

– Recoil reduction

– Flatter SD

– Free velocity potential

– Free BC potential

– Reduced mirage

– Minimal load development

– Improved barrel life

But no specifics as to how much of any of these should be expected.

Recoil reduction, increased velocity, decreased SD, increased BC, and improved barrel life seem like they would be pretty easy to demonstrate against a control, even with a small sample of rifles in a couple of common calibers.

The skeptic in me can't help but wonder if the lack of such an example is an answer in itself.

If we posted our results- this group would call bullshit.

This same group has negated every single one of the 3rd party results, tests, simulations we have made.

Lets take each one:

Recoil reduction- see K2M video. Responses- 3rd party. If the barrel does not move as much - how can you not stay on target easier.

Flatter SD- ELR shooters- 3rd Party. This is one of the primary reasons certain shooters are using them.

Free velocity- theory. If I do not have to straighten an curve how can there not be a velocity gain? If I send a rod into vibration and drop a ring down its length: will the ring drop faster or slower or no change with vibration in place. Third party- "150fps faster than any previous load 338EnAbler.

Free BC- if you don't believe harmonics is playing a part in accuracy: so be it. If it does: how do you release a bullet from a whipping end and not flick the tail sending the nose into motion- a thrown foot ball.

Reduced Mirage- no maybes.

Minimal Load development- multiple 3rd party.

Improved barrel life - multiple 3rd party. Example 1000yd bencher- "yes slight increased life as compared to my standard barrel". "Responds predictably to load input", "barrel is 30% lighter but performs equally", "one of 15 rounds to meet a standard in comps"... bought 2 more barrels. HOWEVER- I was told 1000yd benchers are history and have no credibility in this discussion.

You forgot "runs cooler": unless physics stopped 300-450% more surface area does cool things faster.

As we start to wind through tighter and tighter testing by 3rd party- I have come to the conclusion it won't matter what the results are.

We have three new MRAD's.When I was there in 2022 I talked to them about an MRAD barrel and I believe they had already delivered one/some.

I am also interested in one in .300 Norma Mag but got side-tracked on some other projects in recent months. IIRC as long as you can get a blank in the necessary sizes to fit into an MRAD Barrel "Kit" they can spin one up for you. But I'll let @John Baker address that in more detail.

Cheers,

Sirhr

One built and already out for testing and "hard use".

Ready to talk about an MRAD with you anytime.

Bring that Jeep - in case we sink things again.

And how do barrels function when in contact with the stock?I’ve actually decided to bring a product to market to completely harmonically deaden a barrel. It’s neva been done be4, we basically bed the entire barrel and fix it in place.

Here’s a pic of my prototype:

View attachment 8312142

Groups please.

We have identified two coatings that meet good performance objectives- by Cerokote.I'll be interested in the data on the coatings as well. My barrel is uncoated and I opted not to have the 'blast' finish done on it. Again, see my earlier posts about cooling over a greater surface area.

Coatings as a rule create insulating effects. That said, some of the modern vapor deposit coatings may have some real effects on cooling. And the engineers at Cerokote are doing some interesting stuff. Again, I maintain an open mind and look forward to hearing more!

Cheers and Happy New Year!

Sirhr

Actually- 1000yd BR and a ranked PRS guy are shooting the barrels and have purchased more... read the previous posts.Hahaha.

So now you are comparing structured barrels with EFI? I won't call you an autist becuase that would assume you have some intelligence above retardation.

Look at f1. Money is no object...people who put their fucking money where there mouth is. That's what matters.

In places where titles and money matter no one is using this bullshit. In the years it has been out ( and everyone in the elr world knows who Tacom is) no one is using their snake oil barrels. Fclass? Br? Prs? Nope

So before you go throwing insults look at yourself sport. Also, wipe the baker cream off your lips.

How long did it take for Proof Research to make main stream?

I would ask our statistical crowd- what are the odds that out of 400+ shooters and only 3-4barresls present: why has our barrel held 2 out of the last 4 Cold Bore records... minor, anecdotal, 3rd party.

We tested a 33xc with .025 to .200" of jump.Here’s some questions for the harmonics crowd:

If seating depth is used for making sure the bullet exits at the optimal barrel time, then why does that stop being an issue with the tangent and hybrid designs?

Do harmonics just not happen when a tangent or hybrid bullet is loaded? or maybe seating depth is just to align the bullet relative to the bore (like the people designing the bullets state) and harmonics don’t actually matter

View attachment 8310120

We saw no difference in group accuracy at 1000yds.

However, we have never tested for seating depth to tune beyond bolt set back.

Not sure how seating depth effects harmonics- the bullet is "jumping" in space. Harmonics start on "impact" within the barrel.

Have you watch the glass breakage test bullet vs glass? How do you explain that film?

I’d like to comment on the bias John is talking about as it intertwines with credibility and recognition.

I have seen what I’m about to describe happen more times than not. I have been sitting on about 8 to 10 research papers that I have not released. Why?

Several years ago there was a popular reloading method and something about the method I knew was wrong. Also, there was something I question in the way a reloading method was done and its issue with a certain shooting discipline. I mentioned these to a few people and right away I was discredited because I’ve never won a few national matches or because the way they’ve reloaded was their way for years and everything was fine. So, I said alright f it. Why would I want to help the people I’m competing against anyways.

A couple times I’ve lended some assistance to others all just for them to take my research and pawn it off as if it was what they discovered. That shit pisses me off.

What we have today is a bunch of semantics and rhetoric where someone says “show me your data.” So you show it. They look at it and try to poke holes. Then they go quiet. Never to apologize or even complement for doing the work. Then they move forward and take your knowledge that you freely gave and adopt it as their own. Again, not giving credit.

I get why John wants to have sounds research and publish it. He has a business to run. I on the other hand do not find it enjoyable to to give those who don’t give a damn about me, free information.

Look at Litz. I remember back in 2014-2015 I think, he couldn’t open his mouth without getting attacked. Still to this day too.

I’m not a good guy so I’m not going to pretend I deserve anything. But also, this community is just full of guys that take.

I have seen what I’m about to describe happen more times than not. I have been sitting on about 8 to 10 research papers that I have not released. Why?

Several years ago there was a popular reloading method and something about the method I knew was wrong. Also, there was something I question in the way a reloading method was done and its issue with a certain shooting discipline. I mentioned these to a few people and right away I was discredited because I’ve never won a few national matches or because the way they’ve reloaded was their way for years and everything was fine. So, I said alright f it. Why would I want to help the people I’m competing against anyways.

A couple times I’ve lended some assistance to others all just for them to take my research and pawn it off as if it was what they discovered. That shit pisses me off.

What we have today is a bunch of semantics and rhetoric where someone says “show me your data.” So you show it. They look at it and try to poke holes. Then they go quiet. Never to apologize or even complement for doing the work. Then they move forward and take your knowledge that you freely gave and adopt it as their own. Again, not giving credit.

I get why John wants to have sounds research and publish it. He has a business to run. I on the other hand do not find it enjoyable to to give those who don’t give a damn about me, free information.

Look at Litz. I remember back in 2014-2015 I think, he couldn’t open his mouth without getting attacked. Still to this day too.

I’m not a good guy so I’m not going to pretend I deserve anything. But also, this community is just full of guys that take.

Last edited:

A bit of a story-@John Baker I saw on instagram the other day someone was working with y'all on an mrad barrel. Care to share any details?

We sent a barrel to a "group" for testing. What we did not know was it was for thermal signature. We lost... though interestingly you could see our barrel cooling while the others where getting hotter/brighter during post filming. Our barreled gun "was the favorite" to shoot- objective only. However, the barrel failed in one more aspect- the extension came loose. Even though it was torqued to 120ftlbs it loosened up.

We recently bought three MRAD's in 300 Norma. One was modified an built with the same barrel that had been used in the test- the picture shown earlier- and is out for further testing an "use". Yes- we have learned a bit about the MRAD...

Contact us privately...

It wasThat better be a single malt or you are getting downvoted.....

Have you reached out to us as asked to proceed with test?East

East coast.

6.5 cm 8 twist. I'll have my smith spin it up with the same reamer and process as he will a new cut rifle barrel. M24/mtu or comp contour to make it more similar. Assuming the od will fit in his spindle.

It will go in an impact or tikka...probally the impact so I don't have to step down the OD.

Will video and document everything. Factory ammo so no messing with seating. Every test will be over a chrono ( andi scan and garmin). We will see if your claims are true:

Recoil reduction

– Flatter SD

– Free velocity potential

– Free BC potential

– Reduced mirage

– Greater barrel life

If your claims ring true then it will be documented. I just picked up new recording equipment for making videos and will publish it on youtube. I would be happy to be proven wrong.

We cannot find a contact.

However: based on your continuing "arguments" I would not supply you with a barrel to do gunsmithing on. I have no reason to believe, by any means, that you would perform a fair test or work to peak capability when comparing our barrel to yours.

I would entertain- you build a rifle, we build a rifle- all components as equal as possible. I have my gunsmith do our chamber work and muzzle work. Then - I will fly out to shoot with you. If questions remain- we send both rifles to a third party shooter.

So .3 MOA 8 shot, 1.2 MOA 10 shot (ish)? That’s definitely a solid group, but not out of the norm for factory 6.5 from a good quality blank in my experience. 10 shot group from a Proof SS 6.5 barrel in my old AI AT (shooting factory Federal 140 TMK)View attachment 8311995

22cal

100yds

10shot groups

4 ammo types

Why would I reach out when you never responded? I made the offer and It will be completely transparent, filmed and if your product wins (which is key here since your claims are the following:Have you reached out to us as asked to proceed with test?

We cannot find a contact.

However: based on your continuing "arguments" I would not supply you with a barrel to do gunsmithing on. I have no reason to believe, by any means, that you would perform a fair test or work to peak capability when comparing our barrel to yours.

I would entertain- you build a rifle, we build a rifle- all components as equal as possible. I have my gunsmith do our chamber work and muzzle work. Then - I will fly out to shoot with you. If questions remain- we send both rifles to a third party shooter.

– Recoil reduction (will be sort of subjective but assuming weights of both rigs are the same, should be able to test both prone and positional with reticle measurements)

– Flatter SD (should be apparent over chrono)

– Free velocity potential (should be apparent over chrono)

– Free BC potential ( should be apparent at targets at range since we would shoot the same ammo)

– Reduced mirage ( subjective and dependent on environmental factors)

– Minimal load development ( too many variables and would need to be a separate test with its own set of controls)

– Improved barrel life (Should be easy to see as velocity /groups start to open up assuming the exact same firing schedule between barrels).

I would be the first to congratulate you.

A test like this will take months, assuming something like 6.5CM, I would shoot a about 100-200 rounds per barrel atleast once a week giving enough time for barrels to cool and rest as that is one of the biggest factors in barrel life) If I had to guess, using cut rifle barrels from the same manufacture we would need 6-8K rounds of ammo to shoot out both barrels

We are talking about tens if not hundreds of hours of my time commuting to range, setting up all testing/recording equipment, the actual shooting, rest between strings and whatever cleaning schedule we agree on for both barrels. Everything would need to be done exactly the same, with both rifles for this test to matter. I already have 2 match guns that are identical (impact actions, MPA matrix pro, Gen 3 razors in spuhr, same brakes will be used, probally ATS tuner brakes) Testing will be done around PRS match schedule which gets very busy starting in April.

This is what I need from you. A structured blank for my smith to chamber. We will then spin up a similar weight traditional barrel from the same manufacture in the same twist rate and material. I will pay for the traditional blank and the chamber jobs for both of these. The same reamer will be used on both barrels. You will need to provide the ammo and the blank. Everything will be recorded and documented. We will have to agree on firing schedule and parameters but thats not a big deal. Its not practical to shoot 6-8k rounds of factory ammo for groups so maybe every 100 rounds fired will be for groups, with the rest just for velocity tracking.

The difference between you and me is you have a conflict of interest in how this test is performed. You have a financial stake and as such, I want to control as much as possible to mitigate any advantages for one side. I have no conflict. In fact, I would love to be proven wrong, I think such a test would be fun as hell and provide the shooting community something of actual value instead of all the bullshit half ass tests that are flawed from the start and yield no real value. We could even get some shooters from the hide to participate as independent shooters. There are enough people on this site that know me personally that will vouch if that is your concern. I already have 3 or 4 respected gunsmiths in mind to do the barrel work. Guys who are well respected in the community.

Please explain why ladder test matter? Bullet jump?

Contradictions caught in 4K. Thanks for arguing against yourself, it saves me the time of doing it myselfWe tested a 33xc with .025 to .200" of jump.

We saw no difference in group accuracy at 1000yds.

However, we have never tested for seating depth to tune beyond bolt set back.

Not sure how seating depth effects harmonics- the bullet is "jumping" in space. Harmonics start on "impact" within the barrel.

Have you watch the glass breakage test bullet vs glass? How do you explain that film?

oh so I guess the harmonics caused by:Not sure how seating depth affects harmonics- the bullet is "jumping" in space. Harmonics start on "impact" within the barrel.

•the trigger being pulled

•firing pin falling & impacting primer

•the primer igniting powder

•powder combusting and building pressure against the case

don’t count at all because reasons…

It’s almost like you’re picking and choosing what applies and what doesn’t in order to market a product

Hello,Why would I reach out when you never responded? I made the offer and It will be completely transparent, filmed and if your product wins (which is key here since your claims are the following:

– Recoil reduction (will be sort of subjective but assuming weights of both rigs are the same, should be able to test both prone and positional with reticle measurements)

– Flatter SD (should be apparent over chrono)

– Free velocity potential (should be apparent over chrono)

– Free BC potential ( should be apparent at targets at range since we would shoot the same ammo)

– Reduced mirage ( subjective and dependent on environmental factors)

– Minimal load development ( too many variables and would need to be a separate test with its own set of controls)

– Improved barrel life (Should be easy to see as velocity /groups start to open up assuming the exact same firing schedule between barrels).

I would be the first to congratulate you.

A test like this will take months, assuming something like 6.5CM, I would shoot a about 100-200 rounds per barrel atleast once a week giving enough time for barrels to cool and rest as that is one of the biggest factors in barrel life) If I had to guess, using cut rifle barrels from the same manufacture we would need 6-8K rounds of ammo to shoot out both barrels

We are talking about tens if not hundreds of hours of my time commuting to range, setting up all testing/recording equipment, the actual shooting, rest between strings and whatever cleaning schedule we agree on for both barrels. Everything would need to be done exactly the same, with both rifles for this test to matter. I already have 2 match guns that are identical (impact actions, MPA matrix pro, Gen 3 razors in spuhr, same brakes will be used, probally ATS tuner brakes) Testing will be done around PRS match schedule which gets very busy starting in April.

This is what I need from you. A structured blank for my smith to chamber. We will then spin up a similar weight traditional barrel from the same manufacture in the same twist rate and material. I will pay for the traditional blank and the chamber jobs for both of these. The same reamer will be used on both barrels. You will need to provide the ammo and the blank. Everything will be recorded and documented. We will have to agree on firing schedule and parameters but thats not a big deal. Its not practical to shoot 6-8k rounds of factory ammo for groups so maybe every 100 rounds fired will be for groups, with the rest just for velocity tracking.

The difference between you and me is you have a conflict of interest in how this test is performed. You have a financial stake and as such, I want to control as much as possible to mitigate any advantages for one side. I have no conflict. In fact, I would love to be proven wrong, I think such a test would be fun as hell and provide the shooting community something of actual value instead of all the bullshit half ass tests that are flawed from the start and yield no real value. We could even get some shooters from the hide to participate as independent shooters. There are enough people on this site that know me personally that will vouch if that is your concern. I already have 3 or 4 respected gunsmiths in mind to do the barrel work. Guys who are well respected in the community.

Actually, to us we did respond.... asking you to reach out to us (privately) so we could get addresses and such. Not sure why you cannot see that reply , as I immediately replied to your "rules".

With that- would you have any issues with Dan Warner chambering our barrel?

Second- barrel channels. How big is your barrel channels? To be a fair test the barrels should be near/equivelant weight. If we cut to fit standard barrels our barrel will be 30% lighter (thereabouts). I would still accept the challenge with the lighter barrel but it should be noted.

I think it is time to get off of this Forum. No matter what I say you will shit on it.Contradictions caught in 4K. Thanks for arguing against yourself, it saves me the time of doing it myself

I agreed with the person "overall" concerning bullet jump and its impact on the system. Has nothing to do with overall harmonics- at some point a great enough jump and built velocity will have an impact. Second - I am not a BR guy and do not load to nth degrees. Perhaps you do.

I SAID I ONLY USED BULLET JUMP TO CONTROL BOLT SET BACK. Which was give no me as advice- from an AB guy.

You disagree that the powder explosion has no harmonic impact.

You disagree that engagement of the lands create harmonics.

Fine- I don't agree.

Please educate me (politely) what effects the bullet after it leaves the barrel in which/therefore all bullets shot out of a barrel don't group the same- or do they?

You have shot many more rounds than I have and are obviously much more schooled and brilliant. My simple mind can't wrap around what the external force that acts on bullet placement (outside of obvious) does so with most barrels when loading test of any kind are done. I think you are saying that if we put a barrel on a concrete pillar, create a totally linear recoil event - a barrel will shoot anything put in it the same.

Is that what you are saying?

Simple: we’re not shooting lasers. Minute differences in bullet construction and dimensions, case volume, powder burn and pressure building can and does cause the spread we see. The less consistent ammo is, the worse accuracy you get.

No mumbo jumbo required, no rain dances necessary, and no need to spend money on barrel tuners or structured barrels or anything else with no scientific support.

No mumbo jumbo required, no rain dances necessary, and no need to spend money on barrel tuners or structured barrels or anything else with no scientific support.

@sirhrmechanic can you test any of these sd claims over a chronograph for us. So you see flatter sd’s, free velocity potential, and free bc potential when you shoot a regular barrel vs Tacom barrel?On their website Taccom claims that structured barrels provide the following advantages:

– Recoil reduction

– Flatter SD

– Free velocity potential

– Free BC potential

– Reduced mirage

– Minimal load development

– Improved barrel life

But no specifics as to how much of any of these should be expected.

Recoil reduction, increased velocity, decreased SD, increased BC, and improved barrel life seem like they would be pretty easy to demonstrate against a control, even with a small sample of rifles in a couple of common calibers.

The skeptic in me can't help but wonder if the lack of such an example is an answer in itself.

Hello Sir,Saw this today and wondered if the engineers and gunsmiths on SH had any thoughts on the claims made concerning structured barrels in terms of rigidity, whip, and cooling?

Structured Barrels

tacomhq.com

So I don’t know the folks at this site, and I am not calling them out. Just wondering about the science behind the claims, and if it is worth the coin.

First and foremost, thank you for the opportunity to discuss this subject.

To point out- I have never said harmonics are the only thing that creates accuracy. Nor have I ever said we can outshoot a 1hole gun. The word "potential" on our website is from third party observations. Anything we would post would have been and will be eviscerated.

We can't get past the premises of a tube being stronger than a solid round of the same weight, let alone any other concept.

All we have claimed to do - ourselves- is to make a barrel that is more predicable and less of a Diva. A 10% gain across the board. That is MY ONLY CLAIM personally.

We have tried to be constructive, give examples, let 3rd party results speak for themselves. What a waste of time.

What this has shown me is we will have to jump over a very tall bar- and nobody has shown us how tall it is- and it will keep moving up.

Nobody has posted the standard for a current 30round standard for any caliber- What are we comparing too? You can't tell us we are full of BS when one can't provide a standard when challenging us for specific data.

I don't want to respond to this thread anymore, and will focus our time and energy dealing with people who are open to working with us. Testing will occur. Several layers will occur. All results will be shot down here though if they are in our favor and will only be accepted if it goes against our barrel.

How many people on here have totally negated all - everyone - of our 3rd party shooters - yet have never touched one of our barrels?

Why would anyone of the nay-sayers accept a pro-3rd party test result? They won't.

As noted- if the public starts to use them. We succeeded. We will focus on our immediate cliental. From a business standpoint this is a disastrously bad use of time.

Thank you.

Afraid not as I don't have a Chrono. That's why we would love to see someone with all the quantitative data analysis tools do some testing.@sirhrmechanic can you test any of these sd claims over a chronograph for us. So you see flatter sd’s, free velocity potential, and free bc potential when you shoot a regular barrel vs Tacom barrel?

I can say that the group sizes right out of the gate were amazing and only got better as I fireformed brass and worked up loads. Even at some very impressive ranges it just hammers.

I think a good way to do testing would be to have an MRAD barrel done and be able to swap back and forth between factory and Structured in similar conditions. It was my plan to do a .300 NM MRAD barrel, but this year some other projects side-tracked me. And last year (2022) the build kits were a PITA to get.

I think the guys with the best data will be the ELR folks or someone like Vestals, which I know has built a lot of them. Or visit TACOM. He has a few of his own rifles. Shoot a couple! I found them really accomodating and open! Just don't go during mud season ;-)

Cheers!

Sirhr

@John Baker and @sirhrmechanic (and a few others) thanks for all the informative posts! I learned a lot from the small amount I could comprehend. (Due to my small mind)

Cheers

Cheers

One thing that I think bears repeating is LL's point about Gain Twist. In the world of everything old is new again... this is making a big comeback and is a technology that is well-proven. I would not order any custom barrel these days without putting in a gain twist. At least not in a high-velocity/pressure round.

I'd have to go back and look at notes to recall what the gain twist is in my .300 WM. But it's definitely a gain twist Bartelin and they do a great job of it -- one of the few companies to offer gain twist at the time. Maybe some others have now tooled up for it. @Frank Green can talk more about gain twist... As he is a great contributor to SH! And one of the reasons so much cool stuff happens here... is guys getting stuff done and moving the needle in so many ways.

Cheers,

Sirhr

I'd have to go back and look at notes to recall what the gain twist is in my .300 WM. But it's definitely a gain twist Bartelin and they do a great job of it -- one of the few companies to offer gain twist at the time. Maybe some others have now tooled up for it. @Frank Green can talk more about gain twist... As he is a great contributor to SH! And one of the reasons so much cool stuff happens here... is guys getting stuff done and moving the needle in so many ways.

Cheers,

Sirhr

I agree with the gain twist premise. I’ve used one on all of my competition barrels since 2017. Most have been Bartlein …. Now, all are K&S gain twists. Structured …. At that.One thing that I think bears repeating is LL's point about Gain Twist. In the world of everything old is new again... this is making a big comeback and is a technology that is well-proven. I would not order any custom barrel these days without putting in a gain twist. At least not in a high-velocity/pressure round.

I'd have to go back and look at notes to recall what the gain twist is in my .300 WM. But it's definitely a gain twist Bartelin and they do a great job of it -- one of the few companies to offer gain twist at the time. Maybe some others have now tooled up for it. @Frank Green can talk more about gain twist... As he is a great contributor to SH! And one of the reasons so much cool stuff happens here... is guys getting stuff done and moving the needle in so many ways.

Cheers,

Sirhr

Seems to have worked for me in the ELR game.

Chris Schmidt

Tennesssee

John, send me a box of used endmills and/or drill bits and I’ll sharpen them for free. You earned it.What a waste of time.

From a business standpoint this is a disastrously bad use of time.

Thank you.

Last edited:

Thanks Sirhr!One thing that I think bears repeating is LL's point about Gain Twist. In the world of everything old is new again... this is making a big comeback and is a technology that is well-proven. I would not order any custom barrel these days without putting in a gain twist. At least not in a high-velocity/pressure round.

I'd have to go back and look at notes to recall what the gain twist is in my .300 WM. But it's definitely a gain twist Bartelin and they do a great job of it -- one of the few companies to offer gain twist at the time. Maybe some others have now tooled up for it. @Frank Green can talk more about gain twist... As he is a great contributor to SH! And one of the reasons so much cool stuff happens here... is guys getting stuff done and moving the needle in so many ways.

Cheers,

Sirhr

Howdy Mr Baker.Hello Sir,

First and foremost, thank you for the opportunity to discuss this subject.

To point out- I have never said harmonics are the only thing that creates accuracy. Nor have I ever said we can outshoot a 1hole gun. The word "potential" on our website is from third party observations. Anything we would post would have been and will be eviscerated.

We can't get past the premises of a tube being stronger than a solid round of the same weight, let alone any other concept.

All we have claimed to do - ourselves- is to make a barrel that is more predicable and less of a Diva. A 10% gain across the board. That is MY ONLY CLAIM personally.

We have tried to be constructive, give examples, let 3rd party results speak for themselves. What a waste of time.

What this has shown me is we will have to jump over a very tall bar- and nobody has shown us how tall it is- and it will keep moving up.

Nobody has posted the standard for a current 30round standard for any caliber- What are we comparing too? You can't tell us we are full of BS when one can't provide a standard when challenging us for specific data.

I don't want to respond to this thread anymore, and will focus our time and energy dealing with people who are open to working with us. Testing will occur. Several layers will occur. All results will be shot down here though if they are in our favor and will only be accepted if it goes against our barrel.

How many people on here have totally negated all - everyone - of our 3rd party shooters - yet have never touched one of our barrels?

Why would anyone of the nay-sayers accept a pro-3rd party test result? They won't.

As noted- if the public starts to use them. We succeeded. We will focus on our immediate cliental. From a business standpoint this is a disastrously bad use of time.

Thank you.

A whole lot covered here, but I don’t think it is aimed at me. Regardless I will address what I can. My apologies for the length…

Yes I started this thread because it seemed interesting to me, and I wanted other SH members to be aware of this technology because you were applying it to small arms.

I mentioned harmonics in my earlier posts because it seemed an easy variable to measure, and because the mere presence of a shift in harmonic frequency is evidence that the application of structuring has changed the barrel. Seemed logical, easy to demonstrate, and a pretty low bar to me.

I agree that some here would argue “which way is up” with the Almighty, and others want “experimental proof”and/or “statistical tests”. But I have argued that it is premature until a valid hypothesis is stated, sufficient preliminary data to estimate the necessary sample size is available, and finally an experimental design is developed. Statistical analyses are pointless if you don’t have a question and the means to answer it practically and to a demonstrable level of precision.

I have argued data and evidence will come out eventually, and that we should be patient. I also stated that time is money for businesses engaged in developing new ideas, and therefore it will take time (e.g., answering critics vs meeting customer demands).

I have asked for better decorum (manners) when addressing you, and other contributors to the thread. Mainly because you, and others, have been very willing to answer questions as your time allowed.

Finally, I think this thread has been very interesting, informative, and worthy of the time spent. I know it has occasionally become a bit heated and/or stupid, but time and sincere input wins each time.

So John and Jacob Baker, ignore the bullshit and please continue to contribute as your time allows. Many of us here want to see more information, questions, and responses from you and new barrel users.

Cheers.

And I am a push over for decent people and good discussion.Howdy Mr Baker.

A whole lot covered here, but I don’t think it is aimed at me. Regardless I will address what I can. My apologies for the length…

Yes I started this thread because it seemed interesting to me, and I wanted other SH members to be aware of this technology because you were applying it to small arms.

I mentioned harmonics in my earlier posts because it seemed an easy variable to measure, and because the mere presence of a shift in harmonic frequency is evidence that the application of structuring has changed the barrel. Seemed logical, easy to demonstrate, and a pretty low bar to me.

I agree that some here would argue “which way is up” with the Almighty, and others want “experimental proof”and/or “statistical tests”. But I have argued that it is premature until a valid hypothesis is stated, sufficient preliminary data to estimate the necessary sample size is available, and finally an experimental design is developed. Statistical analyses are pointless if you don’t have a question and the means to answer it practically and to a demonstrable level of precision.

I have argued data and evidence will come out eventually, and that we should be patient. I also stated that time is money for businesses engaged in developing new ideas, and therefore it will take time (e.g., answering critics vs meeting customer demands).

I have asked for better decorum (manners) when addressing you, and other contributors to the thread. Mainly because you, and others, have been very willing to answer questions as your time allowed.

Finally, I think this thread has been very interesting, informative, and worthy of the time spent. I know it has occasionally become a bit heated and/or stupid, but time and sincere input wins each time.

So John and Jacob Baker, ignore the bullshit and please continue to contribute as your time allows. Many of us here want to see more information, questions, and responses from you and new barrel users.

Cheers.

For you personally- I have never thought you misguided or holding ill intent concerning Harmonics. Seems like a simple subject that got way carried away. I intend to show a solid piece of hardened D2 in motion, its heat gain, wave front.... and apply it to barrels. I hope to show barrel movement at light wave level during the bullets passage down the barrel.

I am also very happy to demonstrate and rise to a challenge- but when held to an unknown data, mean value, bell curve etc... let's say at some point my trigger is pulled. Pun intended.

While it was noted that all of the accuracy lies within the bullet (you are going to like my demo on that one) it does not explain how the bullet and the cartridge knows the barrel is getting hot and accuracy degrades. Or we would all be shooting 1/2" diameter barrels. After all how do load cells read pressure if the barrel is not moving....?

I do not claim to be an expert. Most (90% plus) are more expert than I am- I know where I sit on the food chain. However, I am quite happy to take those experts advice (Frank (both of them) Sirhrmechanic, JB.IC, AB, Makinchips 208... and run with it. Until something shows up that questions their position- I accept their position. Almost all of my 3rd party shooters are in that same boat- they bring something to the table I don't have (to note: some don't want their info/results shared- Kind of like the Sniper kill a few years back- the phone call was to tell us not to disclose it). Respect for our cliental.

Tunnels and radar will yield hard data and, I hope, beyond "noise".

I will post the 30-40round groups. I will also complete a round robin test with three 300Normas- all custom. One of which will then be outfitted with a Structured Barrel.

Our goal is to make a highly capable barrel capable of extended precise engagements. And reach for the "stars" from there.

Reducing the inertia based bending ( negative compensation)is not a bad thing and for people to say otherwise indicates that they do not possess the precision needed to see the differences that a barrel the barrel is bending or going out of tune . I just have to laugh when they actually believe that a rifle does not go out of tune and then resort to calling names because they have lost their argument . So John stay at it , don’t let the trolls alter your path . We know you and know you have honest intentions and a real intention to help the sport .

I see the perfect place to test these as F TR and F Open. Shooting twenty rounds for record will show improvements if the design pans out The US Teams already have the best shooters in the country and if there scores go up it’s a win

I just seen two videos TACOM posted which showed the scope flex under recoil. That alone would have me question the repeatability of the system. Not all scopes are made the same. So, when testing the barrels, there needs to be some accepted standard for the scope and scope mount. Even with that standard, there’s no scope to scope guarantee.

Let's see if we can re-align this a bit.And I am a push over for decent people and good discussion.

For you personally- I have never thought you misguided or holding ill intent concerning Harmonics. Seems like a simple subject that got way carried away. I intend to show a solid piece of hardened D2 in motion, its heat gain, wave front.... and apply it to barrels. I hope to show barrel movement at light wave level during the bullets passage down the barrel.

I am also very happy to demonstrate and rise to a challenge- but when held to an unknown data, mean value, bell curve etc... let's say at some point my trigger is pulled. Pun intended.

While it was noted that all of the accuracy lies within the bullet (you are going to like my demo on that one) it does not explain how the bullet and the cartridge knows the barrel is getting hot and accuracy degrades. Or we would all be shooting 1/2" diameter barrels. After all how do load cells read pressure if the barrel is not moving....?

I do not claim to be an expert. Most (90% plus) are more expert than I am- I know where I sit on the food chain. However, I am quite happy to take those experts advice (Frank (both of them) Sirhrmechanic, JB.IC, AB, Makinchips 208... and run with it. Until something shows up that questions their position- I accept their position. Almost all of my 3rd party shooters are in that same boat- they bring something to the table I don't have (to note: some don't want their info/results shared- Kind of like the Sniper kill a few years back- the phone call was to tell us not to disclose it). Respect for our cliental.

Tunnels and radar will yield hard data and, I hope, beyond "noise".

I will post the 30-40round groups. I will also complete a round robin test with three 300Normas- all custom. One of which will then be outfitted with a Structured Barrel.

Our goal is to make a highly capable barrel capable of extended precise engagements. And reach for the "stars" from there.

The most basic question we/TACOMHQ has for ourselves is: if a group stops truing their platforms (1600m x 300Norma) at 7-10 rounds as they can no longer consistently engage the target and we could raise that number to 15-20... what is the issue?

This is like taking a bite of the best chocolate cake in the world and then complaining about an ingredient.

With that.

Laying out the cards: AB does not think this technology works. Brux does not (per a ranking PRS shooter). Bartlein does not. For us personally- I have no problem with that as we use all of the above companies products. However, admittedly a big mountain to climb.

It is obvious a few and a half people watch this thread. Please add to it.

We have been challenged to make 30rd groups:

Someone please provide the base line group size and drift for multiple groups.

Let's say the premises that barrel movement before the bullet leaves the barrel is to small to effect the accuracy.

Is there data that measures at least two points - looking for null/node and barrel muzzle- what are those measurements?

Why is this so important- because I an send a piece of metal into vibration in which it is moving in opposite directions at each end and the center can be moving in directions separate of the exterior. To say these forces don't occur in a barrel needs data.

The premises being proposed is that the energy produced continues to gain after the bullet leaves the barrel. The premises is that energy is still being released and gain is still occurring after the bullet leaves (what is the energy source). I find that removing an energy source almost immediately stops the vibration. Are there other examples of systems gaining amplitude after the source is removed? In my simple mind that is gaining perpetual motion - new term. LOL

Lets say the premises that the bullet and the case (all components within) are the primary driver of accuracy (removing recoil management). To at least some on here - the only driver.

With that if the precision loaded round is the only contributor:

1) How does the precision round know the shot string count and then degrade.

2) Does the degrading group open up or only drop in vertical.

3) If it is expansion of the barrel/bore- then we should be able to create a load that compensates for this change and reduce the group size (question)?

4) If I scribe a line on a bullet will the group degrade?

5) If I dent a bullet will the group degrade?

6) If I precisely load a round as humanely possible- will it shoot the exact same cold bore shot time after time? By some premises -yes.

7) Why does anything beyond a pencil barrel exist?

8) I believe bull barrels are used to keep consistency as heat builds. As heat build barrels distort. However, distortion, is not a "jumpy" random event. Groups get bigger in all directions. How does the round know this and respond to this? Assuming heat is, within reason linear, than I would think the continuing rounds would just make a "line" as the barrel is shot, not random opening group size.

9) With the premises that the round is the only system component that creates accuracy (removing the shooter)- should we/I understand that any given bullet loaded precisely and compensated for twist rate- all will shoot the same group size, same group location(Left right) given a sufficient sample size (For Drew- honest question). Even our barrels will throw some left right into a group with enough speed variation (2200fps to 3400fps same bullet, powder and case).

10) If we assume a barrel will shoot a longer string of accurate shots on a cold day- how does the round know this? If it was the round only, quite simply, why does it just not shoot 100's of rounds accurately if the barrel has no impact from a vibration point.

Concerning the bore and rifling (musing thoughts) - why don't some barrels just plain not shoot? Bad rifling or bad material. Please - a barrel person should answer this. This should be a measurable predictable event. Why does the term "hummer barrel" exists- opposite of a bad barrel?

If harmonics have no effect on a shot- will a non-heat treated barrel - for a a limited set of rounds- shoot as good as a group as a heat treated barrel?

Why does the event of buttoning a barrel cause heat at the point of the bullets position in the barrel- it is moving might slowly? I will guess compression of the metal is creating heat - pressure = heat.

Questions could go on for a while- all this discussion asks is that for those who "negate" our barrel-- PLEASE counter with your own data, finding etc... for instance a 100 shot 22cal test...

AGAIN- the barrels only attribute is not only stiffness and harmonics.

That I agree with... a 1000yd bencher certainly bought on.I see the perfect place to test these as F TR and F Open. Shooting twenty rounds for record will show improvements if the design pans out The US Teams already have the best shooters in the country and if there scores go up it’s a win

All cards on the table- an ranking F class using Brux did shoot our barrels. From what I understand he did win a couple of matches. With a barrel 30% lighter than their normal. The other shooter said he saw no gain in accuracy (1/4moa), with no load development, 30% lighter barrel and "the best three shot cold bore I ever shot".... its hard to move the shooting community. Kind of like granite mountains. An earlier responder who shot F class did note this is the most accurate barrel he has ever had.

Need a brave tester.

Similar threads

- Replies

- 39

- Views

- 7K

- Replies

- 13

- Views

- 1K

- Replies

- 0

- Views

- 1K