I’d like to know what you find out. Even though I fully suspect the quality design of my several Archimedes to never break! My nucleus never have either for that matter.He stated parts will be available. I'm going to call and confirm if any and all parts will be available and for what time frame.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Coup De Grâce, New Action from American Rifle Company, $899 WOW!

- Thread starter karagias

- Start date

I have more than 500 dasher rounds on my sa rh CDG. Totally flawless. The only minor issue I notice ( and it happens in Ted’s videos also )is that sometimes reinserting the bolt into the receiver can be problematic. I have also noticed that Two stronger striker springs are now available ( 80N and 100N ) while my understanding is that 70N is the standard and works well in my action with any primer, cci450 included, being the ones I use most). Did someone give these new springs a try? Is the juice worth the squeeze?

I have more than 500 dasher rounds on my sa rh CDG. Totally flawless. The only minor issue I notice ( and it happens in Ted’s videos also )is that sometimes reinserting the bolt into the receiver can be problematic. I have also noticed that Two stronger striker springs are now available ( 80N and 100N ) while my understanding is that 70N is the standard and works well in my action with any primer, cci450 included, being the ones I use most). Did someone give these new springs a try? Is the juice worth the squeeze?

I have had no ignition issues with the default 70N spring and CCI 450s, but the heavier springs would give the CDG more firing pin energy and reliability margin in dirty conditions at the expense of a heavier bolt lift.

My Archimedes builds use a 22# / 98N firing pin spring by default and the bolt lift still feels nice on them. Also, you can hear the Archimedes "snaps" a lot louder than the CDG when you dry fire them side by side. I'm planning to pick up the 80N and 100N springs from ARC to test in my CDG, and if the bolt lift isn't annoyingly heavy with the 80N or 100N I'll probably leave the heavier spring installed, even though I've had no issues with the default 70N spring. Sometimes you have to mess with something that works just for the sake of messing with it, lol

I keep thinking its me and haven't tried to figure out what is catching when the bolt wont slide back in. Sometimes it does and sometimes it doesnt. Ive just been pulling it out, reinserting and it slides in moat often. If it was more annoying or something I had to deal with more I would try to figure it out. Until then....The only minor issue I notice ( and it happens in Ted’s videos also )is that sometimes reinserting the bolt into the receiver can be problematic.

It’s the ejector I believe. It happens to mine a lot as well.I keep thinking its me and haven't tried to figure out what is catching when the bolt wont slide back in. Sometimes it does and sometimes it doesnt. Ive just been pulling it out, reinserting and it slides in moat often. If it was more annoying or something I had to deal with more I would try to figure it out. Until then....

Does anyone have a list of who all is doing CDG actions for their production class rifles?

Or who’s doing barreled actions?

Mpa and Vudoo are using the CDG in their production class rigs.It’s the ejector I believe. It happens to mine a lot as well.

Does anyone have a list of who all is doing CDG actions for their production class rifles?

Or who’s doing barreled actions?

I’m sure they switched because of the $550 in doing so. I’m assuming they aren’t passing this savings onto the consumer which in turn means more money in their pocket. It’s a wise move and they jumped when the opportunity presented.Mpa and Vudoo are using the CDG in their production class rigs.

Correct. It is the ejector causing the bolt not to slip in, happens to me tooI keep thinking its me and haven't tried to figure out what is catching when the bolt wont slide back in. Sometimes it does and sometimes it doesnt. Ive just been pulling it out, reinserting and it slides in moat often. If it was more annoying or something I had to deal with more I would try to figure it out. Until then....

Anyone who is running a LA and 3.850" CIP magazines seeing that the feed ramp overhangs the leading edge of the magazine by a pretty substantial amount? Its almost like it's not cut for a 3.850" CIP SSSF, this is in a Cadex chassis.

Can you post some photos ?

Yes, I noticed the same issue. I ended up loading longer than magazine length so have to single feed so no issue for me at this point. Was considering taking a dremel to it, but not needed right now. This is for 300 PRC in an MDT ACC Premier Chassis.Anyone who is running a LA and 3.850" CIP magazines seeing that the feed ramp overhangs the leading edge of the magazine by a pretty substantial amount? Its almost like it's not cut for a 3.850" CIP SSSF, this is in a Cadex chassis.

Can you post some photos ?

This is a 212 ELD-X loaded to max mag length, and the bullet tip gets stopped by the feed ramp.

Yes, I noticed the same issue. I ended up loading longer than magazine length so have to single feed so no issue for me at this point. Was considering taking a dremel to it, but not needed right now. This is for 300 PRC in an MDT ACC Premier Chassis.

What bullet are you running?

Well that is discouraging, I was about to blow some $$ on a 300 PRC build and was leaning towards a CDG

That seems odd that the bullet tips would sit under the feed ramp since ARC says the action will support up to a 3.850" length mag... I think I'd be sending ARC an email with pictures before notching the feed ramp (although that's what you might end up having to do.)

They're in the office today, I sent them an email yesterday for a spare parts order and had a quote sitting in my inbox at 7:30am this morning.

They're in the office today, I sent them an email yesterday for a spare parts order and had a quote sitting in my inbox at 7:30am this morning.

I’ll check mine when I get home in a hour or so and will post a photo. I’m figuring on seeing the same thing.Well that is discouraging, I was about to blow some $$ on a 300 PRC build and was leaning towards a CDG

Hornady 230 gr A-Tip. My mag feed issue looked exactly like your photos.What bullet are you running?

Just got my ship notice on a lefty ordered in late July - now if only Bartlein and McMillan could catch up!

I have a friend who bought the CDG LA to replace a Origin, since he loves his SA CDG. He runs mostly MDT for chassis, so I'd expect his action to run into the same issue with magazine positioning. We have compared actions and his is the same as mine.Yes, I noticed the same issue. I ended up loading longer than magazine length so have to single feed so no issue for me at this point. Was considering taking a dremel to it, but not needed right now. This is for 300 PRC in an MDT ACC Premier Chassis.

Its a relatively minor modification, but pretty annoying to be honest. Looking at how the magazine sits, it seems like the cut is likely correct for 3.850" but its position relative to the action screw spacing etc is slightly forward. My conclusion, anyway.That’s an easy fix no? I feel like I’ve seen many a rifles over the years with the front lip of the feed ramp notched just for those long bullet cartridges.

I emailed ARC an inquiry on Dec 2nd, they have not responded...That seems odd that the bullet tips would sit under the feed ramp since ARC says the action will support up to a 3.850" length mag... I think I'd be sending ARC an email with pictures before notching the feed ramp (although that's what you might end up having to do.)

They're in the office today, I sent them an email yesterday for a spare parts order and had a quote sitting in my inbox at 7:30am this morning.

Keep us posted. Looks like notching it would work just fine but not fun to do on a new action. Curious how mine will sit in a KRG w3.

Yup, it's a pretty annoying thing especially since ARC is not new at the action game. The gleaming nitride finish shouldn't have to meet the mill in order to function properly and use available magazine length.I couldn’t get a picture to turn out worth a dang but the feed ramp in the action most definitely overhangs the front of the magazine a bit. Not a lot but enough to hang it up it looks like.

It's for any chassis/stock that you want to not have the ability to over insert an AICS magazine into.I believe that the tab for the CDG is only used when using a Xylo chassis. The Xylo chassis does have a slot that the tab fits into.

Yes, most any other stock/chassis will need an inlet created.

Last edited:

I picked up my long action CDG today from the FFL. I posted a WTB ad and someone had one to spare. I am overall very impressed, especially for the price point. It checks all the boxes for me personally.

And I thought the ejection port on the SA looked loooong!View attachment 8307322

I picked up my long action CDG today from the FFL. I posted a WTB ad and someone had one to spare. I am overall very impressed, especially for the price point. It checks all the boxes for me personally.

Same here. The video made things so much easier.Got my new extractor kit yesterday. Easy to swap it out.

Is the new extractor only for the LA ?Same here. The video made things so much easier.

They sent me a kit for a SA.Is the new extractor only for the LA ?

Kind of bummed the Nucleus is discontinued/backorder not available.

The CRF/mechanical ejector is what sold me on American Rifle company. The new action looks great and Im sure it is, but the Nuk 2.0 was perfection at the $1k price point.

The CRF/mechanical ejector is what sold me on American Rifle company. The new action looks great and Im sure it is, but the Nuk 2.0 was perfection at the $1k price point.

This is better at $101 less.Kind of bummed the Nucleus is discontinued/backorder not available.

The CRF/mechanical ejector is what sold me on American Rifle company. The new action looks great and Im sure it is, but the Nuk 2.0 was perfection at the $1k price point.

I have seen quite a few posts here that say the CDG is better than the Nucleus at a lower price point. Unless of course the low pricing is indicative of introducing a new action into the market.

Considering it's been at the "intro pricing" for nearly a year now, it might as well stay permanent.I have seen quite a few posts here that say the CDG is better than the Nucleus at a lower price point. Unless of course the low pricing is indicative of introducing a new action into the market.

Just an update on the optional heavier striker springs in case people are wondering... the 80N (18#) and 100N (22.5#) striker springs arrived today.

I did a couple of tests. First I removed the bolt shroud and firing pin assembly, supported the collar near the tip of the firing pin on a digital scale, and pressed down on the bolt shroud to check two measurements: pressure on the spring when it first starts to compress, and pressure on the spring when compressed to put the cocking piece flush with the back of the bolt shroud. One thing to note, with the action fully cocked the cocking piece is slightly below flush with the back of the bolt shroud, so the below measurements take some overcocking into account, which explains why the final spring pressure is higher than ARC's specs.

With the stock 70N / 15.74# spring, it took 12.3# to start compressing the spring and 16.8# to have the cocking piece flush with the back of the bolt shroud.

With the 80N / 18# spring, it took 14.8# to start compressing the spring and 19.2# to have the cocking piece flush with the back of the bolt shroud.

Next, bolt lift effort. I used a hook type scale at the center of the stock hourglass bolt knob. Not the greatest test method, but it was pretty repeatable... I tested each spring 10 times and averaged the numbers.

The stock 70N spring took about 4.75# on average to open the bolt.

The 80N spring took about 5.45# on average to open the bolt. The extra effort is noticeable while running the bolt compared to the 70N spring but it's not heavy IMO, the action still operates smoothly. I'm going to run the 80N spring for a while and see how I like it and see if there's any difference in SD/ES or group sizes. Since I've had no failures to fire with the 70N spring and CCI 450s, and SD/ES/group sizes are all great I may reinstall the 70N spring for the lighter bolt lift and keep the 80N spring in my shooting bag just in case.

I did not test the 100N / 22.5# striker spring as I damn near launched the bolt shroud across the garage just trying to install it. It's much longer than the 70N and 80N springs; it's actually longer than the firing pin and you have to partially compress it before you can start sliding the bolt shroud over the firing pin, and I could not compress it enough to install the cocking piece with only fingertip grip on the two small ledges on the bolt shroud. The 100N spring is a pain in the ass to install compared to the 70N and 80N springs which aren't too bad. I need to make a tool that will grab the ledges on the bolt shroud or engage the two bayonet locking tabs that hold it to the bolt body so I can get a more secure grip on it to fully compress the 100N spring while keeping my fingers out of the way to install the cocking piece back on the firing pin.

Once I make a tool and get the 100N spring installed I'll report back with the actual bolt lift measurement. My hunch is the bolt lift with the 100N spring will be about 6.8#. I'm also pretty sure I won't like the bolt lift with the 100N spring installed...

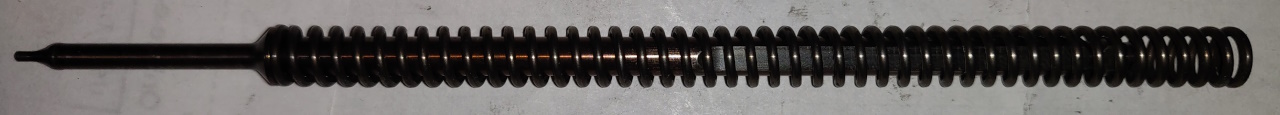

Here's a pic... stock 70N spring on top (80N spring is the same length), 100N spring on bottom. You have to compress the 100N spring nearly to coil bind to get the bolt shroud down far enough to reinstall the cocking piece.

I did a couple of tests. First I removed the bolt shroud and firing pin assembly, supported the collar near the tip of the firing pin on a digital scale, and pressed down on the bolt shroud to check two measurements: pressure on the spring when it first starts to compress, and pressure on the spring when compressed to put the cocking piece flush with the back of the bolt shroud. One thing to note, with the action fully cocked the cocking piece is slightly below flush with the back of the bolt shroud, so the below measurements take some overcocking into account, which explains why the final spring pressure is higher than ARC's specs.

With the stock 70N / 15.74# spring, it took 12.3# to start compressing the spring and 16.8# to have the cocking piece flush with the back of the bolt shroud.

With the 80N / 18# spring, it took 14.8# to start compressing the spring and 19.2# to have the cocking piece flush with the back of the bolt shroud.

Next, bolt lift effort. I used a hook type scale at the center of the stock hourglass bolt knob. Not the greatest test method, but it was pretty repeatable... I tested each spring 10 times and averaged the numbers.

The stock 70N spring took about 4.75# on average to open the bolt.

The 80N spring took about 5.45# on average to open the bolt. The extra effort is noticeable while running the bolt compared to the 70N spring but it's not heavy IMO, the action still operates smoothly. I'm going to run the 80N spring for a while and see how I like it and see if there's any difference in SD/ES or group sizes. Since I've had no failures to fire with the 70N spring and CCI 450s, and SD/ES/group sizes are all great I may reinstall the 70N spring for the lighter bolt lift and keep the 80N spring in my shooting bag just in case.

I did not test the 100N / 22.5# striker spring as I damn near launched the bolt shroud across the garage just trying to install it. It's much longer than the 70N and 80N springs; it's actually longer than the firing pin and you have to partially compress it before you can start sliding the bolt shroud over the firing pin, and I could not compress it enough to install the cocking piece with only fingertip grip on the two small ledges on the bolt shroud. The 100N spring is a pain in the ass to install compared to the 70N and 80N springs which aren't too bad. I need to make a tool that will grab the ledges on the bolt shroud or engage the two bayonet locking tabs that hold it to the bolt body so I can get a more secure grip on it to fully compress the 100N spring while keeping my fingers out of the way to install the cocking piece back on the firing pin.

Once I make a tool and get the 100N spring installed I'll report back with the actual bolt lift measurement. My hunch is the bolt lift with the 100N spring will be about 6.8#. I'm also pretty sure I won't like the bolt lift with the 100N spring installed...

Here's a pic... stock 70N spring on top (80N spring is the same length), 100N spring on bottom. You have to compress the 100N spring nearly to coil bind to get the bolt shroud down far enough to reinstall the cocking piece.

Last edited:

I have both. CDG is way better.I have seen quite a few posts here that say the CDG is better than the Nucleus at a lower price point. Unless of course the low pricing is indicative of introducing a new action into the market.

Thank you @Kiba, excellent report. My takeaway is that maybe having a 80N at hand for a CDG SA could be worth a try, certainly I don’t want to contribute to orbital waste turning my bolt shroud in a geostationary sat trying to install a 100N.

OK, got the 100N spring installed and tested.

Made a little tool out of a 0.065" thick fender washer with a 0.525" wide slot. You slip it over the bolt shroud to put pressure on the 2x bayonet lugs and the large OD fender washer allows you a much more secure grip on everything to compress the firing pin spring. (If you want to make your own, you need something with a minimum 0.510" ID to slip over the groove in the bolt shroud behind the bayonet lugs, and it can be a max thickness of 0.095".)

Even with the tool the 100N spring takes some effort to install and a slip is going to launch things across the garage, possibly sending the bolt shroud and spring to a corner of your garage that's so dark even launched AR detent pins and springs are afraid to go there...

Test numbers:

100N (22.5#) spring compression tests: 19.2# to start compressing the spring from the fired position, 23.2# when the cocking piece is flush with the back of the bolt shroud

Bolt lift effort: 6.74# average (my estimate of 6.8# last night was slightly off, sorry.)

Bolt lift is still smooth but noticeably heavier than the 70N and 80N springs, to the point it will try and rock the rifle a bit on bolt opening depending on your support/grip/bolt lift style. Would I run the 100N spring regularly? Probably not for range or match use where the rifle will be seeing a lot of rounds and you want the action to be smooth and the bolt lift to be light enough not to disturb your sight picture, but if I was using my CDG for say a dedicated hunting rifle that doesn't see a lot of use but needs to be 100% reliable regardless of conditions or dust because you have a lot of money or time wrapped up in the hunt I think I'd run the 100N spring just for peace of mind that it's going to go bang no matter what with the extra firing pin energy the 100N spring provides. No hard data to back that up, just my thoughts on the situation.

I removed the 100N spring and reinstalled the 80N spring for now. I'll do some testing with it before I decide if I want to go back to the 70N spring to keep the bolt lift nice and light and smooth and keep the 80N spring in the range bag just in case.

A couple pics.

80N spring on firing pin, note the spring is short enough to expose the tail of the firing pin, makes it easy to start and align the bolt shroud with the flats. 70N spring is the same length.

100N spring on firing pin, the spring is about 3/4" longer than the firing pin. You have to put a decent amount of compression on the spring before you can even get the bolt shroud onto the firing pin and engage the flats on the firing pin with the bolt shroud. Don't slip...

Finally, the $0.50 modified fender washer turned into a tool to help keep a secure grip on the bolt shroud when installing/removing the 100N spring. It slips into the groove just under the 2x bayonet lugs that hold the bolt shroud to the bolt body and lets you get a very secure grip on the bolt shroud and also keep your fingers out of the way when you reinstall the cocking piece and rotate it 90 degrees.

Made a little tool out of a 0.065" thick fender washer with a 0.525" wide slot. You slip it over the bolt shroud to put pressure on the 2x bayonet lugs and the large OD fender washer allows you a much more secure grip on everything to compress the firing pin spring. (If you want to make your own, you need something with a minimum 0.510" ID to slip over the groove in the bolt shroud behind the bayonet lugs, and it can be a max thickness of 0.095".)

Even with the tool the 100N spring takes some effort to install and a slip is going to launch things across the garage, possibly sending the bolt shroud and spring to a corner of your garage that's so dark even launched AR detent pins and springs are afraid to go there...

Test numbers:

100N (22.5#) spring compression tests: 19.2# to start compressing the spring from the fired position, 23.2# when the cocking piece is flush with the back of the bolt shroud

Bolt lift effort: 6.74# average (my estimate of 6.8# last night was slightly off, sorry.)

Bolt lift is still smooth but noticeably heavier than the 70N and 80N springs, to the point it will try and rock the rifle a bit on bolt opening depending on your support/grip/bolt lift style. Would I run the 100N spring regularly? Probably not for range or match use where the rifle will be seeing a lot of rounds and you want the action to be smooth and the bolt lift to be light enough not to disturb your sight picture, but if I was using my CDG for say a dedicated hunting rifle that doesn't see a lot of use but needs to be 100% reliable regardless of conditions or dust because you have a lot of money or time wrapped up in the hunt I think I'd run the 100N spring just for peace of mind that it's going to go bang no matter what with the extra firing pin energy the 100N spring provides. No hard data to back that up, just my thoughts on the situation.

I removed the 100N spring and reinstalled the 80N spring for now. I'll do some testing with it before I decide if I want to go back to the 70N spring to keep the bolt lift nice and light and smooth and keep the 80N spring in the range bag just in case.

A couple pics.

80N spring on firing pin, note the spring is short enough to expose the tail of the firing pin, makes it easy to start and align the bolt shroud with the flats. 70N spring is the same length.

100N spring on firing pin, the spring is about 3/4" longer than the firing pin. You have to put a decent amount of compression on the spring before you can even get the bolt shroud onto the firing pin and engage the flats on the firing pin with the bolt shroud. Don't slip...

Finally, the $0.50 modified fender washer turned into a tool to help keep a secure grip on the bolt shroud when installing/removing the 100N spring. It slips into the groove just under the 2x bayonet lugs that hold the bolt shroud to the bolt body and lets you get a very secure grip on the bolt shroud and also keep your fingers out of the way when you reinstall the cocking piece and rotate it 90 degrees.

Hahaha! Good stuff!…a slip is going to launch things across the garage, possibly sending the bolt shroud and spring to a corner of your garage that's so dark even launched AR detent pins and springs are afraid to go there...

And a great write up of the informal tests.

Last edited:

No thanks...it's ugly, and I wouldnt own a rifle with that name etched on the reciever.

Kinda punked out, freaky ugly clunky chunk of metal...with a screwed up name, screaming, "trying too hard to be cool"...but in actuallity embarrassing to own.

You lost me with the name on tbe side of the reciever...then the ugly takes over.

Kinda punked out, freaky ugly clunky chunk of metal...with a screwed up name, screaming, "trying too hard to be cool"...but in actuallity embarrassing to own.

You lost me with the name on tbe side of the reciever...then the ugly takes over.

Similar threads

- Replies

- 12

- Views

- 2K

Left Hand Sale

WTS/SOLD: WTT ARC Coup De Grace LA

- Replies

- 3

- Views

- 774

- Replies

- 5

- Views

- 968