If you are running GT at 2800 is there a compelling reasons to continue to use GT over straight BR?

Are you going to run multiple/alternative loads to retain the advantages of the extra case volume? My concern with the latter approach is what happens when the throat erodes and you need to tweak/tune your load, you are stuck wasting barrel life tweaking multiple loads over the course of the barrel?

Apologies if this is off-topic, but figured maybe something people have thought about after a couple of seasons under the belt.

As far as GT vs BR, IMHO, mag spacers suck, and I know like 3 guys off the top of my head that will tell you their Dashers/BR's run 100% even though I see them have a glitch or two pretty much every damn match lol. That, and you pretty much have to lean on a BR fairly hard if you spend a lot of time out at 1000+ yards (which I do).

IMHO 6GT's only real advantage over a 6CM run "slow" is that it can use Varget, which is huge, because as far as powders go, Varget is the easiest of the easy.

The only reason I'll be running "slow" is that I'd much rather have a barrel last a long time rather than push it harder and maybe only gain a tenth or so as far as better trajectory. Wind and/or wobble is usually what makes me miss most of the time, so even with a totally flat trajectory with a blaster out of Star Wars, I'd still manage to suck just fine lol. Plus, my brass lasts forever.

I don't tweak shit anymore, I just load, shoot, rinse, repeat. A huge part of the reason I'm drunk on the bullet-jump kool-aid is that with a longer jump, once you have a load that shoots, you don't have to tweak it for the life of the barrel. Super forgiving too, water-line stays stupid predictable (almost makes it seem like you got better at reloading overnight).

It's pretty simple really: with a longer jump throat erosion slows way down and the barrel becomes boringly forgiving. My first 6CM barrel's throat that I loaded 0.100" off for its whole life, only eroded ~12 thou over the course of 2300rds, guys loading 0.020" off can see that in a 200rd weekend...

It depends on what one is after: IMHO I'd rather have a gun that I don't have to mess with that

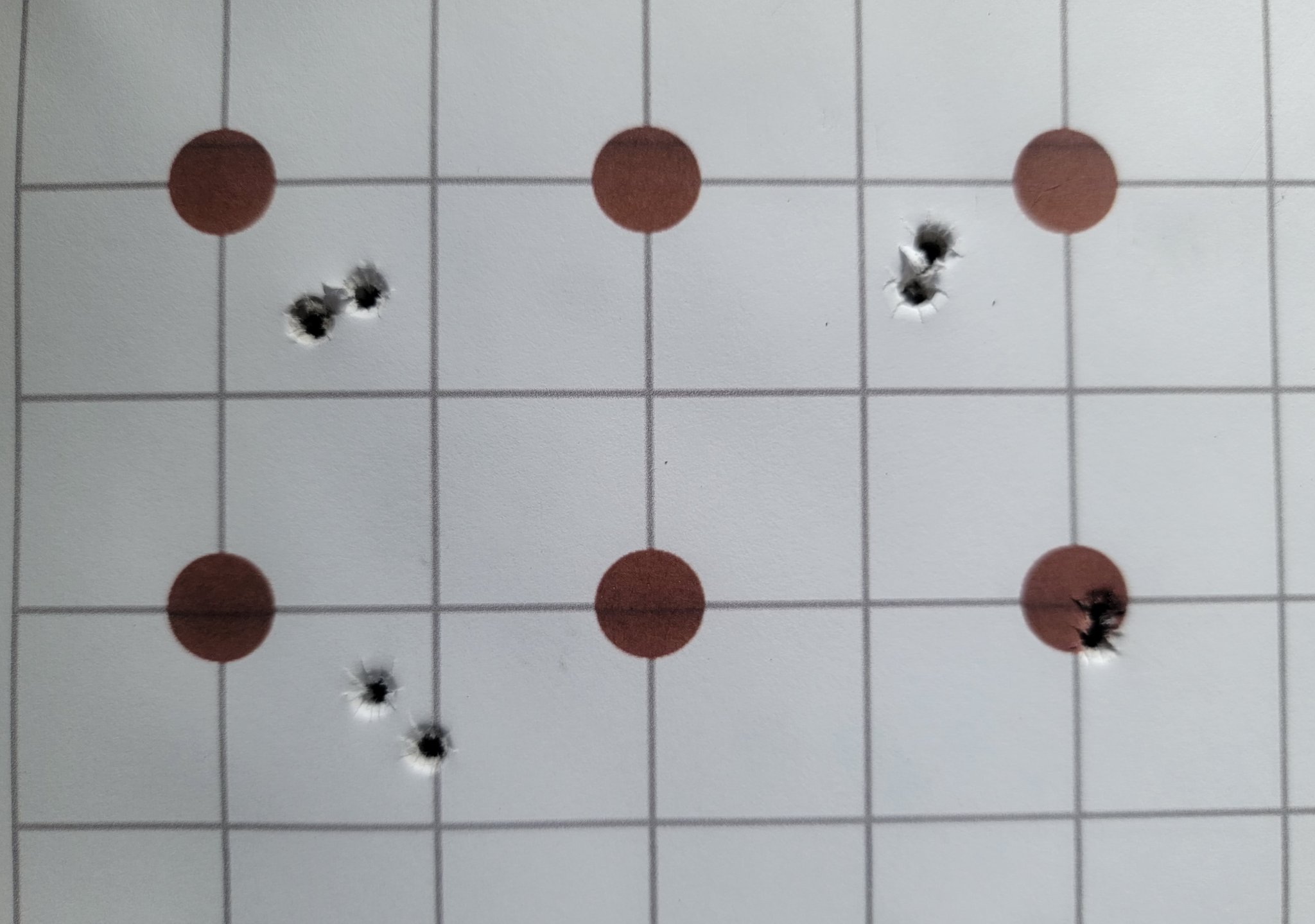

only prints ~.5" at 100 (and stays 1/2 MOA out to past 1000 yards, staying boring that way for its whole long life), rather than a gun that shoots .3" groups and is dead in half the rounds.