Re: Puget Sound Area Shooter's Group

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: attherange</div><div class="ubbcode-body">just got back from benchmark barrels in Arlington. Some guys showed up while I was there with a bunch of scope rings and benchmark bought a bunch of them, they are called B A Gear and seem really well made, I bought a set of 30MM low for my .260,

the guys at benchmark only carry those now as they said they were the best rings they ever saw.

Anybody ever heard of those rings, they weren't cheap?? </div></div>

I just got a sample of a set of BA Gear 30MM lows rings from Killer Innovations. I haven't gotten a chance to inspect them fully (ie use micrometers on them), but I see some good and bad with them.

<span style="text-decoration: underline">The Good</span>:

They look and feel solid.

I like the index key pins that lock in the upper and lower rings together. The edges look smooth. Reason why is that they machine the parts together. Each half of the ring is uniquely machine to another half so you can't necessarily mix and match. Hence they engrave a index to determine who goes with who. Another interesting thing I was told by the manufacturer is that the rings are milled together so the hole is perfect, then they shave a little of the flat surface of one of the halves to allow more ability to clamp down since not all scope circumferences are built equal.

The upper and lower rings are index labeled, hence a match set.

The front & rear rings are also index labeled.

The mounting of the rings to the rail uses a 1/4 allen wrench to tighten the mount. I'm not sure if I like it since it looks like it could strip due to the way they designed it with multiple edges rather than a standard 6 side hex. But with the amount of torque needed to mount on a rail, it probably wouldn't be a issue.

*** Talked to the manufacturer and they state that this was the only type of nut they could find at a reasonable price range. They mention that they tested it and it holds up.

<span style="text-decoration: underline">The Bad</span>:

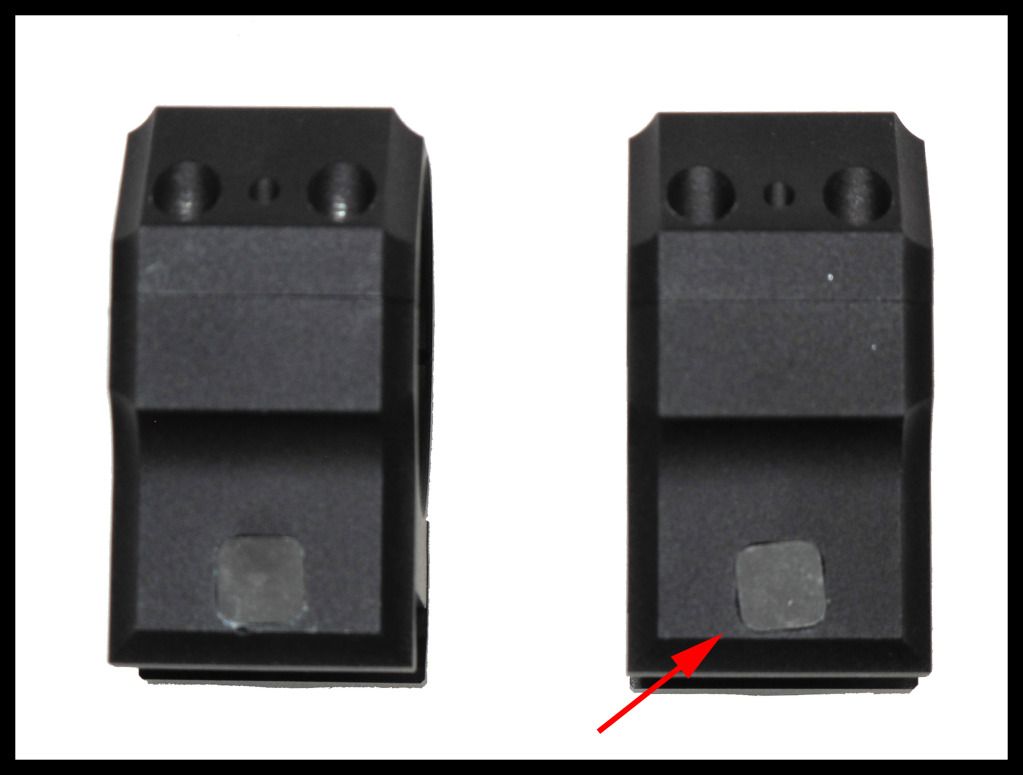

The ring slot that goes into the rail can be twisted. This sample was already twisted, hence it's not a flush surface when contacting the rail.

*** Talked with the company and they recognized this problem and is currently trying to correct it.

Uses a milled screw to key into the rail. I much prefer the method Seekins uses which is a milled key which would allow flush contact to the rail.

*** Talked to manufacturer and he mention that this shouldn't be a issue. I have no scientific proof if this would be a issue. Groping for straws all I can say is if the rotation of the cross bolt is fixed in it's alignment during the course of fire and shift the scope forward. I still prefer a flush contact to the rail though.

Also talking with them more, they believe that the clamping of a cross bolt is stronger than something like Seekin's using two screws. Also a added benefit is that if you do strip the the threads, you can replace the cross bolt, while Seekin's you have to replace the rings.

It costs more than Seekins, but less than Badger rings at a price of $149.

TBD:

Test it mounting on AR-15 rails. Apparently I might not be torquing it down hard enough.. and that would be true. If this is true, then clamping nut would have a uneven pressure distribution, ie more pressure towards the ring side, and bottom of the clamp side would be pushed in towards the center. How drastic that would be I wouldn't know at the moment.

...Okay this went a lot long than I expected.. guess it probably deserves it's own thread..