Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Coup De Grâce, New Action from American Rifle Company, $899 WOW!

- Thread starter karagias

- Start date

So will the depth of the cone/chamber be deeper as the chamber diameter gets larger? If so it seems to me that a .223 would need a larger cone to feed than a 308 since the centerline of the cartridge starts out further from the centerline of the bore.No, the ball doesn’t approximate the cone. The intersection (contact point) between the ball and cone is mathematically determinate for a fixed/known ball diameter and cone angle. That’s what allows an equation to be used to solve for depth.

I'm assuming you cut the complete baseplate out of the AW mag?

Affirmative - follower travels into extension. The ribs don’t align AICS - AW. Rib in extension milled out. MDT spring is same length & config as AW but higher rate. Riveted MDT spring to AW follower. I’ll start with that, but until I have the CDG built to test it I won’t know for sure. MDT also sells a longer spring for use with extensions for like $14 & it could be trimmed if needed.I'm assuming you cut the complete baseplate out of the AW mag?

Thanks, I thought that was the case. I've got a couple of Altus 2 round extensions I'm going to attempt the same thing.Affirmative - follower travels into extension. The ribs don’t align AICS - AW. Rib in extension milled out. MDT spring is same length & config as AW but higher rate. Riveted MDT spring to AW follower. I’ll start with that, but until I have the CDG built to test it I won’t know for sure. MDT also sells a longer spring for use with extensions for like $14 & it could be trimmed if needed.

I believe he said he was going to do so. I’ll let him verify.@357Max trying to understand the additional set screws, did you also remove the external tabs on the bottom plate of the aw mag the A419 extension would traditionally interface with? Needing to use new tension points to hold extension on?

That's really cool. I'm super interested. Any chance you want to post a writeup on parts you chose and how you did this?

Even if I don't have the skills to do it myself, I'm really curious what was involved and why you went the direction you did.

@357Max trying to understand the additional set screws, did you also remove the external tabs on the bottom plate of the aw mag the A419 extension would traditionally interface with? Needing to use new tension points to hold extension on?

The tabs are part of the plate. I cut the welds & removed the whole plate.

The bottom of the AW has more angle to it. You could just cut the bottom of the AW flat & then it’d be easier to mill the extension allowing the mag to slide down in.

I think the angled slot for the tabs on the 419 is machined on a 4 axis setup & I don’t have one. Instead I used an angle finder on the side of the AW = 7.5 degrees. Set my mill angle to 7.5 & then clamped extension in vise also at 7.5. Cutting it this way allows the AW to slide straight down & end up straight in the extension.

Those particular set screws are the key to this. They have a dog point thats .091 diameter x .040 long (mag walls are .040). They lock the mag body in the extension without interference to the mag follower or rounds.

I machined the extension deep enough so the set screws would be in the thick part of the extension & there placement on the corners puts the back 2 in the extractor groove area in case they protruded a little.

Sequence:

1. Cut off bottom plate

2. Mill extension correcting angle & allowing about .550” depth at back.

3. Insert mag, I used mill vise to hold it tight in extension.

4. Drill through the whole assembly with #42 drill (.093). This is for the dog point index in mag body. You don’t want tap drill sized holes in the body.

5. Remove the mag from extension & re center on holes with #42 bit, then drill extension through both sides #35 tap drill (.110).

6. Tap extension 6-32.

7. Stock AW spring rate is to weak IMO. So I robbed a MDT 10 round spring. Spring config & length is same, but rate is much higher. Drill rivets in AW & rivet new spring in place. I ordered an MDT spring for 10rd + ext. I think the std MDT spring will work, but won’t know for sure til gun is built.

It was just coincidence that the extended AW is the same length as a MDT aics 10rd.

As a side note the difference in body taper makes a hell of a difference with these AW mags. I was initially mocking this up with 6.5c rounds & didn’t like how they seemed to be tight on the feed lips near shoulder & loose at the back. When I finished the extension I loaded up 308 instead & they fit like the mag was built for 308 go figure. That extra .008 body taper made a big difference. I’m building a 308 with the CDG, but how are you guys tweaking these to hold Creedmoor rounds squarely? Adjusting feed lips?

Last edited:

Great write up. I wonder if one of the flatter mag extensions, like the MPA mag extender, would have been easier to use?

You'd have to mill even deeper into the rear of the extension to interface the aw mag to the extension like 357max did. The high angle to the bottom of the aw/ax mags is what makes adding an extension tricky, vs the less angled aics mags. Aw mags were originally designed for 308 with its more taper, hence the reason for more angle at base plate.Great write up. I wonder if one of the flatter mag extensions, like the MPA mag extender, would have been easier to use?

The ball sits deeper for larger chamber diameters (A). The cone angle doesn’t change, but the length along the sides of the cone is longer. For smaller cartridges, the bullet tip rides the cone farther.So will the depth of the cone/chamber be deeper as the chamber diameter gets larger? If so it seems to me that a .223 would need a larger cone to feed than a 308 since the centerline of the cartridge starts out further from the centerline of the bore.

I think your question gets to what @bohem was talking about, having different specs for different case head sizes, which I’m sure would be a programming headache.

Last edited:

Ok that makes sense now that you say it. A slightly shorter tenon on the smaller case diameters.The ball sits deeper for larger chamber diameters (A). The cone angle doesn’t change, but the length along the sides of the cone is longer. For smaller cartridges, the bullet tip rides the cone farther.

I think your question gets to what @bohem was talking about, having different specs for different case head sizes, which I’m sure would be a programming headache.

The tenon length is the same on every cartridge. The ball sits in a different location on different case heads.Ok that makes sense now that you say it. A slightly shorter tenon on the smaller case diameters.

I would appreciate some advice on feeding systems for these actions.

I understand the CDG action is designed to feed from AW magazines. Great!

What I don't understand is whether AW magazines (preferably five round magnum rounds) can be made to work with traditional Manners stocks, for example.

I'm guessing the CDG action can also be fed from an AICS magazine which I know will fit Manners stocks. No?

What I really want to do is to feed the CDG action from a BDL box or from a Hawkins Hunter magazine. My understanding is that cannot be made to work. Correct?

Any thoughts on how to feed this action from a five round magazine for 7 SAUM, 300 PRC style cartridges?

I understand the CDG action is designed to feed from AW magazines. Great!

What I don't understand is whether AW magazines (preferably five round magnum rounds) can be made to work with traditional Manners stocks, for example.

I'm guessing the CDG action can also be fed from an AICS magazine which I know will fit Manners stocks. No?

What I really want to do is to feed the CDG action from a BDL box or from a Hawkins Hunter magazine. My understanding is that cannot be made to work. Correct?

Any thoughts on how to feed this action from a five round magazine for 7 SAUM, 300 PRC style cartridges?

Hello @Jon_ARC we're at the beginning of W10 so as per the above let me dare to ask if it still holds true...since we are in the middle of the journey to W14 (+8W from the show opening...) thank you!The website states the lead time is 4+ months for NEW orders. We still are on track to begin shipping the early orders within the 8 weeks initially stated.

it's been 4 weeks since preorder opened...Hello @Jon_ARC we're at the beginning of W10 so as per the above let me dare to ask if it still holds true...since we are in the middle of the journey to W14 (+8W from the show opening...) thank you!

well you'll get them about the same timeI put my order in this morning. This will be my first center fire bolt action rifle build. I may need to get paper work going on a Ti suppressor to match.

Yes, AW mags will work with a Manners stock. I’ve been using both for years now. Not sure if you’ll need to adjust latch length, since mine came together. And yes, it will work with AICS magazines too.I would appreciate some advice on feeding systems for these actions.

I understand the CDG action is designed to feed from AW magazines. Great!

What I don't understand is whether AW magazines (preferably five round magnum rounds) can be made to work with traditional Manners stocks, for example.

I'm guessing the CDG action can also be fed from an AICS magazine which I know will fit Manners stocks. No?

What I really want to do is to feed the CDG action from a BDL box or from a Hawkins Hunter magazine. My understanding is that cannot be made to work. Correct?

Any thoughts on how to feed this action from a five round magazine for 7 SAUM, 300 PRC style cartridges?

ARC said that they are working out the details on fitment for BDL/Hawkins.

That's what I kind of figured!! I'm curious how the Rugged Alaskan Ti will perform. Maybe a Nomad Ti.... options options.well you'll get them about the same time

I'm still not understanding how the tenon length can be the same when the measurement is from the top of the ball to the shoulder but the depth of the ball from the end of the blank is getting deeper into the blank as the cartridge diameter is getting bigger. Unless you are facing the end of the blank to keep it the same length.The tenon length is the same on every cartridge. The ball sits in a different location on different case heads.

I need to go back and look at the print. Don't feel like you have to respond and try to help me figure this out. There is a reason I hire this type of work done. lol

I was pretty close to the release date.. Wonder when mine will arrive? I'm seeing 4 months lead time if ordered today.In Italy was late afternoon that day. I started bothering the website way earlier than the opening…

This was just discussed today, about six posts up or so. Somewhere between four weeks from now and when it actually gets to you.

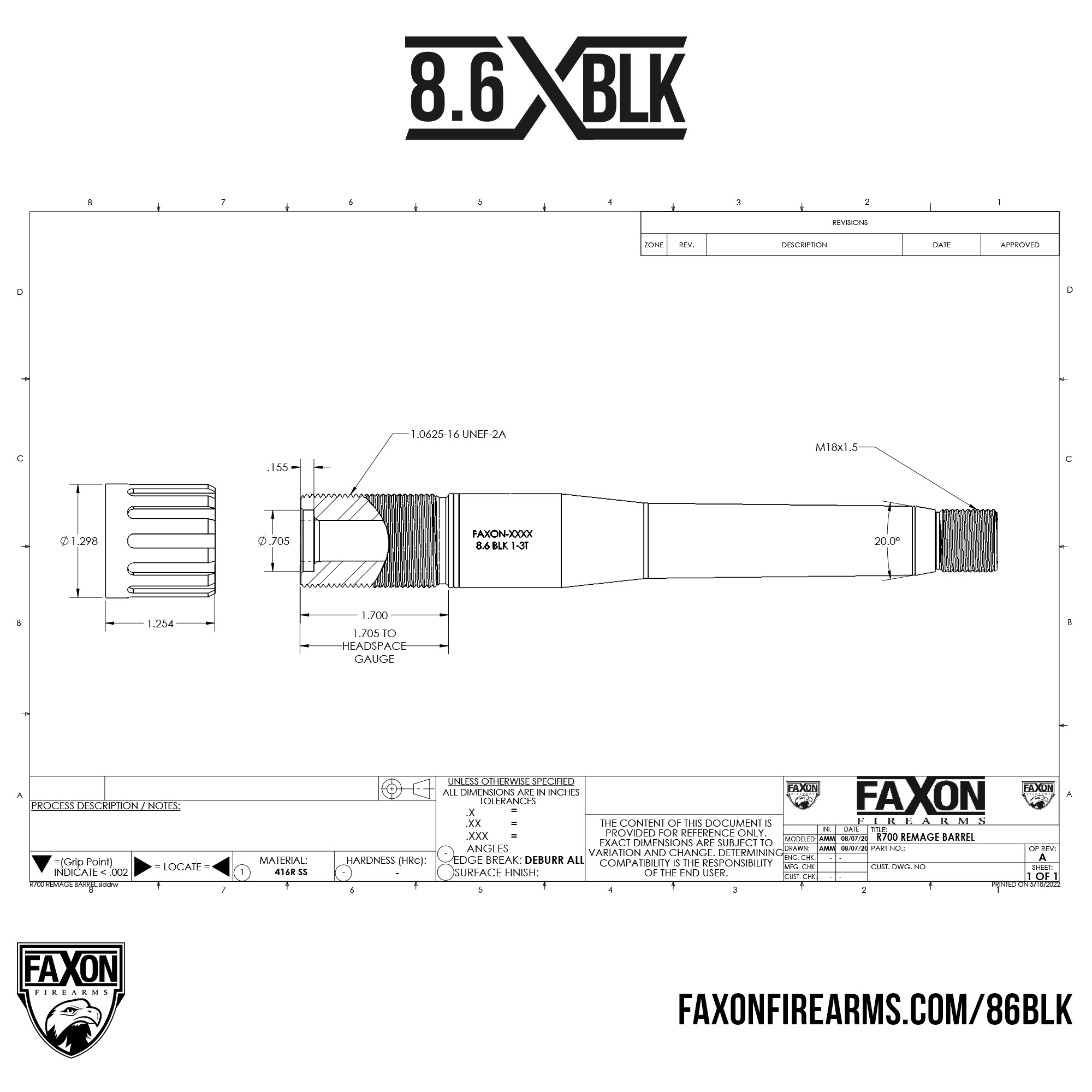

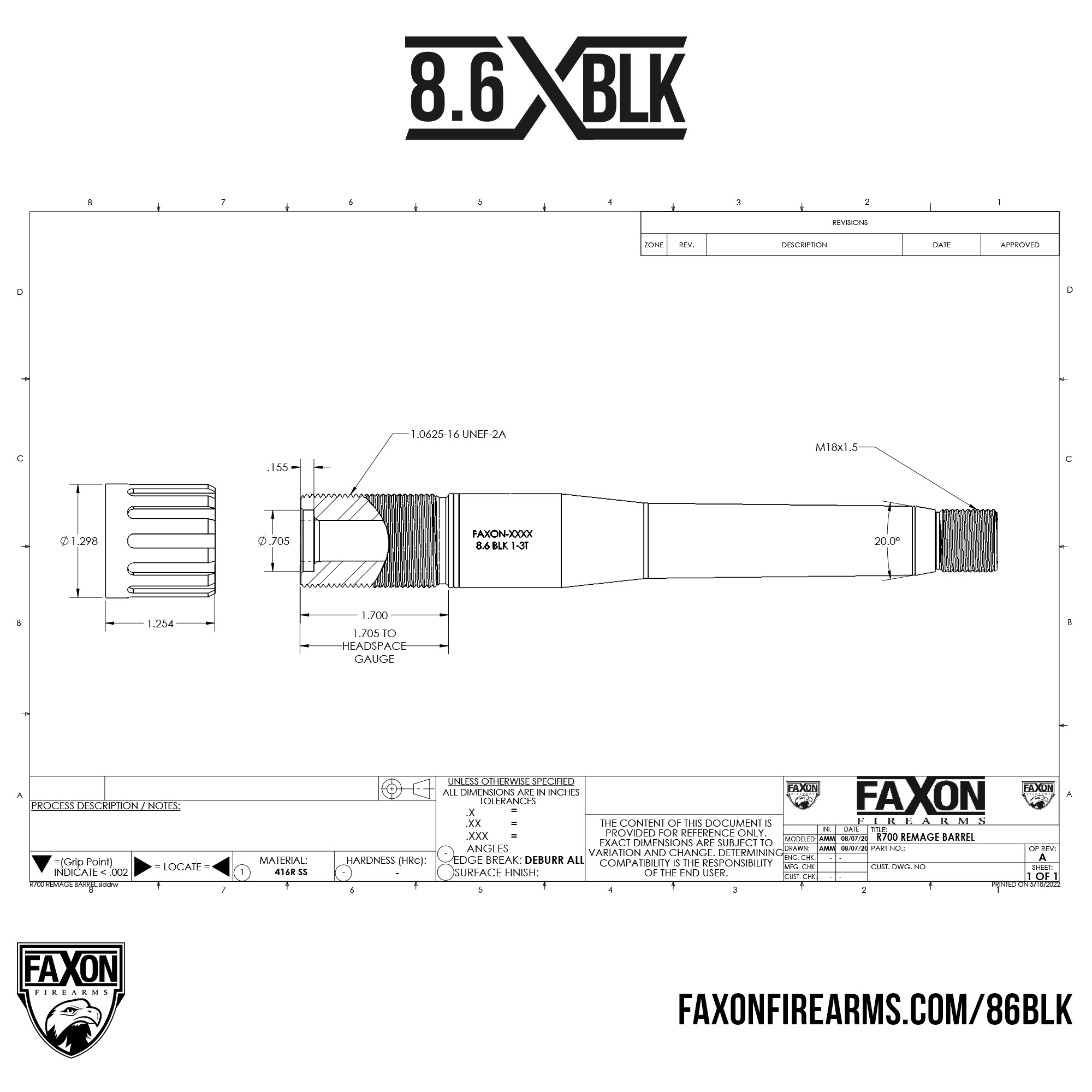

dang. something new to learn. How do I figure out if this barrel is to Spec for the coudegrace?

I have two Nomads and they’ve been good for me. Probably can’t go wrong with either of those.That's what I kind of figured!! I'm curious how the Rugged Alaskan Ti will perform. Maybe a Nomad Ti.... options options.

Any ball that makes contact tangent to the cone would work, but you’d need to redo the math.Got it, thanks. Took me a hot minute to build the geometry in my head with your explanation but it makes sense now, appreciate it.

dang. something new to learn. How do I figure out if this barrel is to Spec for the coudegrace?

If it will feed from aics no reason it shouldn't feed from the hawkins hunter.I would appreciate some advice on feeding systems for these actions.

I understand the CDG action is designed to feed from AW magazines. Great!

What I don't understand is whether AW magazines (preferably five round magnum rounds) can be made to work with traditional Manners stocks, for example.

I'm guessing the CDG action can also be fed from an AICS magazine which I know will fit Manners stocks. No?

What I really want to do is to feed the CDG action from a BDL box or from a Hawkins Hunter magazine. My understanding is that cannot be made to work. Correct?

Any thoughts on how to feed this action from a five round magazine for 7 SAUM, 300 PRC style cartridges?

Someone has to!

It's going in the MK Machining Bullpup chassis, so I figure I'll play around for a few years and then swap the barrel out for something more practical. But putting a Faxon barrel on this thing feels SOO WRONG!

# browses to mos-tek for custom 8.6 blk barrel.

Thats because it is wrong. It wouldnt even screw in to start with.But putting a Faxon barrel on this thing feels SOO WRONG!

If you're adequately determined:Thats because it is wrong. It wouldnt even screw in to start with.

If you're adequately determined:

It's like he's not even trying. No come along or even a ratchet strap.

I'm strongly leaning in this direction. But that means either another round or 4-5 months waiting for a barrelThats because it is wrong. It wouldnt even screw in to start with.

16 doesn't equal 20I'm strongly leaning in this direction. But that means either another round or 4-5 months waiting for a barrel

order a reamer and find a smith to chamber a barrel for you

Any more details on this?That tenon drawing hits and I'm off to convince a very reputable precision shop to produce them.

Just got word today they won't pick this up. Too many variations and start up costs...Any more details on this?

Welp, I happily ordered 1 CDG but I’ve been dreaming of the lighter version in a long action for a hunting rifle build, can’t wait to see what that will look like…

Gauge balls of that size are hard to come by in imperial units in Europe, so I did the math and parameterized it so that you can substitute the diameter of the gauge ball to fit your needs.

In inches:

L_in = 0.6750 + 1.07735*d_ball_in - 0.2887*DimA_in

(Diameter of the gauge ball d_ball_in and cartridge dimension DimA_in need to be in inches)

In millimeters:

L_mm = 17.1450 + 1.07735*d_ball_mm - 0.2887*DimA_mm

(Diameter of the gauge ball d_ball_mm and cartridge dimension DimA_mm need to be in millimeters)

Example: According to CIP, DimA for .308 Winchester is 11.96 mm. Using a metric gauge ball of 32 mm diameter:

L_mm = 17.1450 + 1.07735*32 - 0.2887*11.96 = 48.1673 mm from barrel shoulder to top of the gauge ball

In inches:

L_in = 0.6750 + 1.07735*d_ball_in - 0.2887*DimA_in

(Diameter of the gauge ball d_ball_in and cartridge dimension DimA_in need to be in inches)

In millimeters:

L_mm = 17.1450 + 1.07735*d_ball_mm - 0.2887*DimA_mm

(Diameter of the gauge ball d_ball_mm and cartridge dimension DimA_mm need to be in millimeters)

Example: According to CIP, DimA for .308 Winchester is 11.96 mm. Using a metric gauge ball of 32 mm diameter:

L_mm = 17.1450 + 1.07735*32 - 0.2887*11.96 = 48.1673 mm from barrel shoulder to top of the gauge ball

Last edited:

Just work with the 1.25" ball as described in the document on ARC's website.

What I described above is strictly a European problem: it is hard to source a 1.25" ball here and much easier to find a 32 mm one, therefore I computed it for that size.

What I described above is strictly a European problem: it is hard to source a 1.25" ball here and much easier to find a 32 mm one, therefore I computed it for that size.

except case size on 223 and 308 isn't the same and would change ball size if im reading print correctlyJust work with the 1.25" ball as described in the document on ARC's website.

What I described above is strictly a European problem: it is hard to source a 1.25" ball here and much easier to find a 32 mm one, therefore I computed it for that size.

oh right i read it wrong. it's ball placement that changes. same 1.25" ballOne ball size is used for all cartridges!

Personally I didn't want to deal with who's balls are the right size and ordered from pva

Yep. PVA is doing prefits and you can already order them. I believe Preferred is also doing them (at least they are on the site).Personally I didn't want to deal with who's balls are the right size and ordered from pva

Wondering if anyone else is going to come online with prefits ...Yep. PVA is doing prefits and you can already order them. I believe Preferred is also doing them (at least they are on the site).

the answer is yes. there will be more. just have to wait and see whoWondering if anyone else is going to come online with prefits ...

Similar threads

- Replies

- 12

- Views

- 2K

Left Hand Sale

WTS/SOLD: WTT ARC Coup De Grace LA

- Replies

- 3

- Views

- 774

- Replies

- 5

- Views

- 969