Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New 6mm Advanced Rifle Cartridge

- Thread starter Gtscotty

- Start date

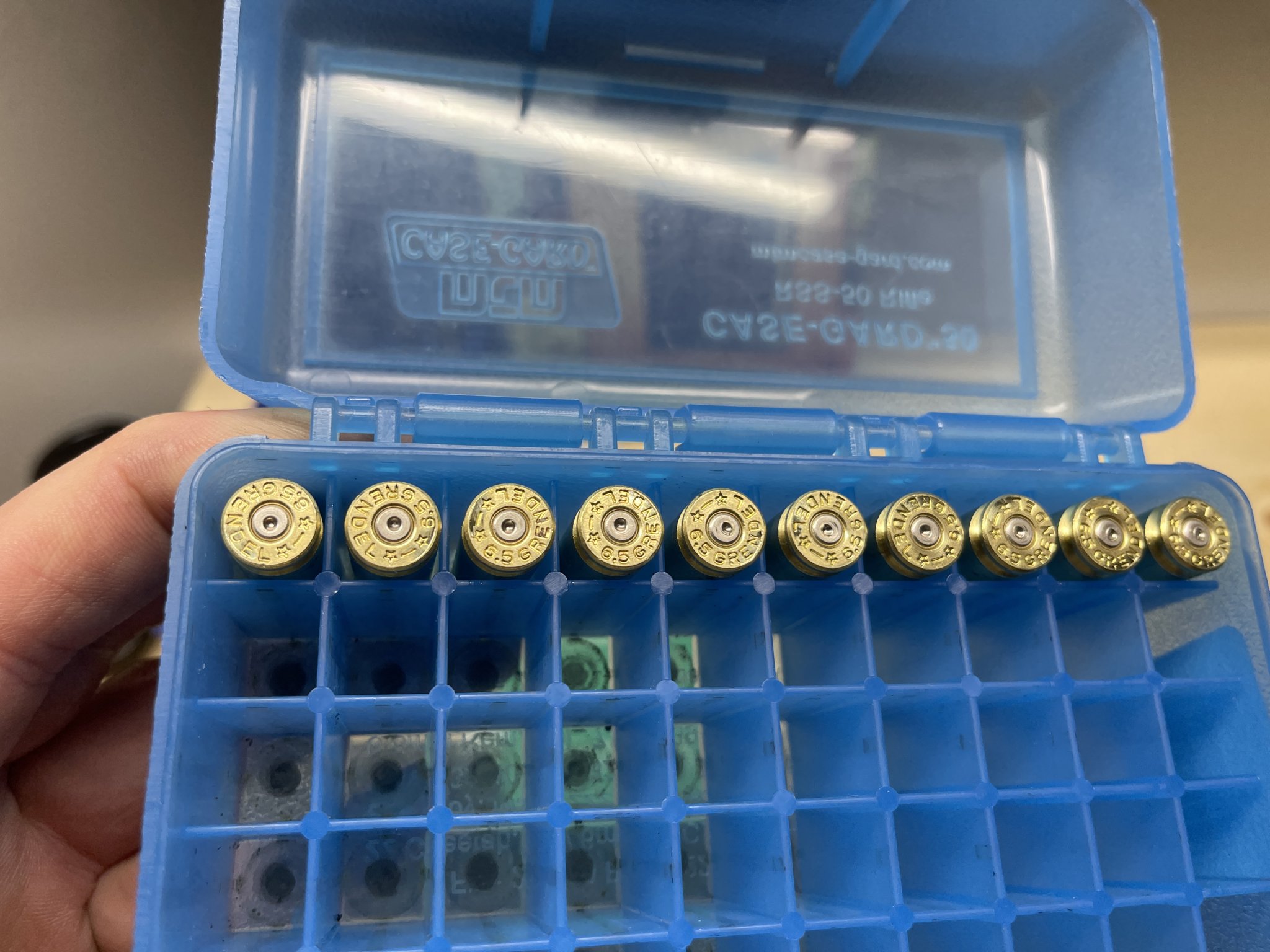

Is it normal to have extractor marks while fire forming ? I necked down some 6.5 brass and fired 10 in my new savage 110 18” barrel.

I had marks on all 10 pieces. Starter at 29.2 and went to 31 in .2 increments. The last 3 loads had very light primer cratering.

29.2 - 2662

.4 - 2689

.6 - 2691

.8 - 2713

30 - 2722

.2 - 2766

.4 - 2769

.6 - 2767

.8 - 2782

31 - 2787

You can kind of see the mark on the 3rd piece.

I had marks on all 10 pieces. Starter at 29.2 and went to 31 in .2 increments. The last 3 loads had very light primer cratering.

29.2 - 2662

.4 - 2689

.6 - 2691

.8 - 2713

30 - 2722

.2 - 2766

.4 - 2769

.6 - 2767

.8 - 2782

31 - 2787

You can kind of see the mark on the 3rd piece.

Extractor, or ejector marks? I see some ejector marks, hopefully you’re not seeing bent rims or other extractor marks.Is it normal to have extractor marks while fire forming ? I necked down some 6.5 brass and fired 10 in my new savage 110 18” barrel.

I had marks on all 10 pieces. Starter at 29.2 and went to 31 in .2 increments. The last 3 loads had very light primer cratering.

29.2 - 2662

.4 - 2689

.6 - 2691

.8 - 2713

30 - 2722

.2 - 2766

.4 - 2769

.6 - 2767

.8 - 2782

31 - 2787

You can kind of see the mark on the 3rd piece.

View attachment 8032393

It looks like you might have a rough edge on the ejector hole in your bolt face, or on the ejector itself.

Excessive headspace can also cause ejector marks, (ie you bumped the shoulders back too far) even at low pressure.

I don’t put any faith at all in cratered primers being an indicator of pressure. Way too many other details can affect fired primer appearance.

I didn’t think ejector because it’s round, and the marks on my brass are oblong. Not a circle. I need to look at the bolt.Extractor, or ejector marks? I see some ejector marks, hopefully you’re not seeing bent rims or other extractor marks.

It looks like you might have a rough edge on the ejector hole in your bolt face, or on the ejector itself.

Excessive headspace can also cause ejector marks, (ie you bumped the shoulders back too far) even at low pressure.

I don’t put any faith at all in cratered primers being an indicator of pressure. Way too many other details can affect fired primer appearance.

I’m going to load some up at 30.4. Seems to be a good flat spot. And I am more than happy with the velocity out of an 18” barrel. If I knew it was going to be pushing 2800, I would have got 500 of the 108’s instead of the 105 bthp.

I just can’t believe I’d have pressure signs at that low of a charge, I guess it’s ejector smear. I fired 1 case and then set my die to bump them back .003. I sized the cases fired here after that

I didn’t think ejector because it’s round, and the marks on my brass are oblong. Not a circle. I need to look at the bolt.

I’m going to load some up at 30.4. Seems to be a good flat spot. And I am more than happy with the velocity out of an 18” barrel. If I knew it was going to be pushing 2800, I would have got 500 of the 108’s instead of the 105 bthp.

I just can’t believe I’d have pressure signs at that low of a charge, I guess it’s ejector smear. I fired 1 case and then set my die to bump them back .003. I sized the cases fired here after that

The bolt rotates.

Don’t make load data decisions based on fireforming rounds. Used formed brass for that.

10.4 when I shoot the brass that’s already former, I’ll color the bottom with a sharpie to see if it does it again.The bolt rotates.

Don’t make load data decisions based on fireforming rounds. Used formed brass for that.

Where the brass is shiny, the edge of the case is a little rough. Could that just be a sharp edge on the extractorExtractor, or ejector marks? I see some ejector marks, hopefully you’re not seeing bent rims or other extractor marks.

It looks like you might have a rough edge on the ejector hole in your bolt face, or on the ejector itself.

Excessive headspace can also cause ejector marks, (ie you bumped the shoulders back too far) even at low pressure.

I don’t put any faith at all in cratered primers being an indicator of pressure. Way too many other details can affect fired primer appearance.

Where the brass is shiny, the edge of the case is a little rough. Could that just be a sharp edge on the extractor

The extractor is on the opposite side of the bolt from the ejector. Your extractor isn't contacting the headstamp area to make those marks, that's the ejector. It's possible you're seeing shiny marks from the extractor cutout on the bolt, but it doesn't look like it; that looks like classic (although very mild) ejector hole swipes. You could have ejector hole burrs like I said earlier, or maybe your rifle is overgassed and needs to be tuned, or a number of other things.

Hopefully you're measuring shoulder bump and comparing it to the rounds you've fired now? Remove the primers first of course, without sizing.

Where did people land on gassing of barrels? Particularly the Proof offerings? I’m assembling an upper and trying to decide if I’m going to include a Riflespeed gas block.

My experience;

Rifle+1 (Proof and CLE) seems to work with non-adjustable gas blocks unsuppressed. Suppressed will still function but be a little over gassed.

Rifle and midlength need adjustable gas if suppressed. Might get away without it unsuppressed.

Rifle+1 (Proof and CLE) seems to work with non-adjustable gas blocks unsuppressed. Suppressed will still function but be a little over gassed.

Rifle and midlength need adjustable gas if suppressed. Might get away without it unsuppressed.

Mine is a bolt gun and yea my dies are set up correctly, off the fired cases. I bought a box of hornady and shot a round, no marks.The extractor is on the opposite side of the bolt from the ejector. Your extractor isn't contacting the headstamp area to make those marks, that's the ejector. It's possible you're seeing shiny marks from the extractor cutout on the bolt, but it doesn't look like it; that looks like classic (although very mild) ejector hole swipes. You could have ejector hole burrs like I said earlier, or maybe your rifle is overgassed and needs to be tuned, or a number of other things.

Hopefully you're measuring shoulder bump and comparing it to the rounds you've fired now? Remove the primers first of course, without sizing.

Then resized a piece of fire formed brass, went with 30.4 gr of lever and colored the bottom wjth a sharpie, no more ejector marks. Must just be from the shoulder when fire forming.

The primer is Barely cratered, but with no marks on the brass, do I need to back off or should this be a safe load

My experience;

Rifle+1 (Proof and CLE) seems to work with non-adjustable gas blocks unsuppressed. Suppressed will still function but be a little over gassed.

Rifle and midlength need adjustable gas if suppressed. Might get away without it unsuppressed.

Man, as much as you usually have good input, that advice is really leaving out a huge key part of the equation.

Gas port diameter matters so much more than just gas system length in determining whether gas adjustment is needed. (Think about it - the gas block adjustment does the same thing as changing gas port diameter.) You really can't make a general statement that one gas system length needs tuning and another doesn't.

With most brands I think it's wise to install an adjustable gas block regardless of gas system length. If you know of specific barrels, like the Proof and CLE you mentioned above, that work well without it, that's different, as long as those companies don't change port diameters on those products.

I'm normally very methodical and common sensical about adding a firearm to the arsenal. It's not uncommon for me to plan a year or more before making a buy. But weird times call for weird actions. All the bizarre politicking of the last 2 years caused me to go off on a tangent and throw down a bundle of cash on the parts for this build. I'm glad I did. I have not hunted since I was a kid if you ignore a little bit of varmint sniping now and again, but I'm ready to get back into it and thought a 6 ARC AR would fill in the space for small game and varmint hunting. Plus, if the SHTF, this would work great as a hybrid battle gun that could kill at a reasonable distance. I just got it put together tonight and plan to take it out tomorrow to sight in.

Wilson Combat lightweight billet receiver and BCG

JP bolt

Proof 18" CF

Smoke Composites stock, grip & forearm

Vortex 4.5-22 x 50 Razor LHT mil

NF 20moa Ultralight mount

Javelin Pro Hunt Tac bipod

(waiting impatiently for the Nomad Ti to arrive...)

I have not yet put it on the scale but for sure it's the lightest AR that I own.

Wilson Combat lightweight billet receiver and BCG

JP bolt

Proof 18" CF

Smoke Composites stock, grip & forearm

Vortex 4.5-22 x 50 Razor LHT mil

NF 20moa Ultralight mount

Javelin Pro Hunt Tac bipod

(waiting impatiently for the Nomad Ti to arrive...)

I have not yet put it on the scale but for sure it's the lightest AR that I own.

Agree with you on this; system length and port size are obviously interrelated. In my case the barrel IS a Proof rifle +1 length which has a published port size on their website and I WILL be suppressing, which is the only reason why I’m considering an adjustable gas block.Man, as much as you usually have good input, that advice is really leaving out a huge key part of the equation.

Gas port diameter matters so much more than just gas system length in determining whether gas adjustment is needed. (Think about it - the gas block adjustment does the same thing as changing gas port diameter.) You really can't make a general statement that one gas system length needs tuning and another doesn't.

With most brands I think it's wise to install an adjustable gas block regardless of gas system length. If you know of specific barrels, like the Proof and CLE you mentioned above, that work well without it, that's different, as long as those companies don't change port diameters on those products.

Nice looking build, but before you sight it in flip that NF mount around the other way. It's on backwards.I'm normally very methodical and common sensical about adding a firearm to the arsenal. It's not uncommon for me to plan a year or more before making a buy. But weird times call for weird actions. All the bizarre politicking of the last 2 years caused me to go off on a tangent and throw down a bundle of cash on the parts for this build. I'm glad I did. I have not hunted since I was a kid if you ignore a little bit of varmint sniping now and again, but I'm ready to get back into it and thought a 6 ARC AR would fill in the space for small game and varmint hunting. Plus, if the SHTF, this would work great as a hybrid battle gun that could kill at a reasonable distance. I just got it put together tonight and plan to take it out tomorrow to sight in.

View attachment 8033352

Wilson Combat lightweight billet receiver and BCG

JP bolt

Proof 18" CF

Smoke Composites stock, grip & forearm

Vortex 4.5-22 x 50 Razor LHT mil

NF 20moa Ultralight mount

Javelin Pro Hunt Tac bipod

(waiting impatiently for the Nomad Ti to arrive...)

I have not yet put it on the scale but for sure it's the lightest AR that I own.

What are you running for buffer and spring?

@TheOE800 I just put the first rounds down a Proof cf 14.5” 6 arc AR today and had some gas related issues.

Using a proof cf 14.5” 6 arc barrel, Geissele gas block, CMC enhanced bcg, and an A5H1 buffer it had cycling issues and would not pick up the second round from a magazine. I tried several magazines from Geissele and ASC and they all had the same issue. (All the magazines work perfectly with my Proof SS 18” upper and a lower with a standard carbine/H2 lower.)

I switched the 14.5” 6 arc over to a lower from another 556 AR I had with me. With a standard carbine buffer spring and H2 buffer, the 6arc ran flawlessly. Also, the 556 upper ran perfectly with the A5H1 buffer system lower I originally had paired with the 6 arc upper.

Using a proof cf 14.5” 6 arc barrel, Geissele gas block, CMC enhanced bcg, and an A5H1 buffer it had cycling issues and would not pick up the second round from a magazine. I tried several magazines from Geissele and ASC and they all had the same issue. (All the magazines work perfectly with my Proof SS 18” upper and a lower with a standard carbine/H2 lower.)

I switched the 14.5” 6 arc over to a lower from another 556 AR I had with me. With a standard carbine buffer spring and H2 buffer, the 6arc ran flawlessly. Also, the 556 upper ran perfectly with the A5H1 buffer system lower I originally had paired with the 6 arc upper.

Nice looking build, but before you sight it in flip that NF mount around the other way. It's on backwards.

What are you running for buffer and spring?

You win! That was intentional and an attempt at humor. Giselle Super 42.

ETA: Done joking, did a scope level and bore-sighted. Time to go play.

Last edited:

@George Mac unsurprised, the A5 system is questionable and overused - what spring did you use, the sprinco green? That would exacerbate the issue. Sounds like the Proof barrels are gassed lighter, overall.

Wow! So whats the weight in this configuration?You win! That was intentional and an attempt at humor. Giselle Super 42.

ETA: Done joking, did a scope level and bore-sighted. Time to go play.

View attachment 8033698

Wow! So whats the weight in this configuration?

I'll get a weight this weekend. Sorry, tough work week chasing my tail.

If I’m building with an Aero adjustable gas block, what would you guys recommend for buffer and spring? It will be suppressed.

I always stay with the standard parts unless the setup dictates otherwise. You’ve got an adjustable gas block so I see no reason to do anything different.

...IMHO, the use of a quality adjustable gas block gives one the capability to mitigate the effects of OVER-GASSING in a platform using standard carbine buffer systems, and does nothing to enhance or mitigate an under-gassed platform. If a platform can not be made functional via the AGB alone, then how fine of adjustments the AGB has becomes a factor, which is why some folks end up adding lightweight BCG's, buffers and springs in a still "under-gassed" system or heavier buffers/springs in a still over-gassed system. If one is considering an AGB, I would suggest one that has a large range of adjustment, not the ones that only have 2 or 3 modes. Also, before assembling, take the time to actually insect the AGB as you make the adjustments to see how much and where the adjustment screw closes/opens the port. Count how many clicks from the "completely closed" position to how many clicks to the "fully opened" position is while viewing the movement of the adjustment rod as is passes over the port hole of the AGB.

Bolt gun folks running 16.5” barrels, what type of velocity are you seeing with factory 108s? I’m estimating 2525-2540fps. Looking for some real world values.

My 18” savage with 31.2 of lever is running just under 2800 with a 107 smk.Bolt gun folks running 16.5” barrels, what type of velocity are you seeing with factory 108s? I’m estimating 2525-2540fps. Looking for some real world values.

Factory Hornady 105 is much slower

Wow... That seems pretty quick. 2800 would be about right for a 6BR with a 26" barrel.My 18” savage with 31.2 of lever is running just under 2800 with a 107 smk.

Factory Hornady 105 is much slower

You are getting close to 6CM velocity:

6 Creedmoor barrel length versus muzzle velocity (31 to 17 inches)

6 Creedmoor barrel length and velocity 6 Creedmoor is rapidly rising in popularity among long range shooters. Combining an efficient case design with the wide range of excellent 6mm bullets, the 6…

rifleshooter.com

rifleshooter.com

Keep doing your thing... but I would expect 2550-2600ish with a 16" barrel.

Skyscrapin' - I think your initial estimate is a good one.

Just went back and double checked. 31.2 gr of lever had me at 2792.Wow... That seems pretty quick. 2800 would be about right for a 6BR with a 26" barrel.

You are getting close to 6CM velocity:

6 Creedmoor barrel length versus muzzle velocity (31 to 17 inches)

6 Creedmoor barrel length and velocity 6 Creedmoor is rapidly rising in popularity among long range shooters. Combining an efficient case design with the wide range of excellent 6mm bullets, the 6…rifleshooter.com

Keep doing your thing... but I would expect 2550-2600ish with a 16" barrel.

Skyscrapin' - I think your initial estimate is a good one.

I’m running 31gr and I believe that’s 2780

That's impressive. Are you seeing pressure signs? How is the brass holding up? I'm using 28 grains of lever in my gas gun and it doesn't want any more. Thanks for sharing.Just went back and double checked. 31.2 gr of lever had me at 2792.

I’m running 31gr and I believe that’s 2780

No pressure signs at all. The primers look good and the boat is not hard to lift. I was a little worried getting this 18 inch savage over the 22 inch at sportsman’s warehouse but I’m pretty impressed with the velocity for this length of barrel.That's impressive. Are you seeing pressure signs? How is the brass holding up? I'm using 28 grains of lever in my gas gun and it doesn't want any more. Thanks for sharing.

This is from a proof 16” gas gun but with 108gr ELD-M’s and 29.2gr of LeveRevolution I’m getting 2512 fps. The closest thing I have in a bolt gun is a 6mmGT in 16” for my Sig Cross and that’s pushing a 108gr ELD-M to 2800 fps. So I keep the 6ARC for gas gun only.Bolt gun folks running 16.5” barrels, what type of velocity are you seeing with factory 108s? I’m estimating 2525-2540fps. Looking for some real world values.

That's impressive. Are you seeing pressure signs? How is the brass holding up? I'm using 28 grains of lever in my gas gun and it doesn't want any more. Thanks for sharing.

"Doesn't want any more" because of actual pressure signs, or because you haven't tuned the gas system for Leverevolution loads? If you haven't tuned the rifle for Lever, that's the reason and you'll see a lot of swipes before you top out on pressure because that powder has such a different burn rate curve.

In my 243 LBC rifles (same thing as the ARC except the shoulder isn't pushed back from the Grendel) I've run a LOT of the 105 BTHP at 31.0gr Lever, although I've backed off to 30.0gr for my summer load. Lever works best when it's run hot too. I'd consider 28.0gr pretty mild, personally.

But even so, he's loading in a bolt action and can get away with hotter loads, so I wouldn't expect to get to that point without cutting bolt life pretty short in a gas gun. And if you're using Lapua or re-formed x39 brass in a gas gun you'll most likely see belts on your cases with that kind of load, within a few firings if not the first.

Still piecing my 6 ARC gas gun together, but had a good day at a local shop. Last bottle of LVR and a case of 108s @ $28/box. Looking forward to getting this thing set up in the next few weeks.

Steve - Have you rechecked head space on that barrel?? I just discovered mine set back the bottom 3 lugs in the extension. All of them actually, but the bottom 3 the most. Once that happens even with a new bolt it's misaligned & a lot of extra stress is on the 3 o clock bolt lug.I get about 1000rnds.

I have a +2 gas tube on a 26" barrel

I pulled a Rainier ultra match at about 700 rounds to switch it out for a Craddock + new bolt.

Put about 60 rnds of factory 108 through it. Already had 100 pc of 1 x Lapua sized and primed from the Rainier barrel. Checked head space of brass & WTF. Big head space difference. Sized brass from the rainier barrel is +.004 - .005 longer than fired factory loads.

I checked both barrels with the same go guage during assembly & they were within .001 & now they're .006 - .007 different.

What I haven't done before if is recheck headspace while in use. I will be now with 6 ARC.

The Rainier after 700 rounds is now gauging no go + 2 pc's of scotch tape.

Never caught it during loading because I just set up dial indicator on a stand alone comparator to a fired case & size accordingly. Guess that's a mistake in my process. I'll be ordering a headspace guage that clips on the caliper so I get an actual measurement. Then I will know if the chamber starts growing.

The bolt I was running was a Maxim and it still looks great. The lugs in the extension are what's giving up. I can live with replacing the bolt every 1000 rounds, but trashing a barrel every 700 rounds isn't going to work for me. I don't know if a new extension will time up to a barrel, never tried it??

The bottom 3 lugs in the extension are the weakest so I think they set back first putting all the stress on 4 lugs, 3 on the left, & just 1 on the right which is undercut by the extractor.

Last edited:

The gas port is drilled after the installation of the barrel extension so I find that unlikely to impossible to achieve without a custom-fitting an extension like I imagine a blended/timed brake is fit.I don't know if a new extension will time up to a barrel, never tried it??

Curious which brand of bolt’s you’ve been using?I get about 1000rnds.

I have a +2 gas tube on a 26" barrel

I don't know if a new extension will time up to a barrel, never tried it??

I've had to replace a barrel extension, once. it was a last-resort, desperation gamble to salvage a (for me) high-dollar non-returnable barrel with a totally out-of-spec BE that wasn't straight. The bore-axis of the BE was machined askew of the barrel bore-axis, crooked, how dafuq. Had to use shims between the new BE and the barrel to get the headspace to come in right. Of course, the original gas port was totally out of time. I had to plug the original gas port: partially threaded for a SS set-screw, only partially threaded so that the set-screw couldn't go fully in, and used red high-temp loctite, and staked the top of the set-screw. The abomination work is covered by the gas block anyways, And then had to drill a new gas port. 0.936" GB shoulder, so plenty of meat there. The operation was a success, i was able to salvage the barrel, otherwise it was a throw-away.

and it shoots just fine.

Last edited:

Where did you get shims?I've had to replace a barrel extension, once. it was a last-resort, desperation gamble to salvage a (for me) high-dollar non-returnable barrel with a totally out-of-spec BE that wasn't straight. The bore-axis of the BE was machined askew of the barrel bore-axis, crooked, how dafuq. Had to use shims between the new BE and the barrel to get the headspace to come in right. Of course, the original gas port was totally out of time. I had to plug the original gas port: partially threaded for a SS set-screw, only partially threaded so that the set-screw couldn't go fully in, and used red high-temp loctite. The abomination work is covered by the gas block anyways, And then had to drill a new gas port. 0.936" GB shoulder, so plenty of meat there. The operation was a success, i was able to salvage the barrel, otherwise it was a throw-away.

and it shoots just fine.

it was for an AR-10. luckily some left-over shims from AR-15 handguard kits were close enough, not perfect, but bubba-enough, I had to stack a couple of those paper-thin SS thousandth's shims. Otherwise I would have to cut them from shim stock, unless McMaster-Carr has some circular ring shims that can be trimmed close enough, I didn't look. On a positive note, I was able to sneak up on the headspace to come in perfect to just fit on the GO-gauge. This desperation work will never see the light of day. Those would've been my alternatives.Where did you get shims?

Last edited:

Steve - Have you rechecked head space on that barrel?? I just discovered mine set back the bottom 3 lugs in the extension. All of them actually, but the bottom 3 the most. Once that happens even with a new bolt it's misaligned & a lot of extra stress is on the 3 o clock bolt lug.

I pulled a Rainier ultra match at about 700 rounds to switch it out for a Craddock + new bolt.

Put about 60 rnds of factory 108 through it. Already had 100 pc of 1 x Lapua sized and primed from the Rainier barrel. Checked head space of brass & WTF. Big head space difference. Sized brass from the rainier barrel is +.004 - .005 longer than fired factory loads.

I checked both barrels with the same go guage during assembly & they were within .001 & now they're .006 - .007 different.

What I haven't done before if is recheck headspace while in use. I will be now with 6 ARC.

The Rainier after 700 rounds is now gauging no go + 2 pc's of scotch tape.

Never caught it during loading because I just set up dial indicator on a stand alone comparator to a fired case & size accordingly. Guess that's a mistake in my process. I'll be ordering a headspace guage that clips on the caliper so I get an actual measurement. Then I will know if the chamber starts growing.

The bolt I was running was a Maxim and it still looks great. The lugs in the extension are what's giving up. I can live with replacing the bolt every 1000 rounds, but trashing a barrel every 700 rounds isn't going to work for me. I don't know if a new extension will time up to a barrel, never tried it??

The bottom 3 lugs in the extension are the weakest so I think they set back first putting all the stress on 4 lugs, 3 on the left, & just 1 on the right which is undercut by the extractor.

View attachment 8083988View attachment 8083989

I admit that I don't have a ton of experience with ARs, but the feed ramp area on your Rainier is more relieved than any AR barrel I've owned. Since it's gold, like the rest of the BE, I'm assuming that's the stock ramp and not a home or smith mod? The center lug looks like it's taken some wear but the others look pretty clean. I just pulled out a new Shaw 6 ARC barrel and the lugs are not so highly relieved.

Correct ramp is stock, all I did was debur the corners. Like you said the relief cuts are pretty big.I admit that I don't have a ton of experience with ARs, but the feed ramp area on your Rainier is more relieved than any AR barrel I've owned. Since it's gold, like the rest of the BE, I'm assuming that's the stock ramp and not a home or smith mod? The center lug looks like it's taken some wear but the others look pretty clean. I just pulled out a new Shaw 6 ARC barrel and the lugs are not so highly relieved.

If you look close at the top of ramp/lug you can see the displaced metal pushed back from the bolt lugs.

Once the bottom 3 (weak lugs) give up, the remaining 4 lugs are doomed. My receiver face is trued but doesn't help when you have set back induced miss alignment.

These Grendel cases really need that Titan lug + extension @Constructor made. Then some Flip asshole stole the IP & stopped him from selling.

I recently grabbed a lightly used beer city bullets 6 arc barrel from tbt PX here. It’s the cut rifled Vortakt blank (500 series).

Using factory 108 ELDM, I had multiple half inch groups. Opened the adj GB up some and it ran well with elander mags. Rifle +1 gas system, 18” barrel. 2460 avg velocity @50 degrees today.

I’m happy and looking forward to developing loads with it using lever.

www.beercitybullets.com

www.beercitybullets.com

Using factory 108 ELDM, I had multiple half inch groups. Opened the adj GB up some and it ran well with elander mags. Rifle +1 gas system, 18” barrel. 2460 avg velocity @50 degrees today.

I’m happy and looking forward to developing loads with it using lever.

18" BCB 6MM ARC SS Match Barrel | Beer City Bullets

Beer City Bullets 18" 6MM ARC SS Match Barrel **Barrels include Black River Tactical MicroPin Gas Block and MarkBlue Gas Tube** Any 6MM ARC Bolts added to cart will be headspaced to your barrel. Add your JP Enhanced Bolt/Bolt Completion Kit here. The BCB 6MM ARC Barrels were created to fill a...

www.beercitybullets.com

www.beercitybullets.com

Steve - Have you rechecked head space on that barrel?? I just discovered mine set back the bottom 3 lugs in the extension. All of them actually, but the bottom 3 the most. Once that happens even with a new bolt it's misaligned & a lot of extra stress is on the 3 o clock bolt lug.

I pulled a Rainier ultra match at about 700 rounds to switch it out for a Craddock + new bolt.

Put about 60 rnds of factory 108 through it. Already had 100 pc of 1 x Lapua sized and primed from the Rainier barrel. Checked head space of brass & WTF. Big head space difference. Sized brass from the rainier barrel is +.004 - .005 longer than fired factory loads.

I checked both barrels with the same go guage during assembly & they were within .001 & now they're .006 - .007 different.

What I haven't done before if is recheck headspace while in use. I will be now with 6 ARC.

The Rainier after 700 rounds is now gauging no go + 2 pc's of scotch tape.

Never caught it during loading because I just set up dial indicator on a stand alone comparator to a fired case & size accordingly. Guess that's a mistake in my process. I'll be ordering a headspace guage that clips on the caliper so I get an actual measurement. Then I will know if the chamber starts growing.

The bolt I was running was a Maxim and it still looks great. The lugs in the extension are what's giving up. I can live with replacing the bolt every 1000 rounds, but trashing a barrel every 700 rounds isn't going to work for me. I don't know if a new extension will time up to a barrel, never tried it??

The bottom 3 lugs in the extension are the weakest so I think they set back first putting all the stress on 4 lugs, 3 on the left, & just 1 on the right which is undercut by the extractor.

View attachment 8083988View attachment 8083989

@357Max / @steve podleski

I've only recently become interested in the 6mm ARC for NRA Highpower competition. Without making me finish reading all 56 pages of this thread can you summarize your experiences?

Are you pushing things to the limit to be getting these reduced round counts??? I shoot a .220 Thunderbolt in a bolt action, but the developer originally used it in an AR for Highpower comp and routinely got several thousand rounds of barrel life.

Thanks for your help.

Ross

@Kimber.204 - The ARC seems like a pretty efficiant little cartridge & I was pushing it fairly hard. Mild recoil & could see trace from a bag shooting 600. Wasn't to picky & liked 95vld's - 109LRHT.

I'm not familiar with the Thunderbolt?

If you decide to go with the ARC, I'd say go 24" or more for barrel. IMO the 6ARC & 224 Valk are ballistically even. The ARC will hit the plates harder at distance. The Valk has been more picky with bullets, but it has a stronger bolt & can be pushed a little harder. If your just punching paper I'd go with a 24" Valkyrie. 77RDF's are consistantly under 3/4 moa @2940 from my 18" barrel.

I haven't had the best luck with the ARC so far as barrels go.

1st was an Odin 21" + 2" gas. It ran great, but accuracy went to shit after the first 60 rounds. It had a bur on the huge (.102) gas port that crossed the land. Started peeling copper. Odin replaced it & I still have that new stick in the corner.

2nd was the 22" + 2 " Rainier UM I bought while impatiently waiting for the Odin replacement. Ran about 150 factory 108 loads & then worked on hand loads trying a bunch of different bullets 95 -110gr. Accuracy was good, but not stellar. Pulled it at about 700

Never blew a primer & pockets still tight after 3 firings. Headspace on that Rainier grew .013, just measured it. Maybe/hopefully the Rainier either had a soft extension or they just chopped to much out of those lower lugs with their ramp cut?

3rd Currently have a Craddock Bartlain 22" + 2" 7.25T I've only put 42 rounds of factory 108 through it so far. It's all set up to allow mag feeding @2.380 max coal.

First hand loads will go down range next weekend. 95 Seneca's, 100TGK, & 105 Hyb's as the main focus. Hoping to find a good load for the 105's @ 2675 - 2720, call it done & shoot some matches with it.

I'm not familiar with the Thunderbolt?

If you decide to go with the ARC, I'd say go 24" or more for barrel. IMO the 6ARC & 224 Valk are ballistically even. The ARC will hit the plates harder at distance. The Valk has been more picky with bullets, but it has a stronger bolt & can be pushed a little harder. If your just punching paper I'd go with a 24" Valkyrie. 77RDF's are consistantly under 3/4 moa @2940 from my 18" barrel.

I haven't had the best luck with the ARC so far as barrels go.

1st was an Odin 21" + 2" gas. It ran great, but accuracy went to shit after the first 60 rounds. It had a bur on the huge (.102) gas port that crossed the land. Started peeling copper. Odin replaced it & I still have that new stick in the corner.

2nd was the 22" + 2 " Rainier UM I bought while impatiently waiting for the Odin replacement. Ran about 150 factory 108 loads & then worked on hand loads trying a bunch of different bullets 95 -110gr. Accuracy was good, but not stellar. Pulled it at about 700

Never blew a primer & pockets still tight after 3 firings. Headspace on that Rainier grew .013, just measured it. Maybe/hopefully the Rainier either had a soft extension or they just chopped to much out of those lower lugs with their ramp cut?

3rd Currently have a Craddock Bartlain 22" + 2" 7.25T I've only put 42 rounds of factory 108 through it so far. It's all set up to allow mag feeding @2.380 max coal.

First hand loads will go down range next weekend. 95 Seneca's, 100TGK, & 105 Hyb's as the main focus. Hoping to find a good load for the 105's @ 2675 - 2720, call it done & shoot some matches with it.

What is everyone’s goto powder for the arc, lever? My 6 arc is a 18” proof for now. I might order a 20” Craddok to match my other 224 Valk craddok barrel.

For 224 Valk I’m using CFE, Varget and H4895.

For 224 Valk I’m using CFE, Varget and H4895.

I admit that I don't have a ton of experience with ARs, but the feed ramp area on your Rainier is more relieved than any AR barrel I've owned. Since it's gold, like the rest of the BE, I'm assuming that's the stock ramp and not a home or smith mod? The center lug looks like it's taken some wear but the others look pretty clean. I just pulled out a new Shaw 6 ARC barrel and the lugs are not so highly relieved.

Yeah, those feed ramps are carved out way bigger than necessary. Not sure why they'd do that, other than the 6 ARC still being new enough that some companies are trying weird stuff. No reason to have that much material taken out of the lugs for those huge feed ramps though, and it makes the lugs weaker.

Steve - Have you rechecked head space on that barrel?? I just discovered mine set back the bottom 3 lugs in the extension. All of them actually, but the bottom 3 the most. Once that happens even with a new bolt it's misaligned & a lot of extra stress is on the 3 o clock bolt lug.

I pulled a Rainier ultra match at about 700 rounds to switch it out for a Craddock + new bolt.

Put about 60 rnds of factory 108 through it. Already had 100 pc of 1 x Lapua sized and primed from the Rainier barrel. Checked head space of brass & WTF. Big head space difference. Sized brass from the rainier barrel is +.004 - .005 longer than fired factory loads.

I checked both barrels with the same go guage during assembly & they were within .001 & now they're .006 - .007 different.

What I haven't done before if is recheck headspace while in use. I will be now with 6 ARC.

The Rainier after 700 rounds is now gauging no go + 2 pc's of scotch tape.

Never caught it during loading because I just set up dial indicator on a stand alone comparator to a fired case & size accordingly. Guess that's a mistake in my process. I'll be ordering a headspace guage that clips on the caliper so I get an actual measurement. Then I will know if the chamber starts growing.

The bolt I was running was a Maxim and it still looks great. The lugs in the extension are what's giving up. I can live with replacing the bolt every 1000 rounds, but trashing a barrel every 700 rounds isn't going to work for me. I don't know if a new extension will time up to a barrel, never tried it??

The bottom 3 lugs in the extension are the weakest so I think they set back first putting all the stress on 4 lugs, 3 on the left, & just 1 on the right which is undercut by the extractor.

Huge feed ramps aside, usually setting back a few lugs on either the bolt or barrel extension (rather than all lugs evenly) means the bolt is mostly making contact on just those lugs. The most likely cause of that is the receiver face being crooked, unless the upper has a tight thermo-fit bore although it's still possible even then. Was this upper receiver face trued prior to assembly?

If the upper was trued, then it's more difficult to sort out, but has to be a dimensional issue with the bolt carrier, barrel extension, or bolt itself. If lug contact was even all around, you shouldn't see 3 lugs set back like that. Something seems screwy there.

I think that's an important detail with any Grendel-based cases, especially for those of us who might care to push the pressures up a little. In my experience, when everything is trued and bolt lug contact is even, the Grendel bolts can last a long time even with hot loads. But with uneven lug contact, all that pressure gets put on just a few lugs, and that's partly why we see broken bolts. IME, with good lug contact the standard AR15 bolt and extension design is completely adequate, but most people don't even consider this even though it's a common topic in bolt action circles.

It wasn't just the bottom 3 lugs but you can visibly see metal pushed back on those. I rechecked headspace with a new bolt to isolate how much of this is extension vs bolt. Used a go guage followed by no go & it still closed with 2 x scotch tape on no go. Put both gauges in head space comparator. From the go gauge it's now +.013 loose just in the extension.Huge feed ramps aside, usually setting back a few lugs on either the bolt or barrel extension (rather than all lugs evenly) means the bolt is mostly making contact on just those lugs. The most likely cause of that is the receiver face being crooked, unless the upper has a tight thermo-fit bore although it's still possible even then. Was this upper receiver face trued prior to assembly?

If the upper was trued, then it's more difficult to sort out, but has to be a dimensional issue with the bolt carrier, barrel extension, or bolt itself. If lug contact was even all around, you shouldn't see 3 lugs set back like that. Something seems screwy there.

I think that's an important detail with any Grendel-based cases, especially for those of us who might care to push the pressures up a little. In my experience, when everything is trued and bolt lug contact is even, the Grendel bolts can last a long time even with hot loads. But with uneven lug contact, all that pressure gets put on just a few lugs, and that's partly why we see broken bolts. IME, with good lug contact the standard AR15 bolt and extension design is completely adequate, but most people don't even consider this even though it's a common topic in bolt action circles.

This is a VLTOR F-15 monolithic upper. I drilled and tapped a lapping tool special for this upper & trued the face. It cleaned up quicker than most. It then got a full wrap of .001 ss shim. Heat gun was needed on the upper to get it in there with the shim stock. The bolt slid in this thing like butter when I assembled it.

Lesson learned for me is that I need to incorporate a better way to monitor head space change when loading. I think I'll just set aside one of the first fired pieces of brass as a control to check against. I never caught this because I just zero my dial indicator to fired brass & bump shoulders back .002

I was non the wiser head space had been growing. Was using the mock up rounds I made when the Rainier was new to check distance to the lands in this Craddock & they chambered fine. Then when I was ready to load I checked the primed/prepped brass & it wouldn't chamber. I thought I'd put away a good barrel, turns out it's junk along with that Maxim bolt dammit.

Just went back and counted all rounds up in my book. That Rainier only had 446 rounds on it. I thought it was closer to 700. Might give them a call. The bolt looks perfect, but I still don't trust it. Now I'm thinking that extension might be soft.

On the bright side I put a new JP bolt in the Craddock & at least I checked the prepped brass before loading a bunch of rounds that wouldn't chamber.

Now I'm thinking that extension might be soft.

That's really the only possible explanation here, if everything else was actually trued up with even lug contact. The extension should be way too hard for any metal to be bent or displaced; lugs can/will break off a normal good extension before that can happen. Same for the bolt lugs; wear is one thing, but bent or displaced metal means it's too soft and a bad part. In-spec AR bolts and barrel extensions are pretty dang hard; not quite as hard as a file but way too hard to be deformed like you've described.

If it were me I'd be contacting Rainier to get that barrel replaced. Their match & ultramatch barrels are usually excellent, but sometimes bad parts slip through like maybe a batch of soft extensions, especially in the last couple years with covid and slipping quality control issues throughout a lot of industries. They may even already be aware of a batch of soft barrel extensions, if not they'll probably want to know about it.

Normally you shouldn't have to track headspace movement; it just plain shouldn't move other than maybe a very tiny amount right at first as the lugs wear a little bit during break in. This is nothing related to the 6 ARC or any other cartridge, and all about an out of spec part.

Similar threads

- Replies

- 21

- Views

- 961