Yeah lol, that's what I get for working on 2 rifles at once.I think you mean .245. I also used honed Forster dies. They are the BEST for low runout, like no more than .001!

David

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.22 br

- Thread starter Dai Bando

- Start date

Seasoning in barrel #2, spun it on, took 3 shots to get close zero, and sent 10 more. 9 shots of 10 touching. 28.3gr varger with 90smk jumping 30k running right at 2900fps. It was a hammer on steel at the range today. Shooting my 6" plate at 400y from kneeling position was just one silver poi at center, easily half for 5 shots. This barrel is a 28" hvy varm muellerworks 7tw 219bore. Manzella Precision cut this with a 255nk 130k freebore chamber. This was done on necked down 6br brass that was formed to someone else chamber prior as I bought this brass with 2-3, firings last year when 6br lapua wasn't easy to find.

Ok my 22br with 88gr at 2960 is showing 1.334 with a 8 twist. Should I try working up a load for them or switch to the 85.5 gr?

Ok my 22br with 88gr at 2960 is showing 1.334 with a 8 twist. Should I try working up a load for them or switch to the 85.5 gr?

Huh?

Is 8 twist with a stability factor of 1.334 enough to pursue considering I'll be using it for prs. There's a big difference between 100 yards and 1000. Would I be better off concentrating on 85.5 berger over the 88eld?

Yea I don't care what bullet you use...8 twist has low rpm and shows stability issues using berger calculator.... I run in the 3030-3050 range with 7.5 twist

So I was necking down virgin 6br brass in my Redding type S FL bushing sizer and ran into some problems, hoping someone here might have an answer. My first pass was with a .260 intermediate bushing, neck was sized all the way down to the shoulder, Bo problems. Next pass was with the final .249 bushing. This one left about an 1/8” unsized. Die won’t go in any farther and is bottomed out on the shell holder, it it shouldn’t need to since the previous bushing sizer the whole neck!

With the die bottomed out, hopefully you're not bumping shoulders back. Does the sized down brass chamber fine in your rifle? If so, load em and send it. This brass will for to your chamber and all will be well. All bushing dies will leave a small portion of the neck unsized.So I was necking down virgin 6br brass in my Redding type S FL bushing sizer and ran into some problems, hoping someone here might have an answer. My first pass was with a .260 intermediate bushing, neck was sized all the way down to the shoulder, Bo problems. Next pass was with the final .249 bushing. This one left about an 1/8” unsized. Die won’t go in any farther and is bottomed out on the shell holder, it it shouldn’t need to since the previous bushing sizer the whole neck!

Chances are, the intermediate bushing was leaving a small portion as well, but it's much less detectable when it's only 005 per side, now it's 010 per side. The only way to eliminate this, is to use a Hornady or equivalent 22cal neck sizing die. They're designed to size the neck only, but completely.

The problem is, going from 268 to 244 the the expander ball to 248, it's a lot of working the brass, and runout occurs. Using an intermediate bushing prior to the neck die helps a lot. But that's a lot of damn work to do when the stuff needs formed anyway. My heavily runout brass shot half moa breaking in the barrel, its a BR variant, it'll shoot.

Neck down with the bushing die as far as you can, but do not shoulder bump, as long it'll chamber(a small amount of resistance on bolt close is okay) load and shoot! Second firing that bulge at the base will be gone. Another tip, make sure you're bushing retention stem is screwed down to where it's tight against the bushing, and back out 1/8th a turn, just enough for the bushing to float, then lock the retention stem into place. This will ensure you're sizing as much neck as possible without bumping the shoulders.

Yeah I measured and I’m not bumping shoulders. I don’t have my barrel back from the gun smith yet so no way to tell if they’ll chamber. It’s far more than a doughnut tho, I use the same Redding dies in all my other calibers and have never seen this much unsized neck. The weird thing is it didn’t do it with the larger bushing, and I could definitely see where it was sizing to. I have the die set up just like you suggest.

I have had this same thing with every full size Forster die I have. I just got my 22BR die from Forster so before I sized any brass I took my measurements. What I do is put the GO gauge in the press with the stem out of the die. I always set my sizing dies up so that the shell holder and the die kiss. This makes my sizing process have a constant volume because a hard case can not stop things prematurely.So I was necking down virgin 6br brass in my Redding type S FL bushing sizer and ran into some problems, hoping someone here might have an answer. My first pass was with a .260 intermediate bushing, neck was sized all the way down to the shoulder, Bo problems. Next pass was with the final .249 bushing. This one left about an 1/8” unsized. Die won’t go in any farther and is bottomed out on the shell holder, it it shouldn’t need to since the previous bushing sizer the whole neck!

So with the GO gauge you want to either have a stronger kiss or a hard stop. My as manufactured dies all have no feel that the GO gauge is touching the shoulder, so hence I can never set the shoulder back to a SAMII minimum chamber. You have 2 choices to fix that. Either you grind the top of the shell holder off or the bottom of the die. I use Redding Competition shell holders to control how much I set back so grinding the top of the die is out. I take the die ut of the press, turn it upside down and put the GO gauge in the die. I measure what the distance is from the rim of the die to the bottom of the GO gauge. This should be .150 but mine have been from .185 to .160. Now I know how much I need to take off. I use the grinding wheel in my drill press and just carefully put the bottom of the die in and grind for a minute and measure, keeping that up till I get what I want.

Another point to remember that the actual shoulder/neck junction is a few thousands higher than a 6BR case junction is. The neck you are sizing down is folded down to form the hypotenuse of a right triangle whose base is the difference between the starting case to the final case. In this example it is .265 - .248 = .017 then to find how high the junction we use Tan(30) x .017 = height change or .0098.

I know it sucks but if you want full control of your brass you have to make sure everything lines up and you can control what happens in order to have the most consistant brass possible. Another point is that different manufacturer's brass sizes differently. That is where the Redding competition shell holders come in. I figure which one is needed for which manufacturer to move the shoulder back to exactly the same spot in the chamber.

Just to remove any doubt I am anal and OCD.

David

Yeah I could see that being an issue if I was unable to bump shoulders, but it’s the neck that’s the issue. I have almost a quarter of the neck left unsized, I would have to trim a whole lot off the die to size that and then I’d be smashing shoulders

Are you sure the bushing is close to the bottom of the die well. Usually you set it to be loose only .010 so it can self center.Yeah I could see that being an issue if I was unable to bump shoulders, but it’s the neck that’s the issue. I have almost a quarter of the neck left unsized, I would have to trim a whole lot off the die to size that and then I’d be smashing shoulders

Have you used a GO gauge to see if the shoulder is even close?

Most bushings have a taper, which leaves a portion unsized, the bushings that have the least amount of taper are whidden.

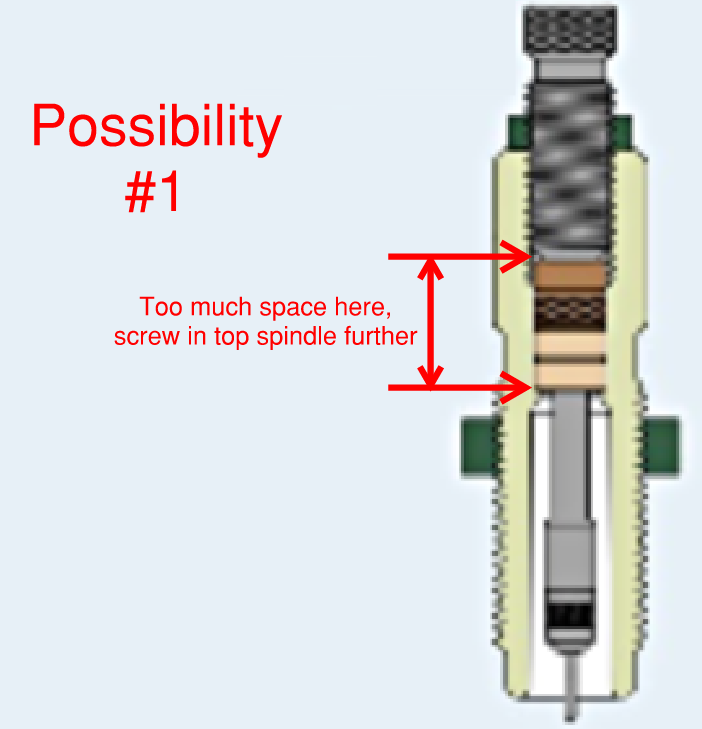

This seems like a die setup problem, unless the bushing has an issue. The two things that come to mind are:

1) The bushing has too much room above it, and it's lifting up during the sizing op. Redding's site says this: "The adjustable decapping rod allows you to adjust the bushing position, sizing only part of the neck length when desired." I suspect this is your issue; you've got this "adjustment" set too high, and just need to screw the bushing down further.

2) The bushing was incorrectly machined, and you're seeing the actual profile of what's inside the bushing. This isn't very likely, but it's super easy to tell: the bushing will have a lip inside that matches what you're seeing on the case neck.

1) The bushing has too much room above it, and it's lifting up during the sizing op. Redding's site says this: "The adjustable decapping rod allows you to adjust the bushing position, sizing only part of the neck length when desired." I suspect this is your issue; you've got this "adjustment" set too high, and just need to screw the bushing down further.

2) The bushing was incorrectly machined, and you're seeing the actual profile of what's inside the bushing. This isn't very likely, but it's super easy to tell: the bushing will have a lip inside that matches what you're seeing on the case neck.

Sorry for the nitpicky questions but: is it bottoming out on the black lock ring, or is it bottoming out on the bushing? The lock ring on the spindle should be free-spinning when the spindle bottoms out.I have the de-capping rod screwed all the way in till it bottomed out, then Back an 1/8th of a turn for a small amount of float

I’m not familiar with Redding bushings, but is there a top and bottom side to it, or can you insert the bushing in either orientation and it works properly both ways?

It’s bottomed out on the bushing not the lock ring, and they have sides but I’ve tried both orientations

I am using a SAC 22BR die sizing 6BR once fire Alpha Brass. I am having a hard bolt closure. Seems like it’s contacting right below the shoulder. I have some ammo that came with the barreled action that chambers fine to measure off of. Included in attachments

Attachments

I am using a SAC 22BR die sizing 6BR once fire Alpha Brass. I am having a hard bolt closure. Seems like it’s contacting right below the shoulder. I have some ammo that came with the barreled action that chambers fine to measure off of. Included in attachments

Did you order or purchase a 22 cal mandrel or decapping pin from them? There dies done work without the mandrel or decapping pin in the dies

Did you order or purchase a 22 cal mandrel or decapping pin from them? There dies done work without the mandrel or decapping pin in the dies

Just the 22BR sizer with .248 bushing

If it’s there newer ones (modular sizing die) then they require a mandrel or there decapping pin in place for proper sizing. The br modular sizing die comes with a 6mm decapping rod and requires a different one for a 22br. I only know this due to issues with there bra die for my 22braJust the 22BR sizer with .248 bushing

If it’s there newer ones (modular sizing die) then they require a mandrel or there decapping pin in place for proper sizing. The br modular sizing die comes with a 6mm decapping rod and requires a different one for a 22br. I only know this due to issues with there bra die for my 22bra

Short Action Customs Modular 6mm BR (Bench Rest), 22 BR (Bench Rest),

The Short Action Customs Modular Neck Sizer Die has a unique design where the cartridge’s body geometry is sized by the die body, the...

This is what I ordered

Short Action Customs Modular 6mm BR (Bench Rest), 22 BR (Bench Rest),

The Short Action Customs Modular Neck Sizer Die has a unique design where the cartridge’s body geometry is sized by the die body, the...www.midwayusa.com

This is what I ordered

Yes so that is their modular sizing die. The way there does work it requires their mandrel or a decapping rod in order for it to work properly. I also was having issues when this is what they told me. I got the mandrel for it and it works perfect.

Because their dies are universal for case bodies and are adjustable for calibers by there neck/shoulder bushing, you’ll will need to order there 22 cal decapping rod or a 22 cal mandrel to fit in the die.

Also, tell me if anyone’s ever heard of this: at the recommendation of folks on this thread, I sent my blank to straight jacket to have nick chamber it up since I’ve been told he’s an expert on 22br. To my surprise he said that it’s a finicky cartridge, high pressure, and I should ditch it in favor of 22GT. He also said that I either need to neck turn (even with a .255 chamber and non bushing size down ) or that he needs to sink the reamer .020” deeper to give room for the donut and then fire form the cases to that spec. Never heard of the need for either of these give the reamer spec. What do you guys think?

Also, tell me if anyone’s ever heard of this: at the recommendation of folks on this thread, I sent my blank to straight jacket to have nick chamber it up since I’ve been told he’s an expert on 22br. To my surprise he said that it’s a finicky cartridge, high pressure, and I should ditch it in favor of 22GT. He also said that I either need to neck turn (even with a .255 chamber and non bushing size down ) or that he needs to sink the reamer .020” deeper to give room for the donut and then fire form the cases to that spec. Never heard of the need for either of these give the reamer spec. What do you guys think?

He's full of shit! And I'd actually say the other way around. Both my 22br barrels shoot lights out with many different bullets and powders... 22GT on the other hand took a lot more effort to find a consistent shooting load.... I'm shooting PVA 22br reamer on one barrel and my custom 22br reamer on another and I've never turned a single neck...

And I have ZERO donut issues on my 500pc of lapua brass...

He's full of shit! And I'd actually say the other way around. Both my 22br barrels shoot lights out with many different bullets and powders... 22GT on the other hand took a lot more effort to find a consistent shooting load.... I'm shooting PVA 22br reamer on one barrel and my custom 22br reamer on another and I've never turned a single neck...

And I have ZERO donut issues on my 500pc of lapua brass...

Buddy of mine who shoots F-class had the same issue. His 22br and 6br shoots light out without any load devs but it was a huge struggle to find a good consitent load with his 6GT, same excellent smith, same blanks manufacture, same reamer (manson with pilot), alpha brass, same bullets etc. It just feels like the BR is much more forgiving ...

As of right now I told him to just sink it .020” deep if that’s what he thinks best and I’ll just fireform to that spec I guess. You guys see any issues with this? Seems like a step I shouldn’t have to do after reading all these posts but also probably won’t hurt

That sounds like a load of crap to me. I’ve had 0 issues and while the gt’s are great cartridges and perform amazing, I don’t know of a single br that hasn’t been the simplest cartridge for the user.Also, tell me if anyone’s ever heard of this: at the recommendation of folks on this thread, I sent my blank to straight jacket to have nick chamber it up since I’ve been told he’s an expert on 22br. To my surprise he said that it’s a finicky cartridge, high pressure, and I should ditch it in favor of 22GT. He also said that I either need to neck turn (even with a .255 chamber and non bushing size down ) or that he needs to sink the reamer .020” deeper to give room for the donut and then fire form the cases to that spec. Never heard of the need for either of these give the reamer spec. What do you guys think?

I've found the gt to take more work if you're seeking micro accuracy, however getting them to consistently shoot 10 shot groups in the 3s and 4s not that difficult. I know br comp chases accuracy in 1s and 2s.Buddy of mine who shoots F-class had the same issue. His 22br and 6br shoots light out without any load devs but it was a huge struggle to find a good consitent load with his 6GT, same excellent smith, same blanks manufacture, same reamer (manson with pilot), alpha brass, same bullets etc. It just feels like the BR is much more forgiving ...

Sinking a 22br reamer 20k deep...........retarded! You can order a reamer with a lil longer neck to compensate for the neck down growth in length, or just trim it. Changing headspace by 20k to make room for a donut, that's a hard no. 22gt is a fun case, I retired my match barrel at 1k due to it requiring tuning more than I liked, but I just had a 22" 3b cut in 22gt for a predator and Antelope gun.

Last edited:

I wouldn’t do that. For reference my OBW 22BR from PVA shot the same exact load with 88’s for over 1k rounds. Then I switched to 85.5’s and shot the same load for another 1k rounds. Speed never changed with either bullet. Sample size of 1, but mine was not difficult to keep in tune.As of right now I told him to just sink it .020” deep if that’s what he thinks best and I’ll just fireform to that spec I guess. You guys see any issues with this? Seems like a step I shouldn’t have to do after reading all these posts but also probably won’t hurt

If you do that you're probably going to have to jam bullets in the lands during fireforming to reduce the chances of case head separation. Wouldn't you think Padom.

Just leave enough neck unsized for minor resistance on bolt close. Will form up no matter of seating depth. However, I strongly disagree with this deep chamber suggestion from SJA.If you do that you're probably going to have to jam bullets in the lands during fireforming to reduce the chances of case head separation. Wouldn't you think Padom.

Last edited:

Yeah, me too.Just leave enough neck unsized for minor resistance on bolt close. Will form up no matter of seating depth. However, I strongly disagree with this deep chamber suggestion from SJA.

Also, tell me if anyone’s ever heard of this: at the recommendation of folks on this thread, I sent my blank to straight jacket to have nick chamber it up since I’ve been told he’s an expert on 22br. To my surprise he said that it’s a finicky cartridge, high pressure, and I should ditch it in favor of 22GT. He also said that I either need to neck turn (even with a .255 chamber and non bushing size down ) or that he needs to sink the reamer .020” deeper to give room for the donut and then fire form the cases to that spec. Never heard of the need for either of these give the reamer spec. What do you guys think?

I don't see how a BR would be higher pressure and more finicky than a GT...

As of right now I told him to just sink it .020” deep if that’s what he thinks best and I’ll just fireform to that spec I guess. You guys see any issues with this? Seems like a step I shouldn’t have to do after reading all these posts but also probably won’t hurt

Sinking the reamer .020 is changing the established headspace. When fireformed ( if it will even fire) will lengthen the case body .020 and shorten the neck. And i don’t see how this solves any problem

David

His theory: the extra necked down brass volume has to go somewhere, it usually ends up at top of shoulder/base of neck. Changing the position of the neck shoulder junction by 0.020 gives this added brass a place to go. The thing is, there isn't a problem so far in 3 sizings on my lapua brass. Necks grew by about 004-007 when I fl sized the necks down with the Hornady die. They've all been trimmed to same length now and all is well.Sinking the reamer .020 is changing the established headspace. When fireformed ( if it will even fire) will lengthen the case body .020 and shorten the neck. And i don’t see how this solves any problem

David

Yes that’s what he told me, he was saying that extra brass has to go somewhere and if you don’t want it to go to the inside of the neck it’s best absorbed into the shoulder. So I’m gonna see how it goes and just jam 20 thou on first firing. I’ll let you know how it goes

Decided to take my most recent 22BR Bartlein out today. I did extensive testing with my Mullerworks 1-7 22BR that PVA chambered with their reamer which I believe is 0.104FB reamer... I had my own 22BR reamer made with 0.130fb a while back and got a Bartlein 1-7.5 HV blank that I had PVA chamber with my reamer last year. I never did load development on the new barrel.. Just loaded up known good loads from my MW 1-7 barrel and shot maybe 100rd through it. It was a tack driver with those loads.

I decided to do a mini OCW today with my favorite bullet, 90smk with IMR 4166. This powder performed great in my first barrel and I have a few 8lb jugs of it so why not.

POI was so consistent across all but the very last charge... Low node right at 28.7-29.0gr with stupid low ES/SD and excellent accuracy. Also a high node around 29.9 - 30.2gr, also with amazing accuracy and stupid low ES/SD. I didn't experience any heavy bolt lift or pressure signs until that very last charge of 30.5gr and it was a hot humid day out... Started to just get a little heavy bolt lift.

High node is too fast for my needs even though the group is in the 0.1's and SD 2.. Ill shoot the low node around 3000 with same SD 2 for barrel life. Will load up a seating depth test with 28.7gr and see if I can shrink that group any more...

Just going from 7 to 7.5 twist in 22BR has really made everything stupid consistent with the heavies. The 7 twist really hammered the 80smk and 80 VLD but I would get unexplained fliers, inconsistent accuracy. That all went away and shoots like any BR with 7.5 twist...

I decided to do a mini OCW today with my favorite bullet, 90smk with IMR 4166. This powder performed great in my first barrel and I have a few 8lb jugs of it so why not.

POI was so consistent across all but the very last charge... Low node right at 28.7-29.0gr with stupid low ES/SD and excellent accuracy. Also a high node around 29.9 - 30.2gr, also with amazing accuracy and stupid low ES/SD. I didn't experience any heavy bolt lift or pressure signs until that very last charge of 30.5gr and it was a hot humid day out... Started to just get a little heavy bolt lift.

High node is too fast for my needs even though the group is in the 0.1's and SD 2.. Ill shoot the low node around 3000 with same SD 2 for barrel life. Will load up a seating depth test with 28.7gr and see if I can shrink that group any more...

Just going from 7 to 7.5 twist in 22BR has really made everything stupid consistent with the heavies. The 7 twist really hammered the 80smk and 80 VLD but I would get unexplained fliers, inconsistent accuracy. That all went away and shoots like any BR with 7.5 twist...

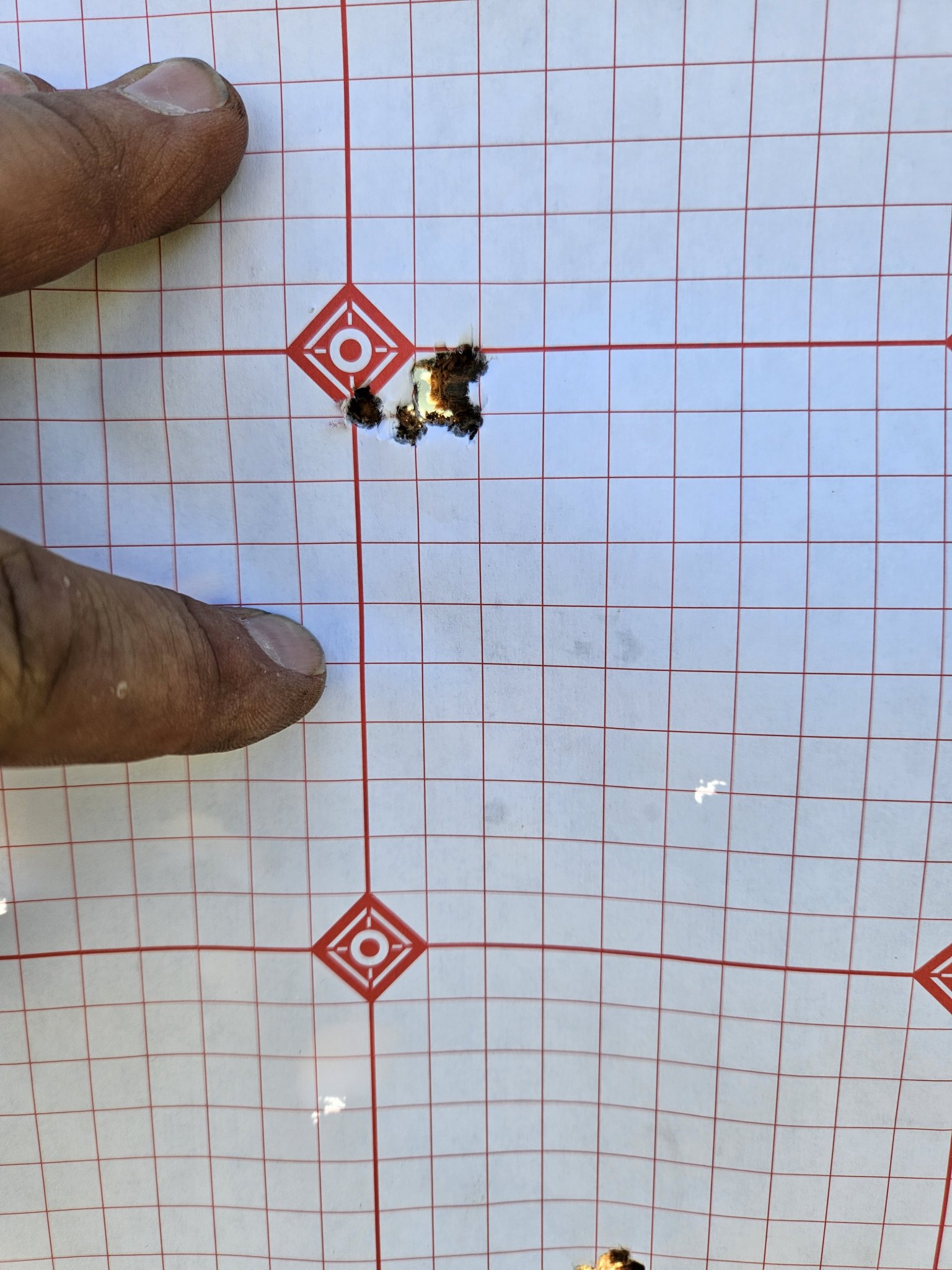

Went back to the shop and loaded up a seating depth test with the 28.7gr charge. We have a pretty nasty storm forecasted here in a few hours, possible tornado, hail and guaranteed high winds/heavy rain. Wind was starting to pick up from this morning's OCW test. Was gusting between 10-13 mph but it obviously didnt matter with these results!

Farthest I tested from the lands shot the tightest group at 0.112". But, every single seating depth shot in the 0.3's or better so this load is pretty darn solid if you ask me. I didn't chrono each seating depth test separately, but I did run the Labradar for all of the tests combined and it still shot 2980 SD 7. The rounds closer to the lands were registering roughly 10-12fps faster than the farther from the lands.

I don't chase velocity. Never have. Accuracy over velocity all day. My 220TB 90smk load I shot for years was 2983 SD 7 with 28.6gr Varget, so this is pretty dead on what I've always shot these 90smk's at.

Time to load up 100rd and get some groups tested from 300-700yd next.

Farthest I tested from the lands shot the tightest group at 0.112". But, every single seating depth shot in the 0.3's or better so this load is pretty darn solid if you ask me. I didn't chrono each seating depth test separately, but I did run the Labradar for all of the tests combined and it still shot 2980 SD 7. The rounds closer to the lands were registering roughly 10-12fps faster than the farther from the lands.

I don't chase velocity. Never have. Accuracy over velocity all day. My 220TB 90smk load I shot for years was 2983 SD 7 with 28.6gr Varget, so this is pretty dead on what I've always shot these 90smk's at.

Time to load up 100rd and get some groups tested from 300-700yd next.

Loaded up 100rd with the 28.7gr 4166 0.02 off lands load. Goal was to go out and do some accuracy testing at 300, 400, 500 and 700. Unfortently, that wasnt happening today. I got to the range and it was crazy windy and full sun. The mirage was horrible and had a switching 10-20mph wind from 6 to 2 oclock.

I decided not to waste ammo and shot a few groups at 200yd.. All groups were 0.4moa or smaller. This was the best group I shot when I timed the wind correctly. Oh well, Ill try again on a calmer day..

I decided not to waste ammo and shot a few groups at 200yd.. All groups were 0.4moa or smaller. This was the best group I shot when I timed the wind correctly. Oh well, Ill try again on a calmer day..

90smk shoot really well in my rifle as well, 28.5 Varg jumping 30k they're at 2950 since the barrel sped up.

Yep Varget shoots really well for me also. I just wanted to try to find a load with some other powders I had a bunch of that I wasnt using for anything else so I tested this 4166.. Its shooting great.

29.4gr with a 90smk is my 22BR Varget load... 3016 SD 1 / ES 2

Seems pretty hot with the heavies...Yep Varget shoots really well for me also. I just wanted to try to find a load with some other powders I had a bunch of that I wasnt using for anything else so I tested this 4166.. Its shooting great.

29.4gr with a 90smk is my 22BR Varget load... 3016 SD 1 / ES 2

How much freebore and what's your COAL with the 90s ?

Seems pretty hot with the heavies...

How much freebore and what's your COAL with the 90s ?

Not even close to hot with my reamer. Im running 0.130 FB and a little tighter Lapua no turn neck than most. I tested up to 30.0gr Varget SD 3 and just started getting a little bit of heavy bolt lift there.

I tested 4166 up to 30.2gr 3093 with the 90smk and was just barely starting to get a little bit of a heavy bolt on that last 30.2gr charge. Nothign on 29.9gr....

Searched through a lot of past posts , anyone have any expedience with the Nosler 85 gn RDF ? I picked up a couple of hundred off my local gun forum, thought I'd load some for cooler weather

Searched through a lot of past posts , anyone have any expedience with the Nosler 85 gn RDF ? I picked up a couple of hundred off my local gun forum, thought I'd load some for cooler weather

What powder? What case?

You can just take any of the 85.5 Berger data Ive posted and work up around that.... Your gonna need to do load workup for your rifle anyway so just start around there...

I'd say start around 28.5 gr Varg, 4166, 15.5, N150 burn rate and work up, max will likely be around 30.5-31grSearched through a lot of past posts , anyone have any expedience with the Nosler 85 gn RDF ? I picked up a couple of hundred off my local gun forum, thought I'd load some for cooler weather

Similar threads

Reloading Equipment

WTS .. Seating dies BR,Dasher , Creed

- Replies

- 3

- Views

- 550