Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

8.6 Blk reloading info

- Thread starter unclemoak

- Start date

If it has space then how is the bolt tight?I don’t feel comfortable fireing it as is cause the brass has room to expand and makes me feel it will blow the brass

And we use brass specifically for its ability to expand.

Compare the brass to a reamer or chamber print then. IF you want to find out what the problem is you will have to do something to find out what the problem is.

Absolutely!Post some before and after measurements for both the fired and sized state of the brass base/shoulder/neck diameters and then the comparator reading for the shoulder set back.

If one of those numbers doesnt get smaller its your culprit.

Dang auto correct it does not have room to expand sorry

Also I shoot a lot of dasher stuff and do a ton of reloading but I just can’t figure this deal out and it being a new caliber for hornady to make dies for makes me think the dies r just a tad off because when I started out the shoulder moved some when I kept moving the die down but I’m to the point now we’re my die is all on the shell holder with a very hard cam over

Also I shoot a lot of dasher stuff and do a ton of reloading but I just can’t figure this deal out and it being a new caliber for hornady to make dies for makes me think the dies r just a tad off because when I started out the shoulder moved some when I kept moving the die down but I’m to the point now we’re my die is all on the shell holder with a very hard cam over

Text me I’ll helpDang auto correct it does not have room to expand sorry

Also I shoot a lot of dasher stuff and do a ton of reloading but I just can’t figure this deal out and it being a new caliber for hornady to make dies for makes me think the dies r just a tad off because when I started out the shoulder moved some when I kept moving the die down but I’m to the point now we’re my die is all on the shell holder with a very hard cam over

I'm curious to find out what they say about 300 Blk as another powder for 8.6 Blk. I wonder if Hornady is trying out different powders as well. I think it's more about the pressures but I hope we would see other alternatives that have been officially tested in a lab.I sent a message into Faxon yesterday, but no response as of yet. I'll be sure to post anything they come back with here.

Also agree on working on some loads with CFE BLK due to proximity in burn chart. I think I remember the charge weights being within a grain or so in 300 BLK, so could probably use those ratios as a starting point and ease into it is what I was thinking.

I finally got it working after bruising my chest - expander will likely never move again. I think lack of lube may also have been a factor; 5 cases later, I got a stuck case (ripped the rim off the head). I bought a set of Hornady dies. Using the exact same method and lube I had been using with the Lee dies, it works fine! Lots of pressure obviously, but it works well.It takes an extreme amount of tightening, bottom line. If it still moves, are you annealing the cases before cutting and then sizing? Knurling on the shaft to make it less smooth might help. Next option: contact Lee for a replacement. are you using a LOT of lube on your case, including the inside? What brand of cases are you using for the conversion? I use RCBS. It's like baby snot.

I am using Lapua 6.5CM cases. These cases are thick! Hopefully, this will translate into more reloadings per case.

I don't completely understand the annealing process (meaning the metalurgical reasoning), so I have been hesitant to adopt it.

Annealing is absolutely necessary when aggressively expanding and sizing brass. I suggest you do some research on why annealing is so important in the case of wildcatting.I finally got it working after bruising my chest - expander will likely never move again. I think lack of lube may also have been a factor; 5 cases later, I got a stuck case (ripped the rim off the head). I bought a set of Hornady dies. Using the exact same method and lube I had been using with the Lee dies, it works fine! Lots of pressure obviously, but it works well.

I am using Lapua 6.5CM cases. These cases are thick! Hopefully, this will translate into more reloadings per case.

I don't completely understand the annealing process (meaning the metalurgical reasoning), so I have been hesitant to adopt it.

When you mention RCBS are you referring to the die cleaner?The stuck case is an indication of why you were having so much trouble with the expander. Not enough lube. To move that much metal around takes something akin to baby snot, and when you pick it up, it's hard to hold on to. That's why I use RCBS, and clean them with Simple Green & water after sizing.

Oh ok…I use brass juice it’s a spray on. I do larger volume and it’s been probably the best I’ve found even better than lanolin spray. It smells like peppermint too.

Probably because you’re not using an AMP annealer. With flame annealers you only get a partial anneal. So I can see why you’d need baby snot consistency for a case lube. I’m running batches of 500 or more during a day so I can’t spend a lot of time rubbing down one case at a time in lube to convert. I just anneal my batch (most time consuming part), run it through a Honey Badger case trimmer to 1.690” then move over to the FL sizing die, then off to the Giraud Case trimmer where it’s final trimmed to 1.680”, chamfered, and debur in one step and brass is ready to go after walnut/cob mix tumbling. I load for resale and time is money.I'm not familiar with it. I have learned to move that much metal takes something that strongly resembles baby snot. When I pick up a lubed one up, I have to be careful, or I will drop it. I have tried several spray-ons, including the ones from Hornady and RCBS. Fine for standard re-sizing, but just not slimy enough for brass conversion, IMO.

Attachments

-

70842425-7169-4D77-A870-126257800819.png601.5 KB · Views: 142

70842425-7169-4D77-A870-126257800819.png601.5 KB · Views: 142 -

FAED5376-0BCB-4DCF-916B-C84B0B739945.jpeg345.1 KB · Views: 151

FAED5376-0BCB-4DCF-916B-C84B0B739945.jpeg345.1 KB · Views: 151 -

E62C8CC5-4330-466A-B9D2-78B8E24B7F01.jpeg864.7 KB · Views: 143

E62C8CC5-4330-466A-B9D2-78B8E24B7F01.jpeg864.7 KB · Views: 143 -

D3FB30CA-ED13-435F-9F06-67A6E6449B0B.jpeg439.4 KB · Views: 160

D3FB30CA-ED13-435F-9F06-67A6E6449B0B.jpeg439.4 KB · Views: 160 -

91FB9300-3B83-4F2D-BCC5-84AC5E4C6A61.jpeg531.4 KB · Views: 152

91FB9300-3B83-4F2D-BCC5-84AC5E4C6A61.jpeg531.4 KB · Views: 152 -

50F3BE50-36C7-4163-ABFB-114325A1A930.jpeg880.7 KB · Views: 151

50F3BE50-36C7-4163-ABFB-114325A1A930.jpeg880.7 KB · Views: 151 -

B849EC4E-4CC4-49F6-ABEF-898D78A908C5.jpeg358 KB · Views: 169

B849EC4E-4CC4-49F6-ABEF-898D78A908C5.jpeg358 KB · Views: 169

So you cut the 6.5CM case first and then expand? When I did that there were too many jagged and rough edges; I had to chamfer and deburr prior to resizing, which is not easy on the shoulder of a case.Probably because you’re not using an AMP annealer. With flame annealers you only get a partial anneal. So I can see why you’d need baby snot consistency for a case lube. I’m running batches of 500 or more during a day so I can’t spend a lot of time rubbing down one case at a time in lube to convert. I just anneal my batch (most time consuming part), run it through a Honey Badger case trimmer to 1.690” then move over to the FL sizing die, then off to the Giraud Case trimmer where it’s final trimmed to 1.680”, chamfered, and debur in one step and brass is ready to go after walnut/cob mix tumbling. I load for resale and time is money.

I’m using a Honey Badger Case Trimmer which partially sized the brass and it uses a Bosch router. Yes I found that it works best. No rough edges but it’s sharp and uniform.So you cut the 6.5CM case first and then expand? When I did that there were too many jagged and rough edges; I had to chamfer and deburr prior to resizing, which is not easy on the shoulder of a case.

It’s always hard to completely get the context someone is trying to express on a forum. I didn’t take any offense but I also wanted to share another option that’s worked for me in a larger quantity production because I sell the ammo I make. So if I came off cocky I apologize.Sorry I brought it up. I didn't mean to offend you. I thought you were having trouble, so I told you what works for me.

There was quite the publicity blitz for the 8.6, mostly from Q, and while some of it was hype there is a very real difference in the way 8.6 handled getting the most possible energy on target. Now silence (good when shooting, not when waiting for info) from all companies, just as you pointed out. I'm going to ping Hornady this week and see if/when they plan on releasing their 8.6 subs and what load they use.Doing anything with 8.6 tends to get frustrating because we are seemingly without support from manufacturers - Very limited and expensive ammo, no brass, other than 5.6 Creedmoor, no load data since the original from Q/Faxon, including from projectile and powder manufacturers, Hornady has been VERY silent, including die availability.

PM me if you need help with anything. I offer annealing services as well.I understand! I am using a 16" 80% 8.6 Blk. AR-10 build. Doing anything with 8.6 tends to get frustrating because we are seemingly without support from manufacturers - Very limited and expensive ammo, no brass, other than 5.6 Creedmoor, no load data since the original from Q/Faxon, including from projectile and powder manufacturers, Hornady has been VERY silent, including die availability.

I bought a bad Caldwell chronograph and got it working, only to find out I couldn't use it at my range. Then I bought a MagnetoSpeed Sporter that was allowed but did not adapt well to my linear compensator, so I was going to have to remove it and the handguard to use the Sporter. A friend loaned me his V3, which works perfectly, so hopefully I can start to make up some subsonic loads after I get my own, and tell what speed my 185gr/TAC supers are running. It is always something. Retirement and reloading are anything but boring. ONWARD AND UPWARD!

I’m waiting for their Sub-X bullets in .338 cal that’s the ticket! Hopefully a cheaper more available option to the Makers since it’s always radio silence over there when trying to get more.There was quite the publicity blitz for the 8.6, mostly from Q, and while some of it was hype there is a very real difference in the way 8.6 handled getting the most possible energy on target. Now silence (good when shooting, not when waiting for info) from all companies, just as you pointed out. I'm going to ping Hornady this week and see if/when they plan on releasing their 8.6 subs and what load they use.

At least dies are now readily available from Hornady, Lee, and Redding. Things are moving in the right direction.

i found it works better to get a little cut off saw and cut the necks down firstI’m using a Honey Badger Case Trimmer which partially sized the brass and it uses a Bosch router. Yes I found that it works best. No rough edges but it’s sharp and uniform.

Sorry guys, see the reply I got from Hornady.I’m waiting for their Sub-X bullets in .338 cal that’s the ticket! Hopefully a cheaper more available option to the Makers since it’s always radio silence over there when trying to get more.

Well…that sucks.Sorry guys, see the reply I got from Hornady.

Just got a box of 500 today. Should have some loaded up for the weekend.I was hearing the same thing, even from Starline for brass... Is anyone using Sierra SMK 300 gr. as subs?

I also have some for load development; they are as close to the weight of the real (read: Maker) bullets I could find. I'm gonna use A1680 and CFEBLK to find the best sub-s grouping. No way am I going to send $3 downrange each time to sight in!Just got a box of 500 today. Should have some loaded up for the weekend.

Yes…just got them in.I was hearing the same thing, even from Starline for brass... Is anyone using Sierra SMK 300 gr. as subs?

I'm not sure how these will expand at sub velocities, which is important to me as I will use this gun mostly for culling. Currently, I only plan on using them for sighting in and load dev. If anyone has input on how these bullets behave at sub velocities, I would greatly appreciate it.Yes…just got them in.

They won’t…they’re target loads. Best for just shooting. Get Maker 350gr Rex or Lehigh 288 fracturing if the intended use is culling…or run the lighter bullets supersonic like a 180gr Nosler Accubond or 210gr Barnes TSX. At the moment that’s all there is.I'm not sure how these will expand at sub velocities, which is important to me as I will use this gun mostly for culling. Currently, I only plan on using them for sighting in and load dev. If anyone has input on how these bullets behave at sub velocities, I would greatly appreciate it.

Where are you getting the Lehigh 288's? I don't see them listed on their site.They won’t…they’re target loads. Best for just shooting. Get Maker 350gr Rex or Lehigh 288 fracturing if the intended use is culling…or run the lighter bullets supersonic like a 180gr Nosler Accubond or 210gr Barnes TSX. At the moment that’s all there is.

I’m sorry it was a typo…I meant 298gr from Gorilla they sell the bullets themselves.Where are you getting the Lehigh 288's? I don't see them listed on their site.

Gorilla 8.6BLK 298gr Subsonic Fracturing Projectiles | Gorilla Ammunition

Maximum of 2 boxes per customer. Initial demand is high and we’re trying to provide access to as many customers as possible.

No worries, just was trying to figure out if there was something I was missing. I did buy a couple bags from them already and the sticker shock is real. Doesn't really make load development "easy".I’m sorry it was a typo…I meant 298gr from Gorilla they sell the bullets themselves.

Gorilla 8.6BLK 298gr Subsonic Fracturing Projectiles | Gorilla Ammunition

Maximum of 2 boxes per customer. Initial demand is high and we’re trying to provide access to as many customers as possible.www.gorillaammo.com

If it’s something that will kill the 8.6, it’s the price of viable projectiles. That’s why I’ve been trying to keep my prices below Gorilla’s so that people have options.No worries, just was trying to figure out if there was something I was missing. I did buy a couple bags from them already and the sticker shock is real. Doesn't really make load development "easy".

Neck sizing is no longer the preferred method and was ONLY used in the benchrest crowd. I use a Sheridan case gauge to check all my brass especially after it’s loaded as brass can spring back more during the seating process. Neck sizing only causes the issues you talked about, stuck casings in gas guns, case stretching from heavy bolt lift, and higher chamber pressures.On the ammo you sell, do you do a ful length resize or just a neck resize? I am wondering if you use a headspace comparator dial calipers to check case head to shoulder length? The reason I'm asking is several in SnipersHide are telling me to only neck resize for each of my guns using the headspace comparator, Any other way is just WRONG! I can see where that would work for tweaking a particular rifle and brass to it's best, but I give a lot of my reloads to my Son and his friends. I even use small base dies when available to make sure my rounds will load in any AR. When I'm at the range and I see someone mortaring an AR to remove a stuck case, I ask them if they are reloads and if they do a neck size only. They have all said "yes." So now I have a conundrum... Maybe you can shed some light on it. It would be greatly appreciated.

Also with 8.6 Blackout there is no neck sizing, only full length sizing because no one makes a die that allows for it. Eventually they might make a bushing die but that still sizes the body to minimum spec. I always anneal prior to sizing so the benefits of not over-working your brass as the neck sizers all claim is mute. Always full length size and you’ll be good to go.

Yeah some people get overly OCD and it becomes the only way and they end up chasing their tails…I’ve done it myself. The only thing I can say is that even with the Sheridan gauge, if you’re installing a Remage barrel it can be tricky to properly install unless you isolate several of the components. Example, you have the barrel, barrel nut, recoil lug if it’s an unpinned Remington 700, and finally the action…that’s 4 individual parts that have to be timed to each other. I use a modular barrel vice, a wrench for the barrel nut, a recoil lug alignment fixture, and an action wrench that I isolate the action with when tightening the barrel nut. So it’s a bit of work but you can circumvent a lot of it by using a custom action that either has an integral recoil lug or pinned recoil lug…or you can have your recoil lug pinned.Thank You! I have been watching YouTube videos today 'till my eyes burn. I have been using Sheridan gauges for years! I just got the new 8.6 one recently. Laura has always been great to work with! In another I got hammered in another thread about about my bump. With the open Sheridan gauge, I didn't worry about it - if it fit the gauge, it would load and eject from anyone's gun. So I thought everything was hunky dory - great groups, long brass life, no ejector swipes or blown primers, still had my face, etc. To be told I was doing it all wrong and so aggressively, I felt like I was caught in a time warp between Deliverance and Twitter! I have ordered the Hornady gauge and may try it for a couple of my bench rest rifles, but I do not see the reason to go away from Sheridan gauges for the ability to work in ANY gun. I have no problem with them doing their thing, it just took me aback that there could ONLY be one way.

Am I understanding correctly that the 270 grain seconds are good if ran below 1520fps?Looks like I need to grab some CX/GMX projectiles. I went out today to test Reloader 10x and IMR 8208 XBR with my 270gr ELD-X's. Turns out the 270s are good up to about 1550FPS. Over that the frequency of jacket separation increases. I tested 8208 XBR from 28gn to 32.1gn and had no pressure signs. The top few loads were compressed.

I gave up on the Reloader 10x at 28.5gn because all the rounds were breaking apart.

I have some gorilla 285's but the length is significantly different so I need to work up a different load.

After jacking up my Palmetto State Armory upper I replaced it with an Aero Precision build.

That looks like a Shepard scope…how are those? The build looks clean. Yeah I can’t leave them alone myself. I have this one Form1’d to 14.5” and LSA did the camo pattern on it.I have a 700ADL that I bought in 1970 with a Redfield WideView 3X9 30-06 that still works great. I don't have the heart to change it.

I guess I'm an addict to building ARs. I've built close to a dozen 80% AR15s and have unmilled lowers for a couple more. I also have built 6 AR10s. I like using the B.A.D. lever, which is a little more tricky on an AR10 upper. My mill isn't CNC, just DRO, so I have to do the curves moving X&Y manually to creat clearance for the head of the B.A.D. lever. I Cerakote .223/5.56 AR-15s black. Every other caliber gets its own color, including the mags. That way I worry less about my Son plugging the wrong mag into the wrong gun. This is my 8.6 BLK - Color is Cerakote smoked bronze. Scope is 4-16X50 FFP. Tony Rumore of Tromix made my linear compensator to use until I can afford a can. He now has them for sale on the Tromix web site. He was a lot of help on my 458 SOCOM build also.

View attachment 8022470

View attachment 8022471

Attachments

I have done subsonic for the most part but tried a few supers. 285gr ELD-M, 300gr SMK, and 350gr Maker Rex. I’m playing around with 180gr Nosler Accubonds as well…will try some Barnes TSX and maybe some lighter Maker bullets if Paul will make them.It is a Monstrum scope. Most of my scopes are FFP Monstrum. I watch their sales for a huge bang for the buck. Big name features for a lot less money. Good glass.

Yours looks very sharp! Quality work shows! Excellent camo pattern! Both my Grendel rifle and carbine have Kryptek camo. Real pain. My black Wylde has dry brushing for effect. Most of my ARs are single primary color. I am doing a 5 pound AR that I call the Lightening Project. I am airbrushing realistic lightning bolts on it. I try for subtle but different on my ARs, including pistols. I have a .45ACP & 9mm. I am finishing up a 10mm. I think it will do well since it has power and shoots pretty flat to 100 yards.

Have you done any sub rounds for the 8.6 yet? I just picked up a MagnetoSpeed V3 to start. I have the Caldwell, but my local range won't let me use it, so I got this one. I hope to try it Monday. I'm putting some rounds together for testing now.

Are you annealing? How are you annealing? With this caliber if you’re converting brass you really need to anneal.

Are you considering turning the necks after sizing? If so, I have the RCBS neck hand turner I believe you’re talking about and it’s very tight with the .338 pilot so turning one down yourself is probably a great idea after all. The picture of those factory seconds are indeed 300gr Sierra SMK’s. They shoot great in the 8.6 so you’ll be happy with those.My comparator came in today. On my 8.6, without changing any of my press settings, I am bumping .0016 for my gas gun. This passes the drop in/fall out test on the Sheridan gauge, and the cut-away opening in the gauge shows my shoulder and neck align perfectly with the gauge. I have had no issues feeding or extracting over a hundred rounds.

On the Nickel plated brass, which I want to use for easy identification of subs, I am going to have to turn the neck because of the added nickel thickness. I ordered the RCBS case neck turner, but the .338 pilot/cutter was not available anywhere, so I ordered the next size up and I will turn it to spec on my lathe.

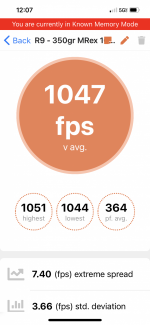

Yes…what barrel length are you using? I have load data for both a 12” gas gun and 16” bolt gun. If you’re shooting a 285gr ELD-M or a 300gr SMK, I’ve used primarily H110 and w296 and some a1680 as well.I have absolutely NO experience with subsonic, so I'm going to start fairly light with powder and work down using a chrono. I plan to go down until it won't lock the bolt back and then go a couple of notches forward until reliable and hopefully, decent groups. I'm starting with the TAC powder I used for my supers and then go from there using 1680 and CFE 223 AND CFE Blk. Any suggestions?

For a 12” with 285gr ELD-M 14.8gr of a1680 gets you 1050 fps average.

For a 12” with 300gr SMK 15.1gr of H110 gets you 1050 fps average.

For a 16” 285gr ELD-M 14.5gr of a1680 gets you 1030 fps average.

For a 16” 300gr SMK 14.6gr of H110 gets you 1066 fps average.

I’m still working up loads.

Thank you for sharing that!Yes…what barrel length are you using? I have load data for both a 12” gas gun and 16” bolt gun. If you’re shooting a 285gr ELD-M or a 300gr SMK, I’ve used primarily H110 and w296 and some a1680 as well.

For a 12” with 285gr ELD-M 14.8gr of a1680 gets you 1050 fps average.

For a 12” with 300gr SMK 15.1gr of H110 gets you 1050 fps average.

For a 16” 285gr ELD-M 14.5gr of a1680 gets you 1030 fps average.

For a 16” 300gr SMK 14.6gr of H110 gets you 1066 fps average.

I’m still working up loads.

All, following up on my email with Hornady, I sent an email to Q. Basically "WTF man?!" My email is below and I will update as soon as I get a reply.

Mr. Brittingham,

A lot of people, including myself, have bought into the 8.6 Blackout world. The science is very sound and the added terminal performance over the 300 BLK is significant. I am speaking for a large number of shooters when I ask, "What happened?"

There was a lot of support from major brands, but now they want nothing to do with it! I emailed Hornady last week, and they told me they have no plans to release ammo for 8.6 Blackout and are not offering their .338 Sub-x bullets either. As the end consumer, we kinda feel collectively left to fend for ourselves, which is disappointing considering how the cartridge was billed. Some of the main questions those of us who have a 8.6 rifle, but no real source of ammo:

Are there plans for collaboration with other major ammo manufacturers?

Will you be making 8.6 brass?

Can you provide guidance on what non-solid copper (aka: traditional) .338 bullets will hold together with the 3" twist rate? (Berger OTM, Norma ORYX, etc)

Can you provide guidance on what bullets that do hold together expand reliably at subsonic velocities?

Any help/advice would be greatly appreciated.

Robert

Mr. Brittingham,

A lot of people, including myself, have bought into the 8.6 Blackout world. The science is very sound and the added terminal performance over the 300 BLK is significant. I am speaking for a large number of shooters when I ask, "What happened?"

There was a lot of support from major brands, but now they want nothing to do with it! I emailed Hornady last week, and they told me they have no plans to release ammo for 8.6 Blackout and are not offering their .338 Sub-x bullets either. As the end consumer, we kinda feel collectively left to fend for ourselves, which is disappointing considering how the cartridge was billed. Some of the main questions those of us who have a 8.6 rifle, but no real source of ammo:

Are there plans for collaboration with other major ammo manufacturers?

Will you be making 8.6 brass?

Can you provide guidance on what non-solid copper (aka: traditional) .338 bullets will hold together with the 3" twist rate? (Berger OTM, Norma ORYX, etc)

Can you provide guidance on what bullets that do hold together expand reliably at subsonic velocities?

Any help/advice would be greatly appreciated.

Robert

Thanks for sharing the email you composed & sent. It is well written and hits all the points in relation to this cartridge. Keep us posted on the reply.All, following up on my email with Hornady, I sent an email to Q. Basically "WTF man?!" My email is below and I will update as soon as I get a reply.

Mr. Brittingham,

A lot of people, including myself, have bought into the 8.6 Blackout world. The science is very sound and the added terminal performance over the 300 BLK is significant. I am speaking for a large number of shooters when I ask, "What happened?"

There was a lot of support from major brands, but now they want nothing to do with it! I emailed Hornady last week, and they told me they have no plans to release ammo for 8.6 Blackout and are not offering their .338 Sub-x bullets either. As the end consumer, we kinda feel collectively left to fend for ourselves, which is disappointing considering how the cartridge was billed. Some of the main questions those of us who have a 8.6 rifle, but no real source of ammo:

Are there plans for collaboration with other major ammo manufacturers?

Will you be making 8.6 brass?

Can you provide guidance on what non-solid copper (aka: traditional) .338 bullets will hold together with the 3" twist rate? (Berger OTM, Norma ORYX, etc)

Can you provide guidance on what bullets that do hold together expand reliably at subsonic velocities?

Any help/advice would be greatly appreciated.

Robert

If Q or KB reply with anything other than "blow it out your ass" I will be genuinely shocked.

First two pieces made up super easy with no jacked up shoulders. As said before, start with Hornady 6.5 LP brass, chop saw to around 1.69 then anneal, chamfer and deburr, and straight to the sizer. These were just to set up the chop saw, AMP and sizing die. I’ll make a batch up where I’ll anneal again after final trim.

Looks really good. What is the length of the case after resizing? I have been forming first and then cutting on the chop saw. Lots of little wrinkles near the base of the neck for me.View attachment 8025603

First two pieces made up super easy with no jacked up shoulders. As said before, start with Hornady 6.5 LP brass, chop saw to around 1.69 then anneal, chamfer and deburr, and straight to the sizer. These were just to set up the chop saw, AMP and sizing die. I’ll make a batch up where I’ll anneal again after final trim.

They only grew maybe .002 after sizing. My first cut was right at 1.685 and were a touch short after trimming. I would cut them closer to 1.69Looks really good. What is the length of the case after resizing? I have been forming first and then cutting on the chop saw. Lots of little wrinkles near the base of the neck for me.

And give you a little room to trim to.

Brass is prepped and primed to do some load development tomorrow.

The Sheridan case gauge is an awesome tool when getting set up to make brass for the first time.

Mocked up a round with the COAL at 2.600 using the 185 CX

The Sheridan case gauge is an awesome tool when getting set up to make brass for the first time.

Mocked up a round with the COAL at 2.600 using the 185 CX

I searched and didn't see it anywhere, but has anyone come up with load data yet for the Gorilla 285 gr bullets? I could probably extrapolate from the Faxon/Q chart for the 300 gr bullets, but that's where their chart, to me at least, is messed up.

I have a hundred Federal SR nickel plated cases. My original plan was to use them for subsonic, so it would be very easy to tell them from the supersonic rounds. Unfortunately, when I loaded them with the 300gr SMK rounds, they would not fit in the Sheridan gauge, apparently from the excess thickness of the nickel plating. They also would not load in my AR. After running through the sizer, the case passed the Sheridan test. It failed after I inserted the 300gr SMK, even with a lite Lee factory crimp. I had never turned brass before, but figured it was worth a try. With the RCBS tool connected to my RCBS Trim Pro 2, it was very easy to set up and operate, using Sheridan gauge as a guide.

View attachment 8031998

Glad to see you chipping away at what appears to be a bit of a problem child round.

Between the super fast twist rate and possibly needing to turn necks, I'll sit this round out for a bit. I'm sure if it takes off the internet will figure out which brands of .308 and 6.5C can be converted without neck turning, kinda like how LC was the initial go-to for 300BO to avoid thick necks, but it also seems there might be some lack of consistency across barrel manufacturers.

Best of luck to you and I look forward to reading what you figure out to be the sweet spot of brass, powder, and projectile(s).

Similar threads

- Replies

- 19

- Views

- 2K

- Replies

- 14

- Views

- 1K

- Replies

- 50

- Views

- 6K

- Replies

- 15

- Views

- 2K