I don't know. It's why I asked. Likely gonna stick with GT since I have the dies, load data, etc.Why? What does the Dasher do for you that the GT isn't? (not rhetorical, not being a smart ass, genuinely curious on your reasoning or thought process)

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6gt

- Thread starter Dthomas3523

- Start date

Early October.When's the last time anyone has seen 109 bergers? I'm down to around 300 105's, so I've got to make a move on some bullets soon.

JulyWhen's the last time anyone has seen 109 bergers? I'm down to around 300 105's, so I've got to make a move on some bullets soon.

Hawkhill are the shit! My personal chocie, love the competition contour.Looks like next barrel is hawk hill. Atleast shipping will be faster

Thanks guys. Looks like the 105 vld's and the 108 BT from Berger are available. Anyone like one over the other?

Iirc. 108 BT is similar to 109s without the pointing.Thanks guys. Looks like the 105 vld's and the 108 BT from Berger are available. Anyone like one over the other?

That's the 108 elite hunter nite. Guys were using them in place of 109s last season. I think these 108s are a different.

With that being said, always take a berger bullet

With that being said, always take a berger bullet

The 108 BT is almost identical in design to the 107 SMK. I like the 108 BTs and you can find them for a lot less than the others and a lot more frequent. The 108 Elite Hunters are a hybrid design with a blended ogive.

HELP HUGE SHOULDER BUMP

Happy holidays everyone. I wanted to ask if anyone has any insight with what I am seeing that has me stumped.I got my 6GT from GA Precision spring 2022 and what an amazing rifle. So far I have loaded and shot 100 new alpha brass for break in process with 105 Nosler RDF because it’s what I had. By the way 34.7 Varget gets barely over 3000 fps and about .2 MOA.

The issue is now I go to reload those original once fired brass and the shoulder bump is HUGE. I have tried two good die’s with Same result. Also using zero press.

Fired brass measures from 1.3040 to 1.3100 with SAC comparator

— When I run SAC die to contact shell holder I get .031 bump

— When I run Micron die to contact shell holder I get about .026 bump

I unscrewed the SAC die until I got the proper .002 shoulder bump and then measured gap between shell holder and bottom of die body and as expected it was about .032

THATS A WHOLE LOTTA BUMPIN’

not sure I have seen that much bump in contact with shell holders for other cartridges. The guys over at SAC are incredible to work with way beyond generous and offered to help troubleshoot so I gave them some examples of fired brass and my die to troubleshoot.

Are you all seeing this much bump when contacting the shell holder? Could something be wrong with my chamber?

Any help I would be thankful for

Thanks

Are you using generation 1 or 2 SAC dies?HELP HUGE SHOULDER BUMP

Happy holidays everyone. I wanted to ask if anyone has any insight with what I am seeing that has me stumped.

I got my 6GT from GA Precision spring 2022 and what an amazing rifle. So far I have loaded and shot 100 new alpha brass for break in process with 105 Nosler RDF because it’s what I had. By the way 34.7 Varget gets barely over 3000 fps and about .2 MOA.

The issue is now I go to reload those original once fired brass and the shoulder bump is HUGE. I have tried two good die’s with Same result. Also using zero press.

Fired brass measures from 1.3040 to 1.3100 with SAC comparator

— When I run SAC die to contact shell holder I get .031 bump

— When I run Micron die to contact shell holder I get about .026 bump

I unscrewed the SAC die until I got the proper .002 shoulder bump and then measured gap between shell holder and bottom of die body and as expected it was about .032

THATS A WHOLE LOTTA BUMPIN’

not sure I have seen that much bump in contact with shell holders for other cartridges. The guys over at SAC are incredible to work with way beyond generous and offered to help troubleshoot so I gave them some examples of fired brass and my die to troubleshoot.

Are you all seeing this much bump when contacting the shell holder? Could something be wrong with my chamber?

Any help I would be thankful for

Thanks

Don’t let the die make contact with your shell holder.HELP HUGE SHOULDER BUMP

Happy holidays everyone. I wanted to ask if anyone has any insight with what I am seeing that has me stumped.

I got my 6GT from GA Precision spring 2022 and what an amazing rifle. So far I have loaded and shot 100 new alpha brass for break in process with 105 Nosler RDF because it’s what I had. By the way 34.7 Varget gets barely over 3000 fps and about .2 MOA.

The issue is now I go to reload those original once fired brass and the shoulder bump is HUGE. I have tried two good die’s with Same result. Also using zero press.

Fired brass measures from 1.3040 to 1.3100 with SAC comparator

— When I run SAC die to contact shell holder I get .031 bump

— When I run Micron die to contact shell holder I get about .026 bump

I unscrewed the SAC die until I got the proper .002 shoulder bump and then measured gap between shell holder and bottom of die body and as expected it was about .032

THATS A WHOLE LOTTA BUMPIN’

not sure I have seen that much bump in contact with shell holders for other cartridges. The guys over at SAC are incredible to work with way beyond generous and offered to help troubleshoot so I gave them some examples of fired brass and my die to troubleshoot.

Are you all seeing this much bump when contacting the shell holder? Could something be wrong with my chamber?

Any help I would be thankful for

Thanks

Adjust it for about .002” bump.

That is odd. I usually see a range of .002 max on fired headspace.Fired brass measures from 1.3040 to 1.3100 with SAC comparator

Honestly I never check the gap between die and shell holder. I screw it in till it touches, back off about 1/2 turn, & then adjust down till I get about .002 bump. I wouldn't want there to be a huge gap, but I wouldn't sweat .035.

Having a little gap is a good thing. It means you have adjustment room for bumping shoulders. This would only be a problem if you start to get clickers after 2-3 firings. That tells you that either the die isn't sizing the lower portion of the case enough or it's not sizing down far enough on that lower portion.

That is odd. I usually see a range of .002 max on fired headspace.

Same, but only when the shoulder is done growing. Sometimes that takes more than one firing.

I don't like to automatically bump back 1st fired brass .002 without making sure that the fired brass shows some resistance when closing the bolt, I want to make sure it's fully grown first.

This is a great point brass for sure has not grown to fill chamber yet. The once fire brass still chambers before sizing but you can feel it on the longer brass barely when closing bolt. But longer brass that fill chamber on second firing would have even more initial bump would it not?Same, but only when the shoulder is done growing. Sometimes that takes more than one firing.

I don't like to automatically bump back 1st fired brass .002 without making sure that the fired brass shows some resistance when closing the bolt, I want to make sure it's fully grown first.

I think second generation because it’s new just got it for this resizing session. It’s the modular sizing die “GT” product I’d 6729Are you using generation 1 or 2 SAC dies?

I went ahead and did just this to go ahead and get them resised for loading. Just dont understand why its so much.Don’t let the die make contact with your shell holder.

Adjust it for about .002” bump.

I have had this before on a 6.5x47.I went ahead and did just this to go ahead and get them resised for loading. Just dont understand why its so much.

Thought I was seeing pressure at first as all my fired brass had ejector marks on them.

After a lot of dicking around, I determined I was bumping shoulders way too far.

I, like you, followed the die instructions and ran into issues.

I didn’t know if it was a die issue or chamber issue, but after adjusting for only .002” shoulder bump, everything worked well.

How far you jumping those 109s? I have 2x gt hawkhill 7.5tw pipes shipping my way. I went with the long freebore alpha reamer.Spun on barrel #7 for the 2023 season and shot it yesterday. Going shorter with a 22" Hawk Hill 7.5 tw, heavy comp. Still performing well. 15 x 2 groups. Shawn at HH did the chambering.

I honestly don't know. lolHow far you jumping those 109s? I have 2x gt hawkhill 7.5tw pipes shipping my way. I went with the long freebore alpha reamer.

I have loaded the same load for several barrels. My CBTO is 1.845. It's likely around 60 thou jump.

You will like the Hawk Hills barrels.

Oh I'm very happy with my 3 other HH barrels! Thanks for the info. Ran 109s in my last 6gt, started at 40k off, by the end it was 120k off and still shot in the 3s.I honestly don't know. lol

I have loaded the same load for several barrels. My CBTO is 1.845. It's likely around 60 thou jump.

You will like the Hawk Hills barrels.

I was also looking at the Area 419 Zero modular shell holder system to get closer to contact and realized that if me and everyone else that shoots a 6GT has to back the die out about .030 to get a .002 shoulder bump than that product is useless for what it is designed to do. It may work on some cartridges I guess or maybe custom dies but can’t see the use of that product.I went ahead and did just this to go ahead and get them resised for loading. Just dont understand why its so much.

I just set mine up. Whidden dies. Slight cam over. +6 shell plate produces perfect shoulder bump. I have 2 turrets for 7 rifles. All set up without any issues.I was also looking at the Area 419 Zero modular shell holder system to get closer to contact and realized that if me and everyone else that shoots a 6GT has to back the die out about .030 to get a .002 shoulder bump than that product is useless for what it is designed to do. It may work on some cartridges I guess or maybe custom dies but can’t see the use of that product.

Well there goes that theory LOLI just set mine up. Whidden dies. Slight cam over. +6 shell plate produces perfect shoulder bump. I have 2 turrets for 7 rifles. All set up without any issues.

Did some searching and couldn’t find it but do I need a special stem for the 109 ELDMs? Running the RCBS match master set now

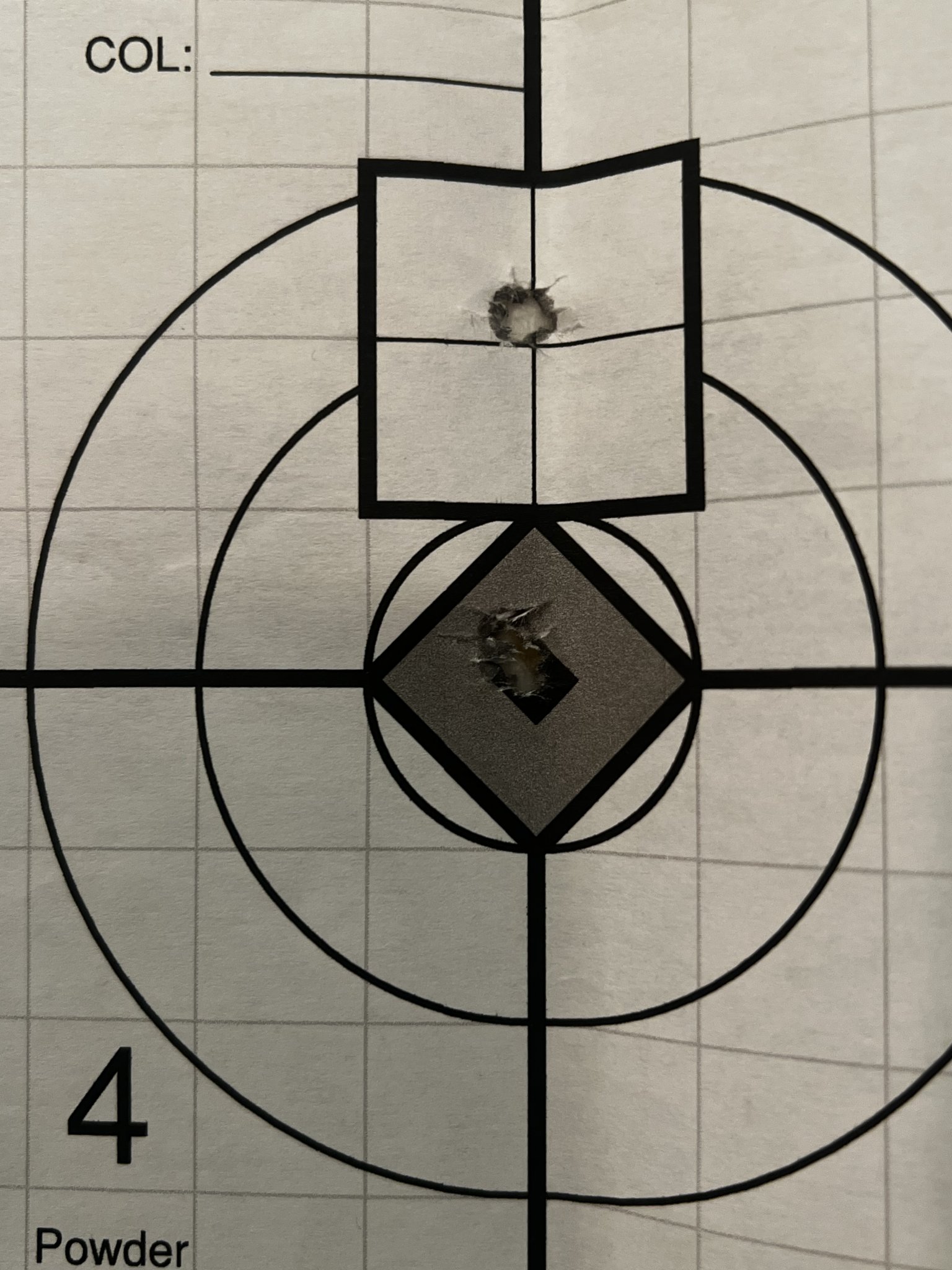

Got the gt dialed in today. I’ll stretch her out next time. This time was just 100 yard groups and some plinking at a 1.5” plate at 325 yards Shooting 108 boat tails over 36.5g h4350 with cci400s in alpha brass. Running right at 2940 fps. These are 2 seperate 3 round groups. shot the bullseye first, dialed up .4 mils and shot the upper group. Easily most accurate rifle I’ve ever owned or shot

Good looking rifle there. And welcome to the club.Got the gt dialed in today. I’ll stretch her out next time. This time was just 100 yard groups and some plinking at a 1.5” plate at 325 yards Shooting 108 boat tails over 36.5g h4350 with cci400s in alpha brass. Running right at 2940 fps. These are 2 seperate 3 round groups. shot the bullseye first, dialed up .4 mils and shot the upper group. Easily most accurate rifle I’ve ever owned or shot View attachment 8035999View attachment 8036000

Im breaking in a new barrel with 32gr 4166 and 108bt bergers running 2780. They're jumping 70ish thou? Not certain but man does it shoot. My previous match load from old barrel with 109 lrht is shooting in the 2s and 3s. This hawkhill shoots better than the bartlein it replaced.

I have 5lbs of IMR 4166 sitting here n a box so now I know wha I can try once my 6GT gets finished

I've settled on shooting Hawk Hills going forward. Not only for the performance but availability and contour (Heavy Comp).Im breaking in a new barrel with 32gr 4166 and 108bt bergers running 2780. They're jumping 70ish thou? Not certain but man does it shoot. My previous match load from old barrel with 109 lrht is shooting in the 2s and 3s. This hawkhill shoots better than the bartlein it replaced.

This is a hvy comp 7.5tw finished at 28" screwed to an Archimedes action. Had a 26" 7tw Marksman cut to a tl3 for the womans first prs rifle as well. Oddly her 26" is only 10fps behind my 28" with the same load. Granted I have 50k more freebore and hers the faster twist which probably the difference.I've settled on shooting Hawk Hills going forward. Not only for the performance but availability and contour (Heavy Comp).

Anyone with any 110 Atip jump experience? Finally caved and went with the atips cause i cant find 109's for the life of me (local shop caters to a couple of shooters and gives them the heads up with no limits on whatever he brings in - so shopping elsewhere now).

Gonna do initial testing at ~0.020" off the lands with some h4350.

Interested in what others have found that works well for them.

Gonna do initial testing at ~0.020" off the lands with some h4350.

Interested in what others have found that works well for them.

Have a 6gt barrel about to do some sort of load development on this weekend. I am using h4350, Berger 105 hybrids. Is there a optimal speed for barrel longevity? Only shooting this for PRS this season. I thought I read some where most are staying in the 2850-2950 speed for barrel life and a good speed? Help me out.

Well, it's a good combination to start. I know several that use this combo with great results. My guess would be your best results are gone be in the upper velocity range with h4350 and 105. With my 26 inch Gt barrels, 34.5 - 35.5 of h4350 will get me in the 2850-2950 range. Most of my combos settle in around 2875 ish. I wouldn't be to concerned with barrel life, it's a 6mm after all. Like most others, It's probably gone die around 1500-2000.Have a 6gt barrel about to do some sort of load development on this weekend. I am using h4350, Berger 105 hybrids. Is there a optimal speed for barrel longevity? Only shooting this for PRS this season. I thought I read some where most are staying in the 2850-2950 speed for barrel life and a good speed? Help me out.

Tried to go stretch the gt out this past weekend but fog was thick so just did some 100 yard paper punching. 10 round group repeated exactly as I had hoped. Looks like I should probably come down a tenth but she’s dialed. Praying for some good weather soon

I don’t think so. I used the one it came with when I was running 109s.Did some searching and couldn’t find it but do I need a special stem for the 109 ELDMs? Running the RCBS match master set now

Ok I have root cause!HELP HUGE SHOULDER BUMP

Happy holidays everyone. I wanted to ask if anyone has any insight with what I am seeing that has me stumped.

I got my 6GT from GA Precision spring 2022 and what an amazing rifle. So far I have loaded and shot 100 new alpha brass for break in process with 105 Nosler RDF because it’s what I had. By the way 34.7 Varget gets barely over 3000 fps and about .2 MOA.

The issue is now I go to reload those original once fired brass and the shoulder bump is HUGE. I have tried two good die’s with Same result. Also using zero press.

Fired brass measures from 1.3040 to 1.3100 with SAC comparator

— When I run SAC die to contact shell holder I get .031 bump

— When I run Micron die to contact shell holder I get about .026 bump

I unscrewed the SAC die until I got the proper .002 shoulder bump and then measured gap between shell holder and bottom of die body and as expected it was about .032

THATS A WHOLE LOTTA BUMPIN’

not sure I have seen that much bump in contact with shell holders for other cartridges. The guys over at SAC are incredible to work with way beyond generous and offered to help troubleshoot so I gave them some examples of fired brass and my die to troubleshoot.

Are you all seeing this much bump when contacting the shell holder? Could something be wrong with my chamber?

Any help I would be thankful for

Thanks

First SAC is amazing, they took my once fired brass and determined rifle had too much headspace and because they work with George at GA Precision sent him a note with the measurements. I offered to pay SAC and they refused saying just wanted to help their customer!

I contacted GA Precision told them the deal and next thing you know I get a call from George. He said not sure what happened but wanted to receive it and check it himself and they would pay for shipping. GA Precision then calls me when they get my rifle and next day George calls me again and says that it did have excessive headspace the exact amount that is the difference between an Impact action and my Defiance action. His Smith setting barrels that day did a bunch of Impact first and didn’t make the adjustment when he put barrel on my Defiance. I told George that I appreciated it getting done so fast and he told me that it doesn’t happen often because of their quality processes but if they get a warranty item in, it goes first and offered to send me new brass to replace what I ruined troubleshooting this issue.

This is amazing service from both GAP and SAC. This is why I will work with both of them again every chance I get and you should too.

If GAP and SAC is reading this, very appreciated guys, class acts!

Fred

Anyone here running Reloader 15.5 and notice the difference in felt recoil or am I losing my mind. My setup now is Impact in a Foundation with a 1-7 proof competition contour running 109 ELDM’s, 33.9 RL15.5 at 2880. Last year same action and Foundation but with a 1.75 MTU and 32.8 Varget at 2840 with 109 ELDM’s. I’m not saying the recoil felt is more but just feels snappier if that makes since.

Anyone here running Reloader 15.5 and notice the difference in felt recoil or am I losing my mind. My setup now is Impact in a Foundation with a 1-7 proof competition contour running 109 ELDM’s, 33.9 RL15.5 at 2880. Last year same action and Foundation but with a 1.75 MTU and 32.8 Varget at 2840 with 109 ELDM’s. I’m not saying the recoil felt is more but just feels snappier if that makes since.

This probably doesn’t help, cause I don’t shoot 15.5 particularly, but your not loosing your mind. (For the first few shots after the powder change) I can tell a difference in recoil impulse when changing types of powder… after shooting the new powder for a “few” rounds the feeling dissipates, and then it’s just recoil again.

Looking for some insight regarding a GAP PPR 6GT. I bought a PPR from GAP a little over a year ago. LOVE it! So much I decided to get another one. One for matches, one for training. My PPR in a serial number 300's last year of the tenacity action. I found a used PPR also tenacity action serial number 100's. When I bought my rifle I had another barrel spun up for it from GAP knowing I would burn through it and need another (side note I got 3100 rounds before significant loss of speed and groups opened up). So I'm at 540 rounds on second barrel. It hammers, just like first one. My loads are the same, nothing needed to change. So when I got the second rifle I was hoping things would be the same or close for reloading purposes since actions and barrels were the same (both tenacity, both bartlein 7.2 to 1, 26". The second rifle also hammers. I've very happy with it! What I can't figure out is why it is so much slower. The other rifle has app 600 rounds on it. I believe that to be true. I stripped barrel with Iosso and bore scoped it, beautiful condition! I did same to my second barrel on original rifle because I wanted to compare data and have an equal starting point. I generally shoot three loads. I will list them below and the differences. I will say it is clear I am going to have to do a completely new load development for second rifle, ES and SD's are just not even close to my acceptable range or that of first rifle. My guess is may be the second rifle had a larger free bore? Not sure why this rifle is over 100fps slower over almost all loads. It hammers, no doubt! I shoot a 3" group at 600 yards with Varget and 112 MBs, rifle is fantastic just different. Any ideas on what the difference is? I'm guessing it is obviously the barrel cut with different reamer but didn't realize (maybe wrong) they used more than one reamer on PPRs.

Loads:

112MB 37.3 RL16 alpha brass CCI450

original PPR 2908fps ES 16 SD 5.1 for 10rounds

2nd PPR 2802fps ES 35 SD 10.2 for 10rounds

105hybrids H4350 35.6 horn brass S&B primers

original- 2892fps ES 15 SD 4.6 10rounds

2nd- 2788fps ES 40 SD 12.4 10 rounds

112MB Varget 34.5 alpha brass CCI450

original- 2924fps ES 20 SD 6.3 10rounds

2nd- 2828fps ES 26 SD 8.6 10 rounds

Any ideas on cause of different speeds?

Loads:

112MB 37.3 RL16 alpha brass CCI450

original PPR 2908fps ES 16 SD 5.1 for 10rounds

2nd PPR 2802fps ES 35 SD 10.2 for 10rounds

105hybrids H4350 35.6 horn brass S&B primers

original- 2892fps ES 15 SD 4.6 10rounds

2nd- 2788fps ES 40 SD 12.4 10 rounds

112MB Varget 34.5 alpha brass CCI450

original- 2924fps ES 20 SD 6.3 10rounds

2nd- 2828fps ES 26 SD 8.6 10 rounds

Any ideas on cause of different speeds?

Are both 236 bore? Perhaps the new barrel is 237 bore and reduces psi/velocity? Your speeds on new pipe do seem slow. Even comparered to my 7.5tw 237 bore barrels.Looking for some insight regarding a GAP PPR 6GT. I bought a PPR from GAP a little over a year ago. LOVE it! So much I decided to get another one. One for matches, one for training. My PPR in a serial number 300's last year of the tenacity action. I found a used PPR also tenacity action serial number 100's. When I bought my rifle I had another barrel spun up for it from GAP knowing I would burn through it and need another (side note I got 3100 rounds before significant loss of speed and groups opened up). So I'm at 540 rounds on second barrel. It hammers, just like first one. My loads are the same, nothing needed to change. So when I got the second rifle I was hoping things would be the same or close for reloading purposes since actions and barrels were the same (both tenacity, both bartlein 7.2 to 1, 26". The second rifle also hammers. I've very happy with it! What I can't figure out is why it is so much slower. The other rifle has app 600 rounds on it. I believe that to be true. I stripped barrel with Iosso and bore scoped it, beautiful condition! I did same to my second barrel on original rifle because I wanted to compare data and have an equal starting point. I generally shoot three loads. I will list them below and the differences. I will say it is clear I am going to have to do a completely new load development for second rifle, ES and SD's are just not even close to my acceptable range or that of first rifle. My guess is may be the second rifle had a larger free bore? Not sure why this rifle is over 100fps slower over almost all loads. It hammers, no doubt! I shoot a 3" group at 600 yards with Varget and 112 MBs, rifle is fantastic just different. Any ideas on what the difference is? I'm guessing it is obviously the barrel cut with different reamer but didn't realize (maybe wrong) they used more than one reamer on PPRs.

Loads:

112MB 37.3 RL16 alpha brass CCI450

original PPR 2908fps ES 16 SD 5.1 for 10rounds

2nd PPR 2802fps ES 35 SD 10.2 for 10rounds

105hybrids H4350 35.6 horn brass S&B primers

original- 2892fps ES 15 SD 4.6 10rounds

2nd- 2788fps ES 40 SD 12.4 10 rounds

112MB Varget 34.5 alpha brass CCI450

original- 2924fps ES 20 SD 6.3 10rounds

2nd- 2828fps ES 26 SD 8.6 10 rounds

Any ideas on cause of different speeds?

Really don't know what the bore size is. Just assumed since both were done by GAP same reamer was used, but don't know that for a fact.Are both 236 bore? Perhaps the new barrel is 237 bore and reduces psi/velocity? Your speeds on new pipe do seem slow. Even comparered to my 7.5tw 237 bore barrels.

They may have used the same reamer, but bore size is completely different.Really don't know what the bore size is. Just assumed since both were done by GAP same reamer was used, but don't know that for a fact.

Bore size is essentially the diameter of the barrel.

Are both barrels made by the same company?

Similar threads

- Replies

- 7

- Views

- 492