Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

In regard to the pre-fit barrels having a Bentz chamber...

The Proof pre-fit barrels that my buddy got engrave the bullet. So, unless they are not going full depth on the chamber when it's cut, it's at the very least a modified Bentz. At best, the rumor of it being a Bentz is false and it's a match chamber of some sort.

For now, I know that it engraves. We'll see how it performs over time. That is the true test.

The Proof pre-fit barrels that my buddy got engrave the bullet. So, unless they are not going full depth on the chamber when it's cut, it's at the very least a modified Bentz. At best, the rumor of it being a Bentz is false and it's a match chamber of some sort.

For now, I know that it engraves. We'll see how it performs over time. That is the true test.

"Time to move this thread on the sticky above thread" good info. Now it might good to use the tight lilja2' chamber on this RIMX action without extraction problem = POSITIVE EJECTION.yeahhh

The best option would be a stock inlet for the Origin as the RimX and Origin share a bolt handle profile. The TL3 will work, but you may need to relieve some material in the bolt pocket.Still wondering about which inlet is best. Want to order a new mini chassis stock, but not dedicated to rimX. Wonder if TL3 or general Rem700.

@padom have any insight?

Thanks - Ray

I'm not sure where you got this information, but Lothar Walther only offers a Bentz chamber by request. All of the stock barrels are chambered with a JGS Match reamer. The print number is 0759 if you would like to see the specs.Yeah, unfortunately that's how I feel about the Bartlein and Walther barrels that use the Bentz chamber.

My apologies, you are correct. I seem to lump them all together when the bullet still fails to engrave the rifling. I have the JGS reamer spec and it's only slightly shorter than the Bentz.I'm not sure where you got this information, but Lothar Walther only offers a Bentz chamber by request. All of the stock barrels are chambered with a JGS Match reamer. The print number is 0759 if you would like to see the specs.

The RimX showed up at my Smith yesterday. I got a chance to swing by and check it out this evening. Definitely interesting checking it out. Different design for sure. Here's a couple of thoughts.

Definitely slicker than a V22. The bolt body is looser in the receiver and the result seems to be a smoother cycling. This is without a trigger however. The internals are quite different. From the two piece bolt body, bolted on beefy extractor, removable firing pin, tiny "keeper", bolt-on ejector. It almost seems a little bit bolted together rather than machined. Some things I wasn't impressed with is the finish on the bolt body, bolt knob, and scope rail. It seemed cheap and poorly done. The anodizing on the bolt knob was textured and rough. Not at all like what I'm used to on my TL3's and Origin. There's already finish wear on the front half of the bolt body and I just took possession of it. Imagine a bolt body made of aluminum and a poor finish applied. That's how it looks. The scope rail is also not what I'm used to on my Bighorn actions. Almost like a dry, coarse phosphate finish on a set of overpriced Larue rings. The receiver is nicely finished tho.

View attachment 7287320

View attachment 7287321

View attachment 7287323

View attachment 7287324

View attachment 7287325

View attachment 7287350

The mag. Really nicely machined and thought out. It is clearly different and incompatible with Vudoo mags. A person can disassemble it by hand. Floorplate slides off, spring rockets out across the room and follower slides out. Four screws on one side of the mag demonstrate how to separate the two halves. The ramp in front of the follower is significantly larger than a Vudoo mag. Kinda tips it's hand as to how much the bullet is going to rely on the ramp. The removable floor plate shows how easy it's going to be to add a +2? +20rd bumper. Here's the bad part. The follower binds... A lot... Mind boggling. It's a hard, dense plastic. It seems like tolerances are precise and the dry anodizing isn't playing well with the follower. Hopefully a very conservative spot of oil helps it slide freely up and down. Kind of unbelievable...

View attachment 7287327

The mag is clearly different than a Vudoo mag is confusing, will not fit a V22.

View attachment 7287329

View attachment 7287331

View attachment 7287333

So the action is at the Smith's. Been waiting for two days for the NIC check to clear. He has the Shilen ratchet rifled barrel and a Calfee 2 reamer. The Smith is going to slug the barrel looking for a tight spot. Shilen says their barrels are taper lapped and you shouldn't find a tight spot. If that's the case we'll go 20". Otherwise Im good anywhere between 16 and 22". He's going for 41 thou headspace and we're going to take measurements on Lapua Center X for land engagement. We're going to go aggressive and throat it out as we go. We're also not above ordering a reamer if we don't like what we see.

Not regarding the RimX, but I felt the same with the V22 compared to my Tikka. I was wondering why my Tikka $700 rifle cycled so much smoother and it was just due to the fact that Tikka's bolt is pretty loose within the receiver so it just cycles easily. The V22 cycles really slick if I am 100% pulling straight back and forward. Any other force in any sort of direction causes the bolt to bind/stick. If I run the bolt hard, I usually don't notice though. I greased my V22 bolt a bit and that helped a ton. I wonder if Vudoo's super tight tolerances on the bolt/receiver also adds to its accuracy though.

The RimX showed up at my Smith yesterday. I got a chance to swing by and check it out this evening. Definitely interesting checking it out. Different design for sure. Here's a couple of thoughts.

Definitely slicker than a V22. The bolt body is looser in the receiver and the result seems to be a smoother cycling. This is without a trigger however. The internals are quite different. From the two piece bolt body, bolted on beefy extractor, removable firing pin, tiny "keeper", bolt-on ejector. It almost seems a little bit bolted together rather than machined. Some things I wasn't impressed with is the finish on the bolt body, bolt knob, and scope rail. It seemed cheap and poorly done. The anodizing on the bolt knob was textured and rough. Not at all like what I'm used to on my TL3's and Origin. There's already finish wear on the front half of the bolt body and I just took possession of it. Imagine a bolt body made of aluminum and a poor finish applied. That's how it looks. The scope rail is also not what I'm used to on my Bighorn actions. Almost like a dry, coarse phosphate finish on a set of overpriced Larue rings. The receiver is nicely finished tho.

View attachment 7287320

View attachment 7287321

View attachment 7287323

View attachment 7287324

View attachment 7287325

View attachment 7287350

The mag. Really nicely machined and thought out. It is clearly different and incompatible with Vudoo mags. A person can disassemble it by hand. Floorplate slides off, spring rockets out across the room and follower slides out. Four screws on one side of the mag demonstrate how to separate the two halves. The ramp in front of the follower is significantly larger than a Vudoo mag. Kinda tips it's hand as to how much the bullet is going to rely on the ramp. The removable floor plate shows how easy it's going to be to add a +2? +20rd bumper. Here's the bad part. The follower binds... A lot... Mind boggling. It's a hard, dense plastic. It seems like tolerances are precise and the dry anodizing isn't playing well with the follower. Hopefully a very conservative spot of oil helps it slide freely up and down. Kind of unbelievable...

View attachment 7287327

The mag is clearly different than a Vudoo mag is confusing, will not fit a V22.

View attachment 7287329

View attachment 7287331

View attachment 7287333

So the action is at the Smith's. Been waiting for two days for the NIC check to clear. He has the Shilen ratchet rifled barrel and a Calfee 2 reamer. The Smith is going to slug the barrel looking for a tight spot. Shilen says their barrels are taper lapped and you shouldn't find a tight spot. If that's the case we'll go 20". Otherwise Im good anywhere between 16 and 22". He's going for 41 thou headspace and we're going to take measurements on Lapua Center X for land engagement. We're going to go aggressive and throat it out as we go. We're also not above ordering a reamer if we don't like what we see.

The bolt shroud on mine has nicks in the finish and finish wear around the edges. It's not huge but it is kind of disheartening when you spend this much on an action. My Vudoo has zero finish issues. I know complaining about finish on this site can open you up to slot of "It's a tool" criticism but if I bought a new wrench with the chrome plating chipped I would take it back.

Attachments

The RimX showed up at my Smith yesterday. I got a chance to swing by and check it out this evening. Definitely interesting checking it out. Different design for sure. Here's a couple of thoughts.

Definitely slicker than a V22. The bolt body is looser in the receiver and the result seems to be a smoother cycling. This is without a trigger however. The internals are quite different. From the two piece bolt body, bolted on beefy extractor, removable firing pin, tiny "keeper", bolt-on ejector. It almost seems a little bit bolted together rather than machined. Some things I wasn't impressed with is the finish on the bolt body, bolt knob, and scope rail. It seemed cheap and poorly done. The anodizing on the bolt knob was textured and rough. Not at all like what I'm used to on my TL3's and Origin. There's already finish wear on the front half of the bolt body and I just took possession of it. Imagine a bolt body made of aluminum and a poor finish applied. That's how it looks. The scope rail is also not what I'm used to on my Bighorn actions. Almost like a dry, coarse phosphate finish on a set of overpriced Larue rings. The receiver is nicely finished tho.

View attachment 7287320

View attachment 7287321

View attachment 7287323

View attachment 7287324

View attachment 7287325

View attachment 7287350

The extractor and ejector are beefy. The way the extractor is fixed it has to be controlled round feed it won't work. The little keeper/ tensioner is spring tensioned. The literature that comes with says in big black bold letters DO NOT SINGLE FEED ROUNDS!!! and DO NOT DRY FIRE!!!

It is obvious the extractor would have to smash past the rim of a case if it didn't slide up the feed ramp and the rim under the extractor. Unlike a TL3, there's no spring tension on the extractor so mag feed only it will be.

The mag. Really nicely machined and thought out. It is clearly different and incompatible with Vudoo mags. A person can disassemble it by hand. Floorplate slides off, spring rockets out across the room and follower slides out. Four screws on one side of the mag demonstrate how to separate the two halves. The ramp in front of the follower is significantly larger than a Vudoo mag. Kinda tips it's hand as to how much the bullet is going to rely on the ramp. The removable floor plate shows how easy it's going to be to add a +2? +20rd bumper. Here's the bad part. The follower binds... A lot... Mind boggling. It's a hard, dense plastic. It seems like tolerances are precise and the dry anodizing isn't playing well with the follower. Hopefully a very conservative spot of oil helps it slide freely up and down. Kind of unbelievable...

View attachment 7287327

The mag is clearly different than a Vudoo mag and will not fit a V22.

View attachment 7287329

View attachment 7287331

View attachment 7287333

So the action is at the Smith's. Been waiting for two days for the NIC check to clear. He has the Shilen ratchet rifled barrel and a Calfee 2 reamer. The Smith is going to slug the barrel looking for a tight spot. Shilen says their barrels are taper lapped and you shouldn't find a tight spot. If that's the case we'll go 20". Otherwise Im good anywhere between 16 and 22". He's going for 41 thou headspace and we're going to take measurements on Lapua Center X for land engagement. We're going to go aggressive and throat it out as we go. We're also not above ordering a reamer if we don't like what we see.

Any issues you have with surface finish can definitely be addressed. The rail looks to have been dinged up a little in shipping. If you'd like that replaced, let us know and we'll take care of it without question. That goes for most parts. If there's a problem with the finish, let us know. When it comes to wear on the bolt body, it's nitrided. Nitride is not a coating and the black is byproduct that's absolutely going to shine up. When it comes to the bolt knob texture, that's due to a change in anodizing processors. We're no longer doing the surface prep (bead blast) in house. It saves us an incredible amount of time and money to send our parts to a facility that can do both so that won't change.

Follower binding. This is a function of the magazine NEVER being used. We found this out after we had a bunch of magazines assembled. We took a couple of them, loaded 2 magazines and fired them through a rifle. It wore in and went away immediately.

We understand there are going to be people reviewing as soon as they get it in their hands. But we don't think it's reasonable to cast all that judgement on a product you've never put to use. It seems like most of what you pointed out is on the surface and can be either corrected very easily or will work itself out when you get the action in a rifle and go out and shoot it. If you'd like anything replaced, email us and we'll work through it with you.

Thanks - Ray

... then there's the fact that almost every rifle builder will hit the barreled action with at least a solid color cerakote before it goes out the door for crazy low cost.It seems like most of what you pointed out is on the surface and can be either corrected very easily

I don't care about a weapons finish for the most part function function/accuracy is all I care about. I don't buy safe queens. I will ding up everything eventually. Let's see some groups. Also the 17 WSM is what I really want.

Mines at Keystone Accuracy right now having the Bartlein and Benchmark fitted. Hope to get this review going very soon!

Called Ray this morning and he was super nice about the finish issue on the bolt/firing pin shroud. He said to send it in with my rail and bolt knob they are swapping out (because I wanted a different moa and style) and he would get a new one on its way. A+++ customer service. Thanks Ray!

I don't agree with the above review that the bolt in this action is looser than the Vudoo. I think it moves around a lot less and is far less prone to hangup. You almost can't make the bolt bind if you try. So far I like the overall feel better than my Vudoo. My proof barrel is supposed to ship from ALTUS this week and hopefully I can get the other parts back quick and get some groups together to post up.

I don't agree with the above review that the bolt in this action is looser than the Vudoo. I think it moves around a lot less and is far less prone to hangup. You almost can't make the bolt bind if you try. So far I like the overall feel better than my Vudoo. My proof barrel is supposed to ship from ALTUS this week and hopefully I can get the other parts back quick and get some groups together to post up.

Ray,

Sorry you felt my initial impressions were unfair. I'm a huge Zermatt fan. There's a big following of TL2's and TL3's in my area and I'm absolutely all in on your products. This is my fourth Bighorn/ Zermatt action. I was really excited when you all debuted this action. But there was very limited info out there for folks. Just teaser and glamour photos. I ..think.. my post above is the first to show details and photos of the mag, it's parts and disassembly, fixed extractor, and ejector. I have been motivated to lay it out for all the other folks in my position. Eagerly waiting to get a better look at the action. My impressions are relatively unbiased. The only bias I have is wanting to replace my V22 with it, so definitely not meant to degenerate you all. But this is a topic of conversation that we locally are having. FWIW. Just the good and bad either way. I won't be returning any parts for small dings but I would like to exchange the rail for one with more bias. Preferably a 40moa.

As I figured, just a little light lube freed the follower up significantly. We'll see how it does with all the grit we get out here in Colorado.

No need for an apology, we didn't think anything was unfair as we greatly appreciate all of the feedback people may have. We just wanted to address the points you made regarding our product and let people know we'll take care of any issues anyone has. We prefer a direct contact for those situations as they're almost always different.

As always, send us an email and we'll get you sorted out.

Thanks - Ray

<low whistle> That's a pretty slick design. It does make me wonder if the mag body could be made from Delrin...certainly would be kinder to the machine tools.

I wonder how tight the tolerances are for the mag catch. Is it going to be something that will need to be fiddled with every time that you decide to change things up chassis wise? Or is it more for "fine tuning" of feeding.

Plastic floats on top of your coolant tank and clogs the pumps and all your small passage coolant through tools. Aluminum is definitely the way to go.And delrin even less...

I wonder how tight the tolerances are for the mag catch. Is it going to be something that will need to be fiddled with every time that you decide to change things up chassis wise? Or is it more for "fine tuning" of feeding.

For the most part, chassis are similar. The adjustable catch is there to assist with the feed cycle. It may need a small adjustment if you change a chassis, but we figure most people won't change chassis every other day.

Plastic floats on top of your coolant tank and clogs the pumps and all your small passage coolant through tools. Aluminum is definitely the way to go.

Ummm...you don't need coolant with delrin. But if you're just arguing to argue...(which is what this sounds like).

Regardless, it's a nice design.

I’m not arguing to argue. If you want to run delrin at its respective SFM without melting it, it needs coolant. Also, what are you going to do, pull the coolant pan out when you run delrin so it doesn’t get into it for when you run something you would run coolant with?

Does look like a fantastic design.

Does look like a fantastic design.

@Zermatt Arms our Rim X arrived today form Altus.

- Great job on the action! Smoother functioning that our Vudoo. The extra guiding length can easily be felt when cycling the bolt.

- Bolt take down is a breeze.

- The aluminum magazine loads like its on an air bearing.

- The adjustable mag catch height built into the magazine is great for setting up everyting in a chassis that is used on more than one barreled action

- No finish issues - looks very good

- Great job overall!

Went with a proof pre-fit and will get it to the range in the next week hopefully.

- Great job on the action! Smoother functioning that our Vudoo. The extra guiding length can easily be felt when cycling the bolt.

- Bolt take down is a breeze.

- The aluminum magazine loads like its on an air bearing.

- The adjustable mag catch height built into the magazine is great for setting up everyting in a chassis that is used on more than one barreled action

- No finish issues - looks very good

- Great job overall!

Went with a proof pre-fit and will get it to the range in the next week hopefully.

Yes. It is our intention to work up a parts kit and have it available shortly. We'll probably be able to launch that as a product on the RimX standalone site first then add it to our new site.@Zermatt Arms Will you be offering a small parts kit once you get caught up and begin stocking the small parts on hand? Firing pin, extractor, ejector, "tensioner", tensioner spring, pin, etc? It looks like a person could replace most of it themelves. It would be nice to have a Deployment kit in the gunbox.

Thanks - Ray

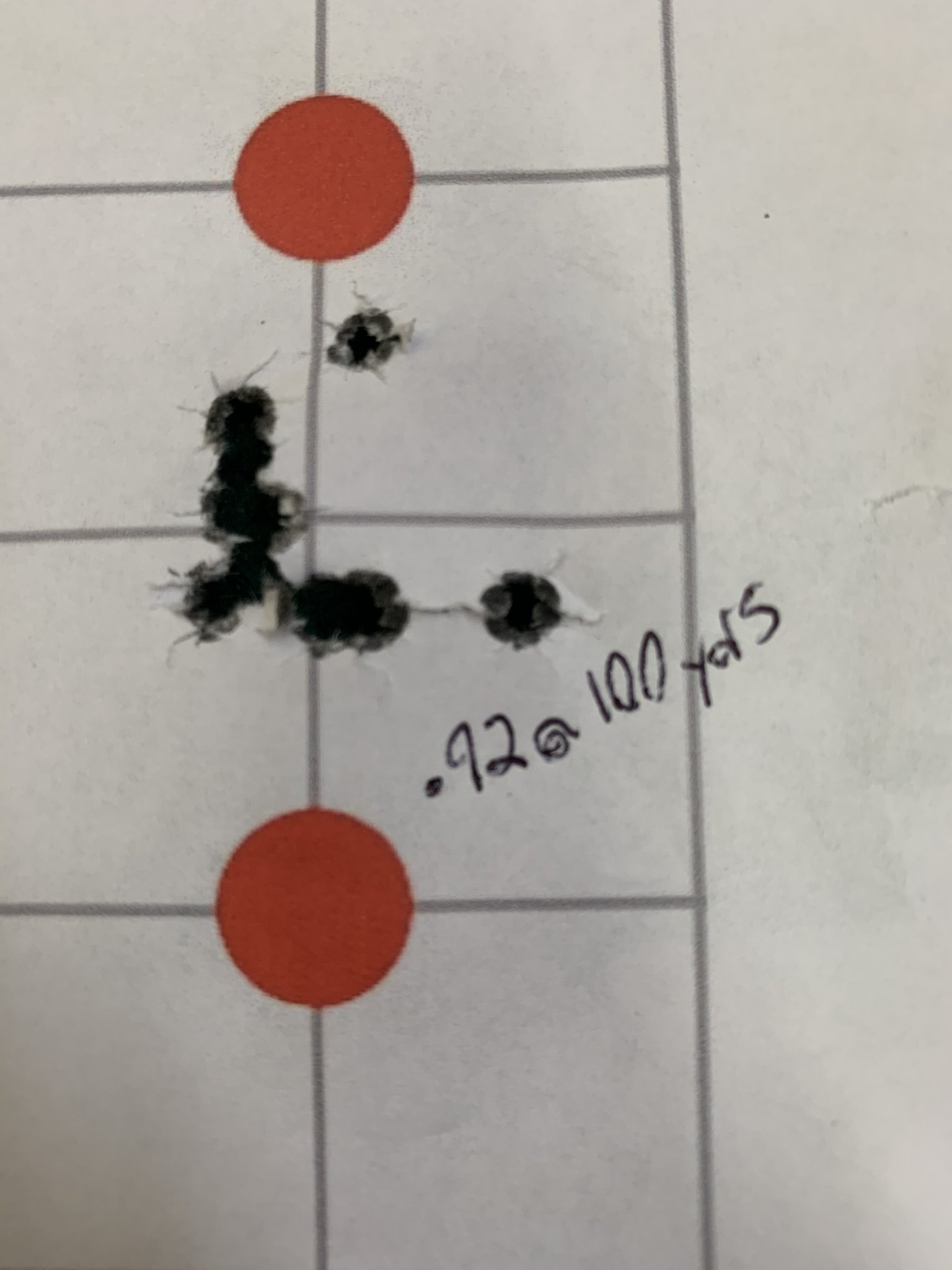

First groups at 50 and 100yds. Proof prefit 18” competition contour with SK+ bare muzzle. I expect groups to tighten up a bit after a few hundred rounds.

Just got my rifle today, threw a TT trigger and MPA chassis on it. So far I'm pleased. The adjustable mag latch proved necessary to get it to feed right. It's terribly windy today and temps dropped to 40°. Still, centerx and surprisingly enough Fed automatch shot really well. 75yds in a full cross wind with no flags gave a pretty good group. Next nice day, I will run some CCI thru it and some SK.

This was shot right after some centerX, and should have burned 3 rounds before shooting for group.

This was shot right after some centerX, and should have burned 3 rounds before shooting for group.

Attachments

Just got my rifle today, threw a TT trigger and MPA chassis on it. So far I'm pleased. The adjustable mag latch proved necessary to get it to feed right. It's terribly windy today and temps dropped to 40°. Still, centerx and surprisingly enough Fed automatch shot really well. 75yds in a full cross wind with no flags gave a pretty good group. Next nice day, I will run some CCI thru it and some SK.

This was shot right after some centerX, and should have burned 3 rounds before shooting for group.

What can are you running? Also try some CCI Green tag trust me

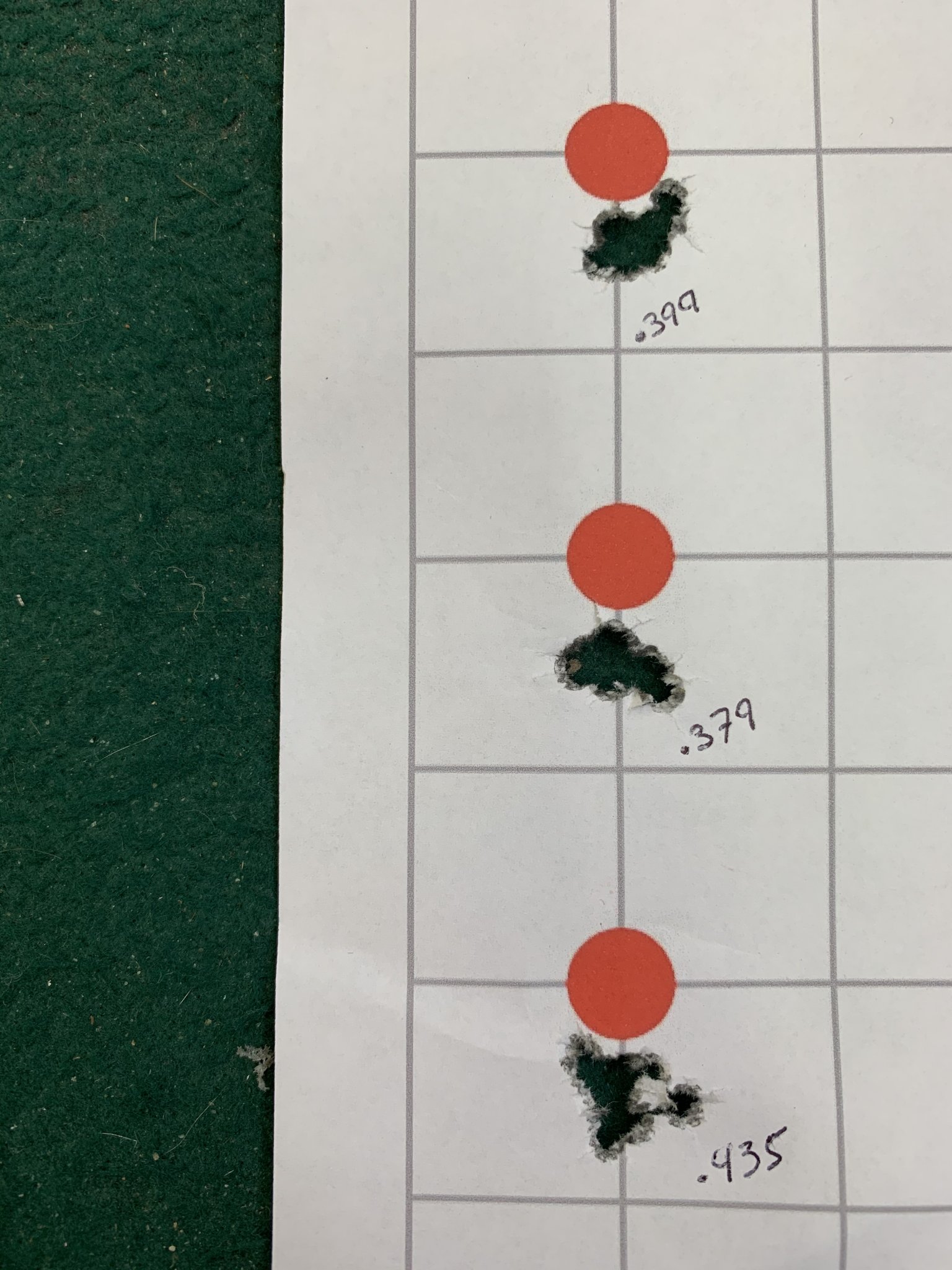

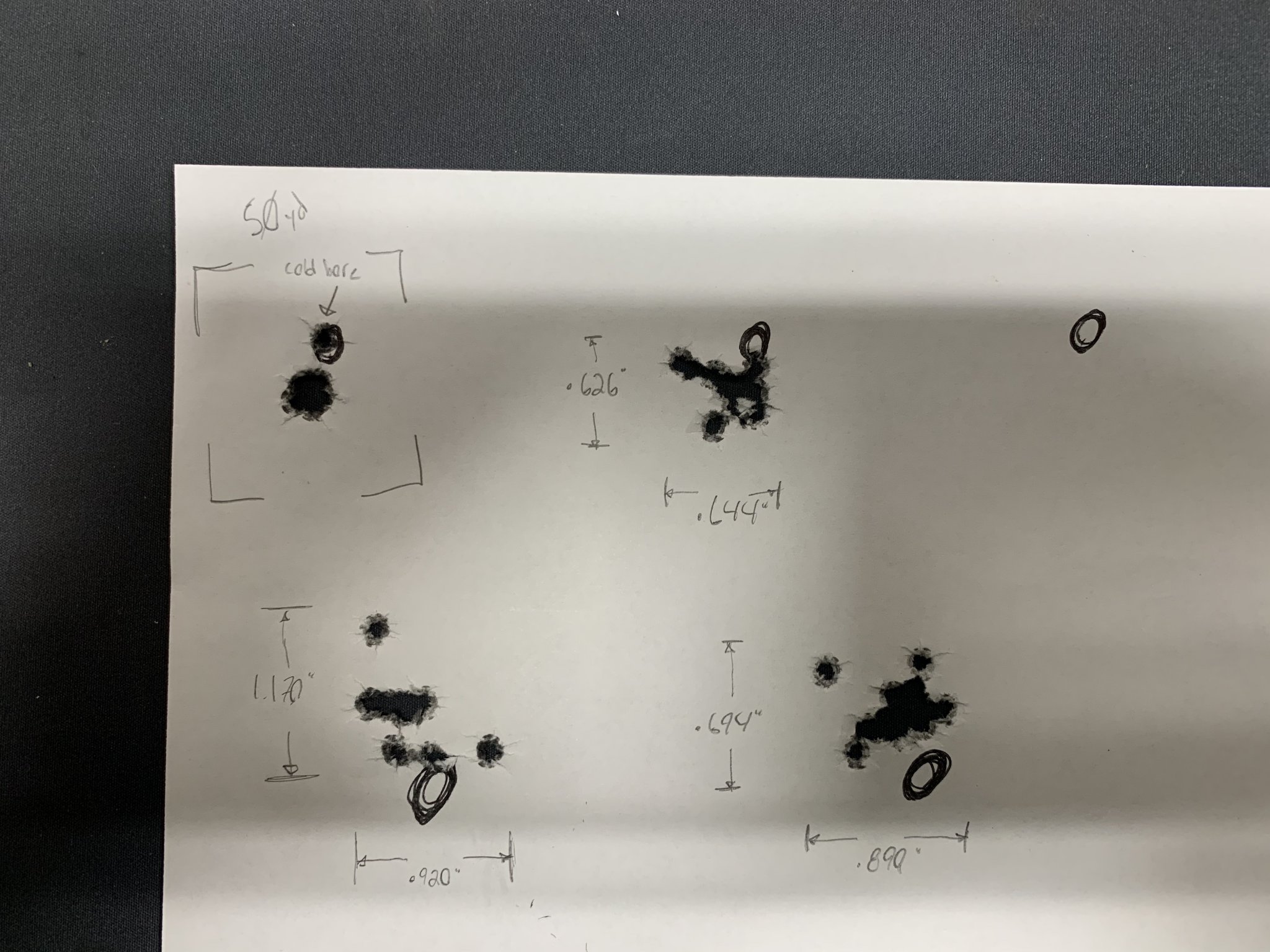

Took another lot of SK+ out. Shot off bipod and bag in the prone, bare muzzle. Top left is 50yds, the rest are 100. All 10 shot groups.

-Rimx, proof prefit 18” comp contour.

-Rimx, proof prefit 18” comp contour.

Never realized that the proof comp contour was so beefy, I was hoping to have my RimX this week but the USPS sent it on the scenic route so maybe it will arrive sometime next week.

It’s new name is beer canNever realized that the proof comp contour was so beefy, I was hoping to have my RimX this week but the USPS sent it on the scenic route so maybe it will arrive sometime next week.

How does it look with a suppressor? It's muzzle diameter is larger than the can isn't it?

Is it true that you cannot dry fire the RimX?

You can dry fire it. You can even pop the firing pin out with no tools, just to be double sure nothing gets damaged.

The literature says you cannot dry fire without removing the firing pin tip. The process is pretty simple for removal, but kind of a pain for reassembly (I’m sure I’ll get better at it with practice). I have let it fire on an empty chamber at the range and did not see any noticeable contact between the firing pin and the breech, not saying that there isn’t some other kind of damage going on.Is it true that you cannot dry fire the RimX? If so that is a difference with Vudoo. Perhaps an important feature to you, perhaps not.

A good friend of mine had a rifle with a headspace of 56 thousandths... and it was one of the best shooting rifles he's ever had.

I've had several 40X's with headspace of 46+, and they too shot very well.

The bolt design of the RimX and their headspace choices don't trouble me in the slightest. If anything, I'm excited for the better ignition that design allows for and the significantly better debris management than traditional setups. I predict this @Zermatt Arms design will prove out to be very accurate and extremely robust.

I've had several 40X's with headspace of 46+, and they too shot very well.

The bolt design of the RimX and their headspace choices don't trouble me in the slightest. If anything, I'm excited for the better ignition that design allows for and the significantly better debris management than traditional setups. I predict this @Zermatt Arms design will prove out to be very accurate and extremely robust.

I was fooling around with headspacing, and when I didn't headspace tight enough, I dropped velocity quite a bit. I don't know much about all this so it'll be interesting to watch and see how this goes.

I wonder how much headspace it caused to have this happen -

I wonder how much headspace it caused to have this happen -

Shot the rimx yesterday. This thing is sweet. Vudoo might be getting left on the shelf. Did a bunch of barrel testing with the owner of the action. Conditions where 8 mph to 12 from

3

3

Last edited:

Boy, someone must have got a form 1 back in record time.

... if not, am I not looking at an unregistered SBR? Does the overall length of the stock invalidate that?

... if not, am I not looking at an unregistered SBR? Does the overall length of the stock invalidate that?

Damn! An (SBR) Short Barreled Rimfire.......Kinda funky, but I like it.Shot the rimx yesterday. This thing is sweet. Vudoo might be getting left on the shelf. Did a bunch of barrel testing with the owner of the action. Conditions where 8 to 12mph from 3. So not good.View attachment 7290347View attachment 7290348

lol!You can't see the buttstock, probably did a Sig Brace conversion on that JAE.

Very good info.all fellows picture itself speak a thousand words.More picture please.This should be in the sticky board now.Wowww

Mine just landed on the hand of my FFL.I took picture after checking all parts no defects on action and magazine even small ding.I can say PERFECT QUALITY.The coated on the action looks very nice and tough stuff.I can only say "PERFECT QUALITY CONTROL",Oh,i forgot the bolt is too smooth like a butter tilt a little bit the bolt slide right away,smooth than my lithgow 101.My only complain is that i only get 30MOA rail on mine.but all in all it is very solid quality control.Atleast this is my personal experience on mine.

Mine just landed on the hand of my FFL.I took picture after checking all parts no defects on action and magazine even small ding.I can say PERFECT QUALITY.The coated on the action looks very nice and tough stuff.I can only say "PERFECT QUALITY CONTROL",Oh,i forgot the bolt is too smooth like a butter tilt a little bit the bolt slide right away,smooth than my lithgow 101.My only complain is that i only get 30MOA rail on mine.but all in all it is very solid quality control.Atleast this is my personal experience on mine.

Attachments

Last edited:

The literature says you cannot dry fire without removing the firing pin tip. The process is pretty simple for removal, but kind of a pain for reassembly (I’m sure I’ll get better at it with practice). I have let it fire on an empty chamber at the range and did not see any noticeable contact between the firing pin and the breech, not saying that there isn’t some other kind of damage going on.

The inspection card just recommends that you remove the firing pin tip if you're going to do any prolonged dry fire practicing. You can absolutely dry fire it without damaging the chamber face. If you don't remove the tip and dry fire practice with the tip installed, we've found it fatigues the tip much faster and can end up breaking that part at a much lower round count than if it's being fired on a live round.

It's hard to explain the process of removing and installing the tip, but it's kept in place by a small retaining pin. Don't use much force to remove it or you could break it. It installs at an angle to get the tip underneath the retaining clip.

Just so folks know, the headspace on the RimX is fixed. If you want to chamber your own barrel you won't be able to go with a custom headspace depth like most rimfires. The bolt face depth from the nose is .0455" so the deepest headspace you'll get is .046". I'm sure Ray will chime in but their theory is that jamming the rim against the breech isn't necessary bc of the fixed extractor. It will hold the case against the bolt face during ignition. We will see. I'm encouraged by MuggyTerras groups. It's a good sign of that theory proving out. I was pretty hot when I found out from my gunsmith. But we will chamber it per Zermatts specs. They have proven to be top-notch in every thing they have put out so far, no reason to distrust them now. Also, the breech face isn't flat. It needs a slight angle cut into it to provide clearance for dirt and grime.

In regards to headspace:

Minimum for the RimX will be .0455" with a maximum of .0500". Yes, we know this is a bit shocking to some people familiar with rimfire chambers. The reasons behind the higher minimum headspace are derived from the geometry of our fixed extractor bolt head. In our design, the extractor controls the round throughout the entire feeding, chambering, firing, and extracting cycle. There is not a time in the bolt cycle of our design that the round is not being controlled by the bolt head and extractor. In the typical claw extractor, extractor slot/reverse cone chamber setup, the extractor lets go of the round while it's chambered creating the ability for the round to move fore and aft if the headspace is not set much closer to the minimum. That's why you see other designs with that claw extractor and timed extractor slots using a much smaller minimum headspace (somewhere in the .0410" - .0430" range).

We feel that our bolt and extractor design is extremely unique and original to the rimfire world and will require an amount of new education and barrel design concepts to get closer to perfect. We're not asking people to throw everything they know about precision rimfire out the window, but we are asking people to be open to the new design concept and learn about the system with us. As some of you that are familiar with our products already know, we aren't going to throw something out in the market that isn't going to perform well from an accuracy or a function standpoint. We've tested this in house and with a good group of shooters pretty extensively and have found that accuracy potential is VERY high with this product. We're seeing this already in this thread among others published out there.

NOT RELATED TO ABOVE COMMENTS:

PLEASE READ THE INSPECTION CARD THAT COMES WITH YOUR ACTION!!!! There is some very important information in there that will eliminate problems you may encounter right away. Magazine catch heights are not set to any precision standard. You WILL have to adjust your magazine catch to your specific stock or chassis to feed rounds properly. If you don't have vertical play limited to 1/16", you will likely not have the best time with feeding and could permanently damage your extractor without knowing. Signs of a damaged extractor will be present in ejection as well as a stiff bolt close. You should feel very little resistance when chambering a round. PLEASE PAY ATTENTION WHEN YOU'RE SETTING THESE RIFLES UP. You'll enjoy the product that much more if it's done right the first time.

Thank you - Ray

Any concern about buildup of gunk on the breech face interfering with chambering? I know guys were machining recessed areas on Vudoos to try to get around this known issue.The inspection card just recommends that you remove the firing pin tip if you're going to do any prolonged dry fire practicing. You can absolutely dry fire it without damaging the chamber face. If you don't remove the tip and dry fire practice with the tip installed, we've found it fatigues the tip much faster and can end up breaking that part at a much lower round count than if it's being fired on a live round.

It's hard to explain the process of removing and installing the tip, but it's kept in place by a small retaining pin. Don't use much force to remove it or you could break it. It installs at an angle to get the tip underneath the retaining clip.

In regards to headspace:

Minimum for the RimX will be .0455" with a maximum of .0500". Yes, we know this is a bit shocking to some people familiar with rimfire chambers. The reasons behind the higher minimum headspace are derived from the geometry of our fixed extractor bolt head. In our design, the extractor controls the round throughout the entire feeding, chambering, firing, and extracting cycle. There is not a time in the bolt cycle of our design that the round is not being controlled by the bolt head and extractor. In the typical claw extractor, extractor slot/reverse cone chamber setup, the extractor lets go of the round while it's chambered creating the ability for the round to move fore and aft if the headspace is not set much closer to the minimum. That's why you see other designs with that claw extractor and timed extractor slots using a much smaller minimum headspace (somewhere in the .0410" - .0430" range).

We feel that our bolt and extractor design is extremely unique and original to the rimfire world and will require an amount of new education and barrel design concepts to get closer to perfect. We're not asking people to throw everything they know about precision rimfire out the window, but we are asking people to be open to the new design concept and learn about the system with us. As some of you that are familiar with our products already know, we aren't going to throw something out in the market that isn't going to perform well from an accuracy or a function standpoint. We've tested this in house and with a good group of shooters pretty extensively and have found that accuracy potential is VERY high with this product. We're seeing this already in this thread among others published out there.

NOT RELATED TO ABOVE COMMENTS:

PLEASE READ THE INSPECTION CARD THAT COMES WITH YOUR ACTION!!!! There is some very important information in there that will eliminate problems you may encounter right away. Magazine catch heights are not set to any precision standard. You WILL have to adjust your magazine catch to your specific stock or chassis to feed rounds properly. If you don't have vertical play limited to 1/16", you will likely not have the best time with feeding and could permanently damage your extractor without knowing. Signs of a damaged extractor will be present in ejection as well as a stiff bolt close. You should feel very little resistance when chambering a round. PLEASE PAY ATTENTION WHEN YOU'RE SETTING THESE RIFLES UP. You'll enjoy the product that much more if it's done right the first time.

Thank you - Ray

That's why we recommend the 10* cone around the chamber face. If you'd like a print, send me an email and we can get that to you.Any concern about buildup of gunk on the breech face interfering with chambering? I know guys were machining recessed areas on Vudoos to try to get around this known issue.

[email protected]

Thank you,

With that cone breech... the amount of neglect required to get enough goo and debris to interfere with function would be... legendary.

Similar threads

- Replies

- 8K

- Views

- 563K

- Replies

- 4

- Views

- 3K

- Replies

- 222

- Views

- 48K

- Replies

- 79

- Views

- 27K

- Replies

- 46

- Views

- 15K