Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Range Report The Hornady 140 amax ammo. The OLD VS THE NEW

- Thread starter Aimsmall55

- Start date

-

- Tags

- hornady

Does anyone know what the lot # was on the stuff Mile High just had for sale? I know it's the new box and I believe it's 313####. I just bought 2 cases two weeks ago. I'm at work and am freakin out after reading this.

Does anyone know what the lot # was on the stuff Mile High just had for sale? I know it's the new box and I believe it's 313####. I just bought 2 cases two weeks ago. I'm at work and am freakin out after reading this.

If you go on gunbroker and search for "Creedmoor" in the ammo listings, Mile High has theirs listed. In the picture you can see the pallet of ammo with all the lot#s visible. I just checked it a few days ago

I had 1,000 rounds of a lot that I recently sold off the remainder of because I have enough 4350 and 140 hybrids. It was definitely in the 313xxxx range but I did not have the issues described above. It chronoed with an ES of around 25. Sometimes it was more sometimes it was less. Grouped well. I would say it was solid 1/2 MOA ammo. I didn't expect it to shoot hole in hole and it didn't often. That doesn't mean its not great Factory Match Ammo.

If you go on gunbroker and search for "Creedmoor" in the ammo listings, Mile High has theirs listed. In the picture you can see the pallet of ammo with all the lot#s visible. I just checked it a few days ago

looks like a few different lots there. I'll have to check when I get home.

Curious to see what the outcome of this is. Hopefully Hornady comes out of the wood works with some information. I have a GAP Crusader in 6.5 creedmoor, and I'm not setup for reloading so I rely on the factory stuff. I recently ordered a couple hundred rounds of the Hornady 140's from sgammo as they had them for a decent price. Hopefully it wasn't a waste of money...

looks like a few different lots there. I'll have to check when I get home.

Yeah, it was, best as I could tell it was all 313xxxx. I don't know that anyone has nailed down where exactly the train left the tracks, but it sounds as though the earlier 313 lot#s may still be okay.

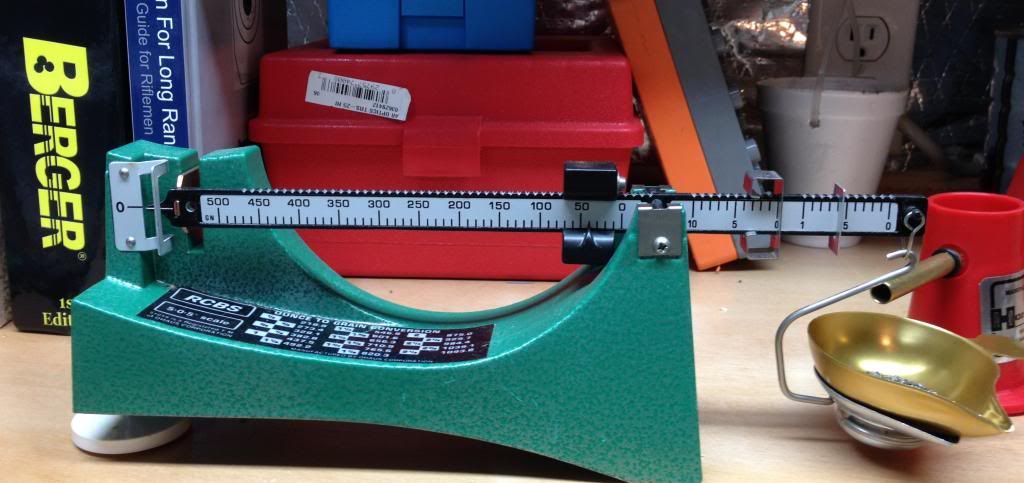

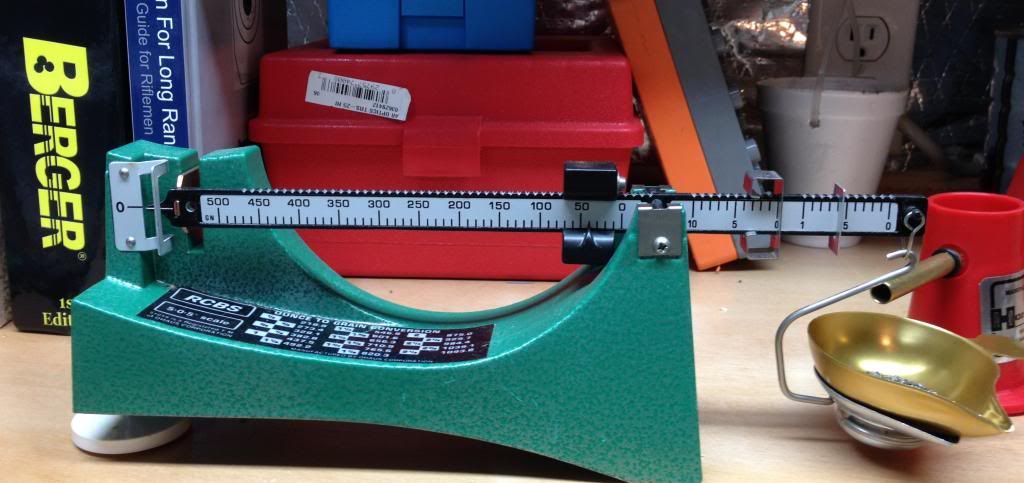

I shot the Hornady 140gr Amax yesterday out of a brand new gun. It was not bad, shot 3 groups at .6 moa at 100 yards. Every single primer was cratered and also had a couple with marks on the headstamp. I got home and broke one apart and measured it and it had 43.8 gr of something in it. It looks black instead of my H4350 powder I opened. The H4350 was more gray. I have no clue what is in the ammo. The ammo was brand new, just bought it the other day.

I just spoke with Gary at Hornady tech. support. He said that the powder is and always was 4350. He said they buy the powder in bulk and the coatings are not always the exact same colors this the differences in this picture. As for the popped primers he said to check for copper fowling. He said to have anyone with issues call them right away and they would be happy to help, even offered to pressure test rounds from the boxes people are having problems with. I had no problems with their customer service and had no hold time at all. Would be very curious to hear what they have to say to KJB1796or others with issues.

I just spoke with Gary at Hornady tech. support. He said that the powder is and always was 4350. He said they buy the powder in bulk and the coatings are not always the exact same colors this the differences in this picture. As for the popped primers he said to check for copper fowling. He said to have anyone with issues call them right away and they would be happy to help, even offered to pressure test rounds from the boxes people are having problems with. I had no problems with their customer service and had no hold time at all. Would be very curious to hear what they have to say to KJB1796or others with issues.

Halleluiah!!!! That's great news that at least Hornady is now tracking the issue and it's hopefully resolved once some more guys with hard data are able to clue them into to what you're seeing. Even though I don't have my 6.5CM rifle yet, it's way too expensive to be used as a floor lamp for lack of ammunition.

I just spoke with Gary at Hornady tech. support. He said that the powder is and always was 4350. He said they buy the powder in bulk and the coatings are not always the exact same colors this the differences in this picture. As for the popped primers he said to check for copper fowling. He said to have anyone with issues call them right away and they would be happy to help, even offered to pressure test rounds from the boxes people are having problems with. I had no problems with their customer service and had no hold time at all. Would be very curious to hear what they have to say to KJB1796or others with issues.

Ha!! No FREAKING WAY that's h4350 with the lots I've pulled for the brass. Hate to tell ya... either Gary doesn't know or he's lying. THE LOADS I'VE PULLED ARE NOT H4350. Unless there has been a new design change from a single based kernel to a ball powder

Ha!! No FREAKING WAY that's h4350 with the lots I've pulled for the brass. Hate to tell ya... either Gary doesn't know or he's lying. THE LOADS I'VE PULLED ARE NOT H4350. Unless there has been a new design change from a single based kernel to a ball powderThat's BULLSHIT

I was just giving him second hand info. it would be much better if you called and let us know what they say.

1-800-338-3220 Option 3

I just spoke with Gary at Hornady tech. support. He said that the powder is and always was 4350. He said they buy the powder in bulk and the coatings are not always the exact same colors this the differences in this picture. As for the popped primers he said to check for copper fowling. He said to have anyone with issues call them right away and they would be happy to help, even offered to pressure test rounds from the boxes people are having problems with. I had no problems with their customer service and had no hold time at all. Would be very curious to hear what they have to say to KJB1796or others with issues.

That isn't the colour of any ADI powder that I have ever seen.

ADI make the H4350, it is ADI 2209.

Also didn't someone post up weights that were different to the H4350 data on the packets ?

I think [MENTION=70]Rob01[/MENTION] should clarify this. If I call they'll probably give me the same story. I wasn't trying to insult you in that post. I was just simply shocked Gary would tell you that crap!!!

That isn't the colour of any ADI powder that I have ever seen.

ADI make the H4350, it is ADI 2209.

Also didn't someone post up weights that were different to the H4350 data on the packets ?

I've seen 41.6 100v and 43.8 r19. 100v is 100%. R19 is the only other powder at 43.8 that would be at a 57,000 psi pressure

Again, I just wanted some clarity since I just dropped 750.00 on 3 case of it (3133078). But all I have to contribute is hearsay and that doesn't hold a glass of water... Bottom line is they do answer their phone and are willing to help. It was starting to sound like they were ducking people. Lets hear what they have to say to the people who actually have the problems.

I think [MENTION=70]Rob01[/MENTION] should clarify this. If I call they'll probably give me the same story. I wasn't trying to insult you in that post. I was just simply shocked Gary would tell you that crap!!!

I have said all I have to say on the subject. Tried to help and got my balls busted. I'm done.

I have said all I have to say on the subject. Tried to help and got my balls busted. I'm done.

Rob, I wasn't trying to bust balls in the other thread, I posted in there stating that. Its no biggie, my frustration was with Hornady and not you but looking back I can see how you thought it may have been with you, my apologies.

Rob, I wasn't trying to bust balls in the other thread, I posted in there stating that. Its no biggie, my frustration was with Hornady and not you but looking back I can see how you thought it may have been with you, my apologies.

That's fine and I accept but this issue has people in a lather and not looking at the big picture or thinking very reasonably about the subject as a whole so I am not going to get into it anymore. As stated Hornady CS is only a phone call away.

I have said all I have to say on the subject. Tried to help and got my balls busted. I'm done.

I don't see where you posted in this thread?

I hope Hornady gets it figured out either way. A little disheartening to have your group size double and its not the shooters fault.

That's fine and I accept but this issue has people in a lather and not looking at the big picture or thinking very reasonably about the subject as a whole so I am not going to get into it anymore. As stated Hornady CS is only a phone call away.

I will be calling tomorrow but this is, IMHO a big issue for people who shoot this caliber that are non-reloaders or not sponsorsed. Most guys that shoot this caliber I think are more "weekend warriors" that like to shoot a very competitive caliber at compeitions with out giving up anything to handloads or substantially more expensive options like Nosler or Copper Creek. Nothing last forever though I guess. Like I said, hopefully Hornady will get this figured out.

Not to say Aimsmall doesn't know what he's talking about but he and a few others on 65creedmoor.com are sure that's not H4350 and with Gary saying it is, I'm not feeling any comfort yet in 2014.

Thanks for the replies though.

I don't see where you posted in this thread?

I hope Hornady gets it figured out either way. A little disheartening to have your group size double and its not the shooters fault.

I didn't. I posted in one of the other threads on the subject but was mentioned here so I responded here.

Punisher those are still 2013 lots. Not 2014.

[MENTION=26751]Pusher591[/MENTION] Im curious to see whats got you all worked up over these newer lots of ammo? Surely youve shot the new stuff more than a couple of times? Care to post any groups from your rifle?

I just shot a 3 day rifle course last weekend with my 26" Krieger barrelled 6.5 Creedmoor with lots 312xxx and 313xxx. At 100 meters I shot a 1/2" group with the 312xxx and a 1/3" group with the 313xxx out of my 2-6th cold bore shots of the morning on day 2 and 3. It was 55 degrees, 1600ft and raining both mornings. I am not having a huge difference in accuracy between the two lots.

***EDIT *** 3/29 I went back to my boxes and they were 309xxx and 310xxx lots.

***EDIT *** 3/29 I went back to my boxes and they were 309xxx and 310xxx lots.

Last edited:

Is this decline in accuracy only the case with the 140 AMAX or is it the case with their entire line of 6.5 Creedmoor rounds?

Do you guys think Hornady may be having just as hard a time as everyone else getting H4350 and had to find a substitute?

Who knows... One observation is that everyone who had a "problem" has failed to post back with an update after contacting Hornady...

Who knows... One observation is that everyone who had a "problem" has failed to post back with an update after contacting Hornady...

I emailed hornady. I had pretty much every 140 (5 boxes of 313xxx) showing pressure signs and crazy large groups 1+ inches. It was also having a lot fo powder fouling that i dont usually get with 4350. my reply from hornady was its probably your rifle, but basically to send us back the unfired rounds and we will reimburse. And of course i just wanted them for the brass so i dont really care, but it is happening. Some rifles more than others. My personal rig is a 22 incher so its a little more sensitive to sweet spots though.

Here's a test I did yesterday at 300 yards with 140 Amax. Orange diamond target is lot #3132438 and black dot target is lot # 3121293

These were shot in succession back to back w/o me knowing which lot I was shooting at the time, loaded in two mags. FWIW...

<iframe src="https://www.flickr.com/photos/120056813@N02/13084054533/player/dbe4aa17e6" height="336" width="500" frameborder="0" allowfullscreen webkitallowfullscreen mozallowfullscreen oallowfullscreen msallowfullscreen></iframe>

"Tactical thumb" covers lot # 312 but not # 313. This is by no means an exhaustive or scientific test. Just someone pulling some rounds out and shooting groups. I only have one more box of the new stuff (#313), and 11 boxes of the older (#312). YMMV.

These were shot in succession back to back w/o me knowing which lot I was shooting at the time, loaded in two mags. FWIW...

<iframe src="https://www.flickr.com/photos/120056813@N02/13084054533/player/dbe4aa17e6" height="336" width="500" frameborder="0" allowfullscreen webkitallowfullscreen mozallowfullscreen oallowfullscreen msallowfullscreen></iframe>

"Tactical thumb" covers lot # 312 but not # 313. This is by no means an exhaustive or scientific test. Just someone pulling some rounds out and shooting groups. I only have one more box of the new stuff (#313), and 11 boxes of the older (#312). YMMV.

I was one of the guys commenting on pressure sighns with the 140A-MAX in a new savage 12 LRP. I contacted Hornady and was told that Savage makes their barrels on the tight side of SAMMI specs and that it doesn't take much fouling to cause pressure spikes. They asked that I slug my barrel and make sure it wasent too small. I'm in the proccess of doing that. They also said I could send in the 10 rounds I have left for pressure testing.

I contacted Savage and was told that I should not have followed the barrel break in procidure on their website because their barrels don't need break in. They only have it on their site because customers demand it. Part of the breakin on their site is to shoot, clean, add two drops of oil to patch and push it through the barrel, then shoot again. I always shoot from a dry barrel but per their instructions I used the two drops of oil. The guy at Savage told me to go out and give it another go and make sure the barrel is DRY.

Once I slug the barrel and make sure that it's within spec I'll consider running the my last 10 rounds through but I'm not sure if/when I'll get to that because my reloading components arrived and I'll likely stick to handloads from here.

I'll report back when I slug the barrel.

I contacted Savage and was told that I should not have followed the barrel break in procidure on their website because their barrels don't need break in. They only have it on their site because customers demand it. Part of the breakin on their site is to shoot, clean, add two drops of oil to patch and push it through the barrel, then shoot again. I always shoot from a dry barrel but per their instructions I used the two drops of oil. The guy at Savage told me to go out and give it another go and make sure the barrel is DRY.

Once I slug the barrel and make sure that it's within spec I'll consider running the my last 10 rounds through but I'm not sure if/when I'll get to that because my reloading components arrived and I'll likely stick to handloads from here.

I'll report back when I slug the barrel.

Last edited:

I was one of the guys commenting on pressure sighns with the 140A-MAX in a new savage 12 LRP. I contacted Hornady and was told that Savage makes their barrels on the tight side of SAMMI specs and that it doesn't take much fouling to cause pressure spikes. They asked that I slug my barrel and make sure it wasent too small. I'm in the proccess of doing that. They also said I could send in the 10 rounds I have left for pressure testing.

I contacted Savage and was told that I should not have followed the barrel break in procidure on their website because their barrels don't need break in. They only have it on their site because customers demand it. Part of the breakin on their site is to shoot, clean, add two drops of oil to patch and push it through the barrel, then shoot again. I always shoot from a dry barrel but per their instructions I used the two drops of oil. The guy at Savage told me to go out and give it another go and make sure the barrel is DRY.

Once I slug the barrel and make sure that it's within spec I'll consider running the my last 10 rounds through but I'm not sure if/when I'll get to that because my reloading components arrived and I'll likely stick to handloads from here.

I'll report back when I slug the barrel.

Remember me posting about the barrel possibly be undersize in the bore and or grooves....? Trying to slug the barrel and measure to the .xxxx" is tough to get a accurate reading. If you want to send us the barrel I'd be willing to measure the bore and groove size for you.

The groove being tighter than the bore (the bore is the tops of the lands) will have more of a impact on pressures.

I've also seen barrels (different maker) where it was completely marked with the wrong caliber. Guy bought a rifle and it was suppose to be a 7mm-08. Turned out the barrel was a .308win. and he was shooting 7mm-08 ammo thru it. He couldn't figure out why the gun was shooting 4" groups at a 100 yards. We sent it back to the factory for him and the factory promptly replaced the barrel with the correct caliber.

Later, Frank

Good shooting.

It is interesting how the ammo performs in .4" groups and 1.25" groups.

I agree... I guess it comes down to what each particular rifle likes.

On another note ... I've been pulling rounds left and right here lately for the brass.. The primer pockets on one lot were so far out of whack I don't know how they even primed them. The pockets had a cone shape ( meaning the flash hole was TOWARDS THE HEAD OF THE CASE). I tried priming one just for the hell of it and it was impossible to do w/ o damaging the primer. So I had open up the pockets ALOT. Then uniformed then and deburred. They were fine after that. Never seen any hornady brass that bad.

So basically I had to pull the bullets.... Then complete EVERY step. Primer pockets... Trimming ... Weight sorting... Ect. I'd buy Nosler if it wasn't so expensive.

. . .If you want to send us the barrel I'd be willing to measure the bore and groove size for you.

Later, Frank

I just may take you up on that. I'll put an order in for the nut wrench so that I'll have it on hand in case It comes to that.

Thanks Frank!

I just picked up my second lot of #313 factory ammo. First lot was 3132922 and the most recent lot is 3133018. Both shoot very well and hold the same 100 yard zero POI and dope out to 500 yards. I only tested accuracy at 100 yards and both lots resulted in multiple 3 round groups with all holes touching or clover leaf.

The only odd thing I noticed was that I cleaned my rifle before this range trip and it took nearly 20 rounds for the groups to settle in at 100 yards. I did not overly clean but it had me worried after 10 rounds and my groups were not consistent. Thought I might have damaged my barrel. After 20 rounds, it was back to typical groups.

The only odd thing I noticed was that I cleaned my rifle before this range trip and it took nearly 20 rounds for the groups to settle in at 100 yards. I did not overly clean but it had me worried after 10 rounds and my groups were not consistent. Thought I might have damaged my barrel. After 20 rounds, it was back to typical groups.

I just realized, if I did the math correctly(?), that my group above with the #312 lot ammo was 0.2 MOA!

It measured 0.649" at 300 yards.

Grp size / (3 x 1.047) -----> 0.649" / 3.141 = 0.206 MOA....is that right?

Pretty dang good? It was only 3 shots though.

I had a little better performance with the #313 lots yesterday though, but shot at 100 on a dot drill. I want to take them to at least 500 and see how they group. I'm not that vested in them because I started reloading and am about out of factory ammo. FWIW.

It measured 0.649" at 300 yards.

Grp size / (3 x 1.047) -----> 0.649" / 3.141 = 0.206 MOA....is that right?

Pretty dang good? It was only 3 shots though.

I had a little better performance with the #313 lots yesterday though, but shot at 100 on a dot drill. I want to take them to at least 500 and see how they group. I'm not that vested in them because I started reloading and am about out of factory ammo. FWIW.

I agree... I guess it comes down to what each particular rifle likes.

On another note ... I've been pulling rounds left and right here lately for the brass.. The primer pockets on one lot were so far out of whack I don't know how they even primed them. The pockets had a cone shape ( meaning the flash hole was TOWARDS THE HEAD OF THE CASE). I tried priming one just for the hell of it and it was impossible to do w/ o damaging the primer. So I had open up the pockets ALOT. Then uniformed then and deburred. They were fine after that. Never seen any hornady brass that bad.

So basically I had to pull the bullets.... Then complete EVERY step. Primer pockets... Trimming ... Weight sorting... Ect. I'd buy Nosler if it wasn't so expensive.

same, i was just getting brass so i didnt care too much about the lot. But damn the primer pockets were killing me. i finally just broke down and set up the drill press to turn the cutter. Some were so deep that the tool didnt even scratch off the burnt powder, others were 20 seconds of scraping to size.

Reloading issue- I have just re-barreled my Defiance Rebel action with a heavy Pac-Nor and it refuses to shoot the 140 AMAX, like up to 2 moa groups at 100 yds. This is the second new barrel fitted as we thought the first one must have been a dud (a different manufacturer). However, the current barrel will shoot 142 SMK's into less than 3/8 moa for 5 rounds all the way to 500 yds.

I am replicating the factory load as well as tweaking it above and below. I really do think there is an issue with this batch of projectiles I have. They are new ones I got early this year. there seems to be nothing else I can check.

My old barrel shot 140 AMAX's below half minute for years.

I am replicating the factory load as well as tweaking it above and below. I really do think there is an issue with this batch of projectiles I have. They are new ones I got early this year. there seems to be nothing else I can check.

My old barrel shot 140 AMAX's below half minute for years.

To complicate the issue, there now appears to be a Lot #314xxx-- available. Has anyone had the chance to try this one and wee how it compares to 312 and 313?

I am going to revise my earlier post. I previously said that lot 313xxx 140's was good for my Scalpel.

I must have not looked at the box correctly when I shot it because I got 2 blown primers and ejector pocket dimples on the 12 rounds I recently shot out of one box before I stopped because cases were difficult to extract after firing.

I ended up calling Hornady and they asked me to send the spent cases and an extra box of the lot to them for testing.

They confirmed receipt of the ammo this week and are supposed to get back to me after they pressure test the boxes I sent.

I will post results once I hear back.

Sent from my SCH-I545 using Tapatalk

I must have not looked at the box correctly when I shot it because I got 2 blown primers and ejector pocket dimples on the 12 rounds I recently shot out of one box before I stopped because cases were difficult to extract after firing.

I ended up calling Hornady and they asked me to send the spent cases and an extra box of the lot to them for testing.

They confirmed receipt of the ammo this week and are supposed to get back to me after they pressure test the boxes I sent.

I will post results once I hear back.

Sent from my SCH-I545 using Tapatalk

Also, so far the Hornady customer service has been exceptional. I called and they answered right away. Within an hour they confirmed the service inquiry with an email and free shipping label. The next business day after receiving the shipment they email confirmed receipt of the ammo and told me they would get to me with the results as soon as possible.

So far they are not afraid to work hard for their customers.

Sent from my SCH-I545 using Tapatalk

So far they are not afraid to work hard for their customers.

Sent from my SCH-I545 using Tapatalk

Last edited:

I am going to revise my earlier post. I previously said that lot 313xxx 140's was good for my Scalpel.

I must have not looked at the box correctly when I shot it because I got 2 blown primers and ejector pocket dimples on the 12 rounds I recently shot out of one box before I stopped because cases were difficult to extract after firing.

I ended up calling Hornady and they asked me to send the spent cases and an extra box of the lot to them for testing.

They confirmed receipt of the ammo this week and are supposed to get back to me after they pressure test the boxes I sent.

I will post results once I hear back.

Sent from my SCH-I545 using Tapatalk

My shooting partner has a 6.5 Scalpal. Mine is a GAP. Both of ours shoot like shit with the newer lots but his Scalpal did the exact same thing. Blowing primers ect.... I thought initially it was a fluke, but the ammo is consistently fucked. Either it's too hot, or the bullet is "flawed" or you get pierced primers... I pulled all my left over stuff and dumped the powder and bullet. The primer pockets were ATTROCIOUS!

Other than some poor groups previously with this ammo, I had my first experience with pressure issues/problems with these yesterday....mostly with the 120 gr. ammo. Temps were high 40's to low 50's, partly cloudy and I was in the shade. Ammo was by no means hot. I had difficult bolt lift and ejector marks on almost all of them. I stopped shooting the stuff. The 140's started to exhibit this too, but the 120's were the worst. I could group 5 in the same hole at 100 with the 140's, but about 1" with the 120's.

When I got home I pulled one of the 120's and the box states 39.0 gr Varget. I weighed 40.6 gr. with it. Who at Hornady do I need to contact? Just basic CS?

L - R: 120 Amax, 120 Amax, 140 Amax

Powder from 120 Amax, 40.6 gr. Varget?

When I got home I pulled one of the 120's and the box states 39.0 gr Varget. I weighed 40.6 gr. with it. Who at Hornady do I need to contact? Just basic CS?

L - R: 120 Amax, 120 Amax, 140 Amax

Powder from 120 Amax, 40.6 gr. Varget?

Last edited:

Similar threads

- Replies

- 2

- Views

- 115

- Replies

- 30

- Views

- 860

Reloading Equipment

Various reloading components, ammo, dies cleanout.

- Replies

- 2

- Views

- 535

- Replies

- 50

- Views

- 2K